- DL manuals

- Badger Basket

- Blower

- 2060

- Operator's Manual

Badger Basket 2060 Operator's Manual

Summary of 2060

Page 1

1 forage blower model 2060 series ii operator's manual do not operate this equipment until this manual has been read and understood. Art's-way manufacturing co., inc. P.O. Box 288 armstrong, ia 50514 tel. 712-864-3131 fax 712-864-3154 340078b98 7/05.

Page 2: General Information

2 general information the purpose of this manual is to assist the operator in maintaining and operating the forage blower. Read it carefully: it furnishes information and instructions that will help you achieve years of dependable service. All replacement parts should be obtained from or ordered thr...

Page 3: Table of Contents

3 table of contents general ........................... Inside front cover identification numbers warranty registration information forage blower inspection checklist ....................................................... 4 safety precautions for the farm................ 7-11 safety decals ...........

Page 4: Forage Blower

4 pre-delivery check list after the forage blower has been completley set- up, check to be certain it is in correct running order before delivering it to the customer. The following is a list of poins to inspect. Check off each item as you have made the proper adjustments and found the item operatin...

Page 5: Forage Blower

5 (dealer copy) pre-delivery check list after the forage blower has been completley set- up, check to be certain it is in correct running order before delivering it to the customer. The following is a list of poins to inspect. Check off each item as you have made the proper adjustments and found the...

Page 6

6 this page intentionally left blank.

Page 7: Precautionary Statements

7 personal safety throughout this manual and on machine decals, you will find precautionary statements followed by specific instructions. These precautions are intended for the personal safety of you and those working with you. Please take the time to read them. Caution warning danger failure to fol...

Page 8

8 personal injury may result if these precautions are not followed the safety of the operator is one of the main con- cerns in machine design. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling farm machinery and...

Page 9

9 know the rules. Read this manual carefully and follow all safety recommendations. Check for the meanings of all signs, flag markings, signals and safe operating practices. Know the rules- live by them. Protect yourself. Wear all protective clothing and personnel safety devices. You may need a hard...

Page 10

10 watch out for traffic. Make sure all re- quired safety pins and chains are in place and secure. Never travel faster than is appropriate for conditions. Avoid injuries to you and others. Rules of the road. If the machine is to be towed over the road, refer to the instructions in this manual for sp...

Page 11

11 be careful with fluids under pressure the hydraulic system is under pressure whenever the engine is running, and may hold residual pres- sure even after shutdown. Before working on any pressurized system, relieve all operating and re- sidual pressures. To relieve the pressure in the hydraulic sys...

Page 12: Safety Decals

12 safety decals 907220 329594b2 337143b2 340248b1 331865b1 331096b2 336957b1 331639b2 16.20178.

Page 13: Safety Decals

13 safety decals 337143b2 331101b2 313865b1 907219 907220 344243b1 340250b1 331096b2 907225 smv sign 17.01155 344428b1 329594b2.

Page 14: Replacement of Decals

14 check all safety decals and replace any that are worn, missing or illegible. Decals may be ordered from your miller dealer. Replacement of decals an smv sign must be displayed when unit is towed on public roads at slow speeds. Check local codes for specific requirements. Safety decals 331865b1 33...

Page 15: Introduction

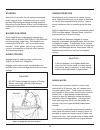

15 this forage blower is a heavy-duty, high capacity machine which blows all types of forage with equal ease, haylage, light hay, silage or grain are all blown with a minimum of plugging or spillage. The auger, formed paddles and the air regulator door ensure a smooth material flow from the hopper t...

Page 16: Tractor/blower Preparation

16 tractor/blower preparation tractor specifications this forage blower is designed for a normal operating power take-off speed of 540 rpm. When forage blower is equipped with optional 1000 rpm gear box, the power take-off speed is 1000 rpm. The tractor should be checked to insure that it is operati...

Page 17

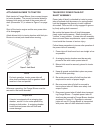

17 important yokes must be kept in proper alignment. Check power take-off shaft engagement. With unit attached to your tractor, and without power take-off shaft turning, make sure that the power take-off shaft does not bottom out at the point of most compression of shaft. Figure 4 shows the correct ...

Page 18

18 telescopic power take-off shaft assembly power take-off shaft is attached to tractor's power take-off splined shaft by means of a spring-loaded lock that engages the groove in tractor's splined drive shaft. Be sure lock is fully engaged in groove by firmly pulling shaft rearward. Be certain that ...

Page 19

19 adjusting hopper height the height of the hopper can be adjusted by turning the wheel adjusting cranks clockwise to raise the hopper or counterclockwise to lower the hopper. Note both wheels are individually adjustable. Turning the wheel adjusting crank on both wheels counterclockwise to the maxi...

Page 20

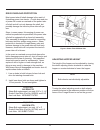

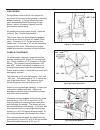

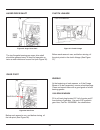

20 leveling the forage blower figure 7. Leveling fore and aft the forage blower should be level while operating to ensure good material flow through hopper. To level the forage blower fore or aft, turn adjusting turnbuckle (figure 7) clockwise or counterclockwise, respectively. Figure 8. Left wheel ...

Page 21

21 positioning the forage blower position the forage blower next to storage facility so that hopper is easily accessible for forage box unloading and in line with forage blower pipe. Forage blower should be level, with drive shaft in a straight line from front to rear with tractor power take-off. Le...

