- DL manuals

- Backyard Discovery

- Swing Set

- Patriot II

- Owner's manual

Backyard Discovery Patriot II Owner's manual

Summary of Patriot II

Page 1

Owner’s manual faq’s assembly instructions warranty information patriot ii wooden playcenter - 2010 model: 44010 manufacturer: backyard discovery 3001 north rouse pittsburg, ks 66762 made in china 44010 patriot ii ver 1-10-0425.

Page 2

Title page ps rev. 01/28/2009 tools required for installation: (these are the tools that are generally required fo r assembly of our playsets. These tools are not included in the playset purchase.) (level 24”) (open end wrenches (nut drivers ½” & 7/16” ) ½” & 9/16” ) (tape measure) (3/8” drive ratch...

Page 3: For Your Records:

Page 1 owner’s manual play set owner ps-2010 rev. 10/21/2009 dear customer: please read entire booklet completely before beginning the assembly process. Warning: children must not use this playcenter until unit has been completely assembled and inspected by an adult to insure set has been properly i...

Page 4

Page 2 owner ps-2010 rev. 10/21/2009 owner’s manual play set please refer to the assembly section of the assembly manual for maximum fall height. Positioning your playcenter 1. The playcenter is designed to be installed on a level surface by an adult with an adult helper. Place in a flat area of you...

Page 5

Page 3 owner’s manual play set owner ps-2010 rev. 10/21/2009 operating instructions: note : your children’s safety is our #1 concern. Observi ng the following statements and warnings reduces the likelihood of serious or fatal injury. Please review these safety rules regularly with your children. 1. ...

Page 6

Owner’s manual play set owner ps-2010 rev. 10/21/2009 maintenance instructions: 1. Check all nuts and bolts twice monthly during the usage season and tighten as required. (but not so tight that you crack the wood) we recommend you check the swing beam and hardware every two weeks due to wood expansi...

Page 7

Page 5 owner’s manual play set owner ps-2010 rev. 10/21/2009 appendix a 11 x3. Consumer information sheet for playground surfacing materials x3.1 the u.S. Consumer product safety commission (cpsc) estimates that about 100,000 playground equipment-related injuries resulting from falls to the ground s...

Page 8

Play set assembly manual faqs: 1. Does the area for the playset need to be level? Yes. Backyard discovery recommends the playset be positioned on a flat level area for maximum safety and durability. The stakes provided should be used to secure it firmly to the ground. 2. What size area is recommende...

Page 9

However, backyard discovery playsets are designed and constructed using the actual dimensions so everything fits properly and remains so during the life of the playset. 11. The end beam is not straight up and down. Why not? This is normal. Backyard discovery designs playsets this way to ensure the s...

Page 10: Using The Hardware

Leisure time products, inc gym sets use a few standard connections. Becoming familiar with these connections will simplify assembly and insure a safer play product for your children. Using the hardware check the positioning of parts in each step's illustration, noting which of the parts should recei...

Page 11: 1-800-856-4445

Patriot ii model 44010 assembly requires two moderately skilled people. For residential use only if you need assistance with parts or have assembly questions, please call customer service at 1-800-856-4445 please read the entire instruction manual carefully before proceeding with the assembly or use...

Page 12

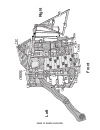

9 '- 6 1 /2 " [2 .9 m ] 6 '- 9 " [2 .1 m ] m a x f a l l 24'-2" [7.4 m] 7 '- 5 1 /2 " [2 .3 m ] 1 9 '- 5 1 /2 " [5 .9 m ] 36'-2" [11 m] page 10 - safe play area dimensions: • the patriot ii has one layout option. Layout: ground dimension safe play area* 7’-5½”x 24’-2” x 9’-6½” high 19’-5 1/2” x 36’-...

