- DL manuals

- Baileigh

- Saw

- STS-14120DRO

- Operator's Manual

Baileigh STS-14120DRO Operator's Manual

SLIDING TABLE SAW

MODEL: STS-14120DRO

© 2013 Baileigh Industrial, Inc.

REPRODUCTION OF THIS MANUAL IN ANY FORM WITHOUT WRITTEN APPROVAL OF BAILEIGH INDUSTRIAL, INC.

IS PROHIBITED. Baileigh Industrial, Inc. does not assume and hereby disclaims any liability for any damage or loss

caused by an omission or error in this Operator’s Manual, resulting from accident, negligence, or other occurence.

Rev. 1/2013

Baileigh Industrial, Inc.

P.O. Box 531

Manitowoc, WI 54221-0531

Phone: 920.684.4990

Fax: 920.684.3944

sales@baileighindustrial.com

OPERATOR’S

MANUAL

Summary of STS-14120DRO

Page 1

Sliding table saw model: sts-14120dro © 2013 baileigh industrial, inc. Reproduction of this manual in any form without written approval of baileigh industrial, inc. Is prohibited. Baileigh industrial, inc. Does not assume and hereby disclaims any liability for any damage or loss caused by an omissio...

Page 2: Table of Contents

Table of contents thank you & warranty .......................................................................................... 1 introduction ............................................................................................................ 3 general notes..................................

Page 3

Operation overview ............................................................................................. 44 operational safety check ................................................................................ 45 emergency stop switch check ..................................................

Page 4

Crosscut table parts list .......................................................................................... 97 extension table parts diagram ...................................................................... 98 extension table parts list ....................................................

Page 5

1 1 thank you & warranty thank you for your purchase of a machine from baileigh industrial. We hope that you find it productive and useful to you for a long time to come. Inspection & acceptance. Buyer shall inspect all goods within ten (10) days after receipt thereof. Buyer’s payment shall constitu...

Page 6

2 2 force majuere. Seller shall not be responsible for any delay in the delivery of, or failure to deliver, goods due to causes beyond seller’s reasonable control including, without limitation, acts of god, acts of war or terrorism, enemy actions, hostilities, strikes, labor difficulties, embargoes,...

Page 7

3 3 introduction the quality and reliability of the components assembled on a baileigh industrial machine guarantee near perfect functioning, free from problems, even under the most demanding working conditions. However if a situation arises, refer to the manual first. If a solution cannot be found,...

Page 8: Important

4 4 learn to recognize safety information this is the safety alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal injury! Follow recommended precautions and safe operating practices. Understand signal words a signal word – danger, warning, ...

Page 9

5 5 save these instructions. Refer to them often and use them to instruct others. Protect eyes wear safety glasses or suitable eye protection when working on or around machinery. Dust hazard wear appropriate dust mask. Dust created while using machinery can cause cancer, birth defects, and long term...

Page 10: Warning:

6 6 protect against noise prolonged exposure to loud noise can cause impairment or loss of hearing. Wear suitable hearing protective devices such as ear muffs or earplugs to protect against objectionable or uncomfortable loud noises. High voltage use caution in high voltage areas. Do not assume the ...

Page 11

7 7 safety precautions (cont.) kickback. Kickback happens when the piece part is thrown back toward the operator at a 4. High rate of speed. Before operating this saw, understand how kickback occurs, and how to prevent it. Reaching over saw blade. Never reach behind or over the blade with either han...

Page 12

8 8 safety precautions (cont.) stay alert. Watch what you are doing and use common sense. Do not operate any tool or 20. Machine when you are tired. Check for damaged parts. Before using any tool or machine, carefully check any part that 21. Appears damaged. Check for binding of moving parts that ma...

Page 13

9 9 safety precautions (cont.) never leave machine running unattended. Turn power off . Don’t leave machine until 36. It comes to a complete stop. Make sure machine is disconnected from power supply while motor is being mounted, 37. Connected or reconnected. Saw appropriate material. Only use this s...

