- DL manuals

- Backyard Discovery

- Swing Set

- 55006

- Owner's Manual

Backyard Discovery 55006 Owner's Manual

Summary of 55006

Page 1

Made in china features the fastening system. Save this assembly manual for future reference in the event that you need to order replacement parts. • owner's manual • frequently asked questions • assembly instructions • warranty information prairie ridge wooden swing set model: #55006.

Page 2

General safety instructions purpose this product is intended for outdoor, domestic use only. It is not suitable for commercial or medical use. Danger for children warning! No eating while using the product this product may only be used with adult supervision at all times. The packaging material is n...

Page 3: Safety Instructions

In certain areas during winter, snow buildup and the low temperatures can damage the product. It is recommended to remove snow buildup and to store the product indoor. We strongly recommend visual inspections every 3 months to insure the integrity of the entire product. Replace any parts as necessar...

Page 4

Consumer information sheet for playground surfacing materials the us consumer product safety commission (cpsc) estimates that about 100 000 playground equipment- related injuries resulting from falls to the ground surface are treated annually in us hospital emergency rooms. Injuries involving this h...

Page 5

Play set assembly manual faqs: 1. Does the area for the playset need to be level? Yes. We recommend the playset be positioned on a flat level area for maximum safety and durability. The stakes provided should be used to secure it firmly to the ground. 2. What age range is appropriate for the playset...

Page 6

(level 24") (open end wrenches 1/2") (square) (tape measure) (3/8" drive ratchet, 1/2" std sockets 1/2" deep sockets) (claw hammer) (cordless drill or electric drill) (an adult w/ an adult helper) (rubber mallet - optional) (ladder) (phillips screw driver) (drill attachments: phillips head) (3/16" &...

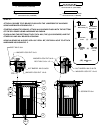

Page 7: Important Assembly Notes

Important assembly notes 1) while assembling unit, take time before and after each phase to make sure fort is level. If fort is not level, assembly will be difficult and improper assembly may result. Extra care must be taken to insure the fort is square. 2) tighten bolts securely, tighten nuts on bo...

Page 8

Parts identification wood components (not to scale) e1 - upright - w101261 1 3/8"x3 3/8"x81 3/4" (36x86x2076) (1) e77 - angle brace - w100991 1 3/8"x3 3/8"x74 3/8" (36x86x1890) (2) e3 - upright - w101256 1 3/8"x3 3/8"x81 3/4" (36x86x2076) (1) f71 - standard angle brace - w100689 1 3/8"x2 3/8"x13" (3...

Page 9

Parts identification wood components (not to scale) j1 - window ledge - w100709 1"x2 3/8"x29 1/2" (24x60x750) (1) j2 - end floor cleat - w100710 1"x2 3/8"x3 3/8" (24x60x86) (4) j3 - floor joist - w100984 1"x2 3/8"x60 1/8" (24x60x1528) (1) k3 - serving board - w101605 5/8"x5 1/4"x28 3/4" (16x134x729)...

Page 10

Parts identification wood components (not to scale) l3 - ground board - w101602 5/8"x4 3/8"x46 7/8" (16x112x1191) (1) l5 - ground board - w100686 5/8"x4 3/8"x30" (16x112x762) (1) l6 - arched rail - w100694 5/8"x4 3/8"x60 1/8" (16x112x1528) (1) l7 - arched sculptured rail - w100695 5/8"x4 3/8"x60 1/8...

Page 11

Parts identification wood components (not to scale) m10 - safety board - w100701 5/8"x3 3/8"x33 7/8" (16x86x860) (1) m11 - upper face board - w102866 5/8"x3 3/8"x26 5/8" (16x86x676) (2) m12 - monkey bar arch board - w103775 5/8"x3 3/8"x30" (16x86x762) (1) m13 - floor rail - w103774 5/8"x3 3/8"x60 1/...

