- DL manuals

- Badger Meter

- Measuring Instruments

- M5000

- User manual

Badger Meter M5000 User manual

Summary of M5000

Page 3: Contents

Contents safety precautions and instructions 5 system description 5 unpacking and inspection 6 rigging, lifting and moving large units 6 meter location, orientation and applications 8 remote amplifier outdoor location 8 pipelines and fluid flow 8 meter orientation 9 vertical placement 9 horizontal p...

Page 4

Mount bracket to amplifier 15 wiring configuration 15 wiring for remote configuration 15 configuring input/output (i/o) 16 circuit board diagram 16 digital output wiring diagrams 17 digital output selections 17 programming the m5000 18 function buttons 18 display 18 icons 18 battery levels 18 m5000 ...

Page 5: System Description

Safety precautions and instructions some procedures in this manual require special safety considerations in such cases, the text is emphasized with the following symbols: symbol explanation warning indicates the potential for severe personal injury, death or substantial property damage comply with t...

Page 6: Unpacking And Inspection

Unpacking and inspection follow these guidelines when unpacking the m-series equipment • if a shipping container shows any sign of damage, have the shipper present when you unpack the meter • follow all unpacking, lifting and moving instructions associated with the shipping container • open the cont...

Page 7

• use the sling-rigged method to lift large detectors into a vertical position while they are still crated use this method to position while they are still crated use this method to position large detectors vertically into pipelines figure 3: sling-rigged lifting methods • do not lift a detector wit...

Page 8

Meter location, orientation and applications the m5000 provides two amplifier mounting options: an integral or meter mount option and a junction box/remote option meter mount amplifier junction box with remote amplifier figure 5: amplifier mounting options remote amplifier outdoor location the ampli...

Page 9

Meter orientation mag meters can operate accurately in any pipeline orientation and can measure volumetric flow in forward and reverse directions note: n a "forward flow" direction arrow is printed on the detector label vertical placement mag meters perform best when placed vertically, with liquid f...

Page 10

Pipe reducer requirements with pipe reducers, a smaller meter can be mounted in larger pipelines this arrangement may increase low-flow accuracy there are no special requirements for standard, concentric, pipe reducers custom fabricated pipe reducers must have an approximate slope angle of 15 degree...

Page 11

Partially-filled pipe situations in some locations, the process pipe may be momentarily only partially filled examples include: lack of back pressure, insufficient line pressure and gravity flow applications to eliminate these situations: • do not install the meter at the highest point of the pipeli...

Page 12

Meter gaskets and grounding gasket and grounding requirements must be considered when determining the meter location, orientation and application meter/pipeline connection gaskets you must install gaskets (not provided) between the detector's isolating liner and the pipeline flange to ensure a prope...

Page 13

Amplifier mounting configuration options meter mount configuration the meter mountconfiguration has the amplifier mounted directly on the detector this compact, self-contained configuration minimizes installation wiring remote mount configuration the remote mountconfiguration places the amplifier at...

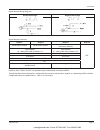

Page 14: Battery

Battery use a two d-cell battery pack (1/2" to 6") or a double two d-cell battery pack (8" to 24") battery life standard pack sampling expected life 0 25 3 months 4 4 years 8 8 years 15 10 years these calculations are for a standard battery pack, with two d-size batteries, with communication and out...

Page 15

Remote mount installation if you are installing the m5000 amplifier in a remote location, review the procedures in this section mount bracket to amplifier 1 align bracket-mounting holes with amplifier mounting holes 2 attach bracket to amplifier with supplied screws torque the screws to 80 inch-poun...

Page 16

Configuring input/output (i/o) this section describes wiring the following m5000 outputs: • digital outputs • communication when the sensor and the amplifier have been wired, wire any outputs to the m5000 amplifier follow all of the safety precautions and local code to prevent electrical shock and d...

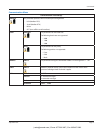

Page 17

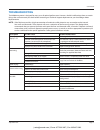

Digital output wiring diagrams positive pulse logic negative pulse logic figure 22: digital output wiring diagram digital output selections output 1 output 2 output 3 output 4 forward pulse output reverse pulse output flow direction (forward vs reverse) ade flow setpoint (0…100% of full scale, resol...

