Backyard Discovery 817220010 Manual

Save this assembly manual for future reference in the event that

you need to order replacement parts.

READ INSTRUCTIONS COMPLETELY BEFORE BEGINNING CONSTRUCTION.

INS-817220010-A-BARN SHED DISASSEMBLY-ENG 4-13-17

Manufacturer: Backyard Discovery

3305 Airport Drive

Pittsburg, KS 66762

1-800-856-4445

READY SHED

8X8 BARN SHED

DISASSEMBLY

MODEL: # 817220010

Summary of 817220010

Page 1

Save this assembly manual for future reference in the event that you need to order replacement parts. Read instructions completely before beginning construction. Ins-817220010-a-barn shed disassembly-eng 4-13-17 manufacturer: backyard discovery 3305 airport drive pittsburg, ks 66762 1-800-856-4445 r...

Page 2

Important! Read instructions completely before beginning. Before you begin • safety first your safety is what matters, follow the instructions fully to ensure it gets dissassembled correctly and safely. • surface preparation to ensure proper disassembly you must uncrate your shed on a level firm sur...

Page 3: Disassembly Tools Required

2 disassembly tools required other tools we suggest • utility knife • 6' ladder • gloves • phillips bit driver • drill.

Page 4: Parts Being Removed

Parts being removed don't skip any steps this crate has been designed to keep it's parts from being damaged and from falling over. Skipping steps could cause parts to fall and land on you or cause damage to your shed or surrounding structures. •these instructions will take you step by step through t...

Page 5: Parts Being Removed

Remove screw (2 pls) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (1) parts being removed •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. (1) rp1 - roof panel - w2a02123 next: remove screw (2 pls) top view remove 4.

Page 6: Parts Being Removed

•only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed top view remove screw (2 pls) remove (1) wp5 - universal right wall panel - w2a02122 5.

Page 7: Parts Being Removed

Top view remove screw (2 pls) •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed remove (1) wp5 - universal right wall panel - w2a02122 6.

Page 8: Parts Being Removed

Top view remove screw (2 pls) •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed (1) wp4 - universal left wall panel - w2a02121 remove 7.

Page 9: Parts Being Removed

Remove 2 screws top view •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. (1) wp4 - universal left wall panel - w2a02121 parts being removed remove 8.

Page 10: Parts Being Removed

Parts being removed top view •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Remove screw (2 pls) remove remove screw (2 pls) (1) wp3 - front center wall panel - w2a02120 9.

Page 11: Parts Being Removed

Remove screw (2 pls) remove screw (2 pls) top view parts being removed •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Remove (1) wp2 - rear center wall panel - w2a02119 caution loose parts behind, move with caution. 10

Page 12: Parts Being Removed

Stop only remove loose parts and move to next step. •only remove item's shown in the current step, do not skip foward or take out any additional parts until instructed to. Parts being removed shingles remove shingles and leveling materials 11 - leveling block - w4l07756 1 1/2"x5 1/2"x6" (2) - leveli...

Page 13: Parts Being Removed

Next: remove screw (4 pls) top view •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed remove remove screw (4 pls) remove screw (2 pls) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (1) (2) lp1 - loft pane...

Page 14: Parts Being Removed

•only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed top view remove screw (2 pls) remove next: remove screw (2 pls) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (1) (1) rp1 - roof panel - w2a02123 caution ...

Page 15: Parts Being Removed

Remove screw (2 pls) top view •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed remove remove caution loose parts behind, move with caution. - door drip board - w4l07675 3/4"x1"x46 3/4" (20x24x1187) (1) - fasc...

Page 16: Parts Being Removed

Remove all loose parts. Caution loose parts, move with caution. Parts being removed - filler board - w4l07701 1"x3 3/8"x21 3/8" (24x86x543) (4) - vertical trim - w4l07674 5/8"x3 3/8"x44 1/2" (16x86x1130) (4) - support block - w4l07669 1 1/2"x3 1/2"x3 1/2" (6) - support board - w4l07668 5/8"x3 3/8"x2...

Page 17: Parts Being Removed

•only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed remove screw (3 pls) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (3) remove screw (3 pls) 16.

