- DL manuals

- Bailey Moyes

- Aircrafts

- 912 Dragonfly

- Maintenance Manual

Bailey Moyes 912 Dragonfly Maintenance Manual

Delete This Page before printing!!

To Keep Page Orientation Correct

Instructions for Printing & Binding

This page gets wasted, to maintain orientation of pages throughout the manual when viewing

online, To allow viewing 2 Pages Up.

Begin printing on Page 1 (the Cover) and print both sides of paper.

Page orientation is important. This can be seen when you get to Pages 22 & 23 which should be

facing you when the Manual is open, as well as many more as you progress through the manual.

This has the Narrative and the proper Drawing facing you at the same time.

Print on 20 Lb (Min.) Premium Paper or better, Printing both sides of paper.

I prefer Spiral Bound with Clear Front Cover and Heavy Black Back Cover.

This allows the manual to be opened and folded back leaving the desired page exposed and lays

flat when opened to expose 2 pages while doing Inspections or Maintenance.

I generally get them printed at Staples or Office Depot where it costs as little as $15.00 USD per

manual in Black & White, printing only the Front Cover (page1) in Color.

Some of the pictures are in Color for the benefit of online viewing, but we print them in black &

white.

Thank you for your interest in our products! Be Safe & Have Fun!! Ed Pitman

Delete This Page before printing!!

To Keep Page Orientation Correct

Summary of 912 Dragonfly

Page 1

Delete this page before printing!! To keep page orientation correct instructions for printing & binding this page gets wasted, to maintain orientation of pages throughout the manual when viewing online, to allow viewing 2 pages up. Begin printing on page 1 (the cover) and print both sides of paper. ...

Page 2

Page 1 publication number df-mm-912 rev 2 05/11/2014 dd/mm/yyyy maintenance manual 912 dragonfly & kit assembly manual 912 dragonfly this manual only applies to slsa dragonfly aircraft and elsa dragonfly kits manufactured by pitman air, in the united states of america. Copyright ed pitman, rhett rad...

Page 3

Page 2.

Page 4

Page 3.

Page 5

Page 4.

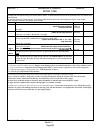

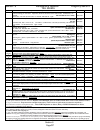

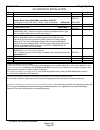

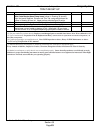

Page 6: Record Of Manual Revisions

Page 5 record of manual revisions note* a current version of this manual is always available on the internet at: http://www.Pitmanair.Com/dragonfly or www.Safety-directives.Org # dd/mm/yyyy revision number & date purpose paragraph page numbers rev.0 04/04/2013 original all all rev 1 31/05/2014 safet...

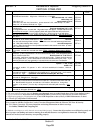

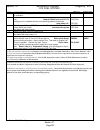

Page 7

Page 6 table of contents 1.1 general .................................................................................................................................................... 11 1.1.1 equipment list, ............................................................................................

Page 8

Page 7 section 6 pilot seat..........................................................................................................................................................33 section 7 fwd wheel throttle & manual brake ...........................................................................

Page 9

Page 8 user’s manual .......................................................................................................................................... 100 grand rapids technologies incorporated .......................................................................... 100 1. Read this first...

Page 10

Page 9 7.15 user definable combination pages ........................................................................................................................ 124 7.15.1 1d1, 1p1, … gd9, gp9 .........................................................................................................

Page 11

Page 10 appendix g – bailey release and tow system ....................................................................... 177 1. General information ................................................................................................................................................. 177 ...

Page 12

Page 11 1.1 general 1.1.1 equipment list, rotax 912 dcdi engine w/e gearbox 4:1 ratio propeller eis 2000- 1ea.-m2std-01, 1ea.-opt-intalt, 2ea.-egt-cf-01, 2ea.-cht-14-01, 1ea.-ft-1827-02, 1ea.- cab-a-02 1.1.2 sources to purchase parts, note: the use of used, overhauled or reconditioned parts or compo...

Page 13

Page 12 1.1.3.2 airframe and systems : (all parts can be purchased direct from pitman air, alternate suppliers listed below) a: clear return fuel lines, # 2100686 ether based superthane only, not ester based newage® industries, inc., 145 james way, southampton, pa 18966-3817 phone: 800-506-3924 or 2...

Page 14

Page 13 performance 912 ul maximum power (5 minutes) 81hp / 59.6kw @ 5800 rpm maximum power (sustained) 79hp / 58.9kw @ 5500 rpm maximum torque 75.9ft-lb / 103nm @ 4800 rpm combustion chambers bore 3.13" / 79.5mm stroke 2.40" / 61.0mm displacement 73.91cu.In. / 1211.2cm³ compression ratio 9.0:1 weig...

Page 15

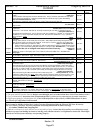

Page 14 1.1.5 weight and balance information, 1.1.5.1 weight and balance chart 1.1.5.2 operating weights and loading (occupants, baggage, fuel, ballast) the cg must never be further forward than 75.67 inches from the datum nor further aft than 80.78 inches from the datum the aircraft must never be f...

Page 16

Page 15 the mean aerodynamic chord (mac) is calculated by adding the wing and flaperon area and divide by span. Mac = area = 183.10 ft sq = 5.37ft / 64.50in mean span 34.08ft 1. Datum - cockpit front cross tube 0.00 2. Pilots pelvis position - pilot cg 35.0in 3. Front axle - front wheels 50.0in 4. L...