Page 14

10 10 machine noise declared noise emission values in accordance with iso 7960. Idling operating declared a-weighted sound power level lward, in db re 1 pw. 73 75 declared a-weighted emission sound pressure level, lpad, in db re 20 μpa, at the operator’s position. 60 62 values determined according t...

Page 15

11 11 specifications cast iron fixed table dimension 22.4” x 39.3” (570 x 1000mm) sliding table dimension 15” x 102.3” (380 x 2600mm) main saw blade Ø 12” (305mm) main saw blade Ø maximum 14” (355mm) optional main saw bore 1” (25.4mm) max. Cutting height with bade at 90 4.1” (105mm) max. Cutting hei...

Page 16

12 12 cutting depths saw blade diameter 10" (225mm) 12” (305mm) 14” (355mm) cutting depths at 90° 0 ~ 2.16 ” (0 ~ 55mm) 0 ~ 3.15 ” (0 ~ 80mm) 0 ~ 4.13” (0 ~ 105mm) cutting depths at 45° 0 ~ 1.5 ” (0 ~ 38mm) 0 ~ 2.2 ” (0 ~ 56mm) 0 ~ 2.87 ” (0 ~ 73mm) cutting lenghts sliding table cutting lengths with...

Page 17: Warning:

13 13 riving knife specification a: main saw diameter range. B: riving knife depth. C: simple riving knife. D: delux riving knife. The machine is delivered as standard with the following riving knives. 305 ~ 355/2.5 specification: saw blade diameter 305~355mm. Saw blade basic body thickness up to ma...

Page 18: Caution:

14 14 transporting and lifting follow these guidelines when lifting: always lift and carry the machine with straps on each end (fig. 1) for balance. Use a straps capable of lifting 1.5 to 2 times the weight of the machine. Take proper precautions for handling and lifting. Check if the load is proper...

Page 19

15 15 use lift truck to transport machine the lift truck must be able to lift at least 1.5 – 2 times the machines gross weight. Make sure the machine is balanced. While transporting, avoid rough or jerky motion, and maintain at least 6 ft. (2m) safe clearance zone around the transport area. The mach...

Page 20: Warning:

16 16 installation important: consider the following when looking for a suitable location to place the machine: overall weight of the machine. Weight of material being processed. Sizes of material to be processed through the machine. Space needed for auxiliary stands, work tables, or other machinery...

Page 21

17 17 clearance dimensions a 126” (3200mm) b 33.5” (850mm) c 59” (1500mm) d 68” (1725mm) e 71.75” (1820mm) f 127” (3230mm) maximum g 138.75” (3525mm) h 136.5” (3470mm).

Page 22: Warning:

18 18 unpacking remove saw from the shipping cartons. Check for damage and ensure all parts are intact. Any damage should be reported immediately to your distributor and shipping agent. Before assembling, read the manual thoroughly, familiarizing yourself with correct assembly and maintenance proced...

Page 23

19 19 intended use table saw and the workpiece guide equipment supplied with it are intended to be used exclusively for the following purposes: laminated and unlaminated board materials (e.G. Chipboard, coreboard, mdf board, ...) solid wood gypsum plasterboard, cardboard, veneer with a suitable clam...

Page 24

20 20 getting to know your machine a: dust guard not only reduce dust produced by chips while cutting, but also warning the operator where the saw-blade position. B: main table main working table. C: rip fence reference positioning while ripping. D: sliding table table for main feeding while cutting...

Page 25: Warning:

21 21 assembly note due to the size and weight of many of the saws components, the assembly of the complete saw will require the use of from 4 – 6 assistants. Note the saw was fully assembled, adjusted, and tested at the factory. Many of the fasteners have been installed into there mounting holes fo...

Page 26

22 22 sliding table installation the sliding table was installed and adjusted for parallelism at the factory. Do not change or 1. Damage the the adjusting bolts (a) during installation of the sliding table. Clean the rust preventative off of the contact surfaces (b) for the main cabinet and the slid...