Page 12

Parts identification wood components (not to scale) sb74 - swing beam extended - w102419 2"x5 1/4"x89 1/2" (50x134x2274) (1) sp1 - floor support cleat - w100711 1"x1"x53 3/8" (24x24x1356) (2) w71 - swing beam support - w102420 2"x3 3/8"x49 5/8" (50x86x1260) (1) (3) fp1 - floor panel - w102861 m16 - ...

Page 13

Parts identification hardware b - nut barrel wh 5/16x5/8 - h100004 (18) d - nut barrel wh 5/16x7/8 - h100005 (45) c - nut barrel wh 5/16x1 1/2 - h100006 (2) f - bolt wh 5/16x1 - h100008 (10) h - bolt wh 5/16x1 1/2 - h100010 (39) j - bolt wh 5/16x1 3/4 - h100011 (6) k - bolt wh 5/16x2 - h100012 (13) ...

Page 14

Parts identification hardware ay - bolt pth 1/4x1 - h100061 (7) ch - screw tapping 14x1-1/2 - h100109 (15) bn - screw pfh 8x1 - h100085 (61) br - screw pfh 8x1 1/8 - h100088 (44) bq - screw pfh 8x1 1/4 - h100087 (24) bp - screw pfh 8x1 1/2 - h100086 (160) bs - screw pfh 8x1 3/4 - h100089 (28) ck - s...

Page 15

Parts identification hardware cy - screw pwh 8x5/8 - h100128 (7) cm - bolt wh 5/16x1/2 - h100115 (13) ks - nut barrel wh 1/4x5/8 - h100136 (9) ky - bolt wh 1/4x1/2" - h100141 (4) kw - washer lock ext 8x15 - h100139 (9) - t-30 torx bit - h100147 (2) - t-40 torx bit - a100042 (2) - t -4 0 t o rx w re ...

Page 16

Parts identification accessories (not to scale) ej - l bracket 54x67 - a100053 (4) ea - hand grip yellow plastic - a100043 (6) ek - slide rail 8' green right - a100054 (1) el - slide rail 8' green left - a100055 (1) em - slide bed 8' yellow - a100056 (1) do - captains glider arm yellow - a100026 (2)...

Page 17

Parts identification a a a ac c c cc c c ce e e es s s ss s s so o o or r r riiiie e e es s s s (not to scale) hc - byd id tag (large) 2011 with ages - a100164 (1) ew - glider support byd green - a100065 (2) ex - glider bushing byd green - a100066 (4) sr - "b" revision tag - a100315 (1) tc - swing b...

Page 18

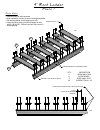

4' rock ladder phase 1 phase notes • assemble slats to rails as shown. • note oreintation of slats, be sure to arrange as shown. • see drawing below for slat spacing on rails. • using slats as a guide, pre-drill top edges of rails with a 1/8" drill bit. Failure to pre-drill may result in board split...

Page 19

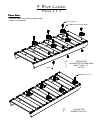

4' rock ladder phase 2 & 3 p p p ph h h ha a a as s s se e e e n n n no o o ot tt te e e es s s s • oreint top edge of rocks with top edge of slats. • fasten rocks as shown. Bolt fa 3/8x1-1/2 climbing rock green small t-nut 3/8 screw pfh 8x1-1/8 qty. Description 6 climbing rock green small 6 bolt fa...

Page 20: 4 Ft Green Extended

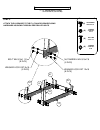

Gd - l bracket 66x66x127 - a100140 (2) tc - swing beam extension bracket-right - a100326 (1) tb - swing beam extension bracket-left - a100325 (1) sb74 - swing beam extended - w102419 2"x5 1/4"x89 1/2" (50x134x2274) (1) tb tc gd sb74 step 1 attach (2) gd brackets to sb74 swing beam using (2) 2-3/4" b...

Page 21

Step 2 attach h80 ground board to (2) e77 angled support boards using (2) 2" bolts, lock washers and 7/8" barrel nuts, as shown. Attach (2) e77 angled support boards to w71 support using 4- 1/2" bolt, lock washers and 7/8" barrel nut, as shown. Attach h79 board to w71 board using (2) 2" lag screws a...

