Summary of WD250U

Page 1

Wd250u service manual for any questions please contact baja motorsports at 888-863-2252.

Page 2

Content content...........................................................................................................................2 chapter i general description........................................................................................6 section 2 special tools, instruments & me...

Page 3

Section 3 maintenance and adjustment of vehicle body.................................................................... 44 (i) wear inspection of front and rear brake............................................................................ 44 (ii) adjustment of front brake..........................

Page 4

Section 3 rear wheel/rear brake/rear wheel axle................................................................ 81 (i) removal steps....................................................................................................... 83 (ii) inspection stepes..........................................

Page 5

Section 2 inspection and maintanence of engine............................................................................... 159 section 3 assembly and adjustment of engine................................................................................... 183 (i) closing assembly of left & right cr...

Page 6: Section 1 Description

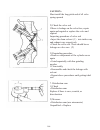

Chapter i general description section 1 description 1. Front wheel 2. Headlight 3. Forward/reverse lever 4. Shift pedal 5. Fuel valve 6. Hand-operated lever 7. Air choke 8. Taillight 9. Rear wheel 10. Rear luggage carrier 11. Exhaust silencer 12. Cushion 13. Fuel tank cover 14. Rear brake pedal 15. ...

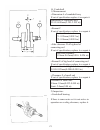

Page 7: (I) Special Tools

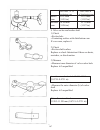

Section 2 special tools, instruments and meters (i) special tools there are special tools needed to properly adjust and assemble this unit. These tools are intended to prevent maintenance defects and damage. 1. Wrench for valve adjustment, mainly used to adjusting the valve clearance. Specification:...

Page 8

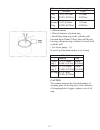

(ii) instruments and meters the following instruments and meters can be selected with reference to the same type of vehicle. 8.

Page 9

Section 3 identification code, label of model and engine no. Identification code engraved in the left or right side of the front supporting main tube of engine of frame engine no. This is engraved on the top middle part of the right crankcase of engine. Section 4 points for attention in maintenance ...

Page 10

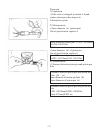

4. Clip 4.1 before assembling, check all the clips carefully. Replace with a new one after removing from piston pin. When mounting clip ring (1), make the sharp end face (2) on the opposite position of impacted face (3) of clip. (see figure at left) 5. Locking washer/shim and location pin 5.1 when r...

Page 11

7. Check of electric parts 7.1 make sure there is no rust, dirt or moisture at the connection, if there is blow it dry or clean. 7.2 the electrolyte inside the battery is corrosive, take extra precautions as to not get this on your body. 7.3 when repairing wires on electrical parts, remove the wire ...

Page 12

B. If there is slack in the joint, bend the plug pin upward, then connect with connector plug (see figure 7.5) 7.6 before mounting the new fuse, check if the load of fuse on the components are correct, especially the portion being broken regularly, then mount the fuse having proper current value. 7....

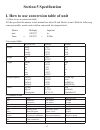

Page 13: Section 5 Specification

Section 5 specification i. How to use conversion table of unit (1) how to use a conversion table all the specified documents in this manual are taken si and metric as unit. With the following conversion table, metric unit could ne conversed into imperial unit. Metric multiply imperial mm 0.03937 in ...

Page 14: II. Basic Specification

Ii. Basic specification item specifications dimension: overall length 1960mm overall width 1010mm overall height 1120mm height of cushion 780mm axle base 1160mm front wheel distance 785mm rear wheel distance 770mm min.Ground clearance 155mm min.Turning radius 2900mm basic weight: engine oil(with ful...

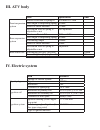

Page 15: III. Atv Body

Iii. Atv body item standard limit steering system type of steering bearing powder metallurgy sliding bearing type spock rim, tubeless tire material of rim steel plate size of tire at22x7-10 size of rim at 10x5.5 radial runout of rim 2.0mm lateral swing of rim 2.0mm type hydraulic disc type spoke rim...

Page 16: III. Atv Body

Iii. Atv body item specification limit elastic coefficient of spring k1 10n/mm/0-117mm free length of suspending spring 293mm stroke of shock absorber 117mm pre-tension force of spring is adjustable or not not adjustable elastic coefficient k2 49n/mm/8-85mm free length of suspending spring 263mm ass...

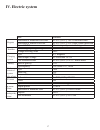

Page 17: IV. Electric System

Iv. Electric system item standard resistence of induction coil/color at 20˚c (68˚f), 189-231Ω blue-black resistence of source coil/color at 20˚c (68˚f), 470-530Ω yellow/green-red type of c.D.I. Electric capacity contactless type no-loading adjusting voltage 14.1-14.9v voltage-resisting value 200v ty...

Page 18

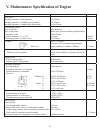

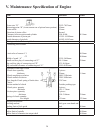

V. Maintenance specification of engine item standard limit axle drive meshing clearance of last end gear meshing clearance of middle gear (forward) meshing clearance of middle gear (backward) 0.1-0.2mm 0.1-0.2mm 0.10-0.25mm lubrication system: type of oil filter type of oil pump clearance of side en...

Page 19

Item standard limit valve spring: outside spring: free length: intake/exhaust setting length when valve is closed: compressing pressure when assembling:intake/exhaust limit value of sqaureness:intake/exhaust twisting direction of spring (top view):intake/exhaust 37.2mm 32.0mm 162.8-200.1n clockwise ...