Page 27

23 23 check the parallelism of the sliding table to the main table. 7. If the sliding table is parallel to the main table and has a maximum gap of 12mm between the tables and 3mm to the spindle face, final tighten the 3 mounting bolts verifying that the table does not move. If the sliding table is e...

Page 28

24 24 install the table lock (e) onto the right end of the 11. Sliding table using the m6 x 20 screw, washer, and m6 nut (f). The lock can fasten the sliding table in the middle and 12. The end positions. Before the sliding table is moved, make sure the 13. Safety lock is unlocked. Lifting the handl...

Page 29

25 25 width cutting extension table installation locate the two extension table supports. 1. Remove the 4 cabinet mounting bolts (a) from the 2. Back of the main cabinet and install the supports with the leveling bolt (b) up and the adjustment opening toward the outside. Tighten the cabinet mounting...

Page 30

26 26 crosscut table assembly lubricate the pivot pin (a) with light grease and 1. Place the stand end of the crosscut table onto the pivot pin. Lift and hold the lock handle (b) so that it is pointing 2. Straight up. Place the slide end of the crosscut table on the on 3. The slide rod (c) of the sl...

Page 31

27 27 crosscut fence assembly the crosscut fence may be mounted in either the near or far set of mountings points on the crosscut table, or it may be removed from the table. This instruction specifically installs the crosscut fence in the far set of mounting points and uses the near set as indicator...

Page 32

28 28 if there is a gap at any point, adjust the outboard 4. Crosscut fence mounting cam to square the fence to the blade. Loosen the two retaining set screws (a) and adjust 5. The cam adjustment bolt (b) to square the fence. When the fence is square, hold the cam in position 6. And evenly tighten t...

Page 33

29 29 rip fence assembly install the screw on the round rod into the right side of the working table, put into the rip 1. Fence base, adjust three nuts on the round rod to make rip fence parallel to the saw blade. Use the gauge to measure the parallelism of the rip fence and the main saw blade. 2. M...

Page 34

30 30 rip fence adjustment after the rip fence is moved, if the moving size and the target size have slight difference, the following is the operating way of the micro-knob: pull the handle (a) upwards and move the rip fence 1. To near the target size. Loosen knob (b). 2. Turn the micro-knob (c) to ...

Page 35

31 31 miter fence assemble loosen the miter fence slide block clamp handle (a) 1. A few turns. From the right end of the slide table, place the miter 2. Fence slide block over the round slide rod (b) on the front of the sliding table and slide it onto the table until it is over the angle scale. Inst...

Page 36

32 32 dust guard and support assembly before the machine is used to cut workpiece, make sure the dust collector work normally. Note: the required air speed at the end of flexible tube is 30 ~ 34m/sec. The required air volume of the machine is 1220 ~ 1390 m³/hr. (43,000~49,000 cu. Ft./hr.). Note: use...

Page 37

33 33 adjust safety guard move the saw guard up or down slightly by hand. 1. Adjust how tight the up/down movement of the saw 2. Guagr in by adjusting the bolt shown. This adjustment will loosen over time and must be 3. Adjusted at least tight enough to prevent the saw guard from moving when uninten...

Page 38

34 34 change safety guard disconnect and lockout power to the saw! 1. Lower the saw blade fully under the saw table. 2. Push up on the saw guard lock button to loosen the 3. Saw blade shield and move backward to remove. Fig. 1 fig.2 note: while cutting workpiece: at 90° cutting, 90° special safety g...

Page 39

35 35 riving knife adjustment disconnect and lockout power to the saw! 1. Open the saw blade guard. 2. Loosen the retaining screw (a) on the riving knife base just enough to allow the riving knife to 3. Move. Adjust the 3 set screws (b) at the sides of the retaining screws as the projected place sho...

