- DL manuals

- Backyard Discovery

- Swing Set

- Next Generation 5007

- Assembly Manual

Backyard Discovery Next Generation 5007 Assembly Manual

The Cedar Mountain Swingset

From Backyard Discovery

Backyard Discovery

3001 N Rouse Ave

Pittsburg, KS 66762

www.swingsetsonline.com

Sales: 855-308-6871

Support: 800-856-4445

YOU MUST START HERE!

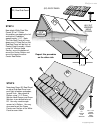

Use these assembly instructions to begin assembly of your Cedar Mountain swingset.

1.

The Cedar Mountain is made from individually packaged components. Each

component has its own assembly instructions in the box.

2.

Build each component according to the instructions in the respective

component box(es) except for the Tunnel.

3.

For the tunnel only, you MUST use the instructions in this package. DO NOT USE

THE INSTRUCTIONS IN THE TUNNEL/ ROCK WALL BOX!

4.

Once all components are complete, attach them to the respective towers to

make the Cedar Mountain configuration as shown. Attach the towers together

using the tunnel and the instructions in this package!

5.

The swing beam can be attached to the back of either fort without causing a

play conflict.

6.

Build the rock wall using the original tunnel/rock wall instructions in the box and

attach it to one of the fort openings as directed in the rock wall instructions.

7.

DO NOT INSTALL THE 10’ SLIDE AND THE 8’ SLIDE NEXT TO EACH OTHER! YOU

MUST LEAVE A TOWER WALL PANEL IN PLACE AS A SPACER TO SEPARATE THE

TWO SLIDES. MOUNTING THEM CLOSE WILL CAUSE A PLAY CONFLICT AND

MAY RESULT IN INJURY!

8.

DO NOT MOUNT THE MONKEY BARS ON THE SAME TOWER/SIDE OF THE

TOWER AS EITHER SLIDE. THIS WILL CAUSE A PLAY CONFLICT AND MAY RESULT

IN INJURY!

Meijer.com

Summary of Next Generation 5007

Page 1

The cedar mountain swingset from backyard discovery backyard discovery 3001 n rouse ave pittsburg, ks 66762 www.Swingsetsonline.Com sales: 855-308-6871 support: 800-856-4445 you must start here! Use these assembly instructions to begin assembly of your cedar mountain swingset. 1. The cedar mountain ...

Page 2: 866-362-1123

Model #5007 assembly manual next generation if you need assistance with parts or have assembly questions, please call customer service at 866-362-1123 our regular office hours are monday through friday, 7:00 a.M. To 4:00 p.M. Central time please read the entire instruction manual carefully before pr...

Page 3

Meijer.Com.

Page 4: Important Tips For Assembly

Prior to assembling your play product, take a installation and at least once per year. Thorough inventory of all components using there are many excellent products, such the parts list. As thompson's waterseal, behr wood conditioner, olympic water guard or sort and lay out all wood pieces, matching ...

Page 5: For Safety'S Sake,

Safety and assembly information for safety's sake, please take time to read all instructions completely and caution your children accordingly caution for your children. Observing the following statements and warnings reduces the likelihood of serious or fatal injury. • instruct children not to attac...

Page 6

Safety and assembly information assembly safety: • keep the work area clean and clear of obstructions. • children should stay out of the work area until the safe play area is cleared of obstacles, the gym set has been completely assembled, all hardware has been tightened and checked and all tools ha...

Page 7: Page 4 - Safety & Assembly

Recommended ground covers suggested material ........Uncompressed depth double shredded bark mulch ...........9" uniform wood chips ........................12" fine gravel .......................................12" fine sand ..........................................12" selecting the correct locatio...

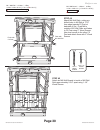

Page 8: Page 5 - Safety & Assembly

© leisure time products inc. Next generation 5007 10-0409 version 4 page 5 - safety & assembly landscape t imbers 6' from play structure sale play area using recommended ground cover landscape t imbers 6' from play structure sale play area using recommended ground cover front left right back meijer....