Page 17

Page 16 1.1.5.3.3 cg with max fuel & 100 kg / 221 lb. Pilot for max forward cg (example) weight arm moment aircraft 515lb 95.9in 49388.5in lb fuel 33lb 60.0iin 1989.0in lb pilot 221lb 35.0in 7735.0in lb 769lb 59112.5in lb cg = moment = 59112.5 = 76.85in mass 769 as a percentage of mac 76.85 – 60.0 =...

Page 18

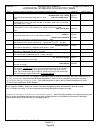

Page 17 1.1.5.4 installed optional equipment list affecting weight and balance or a reference as to where this information can be found. Note— ( retrieve and/or update this information in your poh ( pilot operating handbook ) also. Item location moment weight 1.1.6 tire inflation pressures , 15 to 2...

Page 19

Page 18 1.1.8.1 wear tolerances of cable, bolt or fastener and hole elongation. Bolts and fastener wear: maximum 10% example: ¼” 0.25 * 0.9 = 0.225’ as the thinnest part of bolt or ¼” fastener. Hole elongation: maximum of 15% example: ¼” 0.25 * 1.15 = 0.2875 maximum in longest direction of hole. Exa...

Page 20

Page 19 items (5) and (6) contain things that may require special attention during the inspection. Note: each “section” 1 through 30 of the maintenance instructions must be consulted to identify areas of special interest or “life limited parts” (llp) to identify if part needs special attention or re...

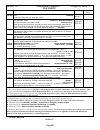

Page 21

Page 20 accessories - for apparent defects in security of mounting. All systems - for improper installation, poor general condition, defects, and insecure attachment. Cowling or fairings- for cracks, and defects. Continued next page (e) each person performing an annual or 100-hour inspection shall i...

Page 22

Page 21 1.3 structures sections 1 through 29 and appendix’s of this manual 1.3.1 wings see sections 14 through 20 , 1.3.2 empennage see sections 1, 2, 4, 8 through 13, 21, & 23 1.3.3 landing gear, see sections 2, 7, 8, and appendix b 1.3.4 structural control surfaces, see sections 9 through 21. 1.3....

Page 23

Page 22 2 inspection, repair, and alterations— 2.1 repairs and alterations—defined 2.1.1 repairs— repairs are to be done in accordance with manufacturer’s instructions for slsa aircraft and/or faa ac 43.13-1b and ac 43.13- 2b for elsa 2.1.2 alterations— note—no alterations may be made to slsa aircra...

Page 24

Page 23 section 1 boom tube section 1 section 1 maintenance & inspection pitman air boom tube assemble the internal and external parts in the following manner. Take care that each bolt that passes through the 5” boom or fuselage tube also passes through an internal tube or sleeve, so that the boom t...

Page 25

Page 24 drawing 1.

Page 26

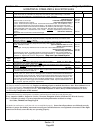

Page 25 section 2 maintenance & inspection dragonfly 582/912 bulkhead step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 llp1000 install (see item 17 of section 13) (llp1000) bolt control pivot assembly into bulkhead as shown. An3 castle nut, cotter pin. Loose....

Page 27

Page 26 drawing 2.

Page 28

Page 27 section 3 maintenance & inspection dragonfly 912 root tube step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 912 only bolt an4-27a, 1/4" washer, engine supp brkt root tube 912, 1/4" washer, an4 full nut. Very tight. Dfo-048 dfi 016 2 n/a 912 3 bolt an4...

Page 29

Page 28 drawing 3.

Page 30

Page 29 section 4 maintenance & inspection dragonfly 912 fuselage step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 bolt an4-27a, 1/4" washer, root supp aft brkt lower, push rod guide aft root, engine mount rotax 912, push rod guide aft root, root supp aft brk...

Page 31

Page 30 drawing 4.

Page 32

Page 31 section 5 maintenance & inspection dragonfly 582/912 fwd cockpit step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 slide spacer 1” tube spacer .875” into cockpit tube fwd. Eye bolt an43 – 15a, spacer stand off .375”, cockpit tube fwd, spacer 1” tube sp...

Page 33

Page 32 drawing 5.

Page 34

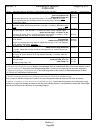

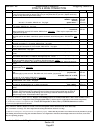

Page 33 section 6 maintenance & inspection dragonfly 582/912 pilot seat step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 100 hr slide seat tube lower fwd through seat-cushion. Bolt an4-21a, 1/4" washer, cockpit tube lower, seat tube lower fwd. Tight. Dfc 020 ...

Page 35

Page 34 drawing 6.

Page 36

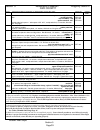

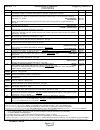

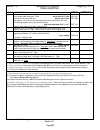

Page 35 section 7 maintenance & inspection dragonfly 582/912 fwd wheel, throttle & brake note: hydraulic brakes see appendix b step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 wheel halves are not symmetrical. Take front wheel rim 8020 and using a 5/16" drill...

Page 37

Page 36 note: for hydraulic brakes see appendix b drawing 7.

