Summary of 5´ Cutter

Page 1

Owner’s operation & parts manual 10-28-2014.

Page 2: To The Dealer:

Page 2 to the dealer: assembly, initial lubrication, and verification of proper installation of this product is the responsibility of the bad boy cutter dealer. Be familiar with the safety rules and instructions found in this manual. Ensure all items on the dealer’s pre-delivery and delivery checkli...

Page 3: Table of Contents

Page 3 table of contents specifications .............................................................................................. 4 safety rules ................................................................................................ 5 general information ..................................

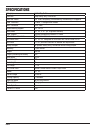

Page 4: Specifications

Page 4 specifications category 5´ bad boy cutter gear box 50hp heavy duty omni rc51 gear box mount 3/8˝ steel; completely surrounded by interlocking ‘h’ supports deck thickness 1 piece, 11 gauge solid welded skirt thickness 3/16˝ steel under-decking support 1/4˝ x 6-1/2˝ skid shoes 1/2˝ x 2˝ x 32˝ (...

Page 5: Safety Rules

Page 5 safety rules training ■ safety instructions are important!! While these instructions and rules may seem lengthy or redundant, they are presented for your safety. Almost all accidents arising from the use of equipment such as this that has resulted in injury or death would have been avoided ha...

Page 6

Page 6 in loss of steering. The weight may be attained with front wheel weights, ballast in tires or front tractor weights. Weigh the tractor and equipment; do not estimate. ■ inspect and clear the area of stones, branches, or other hard objects that might be thrown, causing injury or damage. Operat...

Page 7

Page 7 ■ do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment. ■ keep all persons away from operator control area while performing adjustments, service, or maintenance. ■ do not modify or alter (or permit anyone else to modify or alter) the equi...

Page 8: General Information

Page 8 general information warning the purpose of this manual is to assist you in operating and maintaining your cutter. Read it carefully. It furnishes information and instructions that will help you achieve years of dependable performance. These instructions are the product of extensive field expe...

Page 9: Caution

Page 9 attach cutter to tractor caution ■ make sure driveline will not bottom out at the shortest length and that it has at least 1/3 overlap at its longest length. ■ select a top link mounting pin that will allow floating link to swing freely through the cutter a-frame bars. 1. Attach tractor 3-poi...

Page 10

Page 10 driveline adjustment attach the cutter to the tractor 3-point hitch. Do not attach driveline. Raise and lower cutter to determine maximum and minimum distance between the tractor pto shaft and the gearbox input shaft. If the distance is too large, the driveline will be too short for proper e...

Page 11: Warning

Page 11 cutting height adjustment warning ■ keep all persons away from operator control area while performing adjustments, service, or maintenance. ■ avoid low cutting heights when at all possible. Striking the ground with a cutter blade during operation results in one of the most damaging shock loa...

Page 12: Warning

Page 12 ■ move slowly into material. Adjust tractor ground speed to provide a clean cut without lugging the tractor engine. Proper ground speed will depend on the terrain and the material’s height, type, density, and moisture content. The operator will be able to determine appropriate ground speeds ...

Page 13: Owner Service

Page 13 owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety information in this manual. Warning ■ keep all persons away fro...

Page 14

Page 14 3. With full cutter weight lowered onto jack stands, test the blocking stability carefully, but vigorously, to ensure its stability. 4. If cutter is attached to tractor when blocking, set the brakes, remove the key, and block the cutter before working underneath. Also, securely chock the rea...

Page 15: Caution

Page 15 lubrication points 1. Tail-wheel pivot tube ....................................................................8 hours 2. Tail-wheel .....................................................................................8 hours 3. Pto shaft: front and rear u-joints ..............................

Page 16

Page 16 1. Inspect the blade bolts for nicks or gouges and, if found, replace the damaged blade bolt(s). 2. Insert blade bolt through the blade. Blade should swivel on blade bolt; if it doesn’t, determine the cause and correct. 3. Align crossbar with blade access hole in cutter frame. Apply a libera...

Page 17: Danger

Page 17 driveline shear-bolt replacement ■ always use a 1/2˝ x 3-1/4˝ sae grade 2 bolt as a replacement part. Using a hardened bolt (such as grade 5 or grade 8) may result in damage to driveline or gearbox. 1. Slide the driveline bell shield (covers the u-joint of the pto shaft and input shaft of ge...

Page 18: Troubleshooting

Page 18 ■ inspect the cutter and replace any worn or damaged parts. After an extended period of non-use, any damage to the cutter may be overlooked, or forgotten, when the machine is again put into service. ■ sand down scratches and the edges of areas of missing paint and coat with bad boy touch-up ...

Page 19

Page 19 cutter assembly and part list.

Page 20

Page 20

Page 21

Page 21 assembly instructions note: use cutter part list and accompanying illustration located in the previous section to reference item numbers indicated in the assembly instructions. Item numbers are in parenthesis. Partial or full assembly of the cutter may have been performed prior to purchase. ...

Page 22: -Tail Wheel Assembly-

Page 22 -tail wheel assembly- notes: a) reference item numbers below for tail wheel assembly. B) bushings (3) are pre-installed in hub (2). ■ secure hub (2) to wheel and tire (1) using four hub lock washers (4) and four hub nuts (5). Tighten to 50 ft-lbs. ■ insert 3/4˝ axle bolt (7) through the foll...

Page 23

Page 23 6. Insert post of the tail wheel assembly (8) through the following parts in the order given: 1-1/4˝ flat washer (20); tube on rear a-arm assembly (2) {entering from the ‘bottom’ of the tube}; 1-1/4˝ flat washer (20). Secure by inserting 3/8˝ x 3˝ cotter pin (23) through hole in post of the ...

Page 24: Fastener Torque Chart

Page 24 fastener torque chart notice: torque values given in the above text assume an unlubricated fastener. If using a lubricated fastener, reduce the torque (given in the previous text) by 25%. Fastener item number torque (lubricated/unlubricated) 5/8˝ x 2-1/2˝ hex bolt 9 56 ft-lbs / 75 ft-lbs 1/...

Page 25: Dealer’S Checklists

Page 25 dealer’s checklists pre-delivery check list ■ important- the gearbox was not filled with gear oil at the factory. It must be filled before the cutter can be placed into service (see lubrication, pg. 14). Failure to fill the gearbox with the proper quantity of gear oil will result in damage t...

Page 26: Warranty

Page 26 warranty owner/operator’s responsibility it is the owner and/or operator’s responsibility to read the owner’s manual before use. Failure to read the owner’s manual is considered a misuse of this equipment. It is the owner and/or operator’s responsibility to inspect the product and to have an...

Page 27: Warranty Limitation:

Page 27 warranty limitation: there is no other express warranty. Any warranty that may be implied from this purchase including merchantability and fitness for a particular purpose is hereby limited to the duration of this warranty and to the extent permitted by law any and all implied warranties are...

Page 28

Page 28 102 industrial drive batesville, arkansas 72501 (870) 698-0090