- DL manuals

- Bad Boy

- Lawn Mower Accessories

- 48031001

- Operator's Manual

Bad Boy 48031001 Operator's Manual

Summary of 48031001

Page 1

Operator’s manual pto grass collection system designed for: assembly operation maintenance model 48031001 bad boy pup series mowers manual part#: q0336 $4.00 rev: 0

Page 2

2 pto grass collection system table of contents section page safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2 safety alert symbols - - - - - - - - - - - - - - - - - - - - - - 3 warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4 i introduction and description -...

Page 3

3 safety warning! Warning! Warning! Warning! Safety alert symbol safety signs never only after stopping the mower’s engine and waiting for all moving parts to come to a complete stop. Always up down never never “attention! Become alert! Your safety is involved!” danger, warning, caution operate the ...

Page 4

4 peco limited warranty for new products a. What is warranted? 1. Product warranty: all defective parts must be returned to peco for inspection to determine validity of warranty claims. 2. Parts replaced during warranty: b. Securing warranty adjustments. C. Items not covered by peco warranty. D. Una...

Page 5

5 section i introduction and description 1-1 introduction 1-2 description 2-1 preparation of mower we are pleased to have you as a bad boy customer. Your collection system has been designed to give you a low maintenance, simple, and effective way to collect the grass clippings from your mower. This ...

Page 6

2-2 pto assembly installation remove the (2) existing bolts and nuts from the right side that fastens the mower’s rear frame to the mower’s chassis. Align the (2) lower holes on the pto assembly p#(a0610) (figure 2) to the (2) lower holes on the mower’s rear frame. Fasten by using (2) 5/16”- 18 x 1-...

Page 7

2-6 mount tube stiffener installation place the lower mount tube stiffener p#(b0247) between the lower mount tube (previously installed) and the mower’s rear frame positioning the bend flaps downwards (figure 8). Fasten to the mower’s rear frame by using (2) ½”-13 x 1” hhcs p#(k1231), (2) fender was...

Page 8

8 figure 11. Exploded view of the a0549 - bagger assembly (2) k1144 - 5/16”-18 x 1” carriage bolt (6) k1142 - 5/16”-18 x 3/4” carriage bolt (4) k1010 - 1/4”-20 x 5/8” carriage bolt (1 left, 1 right) b0237 - pivot bracket (1) v1054 - inlet (1) b8002 - plastic screen (2) c0051 - long screen mount stri...

Page 9

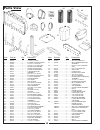

9 1 2 3 5 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 36 34 37 38 39 40 41 42 43 35 43 42 48 47 46 45 49 50 52 53 51 4 6 7 exploded parts view exploded view of the a0610 - pto assembly 44.

Page 10

Parts view item part no. Qty. Description 1 - - - - - k1125 - - - - - - - - 7 - - - - - 1/4”-20 x 1” hhcs 2 - - - - - e4004f - - - - - - - 1 - - - - - blower housing front 3 - - - - - k1225 - - - - - - - - 2 - - - - - 1/4”-20 x 1” hhcs g8 4 - - - - - k1211 - - - - - - - - 1 - - - - - 3/8"-16 x 1-1/2...

Page 11

11 2-9 boot to mower deck installation 60” boot plate mounting instructions 48” & 52” boot plate mounting instructions for all deck sizes to mount the boot plate p#(b0184) to the boot p#(e1113) use (2) 3/8”-16 x 1” carriage bolts p#(k1182) and (2) 3/8”-16 flange nuts p#(k1215). See figure 11 for bol...

Page 12

12 2-10 blower cone installation 2-11 impeller blade removal/replacement thread (1) 5/16”-18 jam nut p#(k0120) onto each end of (2) 5/16”-18 x 2-1/2” hhcs p#(k0125). Now partially thread the bolts into each of the two tabs located on the blower housing. Place blower cone so the two tabs line up with...

Page 13

13 2-12 lengths of hose adjustment 2-13 upper hose installation the hoses in steps 2-13 and 2-14 must be cut to fit your machine. Follow steps 2-13 and 2-14. Do not cut the hoses until you have tried to fit them on your machine. Remember that the hoses have to be long enough to allow for enough clam...

Page 14

14 2-17 installation/removal of collection bags to install the bag onto the bag ring, first make sure the bag ring end caps are fastened to the bag ring. Place the seam openings of the bag onto the bag ring openings and turn the bag until the slot bracket in the bag ring is protruding from the openi...

Page 15

15 section iii operating instructions 3-1 general safety 3-2 operation and tips on mowing only qualified people familiar with this operator’s manual and the mower’s operator’s manual should operate this machine. A. Perform before each use the maintenance list in paragraph 4-1. B. Start mower. C. Wit...

Page 16

16 3. Make sure all shields are in place and in good condition. Repair or replace any missing or damaged shields. 4. Perform lubrication per paragraph 4-2. 5. Listen for abnormal sounds, which might indicate loose parts, damaged bearings, or other damage. Correct any deficiency before continuing ope...

Page 17

17 safety decals to promote safe operation, bad boy supplies safety decals on all products manufactured. Damage can occur to safety decals either through shipment, use or reconditioning. Contact your local service center for replacement decals. Part #: r1050 part #: r1054 part #: r1052 part #: r1057...

Page 18

18 bad boy.

Page 19

Notes 19.

Page 20

Turn any bad boy lawn vac into a total lawn grooming tool with the bad boy wand kit! With your bad boy wand attachment you will double the ability of your bad boy lawn vac. Using the same powerful vacuum/blower that makes your lawn vac work so well, you will be able to get to all those hard-to-reach...