Page 40: Warning:

36 36 change main saw blade disconnect and lockout power to the saw! 1. Push the sliding table towards the bottom. 2. When the pusher rod is seen, push the ball on the pusher rod inwards to push the sliding 3. Table to the bottom. Open the saw blade guard. 4. Warning: blades are dangerously sharp. U...

Page 41: Caution:

37 37 raise the main saw blade to the highest position. 5. Turn the saw blade until the fixing pin is inserted into the spindle fixing hole. 6. Loosen the nut (clockwise), clean the flange and new saw blade and then install them onto 7. The spindle. Important: the main saw blade flange nut must be t...

Page 42

38 38 change spindle rotating speed disconnect and lockout power to the saw! 1. Lower the main saw blade to the bottom position. 2. Open the service door at the back of the machine, loosen the adjusting handle (a), press 3. Down on handle (b) to raise the motor. Lift the rotating speed knob upwards....

Page 43

39 39 main saw height and tilting adjustment hand wheel operation a. Hand wheel for main saw blade height adjustment. The arrow direction (counterclockwise) is down. Clockwise is up. B. Hand wheel for main saw blade tilting adjustment. The arrow direction (clockwise) increases the tilt angle. Counte...

Page 44: Warning:

40 40 change scoring saw blade disconnect and lockout power to the saw! 1. Push the sliding table to the left until the travel release 2. Rod (a) is exposed. Push the ball on the rod inwards to release the sliding 3. Table to allow it to over travel the bed and expose the blade housing. Pull forward...

Page 45: Caution:

41 41 electrical connections a separate electrical circuit should be used for your tools. If an extension cord is used, use only 3-wire extension cords, which have grounding type plugs and receptacles, which accept the tool’s plug. Before connecting the motor to the power line, make sure the switch ...

Page 46

42 42 electrical enclosure disconnect and lockout power to the saw! 1. Use the specific key tools enclosed to unlock the electrical enclosure door. 2. Notes for wiring: power input: ac5v and ac12v / 50~60hz. 1. Signal input: standard proximity sensor or encoder a, b phase signal (dc12v). 2. Unit of ...

Page 47

43 43 power supply connection verify that the voltage of the machine conforms to your company's power. 1. Use the specific tool to open the power controlling box to connect power. 2. Connect three power wires to terminal l1(r), l2(s), l3(t) as shown in the fig. 1 and fig. 3. 3. Connect the earth wir...

Page 48: Warning:

44 44 operation overview safety precautions before operations the operation of power tools involves a certain amount of hazard for the operator. Before attempting regular work we recommend you get the feel of operations using scrap lumber to check settings. Read entire instructions before you start ...

Page 49

45 45 feed the workpiece all the way through the blade while maintaining firm pressure on the 9. Workpiece against the table and fence, and keeping hands and fingers out of the blade path and away from the blade. Stops the saw immediately after the cut is complete. 10. Operational safety check impor...

Page 50

46 46 control panel operation explanation of main keys item name description a. Emergency stop button urgently shut down the machine’s power. B. Main saw start button start main saw. C. Scoring saw start button start scoring saw. D. Saw blade stop button stop the main saw and scoring saw. Explanatio...

Page 51

47 47 correcting current dimension the figure shows 21.5 on the display. If for example, the correct position is 35.1. The following steps will change and set the correct position..

Page 52

48 48 setting parameter the figure shows 3000 as the current parameter. If for example, the correct parameter is 4255. The following steps will change and set the new pararmeter. Notes: the operators must pay attention not to make any change. Otherwise, the controller operation may be unusual and da...

Page 53

49 49 m-10-e controller introduction magnetic measuring the battery life: 1 year multifunction lcd display resolution 5μm、10μm、100μm、1mm max. Gap: 2.5mm 5 absolute offset counters 4 programmable offset settings programmable angular measurement radial mode programmable coefficient setting low battery...

Page 54

50 50 abs/rel definition abs (absolute) rel (incremental) front panel and lcd display 4.000mm 2.000mm 1.000mm zero point: 0 mm zero point: 0 mm 2.000mm 1.000mm 1.000mm.