Page 38

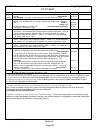

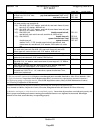

Page 37 section 8 maintenance & inspection dragonfly 582/912 tail wheel step instructions for assembly, for disassembly reverse the order! Part no. Stage 1 wrap mylar shim around vert stab aft. Trim to fit snugly in main boom. Align holes, blind nut should be on fwd. Side of tube. An4 half nut, 1/4"...

Page 39

Page 38 drawing 8.

Page 40

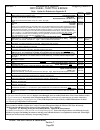

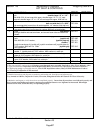

Page 39 section 9 maintenance & inspection dragonfly 582/912 vertical stabilizer step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 wrap mylar shim around vert stab fwd and slide into boom tube. Align holes. An4 half nut, 1/4" washer, bolt vert stab fwd 1/4” x ...

Page 41

Page 40 drawing 9.

Page 42

Page 41 section 10 maintenance & inspection dragonfly 582/912 rudder step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 slide rudder conn sleeve inside rudder fwd. Insert bolt an3-13a temporarily screw into an3 blind nut. Using 1/8" drill bit, drill rudder fwd ...

Page 43

Page 42 drawing 10

Page 44

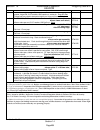

Page 43 section 11 maintenance & inspection dragonfly 582/912 horizontal stabilizer & elevator frame step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 bolt an3-13a, 3/16” washer, horiz stab comp strut inboard, threaded insert 7/16” x 10/32, horiz stab comp str...

Page 45

Page 44 drawing 11.

Page 46

Page 45 section 12 maintenance & inspection dragonfly 582/912 horizontal stabilizer & elevator sails step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 slide spacer aileron hinge 1.125” in end of horiz stab aft. Bolt an3-15a, hinge brkt, horiz stab aft, spacer ...

Page 47

Page 46 drawings 12a & 12b.

Page 48

Page 47 section 13 maintenance & inspection dragonfly 582/912 controls step instructions for assembly, for disassembly reverse the order! Part no. Stage 2 bolt an3-16, 3/16” washer, eyebolt, 3/16” washer, push rod follow block, 3/16” washer, eyebolt, 3/16” washer, an3 castle nut, cotter pin. Snug bu...

Page 49

Page 48 drawing 13.

Page 50

Page 49 section 14 maintenance & inspection dragonfly 582/912 aileron step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 2 bolt an3-7, hinge brkt, grease, hinge point, grease, hinge brkt, 3/16” washer, an3 castle nut, cotter pin. Snug but free. (hinge brkt may ne...

Page 51

Page 50 drawing 14.

Page 52

Page 51 section 15 maintenance & inspection dragonfly 582/912 aileron sails step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. Sprinkle generous amounts of baby powder into fabric aileron port and on aileron frame. Pull sail onto frame until just snug. (patches a...

Page 53

Page 52 drawing 15.

Page 54

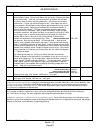

Page 53 section 16 maintenance & inspection dragonfly 582/912 wing step instructions for assembly, for disassembly reverse the order! Part no. Stage 1 bolt an4-26a, 1/4” washer, wing spar leading edge (turn rivet heads to inside), wing tip insert, wing tip, wing tip insert, wing spar leading edge, 1...

Page 55

Page 54 drawing 16.

Page 56

Page 55 section 17 maintenance & inspection dragonfly 582/912 wing battens and sails step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. Remove tape holding trailing edge in place. Unfold sail wing port and sail wing starboard and lay leading edge mylar flat on gr...

Page 57

Page 56 drawing 17.

Page 58

Page 57 section 18 maintenance & inspection dragonfly 582/912 wing sail access holes & sealing step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. * using a hot knife, burn a slot against outboard sides of bent strut plates until they push through fabric. (burn sl...

Page 59

Page 58 drawing 18.

Page 60

Page 59 section 19 maintenance & inspection dragonfly 912 aileron support tubes & mounting step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 bolt an4-30a, 1/4” washer, strut plate a, wing spar leading edge, strut plate b, 1/4” washer, an4 full nut. Very tight....

Page 61

Page 60 drawing 19.

Page 62

Page 61 section 20 maintenance & inspection dragonfly 582/912 struts & wing connection step instructions for assembly, for disassembly reverse the order! Part no. Stage * push spacer strut 1” into strut aft using a length of tubing or wood approx. Six feet long. Cut a notch in one end of pusher tube...

Page 63

Page 62 drawing 20

Page 64

Page 63 section 21 maintenance & inspection dragonfly 912 cable bracing step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 put mirror mount brkt over cockpit tube lower port. Slide mirror tube 3/4” tube through mirror mount brkt and spacer mirror brkt with appr...

Page 65

Page 64 drawing 21.

Page 66

Page 65 section 22 maintenance & inspection dragonfly 582/912 aft seat step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 align seat brkt aft to back hole. Drill 3/16” hole, pop rivet stainless steel 3/16” x 1/4”, seat brkt aft, seat main frame aft. Dfo 045 dft...

Page 67

Page 66 drawing 22.

Page 68

Page 67 section 23 maintenance & inspection dragonfly 582/912 aft seat & controls step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 fit seat belt aft into shackle large 1/4” x 1 1/4”. Bolt an4-23a, aft root supp brkt upper, shackle large 1/4” x 1 1/4”, seat su...