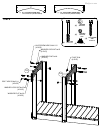

Page 9: Using The Hardware

Playground, inc. Gym sets use a few standard connections. Becoming familiar with these connections will simplify assembly and insure a safer play product for your children. Using the hardware failure to replace this bolt with a shorter one could result in personal injury. Check the positioning of pa...

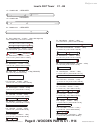

Page 10: Page 7 - Part Locator

© leisure time products inc. Next generation 5007 10-0409 version 4 page 7 - part locator front v iew not shown h6 h13 h8 g3 h7 h14 l1 g4 l2 m6 m6 n2 back v iew n2 m8 c1 m2 h1 1 h1 1 c2 c3 h1 m9 g8 m6 m6 m8 h3 g2 t ent t op g2 n2 m8 m8 c1 g1 g6 g5 c2 c2 c1 c3 h5 h1 h3 m6 h9 h9 h7 h7 m5 m9 m9 m4 e1 e...

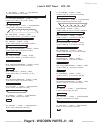

Page 11

E1 entry ladder rail * 4 holes * 1 set left & right req 1-3/8 x 3-3/8 x 52 [ 3.49 x 8.57 x 132.08 ] 1 x 5-1/2 x 78-1/2 [ 2.54 x 13.97 x 199.39 ] g1 base board * 6 holes * 2 req 1 x 5-1/2 x 57-1/2 [ 2.54 x 13.97 x 146.05 ] g2 arched wall rail * 4 holes * 2 req 1 x 5-1/2 x 47 [ 2.54 x 13.97 x 119.38 ]...

Page 12

11/16 x 3-3/8 x 23 [ 1.74 x 8.57 x 58.42 ] m9 wall board * 4 holes * 23 req 11/16 x 3-3/8 x 28-3/4 [ 1.74 x 8.57 x 73.03 ] m8 club house rail * 3 holes * 4 req 11/16 x 3-3/8 x 28-3/4 [ 1.74 x 8.57 x 73.03 ] m7 window trim * 4 holes * 1 req lowe's 5007 tower h10 - n3 l1 floor board * 4 holes * 4 req ...

Page 13: Z5-3.5Hb

Page 10 - hex head bolts screws & washers 5/16 x 1-1/4" hex head bolt z5-1.25hb drawings are to scale but small variations are normal. Z5-3.5hb 16 ths size type 0 1 2 3 4 5 6 7 8 9 mea sure bol ts fr om bo tt om of head to bo tt om of bol t mea sure bol ts fr om bo tt om of head to bo tt om of bol t...

Page 14: Additional Items

Green mesh window 1 13x23 5007 additional items 1 - metal id plaque 4 - ground stakes 1 - assembly manual 1 - pounding block 4 - y28 15 1/4" metal dowels y9 5007 tent top 87" x 57 ½" page 11 - fastener detail list & misc. Parts no te: q u antities include extr a hard w are part # . . . . . . . . . ....

Page 15: Page 12

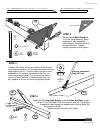

Step 1 start by laying c2, c1 and c3 posts flat on ground. Install 5/16” spike t-nuts in the double holes that are towards the bottom of posts. Then flip posts over so that the t-nuts are towards the ground. Then place h3 floor rail, five-hole board, on c2 and c1 post. Note: the single hole in the h...

Page 16: Page 13

Step 5 this step will take two people. Stand up front and back assemblies. Attach left floor rail h6 to c2 post using 5/16"x3-3/4" hex bolts, internal tooth lock washers, flat washers and spike t nut. Step 6 attach right floor rail h7 to c3 post using 5/16 x 3-3/4” hex bolts, internal tooth lock was...

Page 17: Page 14

Step 7 attach another h7 floor rail to c1 post using 5/16 x 3-3/4” hex bolts, internal tooth lock washers, flat washers and spike t nut. Step 8 attach h8 floor rail, four-hole, to c1 post using 5/16 x 3-3/4” hex bolts, internal tooth lock washers, flat washers and spike t nut. C1 c1 c1 c1 c3 c3 c3 c...

Page 18: Page 15

Step 9 attach g1 front and back baseboards, placing flush with outside of c2 and c3 posts,pilot drill with 3/16" bit using holes in g1 as guide and attach using 5/16x2-1/2” lag screws, internal tooth lock washers and flat washers.Center c1 post straight up and down and finish attaching g1 using 2 1/...