Page 55

51 51.

Page 56

52 52 load datum values (only in abs mode) a. Description.

Page 57

53 53.

Page 58

54 54 b. Load datum.

Page 59

55 55 c. Troubleshooting.

Page 60

56 56 select counting direction (+/-).

Page 61

57 57.

Page 62

58 58 set device resolution.

Page 63

59 59.

Page 64

60 60 enable and disable specified parameter.

Page 65

61 61.

Page 66

62 62.

Page 67

63 63 appendix a - parameter parameter display description default remarks 1 origin load datum value 0 2 dir select counting direction(±) dir - - 3 off sets set tool diameter 0 4 angular enter semi diameter value 0 5 scaling diameter / semi diameter ad 6 lin corr linear correction 1.00000 7 setup fi...

Page 68

64 64 parameter setting.

Page 69

65 65 installation guide the magnetic tape consists of three components: (a) magnetized, highly flexible synthetic tape. Flexible steel tape. (a) and (b) are already factory-bonded. To keep the flexibility for transport and installation, the third part (c), also a steel tape is delivered separately....

Page 70

66 66 installation: must be away from inductive and capacitive interference source as conductor, relays, 1. Engines, switch power pack clocked controllers, etc.. Must be wired separately from heavy-duty current wires. 2. Must be kept a distance to interference sources. 3. Ensure to apply tape on cle...

Page 71

67 67 external dimension mounting / installation 10

Page 72

68 68 appendix b - calibration a. For better accuracy, calibrate for the first time installation, or if the slider has been reinstalled. Gap: 1~2.5mm (recommended: 1mm) gap about 1mm.

Page 73

69 69.

Page 74

70 70 b. Troubleshooting.

Page 75

71 71.

Page 76: Warning:

72 72 maintenance this table saw requires very little maintenance other than minor lubrication and cleaning. The following sections detail what will need to be done in order to assure continued operation of your saw. Proper maintenance can increase the life expectancy of your machine. Check daily fo...

Page 77

73 73 lubrication the table saw has sealed lubricated bearings in the motor housing and the arbor assembly, they will not require any additional lubrication. Use a wire brush to clean off the worm gears and trunnions and apply a white lithium grease to keep them lubricated. It is essential to clean ...

Page 78: Warning:

74 74 troubleshooting trouble check cause action led does not display check if power ac 5v and ac 12v are normal. Input correct voltage. If voltage is normal, that means controller is damaged. Replace controller. Led's value displayed is not the actual value check if the shown size is correct. Corre...

Page 79

75 75 main cabinet parts diagram ce type 011 012 012 011 009 008 007 006 013 014 016 017 015 018 019 002 004 005 075 076 079 078 077 075 081 084 085 083 074 075 080 081 083 ce type 003 001 008 007 006 010

Page 80

76 76 023 024 022 038 031 032 030 030 029 038 028 036 035 037 028 036 049 060 062 061 063 065 067 050 058 059 057 056 054 053 055 052 051 066 064 063 068 033 033 042 048 047 040 039 041 043 086 034 046 044 045 016 016 027 026 025 087 021 020 001 021 020 087 072 073 069 070 071 082 088 073 072.

Page 81

77 77 main cabinet parts list item description specifications item description specifications 001 body 045 stop pillar 002 electron part box 046 handle wheel 003 cap screw m6 x 16 047 washer Φ8 004 control faceplate 048 cap screw m8 x 16 005 button head screw m4 x 8 049 cover 006 cap screw m10 x 30 ...

Page 82

78 78 item description specifications item description specifications 034 countersink head screw m6 x 16 078 lock washer Φ6 035 washer 079 cap screw m6 x 16 036 thrust bearing 51102 080 cap screw m4 x 10 037 bearing base 081 safety switch ek-1-15-r 038 key 5 x 5 x 15 082 cap screw m5 x 12 039 washer...