Page 13: Back

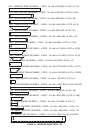

Page 11- parts locator back right left g50 a50 e5 e51 sp50 g1 g9 g13 m17 m6 m6 e5 e6 e1 n1 m3 m3 e7 g7 h6 m13 m8 m8 m12 r1 m4 m15 m19 m22 n4 m14 g3 g8 e3 g6 g1 1 n4 m19 m22 m20 h2 m23 m23 g14 m6 h4 h7 h8 g4 g10 f1 sc1.

Page 14: Front

Page 12- parts locator front right left r1 w100492 w100491 w100489 w100493 w100488 w100487 w100608 w100609 w10061 1 w100610 a50 sp50 e50 e51 g50 g6 e7 g8 e3 g2 k1 m9 m9 e6 g1 1 h2 g7 h6 h4 h7 h8 g1 g9 g4 m17 g15 m18 m10 m10 m16 e1 m24 o1 m5 e3 e4 m14 m14 w100490 m4 m15 m19 m22 n4 n4 m19 m22 m20 f1 m...

Page 15

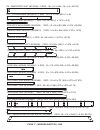

Page 13 - wooden parts e1 - g7 e1 - right front tower leg (w100612) - 1 req - 36 x 86 x 2274 (1.375 x 3.375 x 89.5) e2 - center front tower leg (w100613) - 1 req - 36 x 86 x 2274 (1.375 x 3.375 x 89.5) e3 - left front tower leg (w100614) - 1 req - 36 x 86 x 2274 (1.375 x 3.375 x 89.5) e4 - deck brac...

Page 16

Page 14 - wooden parts g8 - h8 g8 - wall rail (w100624) - 2 req - 24 x 134 x 1244 (1 x 5.25 x 49) g9 - base board (w100625) - 2 req - 24 x 134 x 1156 (1 x 5.25 x 45.5) g10 - floor rail (w100626) - 1 req - 24 x 134 x 1156 (1 x 5.25 x 45.5) g11 - picnic table top (w100627) - 2 req - 24 x 134 x 1142 (1...

Page 17

Page 15 - wooden parts h9 - m11 h9 - floor joist (w100638) - 2 req - 24 x 86 x 908 (1 x 3.375 x 35.75) h10 - btm floor board support (w100677) - 10 req - 24 x 86 x 134 (1 x 3.375 x 5.25) k1 - wall rail (w100639) - 1 req - 16 x 134 x 1156 (.625 x 5.25 x 45.5) l1 - outside filler floor board (w100640)...

Page 18

Page 16 - wooden parts m12 - r1 m12 - window trim (w100654) - 1 req - 16 x 86 x 806 (.625 x 3.375 x 31.75) m13 - wall board (w100655) - 7 req - 16 x 86 x 616 (.625 x 3.375 x 24.25) m14 - wall board (w100656) - 9 req - 16 x 86 x 660 (.625 x 3.375 x 26) m15 - gable board (w100657) - 2 req - 16 x 86 x ...

Page 19

R2 - inner roof slat (w100785) - 2 req - 18 x 114 x 1394 (.75 x 4.5 x 54.875) sc1 - floor board (w100675) - 1 req - 16 x 76 x 1168 (.625 x 3 x 46) t1 - safety rail (w100676) - 1 req - 24 x 34 x 520 (1 x 1.375 x 20.5) btm rock wall board (w100493) - 1 req - 16 x 60 x 675 (.625 x 2.375 x 26.625) ladde...

Page 20

E51 - swing beam angle brace (w100948) - 2 req - 36 x 86 x 2260 (1.375 x 3.375 x 89) e50 - swing beam end support (w100949) - 1 req - 36 x 86 x 1226 (1.375 x 3.375 x 48.25) window shutter (w100786) - 3 req - 16 x 112 x 406 (.625 x 4.375 x 16) window shutter slat (w100787) - 6 req - 16 x 34 x 136 (.6...

