Refrigerant recovery system model 3600 part no. 2000-3600 operation & maintenance manual instruction 2079-0140 rev 2 - december 2012 warning: inhalation of high concentrations of refrigerant vapors is harmful and may cause heart irregularities, unconsciousness, or death. Deliberate inhalation of ref...

Refrigerant recovery system model 3600 2 table of contents chapter 1: introduction ................................................................................................................................. 3 1.1. O verview .........................................................................

Model 3600 refrigerant recovery system 3 chapter 1: introduction 1.1. Overview congratulations on your purchase of the bacharach model 3600 high performance oilless recovery system. Bacharach has worked hard to make the model 3600 the highest performing, most portable and easiest to use recovery sys...

Refrigerant recovery system model 3600 4 refrigerant recovery rates certified per ahri 740-95 & 740-98 refrigerant liquid rate liquid push-pull rate vapor rate r-22 4.96 lb/min 2.25 kg/min 13.01 lb/min 5.90 kg/min 0.37 lb/min 0.17 kg/min r-134a 3.86 lb/min 1.75 kg/min 11.84 lb/min 5.37 kg/min 0.29 l...

Model 3600 refrigerant recovery system 5 chapter 2: safety 2.1. General safety instructions 1. K now y our e quipment read and understand the operation manual and labels affixed to the unit. Learn its application and limitations as well as the specific potential hazards of your equipment. 2. G round...

Refrigerant recovery system model 3600 6 2.2. Operational safety warning: inhalation of high concentrations of refrigerant vapors is harmful and may cause heart irregularities, unconsciousness, or death. Deliberate inhalation of refrigerants is extremely dangerous and death may occur without warning...

Model 3600 refrigerant recovery system 7 chapter 3: features 3.1. Location and description of unit features # component description 1 purge ball valve this valve determines what function the model 3600 performs. This valve is up during recovery operations and down for purging and liquid push-pull op...

Refrigerant recovery system model 3600 8 3.2. Led display led meaning explanation green normal operation indicates that the power switch is on and the compressor is running. Red high pressure condition indicates that there is a high pressure condition that must be corrected. The internal high pressu...

Model 3600 refrigerant recovery system 9 chapter 4: recovery 4.1. Helpful hints for recovering r-410a r-410a has been designated by the epa as a “very-high-pressure” refrigerant. Because of its higher vapor pressure, recovering r-410a has some unique challenges. The higher vapor pressure requires mo...

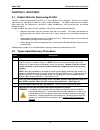

Refrigerant recovery system model 3600 10 step description 6 monitor the led status display . The unit will shut off automatically when the proper vacuum level is achieved and the status display led will turn off. Led description green indicates that the power switch is on and the compressor is runn...

Model 3600 refrigerant recovery system 11 4.3. Liquid/vapor recovery hose connections figure 1. Liquid/vapor recovery hose connections use only approved dot recovery cylinders. Follow precautions and warnings listed on the cylinder. If servicing a system with a compressor burn-out, use a high acid t...

Refrigerant recovery system model 3600 12 4.4. Liquid push-pull recovery general information attention: before attempting the following liquid push-pull recovery operations, please review this page. It may not be possible to recover liquid refrigerant from some types of refrigeration equipment. A sc...

Model 3600 refrigerant recovery system 13 4.5. Liquid push pull recovery procedures liquid push-pull operations are performed by using hot compressor gas to push liquid refrigerant out of a system. The purge valve accomplishes this by re-directing the hot compressor gas around the condenser. See the...

Refrigerant recovery system model 3600 14 4.6. Liquid push-pull hose connections figure 3. Liquid push pull hose connections use only approved dot recovery cylinders. Follow precautions and warnings listed on the cylinder. If servicing a system with a compressor burn-out, use a high acid type filter...

Model 3600 refrigerant recovery system 15 4.7. Pump down operations the model 3600 is equipped with a pump-down purge valve that allows the technician to pump down or evacuate the 3600 before proceeding to the next recovery operation. This procedure not only eliminates cross contamination, but also ...

Refrigerant recovery system model 3600 16 4.8. Dot recovery cylinder safety an optional 80% recovery cylinder shutoff cord is available with the model 3600. If equipped, this cord connects to the recovery cylinder float switch and will automatically shut the model 3600 off when the recovery cylinder...

Model 3600 refrigerant recovery system 17 chapter 5: troubleshooting problem led status possible cause solution compressor will not start • green led vacuum pressure switch has been activated turn unit off. Apply 1-2 psig pressure to inlet port to reset vacuum switch • red led check for restrictions...

Refrigerant recovery system model 3600 18 chapter 6: electrical schematic.

Model 3600 refrigerant recovery system 19 chapter 7: replacement parts part # component description qty 0007-1700 filter/dryer 1.00 2002-0011 compressor re-build kit, includes: suction & discharge valves, springs, one valve plate, & o-rings 1.00 2012-0130 power cord sjto, 18/3, 6ft 1.00 2012-0080 gu...

Refrigerant recovery system model 3600 20 world headquarters 621 hunt valley circle, new kensington, pa 15068 ph: 724-334-5000 • fax: 724-334-5001 • toll free: 1-800-736-4666 web site: www.Mybacharach.Com • e-mail: help@mybacharach.Com p rinted in u.S.A. ® r egistered t rademark.