Page 19: Page 16

Step 11 attach g6 right baseboard on c3 post, flushing with g1 baseboard, pilot drill with 3/16" bit using holes in g6 as a guide. Attach using 2-1/2” lag screws, internal tooth lock washers and flat washers. Step 12 attach g7 center baseboard, 6- hole, on left side of c1 post, pilot drill with 3/16...

Page 20: Page 17

Step 13 attach g9 bottom floor joist between g7 baseboard and left g6 baseboard and attach with four 2-1/2” wood screws. Note: you must pilot drill g6 and center screws into g9. Step 14 attach h4 top floor joist between h6 left floor rail and h7 right floor rail using four 2-1/2” wood screws. Note: ...

Page 21: Page 18

Step 15 attach h14 lower top floor joist to h7 right floor rail and h8 center floor rail using four 2-1/2” wood screws. Note: center screws into h14. Step 16 attach 5/16” spike t-nuts on outside of floor rails on left front and back of upper floor rails and front and back of lower-upper floor rails....

Page 22: Page 19

Step 19 attach l1, four-hole floor boards, between tower posts flushing to outside of left and right floor rail on top floor and between c3 posts on lower floor flush with the right floor rail. Attach using 2” wood screws. 28 3/4" step 18 now at front floor rail and back floor rail measure to center...

Page 23: Page 20

Step 22 drive 5/16” spike t-nuts into inside of c2 and c1 posts. Then attach g2 sculptured rails to front and back of c2 and c1 posts using 5/16 x 3-3/4” hex bolts, internal tooth lock washers and flat washers. G2 g2 c1 c1 c2 c2 h3 1 x 5-1/2 x 57-1/2 [ 2.54 x 13.97 x 146.05 ] g2 arched wall rail * 4...

Page 24: Page 21

Step 24 now install five m3 floor boards on top-lower floor spacing evenly using 2” wood screws. Step 25 attach l1, four-hole floor board, between tower posts flushing to outside of left and right floor rail on bottom floor and between c3 posts. At this point, install lower deck floor boards, m3, us...

Page 25: Page 22

2 1/4" step 26 attach m5, four-hole, clubhouse rail at left side of tower c2 post. Place on top of l1 deck board and flush with outside of c2 post. Attach using 2” wood screws. Step 27 attach m5, four-hole, clubhouse rail at c1 post above lower and top deck; measuring 2-1/4” up from top of m3 floor ...

Page 26: Page 23

Step 28 attach a y9 l-brace to g8 center uprite placing 1/4"x3/4" phillips truss head bolt, lock washer and flat washer in countersunk hole of g8.Note: long end of y9 to g8.Then use phillips barrel nut to finish fastening to g8. Now attach two m8s to g8 using 1/4 x 1-1/4” truss head bolts, 5/16” int...

Page 27: Page 24

© leisure time products inc. Next generation 5007 10-0409 version 4 page 24 step 30 attach o1 to l3 left and l3 right with 1-1/8" wood screw using pilot holes provided. Repeat for both sets. Attach the o2 roof cleat using phillips truss head bolt, two flat washers, lock washer and barrel nut as show...

Page 28: Page 25

© leisure time products inc. Next generation 5007 10-0409 version 4 page 25 step 33 to attach tent top - drop the tent top across the frame, find center and attach with one washer head screw to each side of center support. Attach 3/4" washer head screws on both sides of tent top to o1 tent cleat on ...

Page 29: Page 26

© leisure time products inc. Next generation 5007 10-0409 version 4 page 26 step 34 use two people to lift tent assembly up on top of play set. Attach with four 2-1/2” lag screws, lock washers and flat washers to tower legs, making sure that the h5 roof support is centered and flush with the top of ...

Page 30: Page 27

Step 36 on left side of tower, between c2 posts, attach ten m6 wall boards and one l2 wall board. L2 will be in center with five m6s on each side. Space evenly apart and fasten with 1-1/2” wood screws at top rail and 1-1/4” wood screws at bottom rail. Step 37 attach six m10 wall boards and one n3 wa...