Page 21

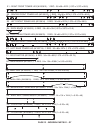

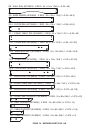

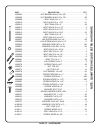

5/16 x 1 1/2" wha bolt h100010 drawings are to scale but small variations are normal. 0 1 2 3 4 5 6 7 8 9 mea sure bol ts fr om bo tt om of head to bo tt om of bol t 5/16 x 5-3/4" wha bolt h100032 h100073 3/8" spike tee nut page 19 - hardware 5/16 x 1 1/4" h ex head bolt h100042 7/8” wha barrel nut ...

Page 22

Drawings are to scale but small variations are normal. 0 1 2 3 4 5 6 7 8 9 mea sure bol ts fr om bo tt om of head t o bo tt om of bol t h100028 5/16 x 2-1/2" lag screw page 20 - hardware 5/16 x 2" lag screw h100027 (5/16") lock nut h100110 8 x 27 fender washer h100105 11 x 25 flat washer h100102 h10...

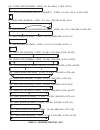

Page 23: Te:

Page 21 - hardware no te: q u antities include extr a hard w are part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Description. . . . . . . . . . . . . . . . . . . . . . . . . . Qty. H100004 . . . . . . . . . . . . . . . . . . Nut barrel wha 5/16 x 5/8”. . . . . . . . . . . . . . . ....

Page 24: Additional Items

Page 22 - accessories large window frame 2 required a100010 additional items green plastic rocks 12 required x20-g 1 - assembly manual 1- a100037 cap end plug spiral slide 1- a100038 tube spiral slide 3” od x 74 ½ long 1 - warranty card 1 - 10’ speedy slide 1 - 37210-zb1 hardware kit 8 - y41 ground ...

Page 25

Step 1 ( note position of pilot holes in tower legs ) attach g2 wall rail to e1 right front tower leg, e2 center front tower leg and e3 left front tower leg using 5/16” x 2” bolts, lock washers and 7/8” barrel nuts and lock washers. Attach g1 base board to e1 right front tower leg using 5/16” x 2” b...

Page 26

Step 2 ( note position of pilot holes in tower legs ) attach g3 wall rail to e5 right rear tower leg, e6 center rear tower leg and e7 left rear tower leg using 5/16” x 2” bolts, lock washers and 7/8” barrel nuts and lock washers. Attach g1 base board to e5 right rear tower leg with 5/16” x 2” bolts,...

Page 27

Step 3 attach g15 floor rail to e1 front right tower leg and h10 floor support with 5/16” x 2 ¾” bolts, lock washers and 7/8” barrel nuts and lock washers and to e2 center front tower legs and h10 floor support with 5/16” x 2 ¾” bolts ,lock washers and 7/8” barrel nuts and lock washers. Attach g12 f...

Page 28

Step 4 with help stand tower assemblies up and attach g6 floor rail to e5 and e1 tower legs with 5/16” x 2” lag screws and lock washers. Attach g5 wall rail/ swing mount to top of e5 and e1 tower legs with 5/16” x 2” lag screws and lock washers. Attach g4 base/sand box board to bottom of e5 and e1 w...

Page 29

Step 5 attach g6 floor rail to e7 left rear tower leg and e3 left front tower leg with 5/16” x 2” lag screws and lock washers. Attach g8 wall rail to top of e7 and e3 with 5/16” x 2” lag screws and lock washers. Attach g7 floor rail to bottom of e7 and e3 with 5/16” x 2” lag screws and lock washers....

Page 30

Step 6 attach g7 floor rail to bottom of e2 center front tower leg and e6 center rear tower leg and between e1 and e5 using 5/16” x 2” lag screws and lock washers. Attach another g7 floor rail to e2 and e6 between e3 and e7on middle floor using 5/16” x 2” lag screws and lock washers. Items needed 2-...

Page 31

Step 7 level and plumb structure and attach four e4 deck braces to g12, g14 and g6 floor rails with 5/16” x 2” bolts, lock washers and 7/8” barrel nuts and lock washers and to tower legs with 5/16” x 2” hex type lag screws, 5/16” flat washers and 5/16” lock washers. Attach four more e4 deck braces t...

