- DL manuals

- Baileigh

- Power Tool

- MD-3500

- Operator's Manual

Baileigh MD-3500 Operator's Manual

OPERATOR’S MANUAL

MAGNETIC DRILL PRESS

MODEL: MD-6000

© 2017 Baileigh Industrial, Inc.

REPRODUCTION OF THIS MANUAL IN ANY FORM WITHOUT WRITTEN APPROVAL OF BAILEIGH INDUSTRIAL, INC.

IS PROHIBITED. Baileigh Industrial, Inc. does not assume and hereby disclaims any liability for any damage or loss

caused by an omission or error in this Operator

’s Manual, resulting from accident, negligence, or other occurrence.

Rev. 06/2017

Baileigh Industrial, Inc.

P.O. Box 531

Manitowoc, WI 54221-0531

Phone: 920.684.4990

Fax: 920.684.3944

sales@baileigh.com

Summary of MD-3500

Page 1

Operator’s manual magnetic drill press model: md-6000 © 2017 baileigh industrial, inc. Reproduction of this manual in any form without written approval of baileigh industrial, inc. Is prohibited. Baileigh industrial, inc. Does not assume and hereby disclaims any liability for any damage or loss caus...

Page 2: Table of Contents

Table of contents thank you & warranty .......................................................................................... 1 introduction ............................................................................................................. 3 general notes ................................

Page 3

1 1 thank you & warranty thank you for your purchase of a machine from baileigh industrial. We hope that you find it productive and useful to you for a long time to come. Inspection & acceptance. Buyer shall inspect all goods within ten (10) days after receipt thereof. Buyer’s payment shall constitu...

Page 4

2 2 force majuere. Seller shall not be responsible for any delay in the delivery of, or failure to deliver, goods due to causes beyond seller’s reasonable control including, without limitation, acts of god, acts of war or terrorism, enemy actions, hostilities, strikes, labor difficulties, embargoes,...

Page 5

3 3 introduction the quality and reliability of the components assembled on a baileigh industrial machine guarantee near perfect functioning, free from problems, even under the most demanding working conditions. However if a situation arises, refer to the manual first. If a solution cannot be found,...

Page 6: Important

4 4 learn to recognize safety information this is the safety alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury! Follow recommended precautions and safe operating practices. Understand signal words a signal word – danger, warning, ...

Page 7

5 5 save these instructions. Refer to them often and use them to instruct others. Protect eyes wear safety glasses or suitable eye protection when working on or around machinery. Protect against noise prolonged exposure to loud noise can cause impairment or loss of hearing. Wear suitable hearing pro...

Page 8: Warning:

6 6 safety precautions metal working can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are certain hazards involved with the operation of the product. Using the machine with respect and caution will considerably lessen the possibility of personal...

Page 9

7 7 7. Do not use electrically powered tools in the presence of flammable gases or liquids. Power tools create sparks that may ignite flammable materials or gases. 8. Tooling adjustments and maintenance. Always keep tooling sharp and properly adjusted for optimum performance. 9. Remove any adjusting...

Page 10

8 8 25. Be sure all equipment is properly installed and grounded according to national, state, and local codes. 26. Inspect power and control cables periodically. Replace if damaged or bare wires are exposed. Bare wiring can kill! Do not touch live electrical components or parts. 27. Do not bypass o...

Page 11: Warning:

9 9 unpacking and checking contents your baileigh machine is shipped complete. Separate all parts from the packing material and check each item carefully. Make certain all items are accounted for before discarding any packing material. Cleaning your machine may be shipped with a rustproof waxy coati...

Page 12

10 10 getting to know your machine item description a forward/reverse switch b drill spindle c speed (rpm) selector d drill motor e coolant reservoir f coolant flow valve g slide adjustment screws h feed handle i start/stop buttons j electro-magnet on/off switch k power cord l electro-magnet b c d f...

Page 13: Caution:

11 11 electrical power specifications your tool is wired for 220 volts, 60hz alternating current. Before connecting the tool to the power source, make sure the machine is cut off from power source. Before switching on the power, you must check the voltage and frequency of the power to see if they me...

Page 14

12 12 • improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is nec...

Page 15

13 13 daily tool use and care requirements • do not touch the cutter while it is in motion. Always follow the personal protection equipment recommendations while operating this tool. • always use both hands to operate the tool. • always ensure that the material you are working on is securely clamped...

Page 16: Warning:

14 14 machine set-up; installing cutters 1. To insert a cutter, first insert the pilot pin, and then slide the cutter into the adaptor. Align the proper flat with the locking screw and tighten securely with the supplied hex wrench. Important: ensure that the locking screw is on a flat of the cutter ...

Page 17: Caution:

15 15 operation this machine is designed specifically for drilling holes in mild steel using the appropriate cutters and accessories. It should not be modified or used for any application other than for which it was intended, including powering other equipment. Ensure that the total work area can be...

Page 18: Warning:

16 16 7. Switch the forward/reverse switch to the desired direction of rotation. 8. With the motor head in the raised position, switch on the motor and allow it to come up to full speed. 9. Turn the crank handle to begin cutting use light pressure at first to keep bit from wandering, and then contin...

Page 19

17 17 troubleshooting in case of electrical or mechanical malfunction, immediately switch off the tool and disconnect the plug, excessive sparking may indicate the presence of dirt in the mater or worn out carbon brushes. Note: proper maintenance can increase the life expectancy of your machine. Adj...

Page 20

18 18 drill parts diagram.

Page 21

19 19 drill parts list item description item description 1 flexible cable 52 bearing 6000 2 switch 53 bearing 6000 3 fuse cap 54 gear 4 fuse 55 5*5*35 key 5 fuse holder 56 gear 6 motor starter 57 bearing 6001 7 cable protector 58 speeder staff 8 cable holder 59 catch spring 9 plate 60 gear 10 m4*8 s...

Page 22

20 20 item description item description 34 slide 85 brush holder 35 slide 86 capacity 36 m5*8 screw 87 connect cap 37 plate 88 cable fixer 38 rack 89 m4*12 screw 39 m6*20 screw 90 motor holder 40 hook 91 field core 41 tank 92 wind catcher 42 valve 93 bearing 6200 43 m6*10 screw 94 motor 44 m5*12 scr...

Page 23

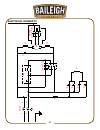

21 21 electrical schematic kcd 4 1 0 l n sa h y5 7 d2 d3 d4 d1 c2 m1 + - f1 l1 l1 l2 kr-06b jqx-1 3f-2 z for. R ev ..

Page 24

22 22 baileigh industrial, inc. 1625 d ufek d rive m anitowoc , wi 54220 p hone : 920. 684. 4990 f ax : 920. 684. 3944 www.Baileigh.Com baileigh industrial, inc. 1455 s. C ampus a venue o ntario , ca 91761 p hone : 920. 684. 4990 f ax : 920. 684. 3944 baileigh industrial ltd. U nit d s wift p oint s...