Page 83

79 79 support arm parts diagram 001 002 003 004 005 007 016 017 015 012 016 007 014 011 013 010 011 010 012 005 007 007 008 009 009 002 001 003 015 018 018 019 020 021 018 023 018 019 022 006 025 024.

Page 84

80 80 support arm parts list item description specification 001 button head screw m5 x 8 002 fixed board 003 clean sheet 004 arm 2.6m, 3.2m arm 1.9m 005 washer m8 006 setscrew m8 x 10 007 cap screw m8 x 16 008 position shaft 009 ball bearing 6203 llu 010 retain ring stw-17 011 ball bearing 6003 zz 0...

Page 85

81 81 rotary base parts diagram 006 009 008 010 011 038 013 014 008 007 007 008 014 013 038 011 010 008 009 016 015 015 016 012 013 014 010 008 009 008 037 017 019 018 010 009 008 020 012 013 014 022 021 024 023 017 032 029 034 ce type 001 002 003 004 005 031 035 036 035 036 024 023 040 039 ce type ...

Page 86

82 82 rotary base parts list item description specification item description specification 001 cap screw m6 x 55 021 setscrew m8 x 25 002 lock washer Φ6 022 joint bar 003 washer 023 washer Φ8 004 rack 024 lock nut m8 005 fixed pole 025 fixed rack 006 rotary base 026 washer Φ6 007 cap screw m8 x 30 0...

Page 87

83 83 main saw blade mount parts diagram 015 016 017 010 018 019 020 021 022 024 023 025 026 027 032 030 031 001 002 003 006 004 007 008 009 011 014 012 013 010 005 034 028 029 013 036 035 024 037 038 039 040 041 042 043 044 045 002 046 002 046 033 033 005 047 048.

Page 88

84 84 main saw blade mount parts list item description specification item description specification 001 hex head bolt m12 x 40 025 key 8 x 7 x 20 002 lock washer Φ12 026 spindle 003 fixed block 027 key 8 x 7 x 32 004 riving knife (simple) 12", 14" 028 button head screw m6 x 10 riving knife (delux) 1...

Page 89

85 85 main blade elevation and tilt parts diagram 035 036 037 038 039 040 039 041 042 006 043 013 012 013 014 012 003 002 001 008 006 005 004 007 009 010 011 028 029 030 032 033 034 031 032 016 017 024 026 023 022 027 018 020 006 021 018 019 025 015 015 046 044 045.

Page 90

86 86 main blade elevation and tilt parts list item description specification item description specification 001 hex head bolt m12 x 20 024 gear 002 washer 025 setscrew m6 x 6 003 join block 026 nut 004 driving nut 027 fixed base 005 setscrew m6 x 30 028 countersink head screw m5 x 12 006 lock washe...

Page 91

87 87 scoring saw mounting block parts diagram 001 002 004 004 003 005 006 008 007 009 010 011 012 014 013 014 015 015 016 015 014 013 013 018 017 015 014 013 015 013 019 019 020 016 017 021 022 023 025 024 026 031 030 029 028 027 034 032 033 063 036 035 038 039 040 041 042 053 052 051 056 055 054 0...

Page 92

88 88 scoring saw mounting block parts diagram item description specs. Item description specs. 1 control knob 7051-42-b8 34 cap screw m8 x 30 2 control knob 7051-52-b8 35 hex nut m14 x p1.5 3 fixed block 36 cover 4 emboss screw 8010-25-m6-20 37 cover Φ22 x 13t 5 button head screw m6 x 10 cover Φ19.5...

Page 93

89 89 main saw motor parts diagram 023 006 007 021 020 019 021 019 024 022 021 020 019 017 018 016 002 001 004 003 013 007 006 005 010 009 008 037 035 036 033 020 034 031 019 033 028 026 030 027 025 026 019 012 032 008 009 014 015 029 011.