Page 32

Step 8 attach h1floor joist to g6 and g7 floor rails on middle floor with 2 ½” wood screws. Now attach a l1 outside filler floor board between tower legs with 1 ½” wood screws in the holes indicated, and 2 ½” wood screws in remaining holes . Evenly space eleven m3 floor boards and attach using 2 ½” ...

Page 33

Step 9 attach g7 floor rail to e6 and e2 tower legs on upper floor between e3 and e7 with 5/16” x 2” lag screws and lock washers. Attach h9 floor joist to g6 and g7 floor rails on upper floor using 2 1/2” wood screws. Now attach a l1 outside filler floor board between tower legs with 1 ½” wood screw...

Page 34

Step 10 on bottom floor attach h3 floor joists to g7 floor rails using 2 ½” wood screws. H3 h3 g7 g7 items needed 2- h3 floor joists hardware needed 8-2 ½” wood screws page 32.

Page 35

Step 11 attach g9 base boards to e1 and e2 on front and to e5 and e6 on back using 5/16” x 2” bolts, lock washers and 7/8” barrel nuts and lock washers. Attach g4 base/sand box board to e1 and e5 and e2 and e6 using 5/16” x 2” lag screws and lock washers. Attach a l1 outside filler floor board betwe...

Page 36

Step 12 attach two g13 sand box seats to g9 and g4 base boards with 2 ½” wood screws. Attach three m5 wall rails to e1and e5 tower legs with 5/16” x 2” lag screws and lock washers. Attach one more m5 wall rail to e2 and e6 tower legs with 5/16” x 2” hex type lag screws and fender washers. G13 g13 m5...

Page 37

Step13 attach m11 wall rail to e7 and e6 tower legs with 5/16” x 1 ½” bolt, lock washer and barrel nut and lock washer. Attach m21 wall rail to e7 and e3 with 5/16” x 2” lag screws and lock washers. Attach k1 wall rail to e1 and e2 using 5/16” x 1 ½” bolts, lock washers and 7/8” barrel nuts and lock...

Page 38

Step 14 attach three m6 wall rails to e5 tower leg using 5/16” x 1 ½” bolts, lock washers, washers. Then level across and attach to e6 tower leg using 5/16” x 2” lag screws and lock washers. Attach two m8 wall boards against e6 and two against e5 using 1 1/8” wood screws. Attach seven m13 wall board...

Page 39

Step 15 drive four 5/16” spike t nuts into g5 wall rail/ swing mount for later use. Now attach two m8 wall boards against e1 and two against e5 tower legs using 1 1/8” wood screws. Attach a l2 wall board then a n3 wall board and another l2 with 1 1/8" wood screws. Now attach three more m8's another ...

Page 40

Step 16 attach g8 wall rail to top of e2 and e6 tower legs using 5/16” x 2” lag screws and lock washers. Attach three m9 wall boards to g8 and g7 on each side of opening and flush with bottom of floor rail g7 with 1 1/8” wood screws. Attach five m14 wall boards to back wall rails 1 ¼” up from floor ...

Page 41

Step 17 attach a m7 wall cap to g2 and g3 with a ½” overhang and 3 3/8” from outside of g8 and g5 using 3” wood screws. Attach m1 roof cap and m2 ridge cap to f1 roof rafters with 1 ½” wood screws now repeat and attach rafter assemblies together using 5/16” x 1” bolts, lock washers, 5/16” x 5/8” bar...

Page 42

Step 18 attach a m4 gable board to f1 rafters using 1 1/8” wood screws. Now attach two m19 then two n4, two m22, one m15 and one m20 gable board using 1 1/8” wood screws. Attach x40-g2 window frame with ¾” washer head screws to m22’s and m19’s attach a o1 wall support to both sides of window frame u...

Page 43

Step 19 attach a h4 picnic table seat support to e7 and e6 tower legs using 5/16” x 2” lag screws and lock washers. Attach a h6 seat upright to h4's with 5/16” x 1-½” bolts, lock washers and 7/8” barrel nuts and lock washers and to g7 floor rails with 5/16” x 2” lag screws and lock washers. Attach a...