Page 31: Page 28

Step 39 attach six m6 wall boards and one n2 on back left placing three m6s, then one n2 and the remaining three m6s then space evenly and fasten using 1-1/4” wood screws in bottom rail and 1-1/2” wood screws in top rail. Step 40 install 5/16” spike t-nuts inside c3 posts and attach h9 using 5/16 x ...

Page 32: Page 29

Step 41 attach h11 wall rails, noting countersunk holes drilled at 2-1/2” from edge go towards c3 posts. Flush h11 to outside of h9 front wall rail at top and bottom pilot drill with 3/16" bit using holes in h11 as guides and fasten using 2-1/2” lag screws, internal tooth lock washers and flat washe...

Page 33: Page 30

Step 44 attach m4 wall rails, noting pre- drilled holes in m4 rail at 1-1/2” from edge towards c2 post at backside of set. Flush m4 to outside of m1 wall rails and fasten to c2 post using 2” wood screws. Now level across to the other c2 post and attach there with 2” wood screws. Step 45 attach six m...

Page 34: Page 31

Step 46 attach eight m9 wall boards to the inside of m1s spacing approximately 2-3/4” apart, again using 1 1/4” wood screws. Step 47 placing entry ladder rail e1, either left or right, flat on ground, drive 15- 1/4” metal dowels, using pounding block, into rail. Then place opposite ladder rail, lini...

Page 35: Page 32

Step 48 stand entry ladder up and line up ladder rails with pre-drilled holes and h12 floor rail and using 3/16” drill bit pilot hole entry ladder rails. Then fasten ladder assembly using 2-1/2” lag screws, internal tooth lock washers and flat washers through h12 floor rail into entry ladder rails. ...

Page 36: Step 94

Green mesh window 1 13x23 5007 © leisure time products inc. Next generation 5007 10-0409 version 4 step 50 install window mesh at top and bottom inside of window using 3/4” washer head screws. Step 94 #8 x 3/4" washer head screw inside tower your lowe's 5007 next generation tower is now finished. He...

Page 37: Maintenance

Maintenance all outdoor wooden products, including playground, inc products, require routine inspection and regular maintenance. After installation, a follow-up inspection should take place after one week and twice a month thereafter for the remaining life of your play products. Maintenance should b...

Page 38: Page 35 - Maintenance

Commonly asked questions and answers question: now that my playset product is assembled and installed, will i have to do anything to it? Answer: yes. You must provide routine inspections and regular maintenance. These procedures are covered in the "required periodic maintenance" section. Question: h...

Page 39: Page 36 - Maintenance

Page 36 - maintenance question: why is my play product leaning (racking)? Answer: leaning occurs in play products installed on uneven ground. Realignment will be necessary and is covered in the "required periodic maintenance" section of this manual question: what can i do about squeaking swing conne...

Page 40

For your records where purchased: _____________________________________________________________________ purchase date: ____________________________ installation date: _______________________ model name & number ____________________________________________________________________ please read this boo...

Page 41

Model #5007 assembly manual detach here and mail next generation leisure time products pla ce pos ta ge here leisur e t ime p roducts , inc. P.O . Bo x 459 siloam spr ings , ar 727 61 warranty registration card leisure time products, inc. P.O. Box 459 siloam springs, ar 72761 1-866-362-1123 toll fre...

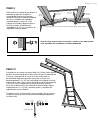

Page 42: Part # 50

H2 h10 h10 step 1 start by removing tent top. Then remove h2 tent support and h10 uprights. Then remove h1 roof support rails from both sides, back and front of set, and you need to mark h1s starting from edge at 1- 3/4”, 20-1/8”, 39-3/8”, and 57-3/4”. Then put a mark at each of these points; 3/4” d...

Page 43

Step 2 now attach two f1 roof rafters together, flushing points, and fasten together using 2-1/2” wood screws. Then repeat on three more sets of rafters #8 x 2-1/2 wood screw " step 3 now replace h1s on set and note the next process will take at least two people. Starting at either corner, start fas...