Page 22

Step 3 insert w71 board into tb and tc bracket opening and secure using (2) 1-3/4" bolts and 7/8" barrel nuts, as shown. Insert (2) 2-1/2" bolts, lock washers and 1-1/2" barrel nuts into the edge of w71 board, as shown. Tb tc sb74 w71 washer lock ext 12x19 (2) washer lock ext 8x19 (2) nut barrel wh ...

Page 23

Sb74 ew ew ex ey ew - glider support byd green - a100065 (2) ex - glider bushing byd green - a100066 (4) ey - tubing cap glider support - a100067 (4) swing hanger quick link (4) bolt wh 5/16x5-3/4 (2) lag screw wh 5/16x2-1/2 (2) nut lock 5/16 (6) washer flat 8x27 (6) step 4 attach (2) ew glider supp...

Page 24

Step 5 insert (4) swing hanger quick link into sb74 swing beam using (4) safety washers, flat washers and 5/16" lock nuts, as shown. Sb74 swing hanger quick link (4) washer safety 17x30 (4) washer flat 8x27 (4) nut lock 5/16 (4).

Page 25

Qty description 1 slide brace 3 bolt wh 5/16x1/2 3 nut barrel wh 5/16x5/8 3 washer lock ext 12x19 1 slide bed 8' yellow nut barrel wh 5/16x5/8 washer lock ext 12x19 m77 slide brace bolt wh 5/16x1/2 slide bed 8' yellow 8 foot slide assembly phase 1 step 1 ● place slide brace centered on the bottom 1/...

Page 26

Qty description 2 m78 center slide brace 24 screw pfh 8x3 1 slide rail 8' green right 1 slide rail 8' green left slide rail 8' green left slide rail 8' green right m78 center slide brace 8 foot slide assembly phase 2 step 2 ● place 1 slide rail on a flat surface and begin inserting slide bed at the ...

Page 27: Monkey Bar Assembly

Monkey bar assembly step 1 you will build a left and right top rail in this step. After building left assembly as shown, repeat steps for a right assembly. See below for oreintation of right side triangle plate. Assemble with hardware as shown. Be sure to place flat side of plate against side of boa...

Page 28: Monkey Bar Assembly

Step 2 assemble with hardware as shown. Repeat process for other side of monkey bar assembly. Monkey bar assembly qz e78 e78 qz bolt wh 5/16x1-1/2 (4) t-nut 5/16 (4) e78 - monkey bar upright - w102370 1 3/8"x3 3/8"x74 3/4" (36x86x1900) (2).

Page 29: Monkey Bar Assembly

Step 3 assemble as shown into pre-drilled holes. Monkey bar assembly screw tapping 14x1-1/2 (12) ec - metal rung 559 - a100045 (6) e71 ec ec e78 e78 e71.

Page 30: Monkey Bar Assembly

H81 - monkey bar brace - w100993 1"x3 3/8"x53 1/4" (24x86x1352) (2) h82 - monkey bar ground board - w100994 1"x3 3/8"x70 3/8" (24x86x1786) (1) step 4 assemble as shown. Monkey bar assembly h81 h81 h82 bolt hex 5/16x2-3/4 (2) washer lock int 8x15 (2) washer flat 9x18 (2) bolt wh 5/16x1-1/2 (4) lag sc...

Page 31: Monkey Bar Assembly

Monkey bar assembly step 5 assemble with hardware as shown. E78 e78 ea ea - hand grip yellow plastic - a100043 (2) lag screw wh 1/4x1-1/2 (4) washer lock ext 6x15 (4).

Page 32

M5 - face board - w101599 5/8"x3 3/8"x43 1/8" (16x86x1094) (2) screw pfh 8x1 1/2 (6) screw pfh 8x1 1/2 (6 plcs) note the holes that are used step 1 attach m5 boards to e2 boards using hardware as shown through pre drilled holes. Note the orientation of the holes with the e2 boards. E2 e2 m5 m5 e2 - ...