Page 18: Parts Being Removed

Remove screw (2 pls) top view caution loose parts behind, move with caution. •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Parts being removed remove (1) rp1 - roof panel - w2a02123 17.

Page 19: Parts Being

Caution loose parts, move with caution. Remove shingles. Parts being removed shingles remove screw (2 pls) next •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Remove screw (2 pls) remove large sheet. - 5/8" osb floor sheathing...

Page 20: Parts Being Removed

Parts being removed •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Caution removing board will reduce stabilty. Remove screw (2 pls) top view - 5/8" osb floor sheathing - w4l07733 5/8"x31 7/8"x92" (1) - 4 x 4 runner - w4l07670...

Page 21

Lay o n f la t s u r f a c e remove 8 screws on each side and separate a-frame structure. •only remove screws shown in the current step, do not skip foward or take out any additional screws until instructed to. Stop lay down remaining parts before moving foward. Remove remove 20

Page 22: Parts Being

Parts being removed note: only one wall panel is shown. So you will do these steps twice. - rim joist - w4l07661 1 1/2"x3 1/2"x91 1/4" treated (2) (2) wp1 - side wall panel - w2a02156 remove screw (1 pls) remove screw (4 pls) 21 •now that the crate is fully dissasembled it's time to start with the a...

Page 23: Ready Shed

Save this assembly manual for future reference in the event that you need to order replacement parts. Read instructions completely before beginning construction. Ins-817220010-a-8x8 barn shed-eng 5/3/17 manufacturer: backyard discovery 3305 airport drive pittsburg, ks 66762 1-800-856-4445 ready shed...

Page 24

Important! Read instructions completely before beginning construction. Before you begin • building restrictions and approvals be sure to check with local building department and homeowners association for specific restrictions and/or requirements before building. • engineered drawings contact our cu...

Page 25: Caring For Your Structure

Caring for your structure wood structures (smart panel) • to prevent leaking and premature aging of your shed, we recommend wood structures be thoroughly prepared before treatment. All joints between wall siding boards, window trim, door trim, corner boards, soffits, fascias, rake trim, vents, and n...

Page 26: Assembly Tools Required

3 other tools we suggest assembly tools required • safety glasses • gloves • pencil • tape measure • 6' ladder • 4' level • square • 1/8" allen wrench • drill with 3/8" bit & phillips head driver • hammer.

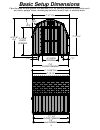

Page 27: Basic Setup Dimensions

Basic setup dimensions place the shed on level ground, not less than 3 ft [1 m] from any structure or obstruction such as a fence, garage, house, overhanging branches, laundry lines, or electrical wires. 7'-10" o.A. 8'-2 1/8" o.A. 5'-11 5/8" door opening 41" door opening 22.5° 67.5° 7'-10 1/4" 7'-11...

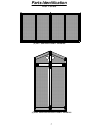

Page 28: Parts Identification

Parts identification wood components (not to scale) 5 - rim joist - w4l07661 1 1/2"x3 1/2"x91 1/4" treated (2) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (7) - 5/8" osb floor sheathing - w4l07733 5/8"x31 7/8"x92" (1) - 5/8" osb floor sheathing - w4l07664 5/8"x43"x92" (1) - side vertical trim...

Page 29: Parts Identification

6 - 7/16" osb gable brace - w4l07667 7/16"x6 1/8"x11" treated (6) parts identification wood components (not to scale) - support board - w4l07668 5/8"x3 3/8"x22 1/8" (16x86x562) (4) - support block - w4l07669 1 1/2"x3 1/2"x3 1/2" (6) - 4 x 4 runner - w4l07670 3 3/4"x3 3/4"x92" treated (2) - door drip...

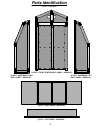

Page 30: Parts Identification

Parts identification wall panels 7 (1) wp2 - rear center wall panel - w2a02119 (2) wp1 - side wall panel - w2a02156.

Page 31: Parts Identification

Parts identification wall panels 8 (1) wp3 - front center wall panel - w2a02120 (2) wp4 - universal left wall panel - w2a02121 (2) wp5 - universal right wall panel - w2a02122 (4) rp1 - roof panel - w2a02123 (2) lp1 - loft panel - w2a02124.