Page 44

© copyright playground inc (r1) roof sub panel (r2) roof panel r1 r2 r1 1-1/4" 1-1/4" 1-1/2" overlap 1/4" green flat washer #8 x 3/4 washer head screw " #8 x 1-1/2 green washer head screw " step 4 now attach white roof sub- panels r1 to f1 rafter assemblies overlapping the left and right of clubhous...

Page 45

© copyright playground inc (r2) roof panel (r3) ridge cap r2 19-1/2" 1/4" green flat washer #8 x 1-1/2 green washer head screw " r3 step 6 at this point, measure up from bottom 19-1/2” and again attach next panel using 1-1/2” green washer head screws and green washers. Now repeat green roof panels o...

Page 46

Step 9 attach m1 roof trim placing 90 degree flat edge pushed towards sub-roof panel until flush and bottom angle panel sitting flat on top of roof rail support and attach at f1 rafter using 1-1/2 wood screws and attach to roof rail h5 using 2-1/2” wood screws. Repeat steps 8 & 9 on opposite end. #8...

Page 47: Part

H2 h10 h10 paso 1 c omience retirando la parte superior de la cubierta. Luego retire el soporte de la cubierta h2 y los parales h10. Luego retire los largueros de soporte del techo h1 de ambos lados, parte posterior y anterior de la unidad y necesita marcar los h1 comenzando desde el extremo a 1-3/4...

Page 48

Paso 2 ahora fije juntos dos cabrios de techo f1, con los puntos a ras y asegúrelos utilizando tornillos de madera de 2-1/2 in. (6,3 cm). Luego repita en tres juegos más de cabrios. Paso 3 ahora reemplace los h1 en el juego y observe que el próximo proceso implicará dos personas. Comenzando en cualq...

Page 49

© copyright playground inc (r1) sub panel del techo (r2) panel de techo r1 r2 r1 1-1/4 in. 1-1/4 in. 1-1/2 in. Overlap arandela verde plana de 1/4 in. (6,3 mm) paso 4 ahora fije los sub paneles blancos de techo r1 a los ensambles de cabrio f1 superponiendo el izquierdo y el derecho de la casa club a...

Page 50

© copyright playground inc (r2) panel de techo (r3) caballete r2 19-1/2 in. R3 paso 6 en este punto mida desde la parte inferior hacia arriba 19-1/2 in. (49,5 cm) y de nuevo fije el siguiente panel utilizando tornillos verdes cabeza de arandela de 1- 1/2 in. (3,8 cm) y arandelas verdes. Ahora repita...

Page 51

Paso 9 fije las riostras del techo m1 colocando el extremo plano a 90 grados presionado hacia el sub panel del techo hasta que quede a ras y el panel de ángulo inferior colocado plano sobre el soporte del larguero del techo y fije en el cabrio f1 utilizando tornillos para madera de 1-1/2 in. (3,8 cm...

Page 52: Cedar Mountain

Manufacturer: backyard discovery 3001 north rouse pittsburg, ks 66762 1-800-856-4445 made in china register your new swing set on-line @ www.Swingsetsonline.Com (you will also find any updates on assembly instructions and information to order replacement parts) save this assembly manual for future r...

Page 53

Parts identification wood components (not to scale) e1 - left tunnel rail 1 3/8"x3 3/8"x62" (36x86x1574.8) (1) e2 - right tunnel rail 1 3/8"x3 3/8"x62" (36x86x1574.8) (1) e3 tunnel floor rail (not used with (2) towers) f1 - left tunnel rail 1"x2 3/8"x33 7/8" (24x60x860) (1) f2 - right tunnel rail 1"...

Page 54

Parts identification wood components (not to scale) m3 - tunnel wall rail 5/8"x3 3/8"x23 1/4" (16x86x590.6) (2) m4 - tunnel floor board 5/8"x3 3/8"x22" (16x86x558.8) (18) n1 - knotched tunnel support 5/8"x2 3/8"x20 1/4" (16x60x514.4) (4) parts identification accessories (not to scale) pt2 - plastic ...