Page 33

Step 2 attach the m6 boards and the l5 board to the e3 and e1 boards using hardware as shown through pre drilled holes. Note the orientation of the e3 and e1 boards. E3 - upright - w101256 1 3/8"x3 3/8"x81 3/4" (36x86x2076) (1) e1 - upright - w101261 1 3/8"x3 3/8"x81 3/4" (36x86x2076) (1) m6 - lower...

Page 34

E2 l2 e2 l2 e3 e1 nut barrel wh 5/16x7/8 (8 plcs) washer lock ext 12x19 (8 plcs) washer lock ext 8x19 (8 plcs) step 3 attach the l2 boards to the e1, e3 and e2 boards using hardware as shown through pre drilled holes. L2 - ground board - w100684 5/8"x4 3/8"x60 1/8" (16x112x1528) (2) nut barrel wh 5/...

Page 35

Step 4 attach m10 and l3 boards to the m5 boards using hardware as shown through pre drilled holes. Attach m9 board to the m10 and the l3 board using hardware as shown through pre drilled holes. L3 - ground board - w101602 5/8"x4 3/8"x46 7/8" (16x112x1191) (1) m9 - angle brace - w100696 5/8"x3 3/8"x...

Page 36

K4 - floor rail - w103700 5/8"x5 1/4"x60 1/8" (16x134x1528) (1) bolt wh 5/16x2 (8) washer lock ext 8x19 (8) t-nut 5/16 (8) step 5 attach m13 board to the e1 board and the e2 board using hardware shown through pre drilled holes. Note the orientation of holes that will be used later in the m13 board. ...

Page 37

Step 6 attach k5 board to e2 boards and attach m14 board to e1 and e3 boards using hardware as shown through pre drilled holes . K5 - floor rail - w103768 5/8"x5 1/4"x30" (16x134x762) (1) washer lock ext 8x19 (6) washer lock ext 8x19 (6 plcs) m14 - floor support board - w103944 5/8"x3 3/8"x30" (16x8...

Page 38

Sp1 - floor support cleat - w100711 1"x1"x53 3/8" (24x24x1356) (2) j2 - end floor cleat - w100710 1"x2 3/8"x3 3/8" (24x60x86) (4) f71 - standard angle brace - w100689 1 3/8"x2 3/8"x13" (36x60x330) (2) nut barrel wh 5/16x7/8 (2) lag screw wh 5/16x2 1/2 (2) bolt wh 5/16x1 1/2 (2) screw pfh 8x1 1/2 (10...

Page 39

Step 8 attach f71 braces to k5 and m14 boards through pre drilled holes with hardware as shown pre drill e1, e3, and e2 braces and fasten f71 boards to them with hardware as shown attach j3 floor joist to m14 and k5 boards with bottom of j3 joist being 3/8" from bottom of m14 and k5 boards with hard...

Page 40

L9 - end floor board - w102863 5/8"x4 3/8"x29 7/8" (16x112x760) (2) screw pfh 8x1 1/2 (10) step 9 place l9 boards on the j3 floor joist and j2 support boards. L9 board will sit up against the e2 boards and the e3 and e1 board as shown. Attach l9 boards to j2 boards and j3 floor joist through pre dri...

Page 41

Screw pfh 8x1 1/2 (45) (3) fp1 - floor panel - w102861 step 10 attach fp1 floor panels to sp1 boards and j3 floor joist using hardware as shown through pre drilled holes. Fp1 fp1 fp1 sp1 k4 m13 j3 screw pfh 8x1 1/2 (45 plcs).

Page 42

M11 - upper face board - w102866 5/8"x3 3/8"x26 5/8" (16x86x676) (2) screw pfh 8x1 1/2 (8) washer lock ext 8x19 (4) t-nut 1/4 (4) m12 - monkey bar arch board - w103775 5/8"x3 3/8"x30" (16x86x762) (1) step 11 attach 1/4" t-nuts to m11 boards as shown. Attach m11 boards to e1 board and e3 board with h...