Page 69

Page 68 drawing 23.

Page 70

Page 69 section 24 maintenance & inspection dragonfly 912 912 engine mount these instructions are for installation of a two-stroke engine onto the engine support brackets as shown on section 3. Step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 bolt an4-10a, 8 ...

Page 71

Page 70 drawing 24.

Page 72

Page 71 section 25 maintenance & inspection dragonfly 912 912 exhaust & muffler installation step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 lubricate muffler and exhaust pipe ball joints with thin film of high temp copper anti-seize or current rotax recomme...

Page 73

Page 72 drawing 25.

Page 74

Page 73 section 26 maintenance & inspection dragonfly 912 912 radiator installation step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 install radiator tangs dfo 050 2 screw two rubber rotax mounts & stainless brackets, radiator mounts & rubber buffer rotax 25x...

Page 75

Page 74 drawing 26.

Page 76

Page 75 section 27 maintenance & inspection dragonfly 912 912 fuel system step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 drill 3/32” hole through cap of fuel tank or ventilation. Dfp 051 2 insert fuel strainer into gates # 27348 fuel line 5/16” i.D. Making ...

Page 77

Page 76 drawing 27.

Page 78

Page 77 section 28 maintenance & inspection dragonfly 582/912 electrical system step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 mount the battery bracket, on the root tube. Dfl 023 2 install rubber cushion pad in bottom of battery bracket. 3 fit battery into...

Page 79

Page 78 wiring1.Jpg drawing 28a.

Page 80

Page 79 wiring2.Jpg drawing 28b.

Page 81

Page 80 eleclights.Jpg drawing 28c.

Page 82

Page 81 section 29 maintenance & inspection dragonfly 582/912 parachute & elt mounting step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 set second chantz 1100 lb. Parachute on root tube, mark holes loose. 2 slide parachute mount assembly onto top of root tube...

Page 83

Page 82 drawing 29.

Page 84

Page 83 section 30 maintenance & inspection dragonfly 912 trim tab set-up step instructions for assembly, for disassembly reverse the order! Part no. Stage cert. 1 an42b-14a 2 each hold elevator trim tab to elevator. With cable bracket hose clamp loose (shown in drawing 30 item #3) align horizontal ...

Page 85

Page 84 drawing 30

Page 86

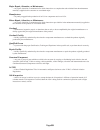

Page 85 3 level of certification— 3.1 owner— items that can be expected to be completed by a responsible owner who holds a pilot certificate but who has not received any specific authorized training. I.E. May do certain preventative maintenance on slsa as defined in appendix d of this manual. Note:—...

Page 87

Page 86 4.2.4.4 starters/generators/alternators, (may require additional rotax ratings) 4.2.4.5 exhaust manifolds/mufflers, (may require additional rotax ratings) 4.2.4.6 wheel and brake assemblies, 4.2.4.7 propellers, (may require additional ratings, see manufacturers manual) 4.2.4.8 sparkplugs, ig...

Page 88

Page 87 6.3 typical components that are overhauled include: 6.3.1 engines, must be performed by rotax authorized service centre, refer to rotax manuals and website: www.Flyrotax.Com for specific information. 6.3.2 carburettors/fuel injection systems, refer to rotax manuals and website: www.Flyrotax....

Page 89

Page 88 9.2.4 the level of certification needed to accomplish the task, for example, a&p, repairman inspection, etc.. 9.2.5 detailed instructions and diagrams as needed to perform the task, and 9.2.6 method to test/inspect to verify the task was accomplished properly. 9.3 service directives are cons...

Page 90

Page 89 major repair, alteration, or maintenance —any repair, alteration, or maintenance for which instructions to complete the task excluded from the maintenance manual(s) supplied to the consumer are considered major. Manufacturer —any entity engaged in the production of an lsa or component used o...

Page 91

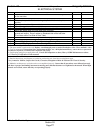

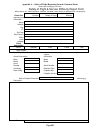

Page 90 appendix a -- safety of flight reporting form & comment form (make copies of this page as needed) safety of flight & service difficulty report form mail to: pitman air, 1840 airport blvd., red bluff, ca 96080 and/or online at: www.Pitmanair.Com/dragonfly/ check one item of concern safety of ...

Page 92

Page 91 appendix b brakes manual for bx1320 & bx1000 appendix b page 1.

Page 93

Page 92 appendix b page 2.

Page 94

Page 93 appendix b page 3.

Page 95

Page 94 double caliper parts on ¾” axle one caliper up and one aft of axle. Elbow changes to dfn 003 ¾ & bolts go up one size through elbow and axle appendix b page 4.

Page 96

Page 95 appendix b page 5.

Page 97

Page 96 appendix b page 6.

Page 98

Page 97 appendix b page 7.

Page 99

Page 98 every 100 hours or annual inspection loosen set screw ½ turn and insure there is no significant play in woodruff key, then re tighten. Inspect to insure 3 allen screws that disc floats on are tight, that there are no leaks, no significant scoring of disc and that fibre pads both sides of dis...

Page 100

Page 99 since these are disc brakes there is no need for a shuttle valve. When the brake piston starts to move it covers the reservoir return hole, then starts to add pressure to the system. If the piston does not return to the full back position, it will not open the reservoir return port. Thus bec...