Page 55

Parts identification hardware aj - bolt hex 5/16x1 1/4 - h100042 (2) ah - bolt hex 5/16x1-1/2 - h100041 (9) tr - bolt hex 5/16x1 3/4 - h100043 (4) al - bolt hex 5/16x2 1/2 - h100045 (11) yl - bolt hex 5/16x3 1/4 - h100050 (4) bc - screw pwh 8x3/4 - h100070 (2) bg - t-nut 5/16 - h100074 (26) cc - was...

Page 56

Step 1 t-nut 5/16 (10 plcs) e1 e2 t-nut 5/16 (10) washer flat 8x19 (4 plcs) nut lock 5/16 (4 plcs) washer flat 8x19 (4 plcs) washer lock int 8x15 (4 plcs) bolt hex 5/16x1 3/4 (4 plcs) bolt hex 5/16x1-1/2 (2 plcs) washer lock int 8x15 (2 plcs) washer flat 8x19 (2 plcs) y27 y27 y27 y27 washer lock int...

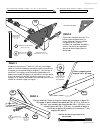

Page 57

Step 3 screw pfh 8x1 3/4 (8 plcs) screw pfh 8x1 3/4 (8) m4 m4 m4 - tunnel floor board 5/8"x3 3/8"x22" (16x86x558.8) (2) 3/4" meijer.Com.

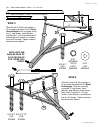

Page 58

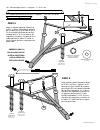

F1 f2 f3 f3 f3 f3 bolt hex 5/16x2 1/2 (8 plcs) washer lock int 8x15 (8 plcs) washer flat 8x19 (8 plcs) step 4 bolt hex 5/16x2 1/2 (2 plcs) washer lock int 8x15 (2 plcs) washer flat 8x19 (2 plcs) t-nut 5/16 (2 plcs) washer lock int 8x15 (10) washer flat 8x19 (10) t-nut 5/16 (2) bolt hex 5/16x2 1/2 (1...

Page 59

Step 5 screw pfh 8x1 3/4 (64 plcs) m4 screw pfh 8x1 3/4 (8) m4 - tunnel floor board 5/8"x3 3/8"x22" (16x86x558.8) (16) meijer.Com.

Page 60

Step 6 lag screw hex 5/16x2-1/2 (4 plcs) washer lock int 8x15 (4 plcs) washer flat 8x19 (4 plcs) bolt hex 5/16x3 1/4 (4 plcs) washer lock int 8x15 (4 plcs) washer flat 8x19 (4 plcs) t-nut 5/16 (4 plcs) washer flat 8x19 (4) washer lock int 8x15 (4) t-nut 5/16 (4) bolt hex 5/16x3 1/4 (4) lag screw hex...

Page 61

Step 7 screw pfh 8x1 1/2 (8 plcs) m3 m3 screw pfh 8x1 1/2 (8) m3 - tunnel wall rail 5/8"x3 3/8"x23 1/4" (16x86x590.6) (2) meijer.Com.

Page 62

Step 8 1 7/8" (3 spcs) screw pfh 8x1 1/8 (6 plcs) screw pfh 8x1 1/8 (6 plcs) m2 m2 - picket 5/8"x3 3/8"x33 1/8" (16x86x840) (6) screw pfh 8x1 1/8 (12) meijer.Com.

Page 63

Step 9 flush flush flush flush screw pfh 8x1 1/4 (12 plcs) hand tighten all screws in this step. Screw pfh 8x1 1/4 (12) n1 n1 n1 n1 n1 - knotched tunnel support 5/8"x2 3/8"x20 1/4" (16x60x514.4) (4) meijer.Com.

Page 64

Step 10 m1 screw pfh 8x1 3/4 (6 plcs) screw pfh 8x1 3/4 (6) flush m1 m1 - knotched tunnel rail 5/8"x3 3/8"x36 1/4" (16x86x920.8) (2) hand tighten all screws in this step. Meijer.Com.

Page 65

Step 11 pt2 pt2 pt2 m1 n1 n1 n1 screw pwh 8x3/4 (1 plc) screw pwh 8x3/4 (1) m1 n1 loosen the 'm1' and 'n1' notched boards. Slide one side of the 'pt2' plastic tunnel into the grooves of the vertical 'n1' notched boards and down until the edge of the 'pt2' plastic tunnel bottoms out in the groove of ...