Page 43

L6 - arched rail - w100694 5/8"x4 3/8"x60 1/8" (16x112x1528) (1) l7 - arched sculptured rail - w100695 5/8"x4 3/8"x60 1/8" (16x112x1528) (1) nut barrel wh 5/16x7/8 (8) washer lock ext 8x19 (8) washer lock ext 12x19 (8) step 12 attach l6 board as shown to e1 and e2 boards through pre drilled holes us...

Page 44

K2 k1 e3 e1 e2 e2 washer lock ext 8x19 (8) t-nut 5/16 (6) t-nut 5/16 (6 plcs) lag screw wh 5/16x2 (8 plcs) washer lock ext 8x19 (8 plcs) step 13 attach 5/16 t nuts to k1 board as shown and attach to e2 boards through pre drilled holes with hardware as shown. Attach k2 board to e1, and e3 boards with...

Page 45

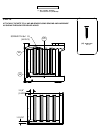

Step 14 attach m1 board to e2 boards as shown. Attach m18 pickets to m1 board and k5 board using spacing as shown 2 11/16" (5 spcs) m1 m18 e2 e2 k5 screw pfh 8x1 1/8 (16 plcs) washer lock ext 8x19 (2 plcs) lag screw wh 5/16x2 (2 plcs) lag screw wh 5/16x2 (2) washer lock ext 8x19 (2) m1 - picket rail...

Page 46

Step 15 attach m7 board to l6 board and m13 board through pre drilled holes using hardware as shown. Attach m8 board to m7 board and e1 board using hardware as shown through pre drilled holes. Nut barrel wh 5/16x5/8 (2) screw pfh 8x1 3/4 (2) screw pfh 8x1 1/8 (2) bolt wh 5/16x1 (2) washer lock ext 8...

Page 47

Step 16 attach m17 pickets to l6 and m8 boards using spacing and hardware as shown through pre drilled holes. M17 - picket - w100705 5/8"x3 3/8"x27 1/8" (16x86x690) (4) screw pfh 8x1 1/8 (16) l6 m17 m8 3 1/8" (5 spcs) 1 13/16" screw pfh 8x1 1/8 (16 plcs).

Page 48

Step 17 place (2) k9-2 boards on floor against l7 and k4 boards, and against e3 board lip of k9-2 touching e3 board and attach with hardware as shown through pre drilled holes. Attach k9-1 boards and (2) k9-2 boards l7 and k4 board against previously attached k9-2 boards. Attach j1 shelf to top of k...

Page 49

M3 - tarp support - w100692 5/8"x3 3/8"x60 1/8" (16x86x1528) (2) screw pfh 8x2 (8) step 18 attach m3 boards to k1 and k2 boards through pre drilled holes using hardware as shown. M3 k1 k2 screw pfh 8x2 (8plcs).

Page 50

Step 19 attach m16 boards as shown to k1 and k2 boards. Attach m4 board flush to m16 boards as shown. Bolt wh 5/16x1 (2 plcs) washer lock ext 8x19 (2 plcs) washer lock ext 12x19 (2 plcs) nut barrel wh 5/16x5/8 (2 plcs) bolt wh 5/16x1 (2) washer lock ext 8x19 (4) washer lock ext 12x19 (2) m4 m16 m16 ...

Page 51

Step 20 center hy tarp over m4 tarp top support and attach using (4) 1/2" tapping screws, as shown. Next, drape hy tarp evenly over (2) m3 tarp supports and wrap underneath and up the back side of m3 support approximately 1-13/16" from the top and attach using (8) 1/2" tapping screws, as shown. Hy -...

Page 52

Front back k4 l8 e3 k9-3 k9-4 l2 k9-4 k9-3 k9-5 step 21 attach l8 board to e3 board flush with the underside of k4 board using hardware as shown fig. 1. Starting against e3 board, attach a k9-3 board flush with the bottom of the sp1 board using hardware as shown. Flush along the bottom attach the a ...