Page 44

Step 20 attach w100611 ladder rungs to w100608 left ladder upright and w100609 right ladder upright with 2” wood screws. Attach w100610 ladder rear support to ladder uprights using 2” wood screws 1 ½” down from angle point of ladder uprights. Set ladder assembly against g15 floor rail and using hole...

Page 45

Step 21 attach x20-g rocks to w100491 and w100492 rock wall boards using ¼” x 1” phillips truss head bolts and lock washers and ¼” barrel nuts and fender washers. Set rock wall rails w100488 and w100487 up against g12 floor rail and attach w100490 rock wall end board to end of rails using 1 ½” wood ...

Page 46

Step 22 on right side of set attach seven m17 wall boards to wall rails with a 2-7/8” space using 1-1/8” wood screws. On back side of set attach six m17 wall boards to wall rails with a 2-5/8” space using 1-1/8” wood screws. M17 m17 items needed 13-m17 wall boards hardware needed 52-1 1/8” wood scre...

Page 47

Step 23 attach window shutters by using 1-½” wood screws through w100787 window shutter slats through w100786 window shutter into wall boards. W100786 w100787 items needed 6-w100787 window shutter slats 3-w100786 window shutters hardware needed 12-1 ½” wood screws page 45.

Page 48

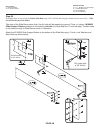

A50 step 24 attach e51swing beam angle braces to sp50 swing beam support using 5/16” x 6 ½” bolt, lock washer and 5/16” spike t nut. Attach g50 swing beam ground board to e51angle braces with 5/16” x 2” bolts, lock washers, 5/16” x 7/8” barrell nuts and lock washers. Attach e50 swing end support to ...

Page 49

Hardware illustration: swing hanger glider support 5/16” lock nut fender washer glider caps swing bushing swing hanger note: circular bend on swing hanger must run parallel with board. Step 25 attach z1 swing hangers to glider supports using y28-g4 swing hanger bushings, fender washers and 5/16” loc...

Page 50

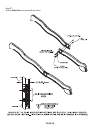

Page 48 step 26 items needed 1- 10' speedy slide 6- y41 ground stakes hardware needed 6- ¼” x 1” phillips truss head bolts 6- ¼” phillips barrel nuts 12- fender washers 6- 5/16” lock washers drill three holes at one end of the plastic slide bed using a 3/8” drill bit and using the dimensions shown i...

Page 51

Page 49 step 27 gather slide rails and assemble as shown..

Page 52

Page 50 step 28 place one slide rail on a flat surface and begin inserting slide bed at the bottom of the slide rail. Put slide support bottom into the support pocket at the bottom of rail and have a helper bend the slide bed towards the top of the slide and insert the bed into the cavity. Make sure...

Page 53

Page 51 step 29 slide attachment.: you will need to drill holes where the slide will attach . Do this by placing the slide assembly on the fort floor in the opening shown. Center the slide in the opening and transfer the three attachment holes to the fort floor by using the holes in the slide bed as...

Page 54

Step 30 stake set down using y41 stakes at locations shown using ¼” x 1” phillips truss head bolts, flat washers and ¼” barrel nuts. Measure in 6” from each end of swing beam ground board and screw stake into ground until 3” from top of ground board. (you can use a screwdriver for leverage if needed...

Page 55

Limited warranty this limited warranty by backyard discovery applies to products manufactured under the backyard discovery brand or its other brands including but not limited to backyard botanical, adventure playsets, and leisure time products. Backyard discovery warrants that this product is free f...

Page 56

Garantía limitada esta garantía limitada de backyard discovery se aplica a productos fabricados bajo la marca backyard discovery o sus otras marcas incluyendo a título informativo pero no limitativo backyard botanical, adventure playsets, y leisure time products. Backyard discovery garantiza que est...