Page 22

22 grooves along each edge of blower band are firmly seated on side sheets. It may be necessary to tap edges of blower band lightly while tightening to help seat the band properly. Recheck gap space. If greater than prior measurement, clean out grooves to seat band properly. Check and reset shear ba...

Page 23: Operation

23 checklist before preparing to use forage blower, walk com- pletely around machine and observe all caution, warning and danger decals. These are care- fully placed to provide a safe work attitude. Ob- serve them and obey them. Warning make sure children are kept away and under constant adult super...

Page 24

24 important it will be necessary to re-tighten band after every load for first ten loads, and daily during the first few days of operation, or after having made a band adjustment or replacement. Starting start with a low tractor throttle setting and engage power take-off drive. Gradually work up to...

Page 25

25 adding water, continued your forage blower may be equipped with a sec- ondary water coupling (figure 15) attached to the blower band. This location can be used for adding water to prevent gum buildup inside blower. Al- though it is available it is not the preferred location for adding water. To u...

Page 26: Transporting and Storage

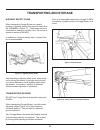

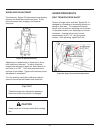

26 highway safety chain when transporting forage blower on a public highway, a highway safety chain must be used (part no. 322580b91) (figure 17). Check state and local codes before towing on a public road. Do not tow at speeds in excess of 20 mph. In addition to a highway safety chain, a safety hit...

Page 27

27 important when transporting forage blower on a road or highway, always display an smv (slow moving vehicle) emblem. At night, use accessory warning lights as required by government regulations. Maximum towing speed is 20 mph. Storage instructions remove all dirt and ensilage that may be on or in ...

Page 28: Adjustments

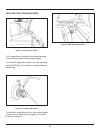

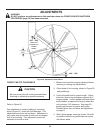

28 check fan tip clearance caution be sure power take-off is disconnected before checking or adjusting fan paddle clearance. Refer to figure 20. Fan adjustment is made by adding or removing shims (figure 21) under fan shaft bearings. This adjustment moves fan up and down. Adjustment is also made wit...

Page 29

29 fan paddle forage blower sides must be fully seated into grooves of blower band while gauging or adjusting paddle clearance. If forage blower has been used, disassemble blower band from forage blower, remove all material deposit from the grooves and reinstall band. All paddles must be the same le...

Page 30

30 figure 24. Band adjustment important fan tip and shear bar clearance must be readjusted whenever outlet boot is repositioned. When tightening, be sure that forage blower sides are firmly seated in band grooves. Firm hand tightening is sufficient. Important never operate forage blower with a loose...

Page 31

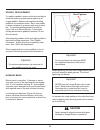

31 auger drive belts belt tension-drive shaft tension of auger drive shaft belt (figure 26), is changed by increasing or decreasing tension on spring on idler arm. To increase belt tension, loosen lock nut and turn adjusting nut clockwise. To decrease tension, turn adjusting nut counter- clockwise. ...

Page 32

32 belt tension-auger drive tension of auger drive belt is changed by adjusting clutch compression or yoke (figure 27). Remove pin. Turn yoke clockwise to decrease tension and counterclockwise to increase tension. Figure 27. Auger drive belt adjustment auger drive belt is properly tensioned when a f...

Page 33

33 auger clearance should it become necessary to adjust auger clear- ance, slightly loosen the eight auger bearing mount- ing bolts (figure 29) and adjust auger to run parallel with trough bottom and parallel with stripper along right side of auger. These measurements are made from the auger bearing...

Page 34: Lubrication and Maintenance

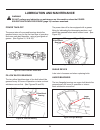

34 power take-off the power take-off cross and bearings should be greased twice a say for the first two days of operation and once each day thereafter, using a good grade of grease. (see figures 31, 32 & 33). Figure 31. Power take-off tractor end pillow block bearings the two pillow block bearings o...

Page 35

35 auger drive shaft figure 35. Auger drive shaft the two flangette bearings on auger drive shaft should be greased every 30 hours of operation or twice a week whichever occurs first (see figure 35). Idler pivot clutch linkage figure 37. Clutch linkage before each season's use, and before storing, o...

Page 36: Torque Specifications

36 note: use these torque values when tightening hardware (excluding: locknuts and self-tapping, thread forming and sheet metal screw) unless specified otherwise. All torque values are in lb-ft except those marked with an * which are lb-in (for metric torque value nm, multiply lb-ft value by 1.355 o...

Page 37: Troubleshooting

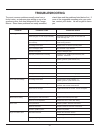

37 troubleshooting the most common problems usually arise from a faulty tractor, an improper pipe setting or use of an accessory other than one designed for the forage blower. Since these problems are easily remedied, check them and the problems listed below first. If none of the suggested remedies ...

Page 38: 540 Rpm 1000 Rpm

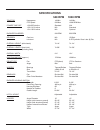

38 540 rpm 1000 rpm tractor horsepower 140 min 140 min pto speed 540 max 1000 rpm max power take-off 1-3/8 6b driveline standard n/a 1-3/8 -21 driveline n/a standard 1-3/4 -20 driveline n/a optional blower fan speed 540 rpm 650 rpm gearbox cast iron n/a oil bath lubricant n/a 6 ep synthetic gear lub...

Page 39: Warranty

39 art's-way manufacturing co., inc. Warrants new miller forage blower to be free from defects in mate- rial and workmanship under recommended use and service, as stated in the operator's manual, as follows: 1. Base warranty. Art's-way will replace, f.O.B armstrong, ia, or repair, as art's-way elect...

Page 40

40 by art's-way manufacturing co., inc..