Page 53

Step 23 attach the shelf built in the previous step to the k9-3, k9-4, and k9-5 wall boards by resting the k3 board on top of the opening and fastening with hardware shown through pre drilled holes. Step 22 attach h3 shelf supports to k3 and h1 boards using hardware as shown through pre drilled hole...

Page 54

Ea - hand grip yellow plastic - a100043 (4) bolt pth 1/4x1 (6) screw tapping 14x1-1/2 (2) t-nut 1/4 (2) washer lock int 8x15 (8) washer flat 9x18 (8) step 24 attach ea handle to e2 board using hardware as shown (fig. 1). Insert 1/4" t-nuts into m7 board and attach ea handle as shown (fig. 2). Attach...

Page 55

Step 25 attach (2) ej brackets to h6 bench ground boards using (2) 1/2" bolt, lock washers and 7/8" barrel nut, as shown. Attach h5 bench uprights to h6 bench ground boards using (8) 1-3/4" wood screws, as shown. Attach h4 bench seat supports to h5 bench uprights using (8) 1-3/4" wood screws, as sho...

Page 56

Bolt wh 5/16x1/2 (2) washer lock ext 12x19 (2) nut barrel wh 5/16x5/8 (2) step 26 using bench assembly brackets as a template, drill two 3/8" thru holes and attach ej bracket to l2 ground board using (2) 1/2" bolts, lock washers and 5/8" barrel nuts, as shown. (1) - bench assembly 7-1/2" bench locat...

Page 57

Step 27 center the wave slide assembly in opening, as shown. Using a 3/8" drill bit, drill three through holes into the slide bed and deck boards, as shown below. Attach the slide assembly to the deck using (3) 1/2" bolts, lock washers and 5/8" barrel nuts, as shown. Bolt wh 5/16x1/2 (3) washer lock...

Page 58

Lag screw wh 5/16x2 1/2 (2) washer lock ext 8x19 (2) (1) - rock ladder assembly step 28 center ladder on 'm13' board and pilot drill 3/16" holes for ladder attachment. Attach the rock ladder assembly to m13 floor rail support using (2) 2-1/2" lag screws and lock washers, as shown. M13 lag screw wh 5...

Page 59

Bolt hex 5/16x1 (4) screw pwh 8x5/8 (4) washer split 5/16 (4) washer flat 8x27 (4) hc - byd id tag (large) 2011 with ages - a100164 (1) (1) - swing beam assembly step 29 attach swing beam assembly to k1 roof swing beam support using (4) 1" bolts, split washers and flat washers, as shown below. Attac...

Page 60

Step 30 attach monkey bar assembly to m12 arch board using hardware as shown. (1) - monkey bar assembly bolt wh 5/16x1/2 (2) washer lock ext 12x19 (2) nut barrel wh 5/16x5/8 (2) m12 bolt wh 5/16x1/2 (2 plcs) washer lock ext 12x19 (2 plcs) nut barrel wh 5/16x5/8 (2 plcs).

Page 61

Fb - swing seat yellow - a100070 (2) ez - chain green 51.25" - a100068 (4) quick link (8) bolt wh 5/16x5 3/4 (2) nut lock 5/16 (2) washer flat 8x27 (2) ez fb dn - glider seat dark green - a100025 (1) do - captains glider arm yellow - a100026 (2) step 31 attach fb swing seat to (2) ez chains using (2...

Page 62

Anchoring instructions final step double check every bolt, screw and nut for tightness. Make sure every board is secure and make sure the play set is level. Enjoy your new play set! Note: failure to use ground stakes can void warranty & cause injury! Stake a stake b stake a stake a stake a stake a s...

Page 63: Warranty

Warranty australian consumer law many of our products come with a guarantee or warranty from the manufacturer. In addition, they come with guarantees that cannot be excluded under the australian consumer law. You are entitled to a replacement or refund for a major failure and compensation for any ot...