Page 101: Model 4000/6000

Page 100 appendix c eis 4000 912/914 model 4000/6000 engine information system user’s manual grand rapids technologies incorporated 3133 madison ave se grand rapids, mi 49548 (616) 245-7700 fax (616) 245-7707 rev l applicable to software versions 7.5 and above. Software version_____________ serial n...

Page 102

Page 101 1. Read this first! .................................................................................................................................. 105 2. An overview of installation & setup ................................................................................. 105 3. Using th...

Page 103

Page 102 7.15.2 table of user-definable page entries. 125 7.16 example worksheet for setting up your custom pages. ......................................................................................... 128 7.17 worksheet for planning user-definable pages .............................................

Page 104

Page 103 figure 1a - description of display pages.

Page 105

Page 104 figure 1b. Description of display pages.

Page 106

Page 105 congratulations on your purchase of grand rapids technologies' engine information system (eis). We are pleased that you have chosen our product to meet your aircraft instrumentation needs. You will find this system will enhance your flying pleasure while increasing your level of safety. 1. ...

Page 107

Page 106 3.1 the basics of the engine information system operation power to eis when starting the engine. It is good practice to turn on the eis before starting the engine, and verify a low oil pressure warning is generated. This verifies the oil pressure sensor is able to sense zero pressure correc...

Page 108

Page 107 all engine limits are stored with a checksum. If the instrument determines a user setting has been lost, it will generate a “check entries” message at power-up. If you see this message, carefully review all user settings. At power-up, the eis will automatically select the page you have set ...

Page 109

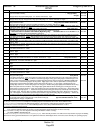

Page 108 4.1 set page table of limits. [brackets denote dragonfly factory settings] n/u = not used setting use recommended setting cont [ 2 or 3 ] contrast - adjusts screen for maximum readability based on viewing angle and instrument temperature. *see end of table for more information about this se...

Page 110

Page 109 used as a warning that the engine rpm is dropping too low on the landing rollout which could result in engine stall. Min fuel n/u [ 0 ] minimum fuel quantity – generates a warning when the fuel flow function’s fuel quantity drops below this limit. Set to at least enough useable fuel to prov...

Page 111

Page 110 max egt-inc n/u [ 0 ] maximum increase in egt from the lean point. This alarm is active while lean point is active. This alarm will often generate a false alarm when the load on the engine significantly reduced during descent. To avoid this false alarm, reset the lean point. (selecting “set...

Page 112

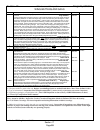

Page 111 the instrument should be secured using the mounting holes in the faceplate. Figure 4 provides the physical dimensions of the instrument and a full-size mounting template. If the mounting template is used, its dimensions should be verified, as paper may expand and contract with humidity. Not...

Page 113

Page 112 3) do not use the same ground lead for the instrument, and the ignition kill switch(es). Be sure these separate ground leads do not connect to the engine in such a way that they could become disconnected from the engine, but remain connected together. 4) the remainder of the signals are now...

Page 114

Page 113 5.2.6 external alarm output this output is used to control the external warning light included. The output is an open/ground type output. This means that when this output is off (the alarm is not active), this line is equivalent to an open circuit. When this output is on, this output is swi...

Page 115

Page 114 4) position the hole around the manifold so that the probe does not interfere with the cowl, and takes into consideration practical needs related to maintenance (does not interfere with the access to the oil filter, etc.), inspections, or probe mounting. Insert the probe into the exhaust ma...

Page 116

Page 115 crimp the mating connectors onto the extension wire. Plug the color-coded leads onto the matching color extension wires. Secure the probe leads with suitable wire clamps to prevent them from chaffing against the engine or airframe. Heat shrink tubing can be used to protect the leads from ab...

Page 117

Page 116 if desired, a combination page can be programmed to display the tachometer reading being sensed by the tachometer input #2. This is accomplished by selecting "n2" to be displayed on a combination page. N2 will always show the rpm calculated from tachometer input #2. The normal "tach" displa...

Page 118

Page 117 the settings shown on the “configuration set” pages are as follows. The order has been altered by grouping everything related to the auxiliary inputs at the beginning, with the remainder of the settings, in order, following the auxiliary section. 7.1 setting up your auxiliary inputs – label...

Page 119

Page 118 the auxiliary inputs can be configured to provide accurate readings when connected to a fluid temperature sensor by setting the auxiliary scale factor to a special code of 0. This tells the instrument that the auxiliary input has been wired to a fluid temperature sensor (of the type the ins...

Page 120

Page 119 7.1.7 transfer function the transfer function mathematically defines the relationship between the auxiliary input voltage, and the numeric data displayed on the instrument. This function is of no use to most users, but is provided here for those interested in creating custom applications fo...

Page 121

Page 120 7.5 flocalr (return fuel flow calibration) this entry adjusts the scaling of the return fuel flow sensor. It is not used unless your fuel system requires monitoring the outgoing and return fuel, using two fuel flow sensors. If only one flow sensor is used, this setting is ignored, and will ...

Page 122

Page 121 an external switch may also be used to manually select which ignition system provides the tachometer source. Since magneto problems can often be detected early on by erratic tachometer readings, an external switch allows the pilot to choose which magneto is to be monitored, allowing him to ...