Page 66

Step 12 t-nut 5/16 (4 plcs) washer flat 8x19 (4 plcs) washer lock int 8x15 (4 plcs) bolt hex 5/16x1 1/4 (4 plcs) screw pfh 8x1 3/4 (4 plcs) screw pfh 8x1 3/4 (4) washer flat 8x19 (4) washer lock int 8x15 (4) t-nut 5/16 (4) bolt hex 5/16x1 1/4 (4) 1" 3" 1" 2 1/2" 3/4" 3/4" 6" 23" pilot drill holes us...

Page 67

Step 13 bolt hex 5/16x1 1/4 (4 plcs) washer lock int 8x15 (4 plcs) washer flat 8x19 (4 plcs) t-nut 5/16 (4 plcs) screw pfh 8x1 1/2 (4 plcs) screw pfh 8x2 (4 plcs) pilot drill holes using 1/8" drill bit. Pilot drill holes using 3/8" drill bit. (see step 12 for drilling locations) bolt hex 5/16x1 1/4 ...

Page 68

At this point, make sure the set is at its permanent location. Make sure to stake down the set with ground stakes. Attach the slide to the set using 1” step bolts, barrel nuts, lock washers and flat washers. Use holes in slide and mark hole locations, move slide out of the way and drill the holes wi...

Page 69: Part # 50

Fasten the five monkey bar ladder rungs y14 to the monkey bar rails e2 left rail and e3 right rail using 2 ½” joint connectors, lock washers and flat washer. Make sure the rails are approximately 22 ½” across the end. Tighten the joint connectors just snug. You will need to remove wall to create ope...

Page 70

Step 4 pound the metal end ladder rungs y15 into one of the end ladder rails e1. Use spacer block as a cushion between the rungs and your hammer. Line up the rungs with the holes in the other end ladder rail e1 and pound it down using the spacer block to prevent marking the ladder rail with the hamm...

Page 71

Step 5 drill 3/16” pilot hole using the pre-drilled holes in the monkey bar ground board g1 as guide and attach it to the end ladder assembly using two 2-1/2” lag screws, lock washers and flat washers. Tighten the screws securely but do not over tighten. Step 6 attach the two short angle braces e4 t...

Page 72

Step 7 6”metal triangle brace lay the monkey bar assembly and the end ladder assembly end to end as shown. Then connect them with 6” metal triangle brace between them as shown with 3” hex head bolts, lock washers, flat washers and spike tee nuts and 1- 1/2” hex head bolts, lock washers, flat washers...

Page 73

Step 9 turn the monkey bar assembly over and put into position. Secure the monkey bar assembly to sculptured rail g2 with 1-1/4” hex head bolts, lock washers, flat washers and spike t nuts according to the bolting diagram shown below. Also 2” lag bolt, lock washers and flat washers. Drill 3/8” hole ...

Page 74: Part

Asegure los cinco peldaños de la escalera para el pasamanos y14 a los largueros del pasamanos larguero izquierdo e2 y larguero derecho e3 utilizando dos conectores de uniones de 2-1/2 in. (6,3 cm), arandelas de seguridad y arandela plana. Cerciórese de que la distancia entre los largueros sea 22-1/2...

Page 75

Paso 4 martille los peldaños de metal de la escalera terminal y15 en uno de los largueros e1 de la escalera terminal. Use un bloque espaciador como amortiguador entre los peldaños y el martillo. Alinee los peldaños con los agujeros en el otro larguero de escalera terminal e1 y martille utilizando el...

Page 76

Paso 5 taladre agujero piloto de 3/16” in. (4,8 mm) utilizando los agujeros pre-taladrados en la tabla de tierra g1 para el pasamanos como guía y fíjela al ensamble de escalera terminal utilizando tornillos tirafondo de 2-1/2 in. (6,3 cm), arandelas de seguridad y arandelas planas. Apriete los torni...