Page 94

90 90 main saw motor parts list item description specs. Item description specs. 001 retain ring Φ4 020 lock washer Φ10 002 position shaft 021 hex nut m10 003 spring 022 pivot axis 004 bush 023 spring sheet 005 sensor pm08-02n-3m 024 hex head bolt m10 x 40 006 cap screw m6 x 12 025 adjust handle 95ka...

Page 95

91 91 scoring saw motor parts diagram scoring saw motor parts list item description specs. Item description specs. 001 hex nut m20 010 spring 002 lock washer Φ20 011 pivot axis 003 washer 012 stop board 004 belt 15 x 690 x 1.8t 013 cap screw m8 x 16 005 countersink head screw m6 x 16 014 washer Φ12 ...

Page 96

92 92 main table parts diagram main table parts list item description specs. Item description specs. 001 cap screw m8 x 20 013 cap screw m6 x 30 002 protec bar 014 scale base 1m 003 main table scale base 1.3m 004 setscrew m16 x 120 scale base 1.5m 005 hex nut m16 015 countersink head screw m6 x 35 0...

Page 97

93 93 sliding table parts diagram 001 024 020 018 021 023 022 026 025 020 028 016 030 027 016 015 014 017 013 013 012 010 011 009 007 008 041 042 043 040 044 036 037 038 022 095 050 049 045 046 047 048 060 058 035 064 063 065 066 062 061 069 071 068 068 072 067 070 081 081 082 082 081 083 078 077 07...

Page 98

94 94 sliding table parts list item description specs. Item description specs. 001 sliding table 1.9m 050 handle sliding table 2.6m 051 counersink head screw m6 x 12 sliding table 3.2m 052 retain ring rtw-32 002 scale 053 ball bearing 6002 llb 003 cap screw m6 x 16 054 slide wheel 004 position block...

Page 99

95 95 item description specs. Item description specs. 031 cap screw m8 x 20 079 phillips head screw m5 x 8 032 cap screw m6 x 30 080 cover 033 washer Φ6 081 counersink head screw m6 x 12 034 connect block 082 position block 035 connect bar 1.9m 083 support base 1.9m connect bar 2.6m support base 2.6...

Page 100

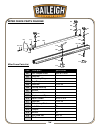

96 96 crosscut table parts diagram 001 003 001 002 001 001 005 006 008 009 010 011 012 007 006 005 004 028 029 013 015 014 016 017 018 019 020 021 022 026 025 023 024 030 029 028 032 029 031 033 033 027.

Page 101

97 97 crosscut table parts list item description specs. Item description specs. 001 rectangle insert 018 fixed board 002 short 019 lock bar 003 short 020 retain ring stw-14 004 fixed base 021 hex nut m6 005 hex nut m8 022 setscrew m6 x 16 006 setscrew m8 x 35 023 retain ring stw-20 007 adjust block ...

Page 102

98 98 extension table parts diagram extension table parts list item description specs. Item description specs. 001 table extension normal 011 washer Φ6 table extension ce 012 support rack 1m 002 hex nut m12 support rack 1.3, 1.5m 003 hex head bolt 013 hex nut m16 004 hex head bolt m8 x 20 014 washer...

Page 103

99 99 rip fence parts diagram 005 006 004 003 007 008 002 001 041 014 017 019 018 014 016 019 018 008 007 011 021 022 020 023 015 012 013 024 025 026 027 031 032 033 028 030 029 009 034 035 036 038 038 039 040 039 038 037 009 010 042.

Page 104

100 100 rip fence parts list item description specs. Item description specs. 001 fixed base 023 rip fence 002 hex head bolt m8 x 40 024 screw 003 adjust block 025 guide key 004 slide wheel 026 fixed ring 005 washer Φ8 027 countersink head screw m5 x 12 006 lock washer m8 028 slide rail 007 hex head ...