Page 32: Parts Identification

Parts identification shingle components (not to scale) materials: supplied by owner caulk paint 9 roof coating - 2" concrete block - cb000002 (2) - 4" concrete block - cb000001 (1) - leveling block - w4l07757 1"x5 1/2"x6" (2) - leveling block - w4l07756 1 1/2"x5 1/2"x6" (2) leveling materials: full ...

Page 33: Parts Identification

Parts identification hardware - 7/8" roofing nail galv. - h100446 (362) 10 - t-40 torx wrench - a100041 (1) - t-40 torx bit - a100042 (2) - t-25 torx impact driver - a100580 (1) j - bolt wh 5/16x1 3/4 - h100011 (7) m - bolt wh 5/16x2 1/2 - h100014 (4) q - bolt wh 5/16x3 1/4 - h100017 (11) ac - washe...

Page 34: Parts Identification

Parts identification accessories (not to scale) 11 - vent (8x16) - a4m00771 (2) - s pr in g la tc h as se mb ly - a 4m 00 77 4 (2) mx - byd id tag (medium) without ages - a100240 (1) - l oc ki ng d oo r ha nd le (1).

Page 35: Floor Frame

Floor frame floor joist (7 plcs) rim joist (2 plcs) door 12 16" 32" 48" 64" 80" 14" 14" 4 x 4 runner (2 plcs) - rim joist - w4l07661 1 1/2"x3 1/2"x91 1/4" treated (2) - floor joist - w4l07662 1 1/2"x3 1/2"x89" treated (7) - 4 x 4 runner - w4l07670 3 3/4"x3 3/4"x92" treated (2) - screw t-25 9x3 - h10...

Page 36: Floor Sheathing

Floor sheathing 13 • bring sheathing to square before securing with 2" torx drive fasteners. 5/8" osb floor sheathing 92" d o o r door - 5/8" osb floor sheathing - w4l07733 5/8"x31 7/8"x92" (1) - 5/8" osb floor sheathing - w4l07664 5/8"x43"x92" (1) - screw t-25 9x2 - h100579 (81) - 5/8" osb floor sh...

Page 37: Floor Leveling Options

Floor leveling options there are multiple ways to level your floor frame. Our recommended leveling method is shown below. Always support floor frame seams. Leveling • locate leveling material at the end of the runners. • asphalt shingles should be used between blocks and frame lumber to fine-tune an...

Page 38

Right side wall installation 15 screw t-25 9x3 (4 plcs) - screw t-25 9x3 - h100578 (4) do or wp6 wp1 note siding joint. Note: make sure screws either go into rim joists or floor joists when mounting walls. (1) wp1 - side wall panel - w2a02156 important: make sure to mate the wall panel siding with j...

Page 39

Front right wall installation • attach (wp5) front right side wall to (wp1) right side wall securing with 3" torx drive fasteners, approximately 3-1/2" from both the top and bottom plates. Wp5 flush (1) wp5 - universal right wall panel - w2a02122 - screw t-25 9x3 - h100578 (4) 16 door wp1 • importan...

Page 40

Front center wall installation 17 wp3 (1) wp3 - front center wall panel - w2a02120 bg - t-nut 5/16 - h100074 (4) ac - washer lock ext 8x19 - h100030 (4) q - bolt wh 5/16x3 1/4 - h100017 (1) v - bolt wh 5/16x5 - h100022 (3) • important: make sure to mate the wall panel siding with joists. Do not leav...

Page 41

Front left wall installation 18 bg - t-nut 5/16 - h100074 (4) ac - washer lock ext 8x19 - h100030 (4) wp4 screw t-25 9x3 (1 plc) t-nut 5/16 (4 plcs) bolt wh 5/16x5 (3 plcs) washer lock ext 8x19 (4 plcs) bolt wh 5/16x3 1/4 (1 plc) (1) wp4 - universal left wall panel - w2a02121 q - bolt wh 5/16x3 1/4 ...

Page 42

Left side wall installation 19 - screw t-25 9x3 - h100578 (7) screw t-25 9x3 (4 plcs) screw t-25 9x3 (3 plcs) • attach (wp1) side wall assembly by securing with 3" torx drive fasteners as shown below. Wp4 wp6 wp1 • important: make sure to mate the wall panel siding with joists. Do not leave any gap ...