Page 77

Paso 7 abrazadera triangular metálica de 6in. (15,2 cm) coloque el ensamble del pasamanos y el ensamble de la escalera terminal hacia el extremo como se ilustra. Luego conéctelos con la abrazadera triangular de metal de 15,2 cm entre ellos como se ilustra con pernos cabeza hexagonal de 7,6 cm, arand...

Page 78

Paso 9 déle vuelta al ensamble del pasamanos y colóquelo en posición. Asegure el ensamble del pasamano al larguero tallado g2 con pernos cabeza hexagonal de 3,2 cm, arandelas de seguridad, arandelas planas y tuerca en t con espigas de acuerdo al diagrama que se ilustra más abajo. También pernos tira...

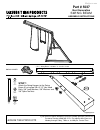

Page 79: Part # 50

© copyright playground inc swing hanger ( ) swing beam * 15 holes * 3-1/4 x 5-1/4 x 94 a1 step 1 3/8" spike tee nut 3/8" internal tooth lock washer sae 3/8" flat washer 3/8 x 5-1/2" hex head bolt part # 50 3 7 next generation swing beam assembly instructions a1 attach the swing hangers to the swing ...

Page 80

© copyright playground inc thread a 3/8" spike tee nut as shown in the illustration so that you can pound it into the countersunk hole on one long angle brace e1. Once the spike tee nut is firmly embedded in the wood at the bottom of the hole, un- screw and remove the bolt. This is the easiest way t...

Page 81

© copyright playground inc pilot drill with 3/16" bit using holes in g1 as guide and attach the g1 beam ground board to the assembly using four 2" lag screws, lock washers and washers . The ground board will overhang the e1 boards, as shown in the inset illustration. Tighten securely, but do not ove...

Page 82

© copyright playground inc attach the support assembly to the swing beam with the metal triangles y1 using two 4” hex head bolts, lock washers, flat washers and lock nut . 5/16" x 2018 nylock lock nut 5/16 x 4" hex head bolt 5/16" lock washer 5/16" flat washer y1 attach the y16 swing assembly mounts...

Page 83

G4 m5 h6 c2 c2 step 9 using the pre-drilled holes in the g4 club house wall rail as a guide, drill thru the wall boards using a 3/8” drill bit. Install four 5/16” spiked t nuts, from the inside of the tower, into these holes. Turn over the swing beam assembly, stand it up, and line up the holes in t...

Page 84: Part

© copyright playground inc colgador del columpio ( a1 ) barra para columpio * 15 agujeros * 3-1/4 x 5-1/4 x 94 paso 1 tuerca en t de 3/8 in. (9,5 mm) con espigas arandela de seguridad de 3/8 in. (9,5 mm) con dientes internos arandela plana sae de 3/8 in. (9,5 mm) perno cabeza hexagonal de 3/8 x 5- 1...

Page 85

© copyright playground inc introduzca una tuerca en t de 3/8 in. (9,5 mm) con espigas como se ilustra de modo que la pueda martillar para avellanar el agujero en un refuerzo largo en ángulo e1. Una vez que la tuerca en t con espigas esté firmemente introducida en la madera en el fondo del agujero, d...

Page 86

© copyright playground inc haga un agujero piloto con la broca de 3/16 in. (4,8 mm) utilizando los agujeros de g1 como guía y fije la tabla de tierra g1 al ensamble utilizando dos tornillos tirafondo de 2 in. (5 cm), arandelas de seguridad y arandelas. La tabla de tierra sobresaldrá de las tablas e1...

Page 87

© copyright playground inc fije el ensamble del soporte a la barra para columpio con los triángulos de metal y1 utilizando dos pernos cabeza hexagonal de 4 in. (10 cm), arandelas de seguridad, arandelas planas y tuerca de seguridad. Tuerca mecÁnica de seguridad de 5/16 in. (8 mm) p e r n o c a b e z...

Page 88

G4 m5 h6 c2 c2 paso 9 utilizando los agujeros pre-taladrados en el larguero para pared de la casa club g4 como guía, taladre a través de las tablas de pared utilizando una broca de 3/8 in. (9,5 mm). Instale cuatro tuercas en t de 5/16 in. (8 mm) con espigas desde la parte interior de la torre en est...