Page 123

Page 122 7.7 tachsen each tachometer input includes a sensitivity adjustment, identified as tach1sen and tach2sen on the configuration set pages. The "l" (low) sensitivity setting is best for most tachometer connections as it provides the greatest amount of filtering and tolerance of noise on the ta...

Page 124

Page 123 b) the tachometer must exceed the tachhi setting, and then go below the tachlo entry. This will generate an tachometer warning (the red warning light will flash, the page will change to the labeled page that includes tachometer, and the tachometer will flash). Acknowledging this alarm (by p...

Page 125

Page 124 to calibrate the altimeter so that the barometric pressure it registers is correct, the follow procedure should be followed. This procedure must be performed with a new instrument, and should be re- checked on an annual basis. A) turn on the instrument and allow 5 minutes or more for its in...

Page 126

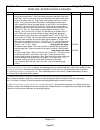

Page 125 note: the items set up for the graphical leaning pages (that is, the pages with the bar graphs), apply to both of the bar graph pages. Three or four letter identifiers are used to define the data that can be displayed, and a numeric entry describes the position on the screen where this data...

Page 127

Page 126 tach tach 4 highest cht chh 3 chs factory use only cht rate chr 3 highest egt egh 4 egt span egs 4 highest egt change egpk 4 leaning info (egt or delta from peak egt) for first cylinder to peak. (frst2pk indicates which cylinder was first to peak.) frst2pk 1p 1 cylinder number of first to p...

Page 128

Page 127 the following illustration shows the numbering of positions on the display screen for the user-defined pages. Note how the 32 character positions are numbered from 1-32 starting in the upper left corner. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32.

Page 129

Page 128 7.16 example worksheet for setting up your custom pages. The easiest way to create your custom pages is to plan them on page, and then translate you plan into the entries that you will make in the instrument. To illustrate this, lets create a simple page. 1. Start with a blank worksheet. Fi...

Page 130

Page 129 7.17 worksheet for planning user-definable pages ( shown as set at pitman air ) note: > denotes field going further spaces 1 t 2 a 3 c 4 h 5 6 o 7 t 8 > 9 / 10 o 11 p 12 13 e 14 g 15 h 16 > 17 a 18 l 19 t 20 > 21 > 22 23 + 24 v 25 s 26 27 28 29 30 c 31 h 32 h combo page #1 1d1 = tach 1d7 = ...

Page 131

Page 130 bar graphs use the first 8 character positions. ( shown as set at pitman air ) 1 2 3 4 5 6 7 8 9 10 11 12 h 13 r 14 : 15 m 16 n 17 t 18 a 19 c 20 h 21 22 o 23 t 24 > 25 / 26 o 27 p 28 29 v 30 o 31 l 32 t graphical (leaning) pages note: don’t assign any items to position 1-8, as this space i...

Page 132

Page 131 8. Disabling pages ( pitman air disables pages 0, 4, 6, 7, 9, 11, 12, 13, 14, & 15 ) up to 10 display pages may be disabled so that they do not appear when pressing the "next" and "previous" buttons. Disabling pages can make it easier to get to the pages that you find the most useful. You m...

Page 133

Page 132 the tracking function may also be activated during climb or descent if desired. This is especially useful when troubleshooting an intermittent problem. (it may be necessary to re-activate it during this phase of the flight to account for the change in exhaust gas temperatures resulting from...

Page 134

Page 133 cylinders which were leaned past peak with first increase, and then decrease. The key to making it simple, it to ignore all but the first to peak (the first to go negative). Use this cylinder to adjust mixture to your desired setting (such as 50 degrees rich of peak). Note that the leaning ...

Page 135

Page 134 10. Detailed description of other functions 10.1 flight timer at power-up of the eis, the flight timer shows the length of the previous flight in hours and minutes. This makes it easy to recall the last flight time if power is turned off to the instrument before the time is noted. This time...

Page 136

Page 135 12. Updating the eis software eis model 4000 instruments with software version 70 or greater (as shown in the software version number on the label, or as might be displayed on the screen at power-up) include field re- programmable memory that allows the instrument to have software updates l...

Page 137

Page 136 ground. If the eis show a high temperature, the connection to the instrument is good. If it does not change, check the wire between the instrument, and the oil or coolant temperature sensor, especially the crimp on the quick-disconnect that plugs onto the coolant temperature sensor. Tach re...

Page 138

Page 137 appendix c eis 4000 912/914.

Page 139

Page 138 appendix c eis 4000 912/914.

Page 140

Page 139 appendix c eis 4000 912/914.

Page 141

Page 140 appendix c eis 4000 912/914 end appendix c.

Page 142

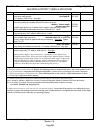

Page 141 appendix d: items permitted under the privileges of preventive maintenance taken from an article for your help in determining if you are qualified! Special note: please read carefully the following 32 items that are permitted under the privileges of preventive maintenance and the short brie...

Page 143

Page 142 use a magnet to extract ferrous particles, and save them for later examinations. Filter the remaining solvent through a coffee filter, and examine the remains. You should ask your a&p mechanic for advice on what you see the first couple of times. Many people will save the coffee filter and ...

Page 144

Page 143 14. Replacing safety belts. You are allowed to replace your seat belts and shoulder harnesses with approved belts for your make and model airplane. If you elect to change the belts it is strongly suggested that you follow the service manual instructions for installation. If the manual calls...