Page 18: Programming The M5000

Programming the m5000 the m5000 amplifier is pre-programmed from the factory no additional programming is necessary, however, for special features, the meter can be programmed for specific requirements function buttons all m5000 programming is accomplished using the three function buttons located on...

Page 19

M5000 main menu programming options the following m5000 programming options are available from the main menu: • meter setup • measure • in/out • communication • miscellaneous • information • pin • faults the applicable security level for each menu option is indicated as follows: a s u administrative...

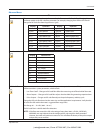

Page 20

Using the m5000 main menu programming options display menu screen hierarchy structure main_menu → meter setup → calibration scale factor frequency period empty pipe measure → flow unit totalizer unit full scale flow low flow cutoff flow direction totalizer1 reset median filter display in/out → simul...

Page 21: Security

Security the m5000 security feature allows the option to restrict access to the meter by way of a 6-digit personal identification number (pin) the system administrator can set up a single pin for each of the three different levels of access: • administration – allows access to all m5000 menu configu...

Page 22

Meter setup menu meter setup calibration diameter a this parameter is set at the factory in the event the amplifier is replaced, verify that the pipe diameter matches the installed pipe size detector factor a this parameter is set at the factory this factor compensates for accuracy error as a result...

Page 23

Measure menu measure flow unit u this parameter establishes the unit of measure for the flow rate and full scale flow changing this parameter readjusts the full scale flow parameter for example, changing from gpm to gps would change the full scale flow from 60 gal/min to 1 gal/s display flow unit di...

Page 24

Measure low flow cutoff u low flow cutoff defines the threshold at which flow measurement will be forced to zero the cutoff value can be set from 0% to 10% of the full scale flow increasing this threshold will help prevent false readings during “no flow” conditions possibly caused by pipe vibration ...

Page 25

Inputs/outputs menu inputs/outputs flow simulation s flow simulation provides output simulation based on a percentage of the full scale flow simulation will not accumulate the totalizers the range of simulation includes –100…100% of the full scale flow the flow simulation parameter lets you set the ...

Page 26

Inputs/outputs digital outputs (continued) set min. S this parameter establishes, as a percentage of full scale flow, the threshold at which the output alarm will be activated flow rates below the threshold will activate the output alarm set max. S this parameter establishes, as a percentage of full...

Page 27

Communication menu communication: port settings interface s this parameter provides communication port configuration • irda (modbus rtu) • serial (modbus rtu) • m-bus • off (turns off the serial interfaces) serial baud rate s this parameter sets the baud rate the following baud rates are supported: ...

Page 28

Miscellaneous menu misc battery voltage displays the current battery voltage this parameter is read only battery ah displays the current battery capacity for example, 0/38ah to 38/38ah this parameter is read only note: n a new battery should be at or near a 0/38 reading language u this parameter all...

Page 29

Pin menu pin control a two options are available: • on (requires pin configuration) • off user u users logged in with this pin have access to all user levels users at this level do not have access to service or admin functions service s users logged in with this pin have access to both service and u...

Page 30: Maintenance

Maintenance mandatory, routine or scheduled maintenance should not be required for the m5000 mag meter electronics or flow tube after proper installation however, some occurrences may require personnel to perform the following: • flow tube and electrode cleaning • circuit board replacement do not cl...

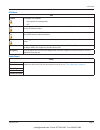

Page 31: Troubleshooting

Troubleshooting the m5000 mag meter is designed for many years of optimal performance however, should it malfunction, there are certain things that we recommend you check before contacting our technical support department or your local badger meter representative note: n if the fluid measured has a ...

Page 32

Errors & warnings what you see why it happened how to fix it measure_timeout the board may be damaged contact badger meter technical support common_mode_voltage_ overload common mode voltage is smaller than –2 0v or larger than +4 1v make sure the meter is properly grounded empty detector switch emp...