Page 43

Rear left wall installation (1) wp5 - universal right wall panel - w2a02122 20 screw t-25 9x3 (3 plcs) - screw t-25 9x3 - h100578 (4) wp5 important: make sure to mate the wall panel siding with joists. Do not leave any gap between the panel siding and any of the floor joist. Screw t-25 9x3 (1 plc).

Page 44

Rear center wall installation 21 wp2 bolt wh 5/16x3 1/4 (4 plcs) washer lock ext 8x19 (4 plcs) t-nut 5/16 (4 plcs) bg - t-nut 5/16 - h100074 (4) ac - washer lock ext 8x19 - h100030 (4) (1) wp2 - rear center wall panel - w2a02119 q - bolt wh 5/16x3 1/4 - h100017 (4) • important: make sure to mate the...

Page 45

Rear right wall installation 22 bg - t-nut 5/16 - h100074 (4) ac - washer lock ext 8x19 - h100030 (4) (1) wp4 - universal left wall panel - w2a02121 wp4 screw t-25 9x3 (1 plc) bolt wh 5/16x3 1/4 (4 plcs) washer lock ext 8x19 (4 plcs) t-nut 5/16 (4 plcs) screw t-25 9x3 (3 plcs) - screw t-25 9x3 - h10...

Page 46: Wall Panel Fasteners

Wall panel fasteners 23 screw t-25 9x2 (6 plcs) screw t-25 9x2 (6 plcs) screw t-25 9x2 (6 plcs) screw t-25 9x2 (4 plcs) - screw t-25 9x2 - h100579 (22) - screw pfh 8x2 blk - h100391 (4) screw pfh 8x2 blk (4 plcs) -optional- for your convenience we recommend that the painting be done at this time. Se...

Page 47

Right roof panels installation 24 (2) rp1 - roof panel - w2a02120 j - bolt wh 5/16x1 3/4 - h100011 (2) m - bolt wh 5/16x2 1/2 - h100014 (2) ac - washer lock ext 8x19 - h100030 (4) bg - t-nut 5/16 - h100074 (4) t-nut 5/16 (2 plcs) bolt wh 5/16x1 3/4 (2 plcs) washer lock ext 8x19 (2 plcs) t-nut 5/16 (...

Page 48

Left roof panels installation 25 washer lock ext 8x19 (2 plcs) bolt wh 5/16x2 1/2 (2 plcs) t-nut 5/16 (2 plcs) bolt wh 5/16x1 3/4 (2 plcs) washer lock ext 8x19 (2 plcs) t-nut 5/16 (2 plcs) bolt wh 5/16x1 3/4 (2 plcs) washer lock ext 8x19 (2 plcs) bg - t-nut 5/16 - h100074 (6) ac - washer lock ext 8x...

Page 49: Gable Braces

Gable braces 26 screw pfh 8x1 1/2 (36 plcs) 7/16" osb gable brace (6 plcs) - 7/16" osb gable brace - w4l07667 7/16"x6 1/8"x11" treated (6) bp - screw pfh 8x1 1/2 - h100086 (36).

Page 50: Front Trim Boards

Front trim boards 27 screw pfh 8x1 1/2 (34 plcs) fascia board (2 plcs) side vertical trim (2 plcs) vertical trim (2 plcs) angled roof trim (4 plcs) 3 3/8" - side vertical trim - w4l07665 5/8"x2 3/8"x44 1/2" (16x60x1130) (2) - angled roof trim - w4l07666 5/8"x3 3/8"x36" (16x86x914) (4) - fascia board...

Page 51: Rear Trim Boards

Rear trim boards 28 side vertical trim (2 plcs) vertical trim (2 plcs) angled roof trim (4 plcs) screw pfh 8x1 1/2 (24 plcs) 3 3/8" - side vertical trim - w4l07665 5/8"x2 3/8"x44 1/2" (16x60x1130) (2) - angled roof trim - w4l07666 5/8"x3 3/8"x36" (16x86x914) (4) - vertical trim - w4l07674 5/8"x3 3/8...

Page 52: Vent Installation

Vent installation 29 vent (8x16) (2 plcs) the vent is installed the same on both the front & back center walls. - vent (8x16) - a4m00771 (2) door drip board screw pfh 8x1 1/2 (4 plcs) screw pwh 8x5/8 (8 plcs) • the vent (8x16) is installed over the 4-1/2" holes in the front and rear center panels. D...