Page 145

Page 144 24. Replacing and servicing batteries. When replacing your airplane’s battery, use only an approved battery for your make and model airplane. You are also permitted to add water (distilled water) and charge your battery. If you need to clean the battery, terminals, or battery box area, baki...

Page 146

Page 145 advisory circular 43-12a preventive maintenance subject: preventive maintenance date: 10/28/83 ac no: 43-12a initiated by: aws-340 1. Purpose. This advisory circular (ac) provides information concerning preventive maintenance, who may perform it, the standards of performance applicable to i...

Page 147

Page 146 2. Far 43.13 requires the use of the tools, equipment, and test apparatus necessary to assure completion of the work in accordance with accepted industry practices. This means that the proper tools and test apparatus must be used. Normally these are listed as part of any faa-approved manufa...

Page 148

Page 147 (a) each person performing maintenance, alteration, or preventive maintenance on an aircraft, engine, propeller, or appliance shall use the methods, techniques, and practices prescribed in the current manufacturer's maintenance manual or instructions for continued airworthiness prepared by ...

Page 149

Page 148 appendix e1 kievprop installation kievprop installation instructions www.Kievpropamerica.Com for engine type with rotax 912 series 75mm bolt pattern 8 lb. 1 oz. W/o 6 mounting bolts cg datum point 132” 1. Disassemble prop hub, noting orientation of prop hub halves. The stamped number on eac...

Page 150

Page 149 4. On rotax 912 applications, the hub does not require the insert to bolt directly onto the prop flange. However, if you are installing a kievprop spacer, you will need to install the supplied insert into the prop hub . Important! On pusher configurations with the propeller installed, make ...

Page 151

Page 150 pusher tractor 9. For pusher aircraft, place the notched end of the protractor against the trailing edge of each prop blade. For tractor applications, the notched end should be on the leading edge of each blade. Rotate the blade until it sits flat against the leading and trailing edge of th...

Page 152

Page 151 11. A static check of rpm’s must be performed before flight. Refer to engine manual for specific instructions. With engine off, make sure your throttle has full travel and the carburetors are adjusted properly and open fully. Note: do not fly until you have checked and rechecked your propel...

Page 153

Page 152 appendix e1 page 5 end of appendix e1 mounting bolts (undrilled shank): an5-36a thick washers: an960-516 jam nut: ms21045-5 mounting bolts (drilled shank): an5-36 thick washers: an960-516 castle nuts: an310-5.

Page 154

Page 153 appendix e2 powerfin installation powerfin type f 72” 3 blade pitch to 5250 rpm static installation instructions 9.7 lbs. W/o 6 mounting bolts @ cg datum point 132” appendix e2 powerfin prop page 1.

Page 155

Page 154 appendix e2 powerfin prop page 2.

Page 156

Page 155 appendix e2 powerfin prop page 3.

Page 157

Page 156 appendix e2 powerfin prop page 4.

Page 158

Page 157 appendix e2 powerfin prop page 5.

Page 159

Page 158 appendix e2 powerfin prop page 6.

Page 160

Page 159 appendix e2 powerfin prop page 7.

Page 161

Page 160 appendix e2 powerfin prop page 8.

Page 162

Page 161 appendix e2 powerfin prop page 9.

Page 163

Page 162 appendix e2 powerfin prop page 10

Page 164

Page 163 appendix e2 powerfin prop page 11 end of appendix e2.

Page 165

Page 164 appendix f ameri-king ak-451 & ak-450 general information scope this contains most information necessary for the installation, test and operation of the model ak-451, emergency locator transmitter, manufactured by ameri-king corporation, california, u.S.A. For more detailed information refe...

Page 166

Page 165 the elt (af)(ap) has an automatic activation g-switch. It is activated automatically upon a crash or manually operated. If for any reason, a fixed mounting is not required, the elt (af)(ap) can be used as a portable device, due to it ‘s manual operated hand use portability. Check local and/...

Page 167

Page 166 • general specifications (standard conditions): • transmitter: operating frequencies: 406.028 mhz ± 0.001 mhz (not on ak-450) 121.500 mhz ± 0.005 % 243.000 mhz ± 0.005 % short term stability ≤ 2 x 10 /100ms medium slope -1 to +1x10 9 /min medium residual variant ≤ 3 x 10 9 modulation char...

Page 168

Page 167 figure 1: mounting tray for elt- (af)(ap). P/n 450 013 figure 2: holder for elt- (af)(ap) p/n 450 014 figure 3: mounting tray with velcro holder and portable antenna for appendix f page 4.

Page 169

Page 168 elt- (af)(ap) figure 4: battery pack replacement for elt main unit (actual view) figure 5: battery cell replacement for elt main unit (actual view) (ak-450 has 6 d cell alkaline batteries) mechanical installation the elt is designed with the installer in mind. All accessories, which are req...

Page 170

Page 169 installations must be made by qualified personnel in accordance with faa regulations. Duplicating a previous installation may not be acceptable. Refer to the department of transportation regional aco for detailed information. Please refer to faa ac 43.13 for guideline. Quick operation check...