Page 105

101 101 rip fence digital display parts diagram 045 044 046 043 047 048 017 018 049 042 041 040 043 039 019 038 037 036 027 051 050 055 001 002 003 004 009 011 008 007 006 005 013 014 015 016 010 019 020 022 004 017 018 003 012 021 024 023 026 025 027 032 033 034 035 028 029 029 028 028 030 031 056 ...

Page 106

102 102 rip fence digital display parts list item description specs. Item description specs. 001 fixed base 031 slide rail 1m 002 hex head bolt m6 x 40 slide rail 1.3m 003 guide wheel slide rail 1.5m 004 hex head bolt m6 x 16 032 stop block 005 adjust block 033 lock washer Φ8 006 slide wheel 034 hex...

Page 107

103 103 crosscut fence two digital display parts diagram 092 062 063 058 068 064 070 091 072 073 087 081 082 083 088 090 071 062 069 066 085 065 066 067 086 089 009 008 007 005 006 004 003 001 002 012 011 010 001 014 015 016 017 018 019 020 021 022 023 024 025 026 027 028 029 031 030 032 033 035 034...

Page 108

104 104 crosscut fence two digital display parts list item description specs. Item description specs. 001 digital display 50cm 051 cap screw m8 x 16 002 cover 052 lock washer Φ8 003 cap screw m5 x 12 053 washer Φ8 004 lock washer Φ5 054 position pipe 2.6m, 3.2m 005 washer Φ5 position pipe 1.9m 006 w...

Page 109

105 105 item description specs. Item description specs. 032 spring 079 fixed block 033 lock slide block 080 cap screw m5 x 10 034 setscrew m8 x 90 081 retain ring stw-08 035 lock bush 082 tighten ring 036 star-shaoed knob m8 083 cap screw m6 x 16 037 cover 084 cap screw m3 x 10 038 lock slide base 0...

Page 110

106 106 miter fence parts diagram miter fence parts list item description specification 001 star-shaped knob 1083-810-m10 002 setscrew 003 positioning ring 004 gap ring 005 setscrew m10 x 60 006 locking bushing 007 washer 008 square insert 009 displacement pipe 010 adjust handle da7012-a10 011 setsc...

Page 111

107 107 dust-collecting fastening rack parts diagram dust-collecting fastening rack parts list item description specs. Item description specs. 001 fixed stand 008 fasten base fixed stand(400type) 009 adjust block 002 fixed base 1m 010 setscrew fixed base 1.3m 011 cap screw m8 x 16 fixed base 1.5m 01...

Page 112

108 108 safety guard connecting arm parts diagram safety guard connecting arm parts list item description specs. 001 rotary arm 1m rotary arm 1.3m rotary arm 1.5m 002 connect block 003 bush 004 cap screw m8 x 16 005 lock shaft 006 fixed block 007 knob 7083.710-m8 008 lock washer Φ8 009 cap screw m8 ...

Page 113

109 109 delux saw guard parts diagram 027 017 030 031 022 020 019 036 032 034 045 035 049 014 040 034 037 035 048 034 026 016 018 023 001 002 003 004 005 043 042 041 050 029 033 044 006 007 008 009007 010 006 013 005 012 038 025034 024 015 039 028 011 021 050 034 032 046 047 051 032.

Page 114

110 110 delux saw guard parts list item description specs. Item description specs. 001 push stick 027 cap screw m6 x 35 002 left safety guard 028 cap screw m6 x 25 003 open/lock button 029 cap screw m8 x 40 004 right safety guard 030 retain ring Φ22 005 chip guard cover 031 ball bearing 6900 006 gri...

Page 115

111 111 notes.

Page 116

112 112 baileigh industrial, inc. 1625 d ufek d rive m anitowoc , wi 54220 p hone : 920. 684. 4990 f ax : 920. 684. 3944 www . Baileighindustrial . Com baileigh industrial, inc. 1455 s. C ampus a venue o ntario , ca 91761 p hone : 920. 684. 4990 f ax : 920. 684. 3944 baileigh industrial ltd. U nit 1...