Page 53: Door Components

Door components preferred handle installation spring latch installation 30 8x1 pfh screw blk - wc (2 plcs) - spring latch assembly - a4m00774 (2) tap the top of the spring latch pin to make indention in floor and header. - 8x1 pfh screw blk - wc - h100445 (2) vt - screw pfh 8x1-1/2 blk - h100200 (8)...

Page 54: Starter Shingles

31 • note how the shingle placement changes as you switch sides while working from left to right. This works the same way in the following pages only you will be working from right to left. 1/2" overhang on all sides of shed. Top view left side right side left side right side • work left to right wh...

Page 55: Shingle Course - Start

Shingle course - start start here - 7/8" roofing nail galv. - h100446 (8) note: start shingles with 1/2" of overhang off the edges of the shed and flush with the starter shingles. Full - asphalt shingle 12 x 36 (1) 1 - asphalt shingle 12 x 30 (1) important note: shingle #1 starts approximately 5 1/4...

Page 56: Finish Shingle Courses

Finish shingle courses - 7/8" roofing nail galv. - h100446 (141) •repeat courses 1 & 2 all the way up the shed until you reach the peak as shown below. Full full - asphalt shingle 12 x 36 (19) 2 2 - asphalt shingle 12 x 22.25 (7) 1 1 - asphalt shingle 12 x 30 (5) 3 3 - asphalt shingle 12 x 28.25 (6)...

Page 57: Ridge Cap Installation

Front of shed. 34 • install first ridge cap flush with shingles below as shown. Start at the front of your shed and work towards the rear. - ridge cap 12 (17) - ridge cap 9.25 (1) - shingle cap 5 x 11.75 (1) - 7/8" roofing nail galv. - h100446 (38) ridge cap installation • if needed bend excess shin...

Page 58: Shingles - Ridge Cap

Shingles - ridge cap • you have finished your ridge cap. 35 flush front of shed. • install ridge caps 5" back, as shown. Ridge cap 12 (1 plcs) ridge cap 12 (2 plcs) note: nails are covered by new ridge caps. Repeat this step (15 times) 7/8" roofing nail galv. (2 plcs) note: this is the only short 9 ...

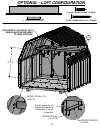

Page 59

Optional - loft configuration 36 screw pfh 8x1 3/4 (8 plcs) 51 1/4" screw pfh 8x1 (16 plcs) support board (4 plcs) equally space the (4) support boards along the bottom of the (2) loft panels. Lp1 (2) lp1 - loft panel - w2a02124 - support board - w4l07668 5/8"x3 3/8"x22 1/8" (16x86x562) (4) bn - scr...

Page 60

Optional - shelf configuration - support block - w4l07669 1 1/2"x3 1/2"x3 1/2" (6) bv - screw pfh 8x2 1/4 - h100091 (12) screw pfh 8x2 1/4 (12 plcs) secure support (6) blocks in desired height locations no higher than 43". 37.

Page 61

Optional - shelf configuration continued 38 - support board - w4l07668 5/8"x3 3/8"x22 1/8" (16x86x562) (4) (2) lp1 - loft panel - w2a02124 lp1 support board (2 plcs) screw pfh 8x1 3/4 (4 plcs) assemble (2) shelves before installation. Support block (assembled in previous step) screw pfh 8x1 3/4 (8 p...

Page 62

Branding plate installation screw pwh 8x5/8 (4 plcs) byd id tag (medium) without ages cy - screw pwh 8x5/8 - h100128 (4) mx - byd id tag (medium) without ages - a100240 (1) 39.

Page 63: Post Installation Faqs

40 post installation faqs shingles aren’t laying flat this is a normal condition. Please allow a minimum of (2) full weeks of temperatures above 60º f for shingles to seal. Subfloor sheathing small gaps between subfloor sheathing sheets are a normal aspect of construction. You may caulk gaps to fill...

Page 64

Backyard discovery sheds 15 year limited warranty this limited warranty by backyard discovery applies to products manufactured under the backyard discovery brand. Backyard discovery warrants this product is free from defects in material and workmanship for a period of fifteen (15) years from the ori...