Page 171

Page 170 4. Elt self test: (does not apply to ak-450) place the main switch position from “off” to “arm.” the buzzer sounds, and the 2 elt green “on” lights (red light for ak-450) shall illuminate for 4 seconds, then extinguish. After 25 seconds, a 406 mhz test signal is transmitted. However it is s...

Page 172

Page 171 detailed operation check: 1 main switch on/off/arm operation: in normal operation, the main switch, located on the elt main unit, must be in the "arm" position. In the event of a crash, an acceleration activated crash censor (g- switch) turns the elt 'on' automatically when the elt experien...

Page 173

Page 172 figure 6: elt front panels-main unit and remote unit. 3 system integration test: (some parts may not apply to ak-450) the test consists of turning the unit “on” and then “resetting” it to verify that the transmitter, latch circuit, batteries, and associated equipment are operating properly....

Page 174

Page 173 3.1 monitor 121.5 mhz using the aircraft com receiver or portable hand held receiver. Turn the squelch all the way up or on. 3.2 ensure that the main switch on the elt is on “arm” position. • push the “on” button on the cockpit remote switch unit. Verify that both the green on lights, locat...

Page 175

Page 174 (tuning dial on any setting) is held about 6 inches from the activated elt antenna, the elt aural tone will be heard (see note below). The elt must be reset by pressing either the reset push button located on the elt main unit or the elt remote unit. Note: this is not a measured check, but ...

Page 176

Page 175 6 periodic maintenance (instructions for continued airworthiness): references: far part 91.207, part 43 appendix d (i). Far part 91.207 paragraph (d) far part 91.407 purpose: to insure continued reliability of your elt, it must be inspected for damage and wear which could be caused by age, ...

Page 177

Page 176 6.8 verification of digital message note: this test is not mandatory per far 91.207(d) however ameri-king strongly recommends that it be performed as part of periodic maintenance, at least every year. Verify the 406 mhz digital message using a computer test set or equivalent, capable of rec...

Page 178

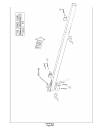

Page 177 appendix g – bailey release and tow system refer to pilot operating handbook for complete towing operation and limitations 1. General information 1.1 introduction the bailey release and tow system has been used and refined since 1990 on the bailey moyes dragonfly for towing hang gliders, ul...

Page 179

Page 178 b: quick release and safety link quick change pin and retainer showing configuration of safety link. C: slider ring or karabiner.

Page 180

Page 179 d: top post quick change line retainer and simple knot. Simple granny knot with tail tucked in tube ahead of knot e: small karabiner or ring with funnel device for wind resistance and additional drag to make the untethered line fly higher behind the tow plane. It also protects the ring atta...

Page 181

Page 180 single point glider attachment , picture shows single loop doubled to give 4 strands of 130 lb. Safety link connecting glider to towline. 2 point glider attachment , picture shows a single loop safety link of 130 lb. Solo or 200 lb. Tandem, attached by passing it through itself and attachin...

Page 182

Page 181 f: release handle release pressure is easily measured with a digital postal scale. Normally 5 lb. 4 oz. 4 to 9 lbs. Of pressure are acceptable. More than 9 lbs. Pressure indicates cable needs replacement or there is excessive resistance somewhere in the system. 2. Limitations 2.1 introducti...

Page 183

Page 182 figure 2 knots used for safety links caution: any increase in safety link strength or change of configuration can cause structural damage and/or allow either or both aircraft to get into unsafe attitudes. Safety links must be installed in the configurations outlined within! Note: automotive...

Page 184

Page 183 2.6 specifications 2.6.1 tow lines and safety links. Towlines and bridle are made of spectra 1000 or dyneema ( uhmwpe). 1100# to 2200# due to the dragging of the line during landing and taxi we use a more durable line. The small diameter and light weight of the towline, allows it to maintai...

Page 185

Page 184 3.3 post-flight 1) conduct the pre-flight inspection to see if maintenance is needed before next operation. 4. Maintenance and service 4.1 general proper service and maintenance of the tow and release system is critical to safe operations. Safety links in prescribed configurations protect t...

Page 186

Page 185 caution: proper materials and installation of safety links are required. 4.5 corrosion, wear and breakage the components in the bailey release and towing system are made of materials that resist corrosion. Any excessive corrosion, cracks, breakage or wear of parts or assemblies, requires re...

Page 187

Page 186 by memphis soaring figure 3 common signals.

Page 188

Page 187 figure 4 common arm and hand signals by evergreen soaring figure 5 common aircraft signals by evergreen soaring.

Page 189

Page 188 5.3 radio communications radio communications are usually plain language. However, radio communications should always be accompanied by arm, hand and aircraft action & control surface signals! All persons involved in the tow operations must understand and use the same set of signals. 6. Saf...

Page 190

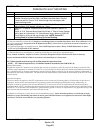

Page 189 safety of flight & service difficulty report form mail to: pitman air, 1840 airport blvd., red bluff, ca 96080 or online at: www.Pitmanair.Com/dragonfly/ check one item of concern safety of flight service difficulty reporting party contact information name address city st zip code day phone...

Page 191

Page 190 safety of flight & service difficulty report form mail to: pitman air, 1840 airport blvd., red bluff, ca 96080 or online at: www.Pitmanair.Com/dragonfly/ check one item of concern safety of flight service difficulty reporting party contact information name address city st zip code day phone...