Page 20

V. Maintenance specification of engine item standard limit piston piston size “d” measuring point “h” (from bottom line of piston lower portion) piston offset direction of piston offset clearance between piston and cylinder outside diameter of piston pin inside diameter of pin hole 70.92-70.97mm 4.0...

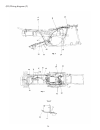

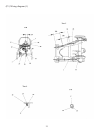

Page 21: Section 6 Wiring Diagram

Section 6 wiring diagram 1. Technical explanation [a] main switch wire, indicator wire, mileage meter wire (mounting digital mileage meter) must be put through the guide grip of holding seat of steering bar (see figure 1). [b] rear brake vent-pipe, carburetor vent-pipe and vent-pipe of rear driving ...

Page 22

[u] when assembling, mount supporting pad of vent-tube should be free of leaks, and pay at - tention to let the direction of mark upward (see view d). [n] taillight wire must be put through the slot hole preset by tool kit from the bottom of tool kit (see view f). 2. Technical requirement 1) in this...

Page 23

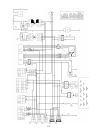

(ii) wiring diagram (1) 23.

Page 24

(iii) wiring diagram (2) 24.

Page 25

(iv) wiring diagram (1) 25.

Page 26

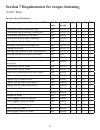

Section 7 requirements for torque fastening (i) atv body locking component and location on atv hard- ware size of thread qty nm m·kg ft·lb front wheel rim & front brake hub nut m10x1.25 8 55 5.5 40 front brake hub & steering vertical post nut m12x1.25 2 25 2.5 18 front brake cam arm & cam shaft nut ...

Page 27

(i) atv body torque value of fasteners locking component and location on atv hard- ware size of thread qty nm m·kg ft·lb rear fender & rear luggage carrier bolt m8x16 2 7 0.7 5.1 left & right foot rest & frame bolt m6x20 4 65 6.5 47 left & right foot rest & frame bolt m10x22 2 30 3 22 supporting wel...

Page 28

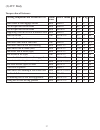

(ii) engine torque value of fasteners locking component and location on engine hardware size of thread qty nm m·kg ft·lb remarks observing screw hole of cylinder head cap nut m6 1 7 0.7 5.1 cylinder head flange bolt m8 4 22 2.2 16 apply oil to washer cylinder head & cylinder bolt m8 2 22 2.2 26 spro...

Page 29

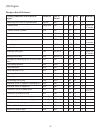

(ii) engine torque value of fasteners locking component and location on engine hardware size of thread qty nm m·kg ft·lb remarks exhaust pipe bolt m6 2 10 1 7.2 crankcase (closing case) screw m6 11 7 0.7 5.1 left side cover screw m6 6 7 0.7 5.1 left crankcase cover screw m6 8 7 0.7 5.1 right crankca...

Page 30

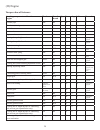

(ii) engine torque value of fasteners locking component and location on engine hardware size of thread qty nm m·kg ft·lb shift pedal bolt m6 1 10 1.0 7.2 megneto stator screw m6 3 7 0.7 5.1 neutral switch m12 1 20 2.0 14 reverse gear switch m12 1 20 2.0 14 hand-started driving disc screw pin m6 1 12...

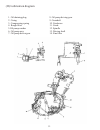

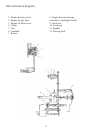

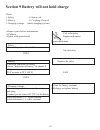

Page 31: Section 8 Lubrication

Section 8 lubrication (i) lubrication oil way 31.

Page 32

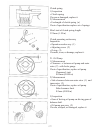

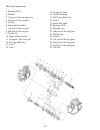

(ii) lubrication diagram 1. Oil draining plug 8. Oil pump driving gear 2. O-ring 9. Camshaft 3. Compressing spring 10. Crankcase 4. Rough filter 11. Crank 5.Oil pump washer 12. Spindle 6. Oil pump assy 13. Driving shaft 7. Oil pump driven gear 14. Fine filter 32.

Page 33

(ii) lubrication diagram 1. Single-direction valve 8. Single-direction bearing 2. Engine oil fine filter (automatic centrifugal clutch) 3. Engine oil fillter cover 9. Crank pin 4. O-ring 10. Crank pin 5. Clip 11. Spindle 6. Camshaft 12. Driving shaft 7. Rocker 33.

Page 34

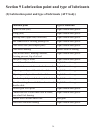

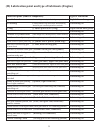

Section 9 lubrication point and type of lubricants (i) lubrication point and type of lubricants (atv body) lubricant point type of lubricants lip of oil seal (full) light lithium-base grease o-ring (full) light lithium-base grease steering shaft (upper end, lower end) light lithium-base grease ball ...

Page 35

(ii) lubrication point and type of lubricants (engine) lubricant point (name of component) type of lubricant lip of oil seal (crank,shift,gearshaft,spindle,shiftgear operation shaft) light lithium-base grease all bearing (crank,spindle,driving shaft,output shaft,balancing shaft,shift gear camshaft,p...

Page 36: Chapter Ii Maintenance

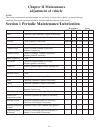

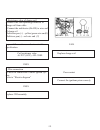

Chapter ii maintenance adjustment of vehicle note: the correct maintenance and adjustments are necessary to ensure the vechicle’s in normal driving condition. The repair personnel should be familiar with the contents of this article. Section 1 periodic maintenance/lubrication item requirement 1mo 3m...

Page 37: Fender And Fuel Tank

Section 2 disassembly and assembly of cushion, fender and fuel tank (i) cushion 1.Disassembly 1- place the vehicle on level ground. 2- disassemble the cushion (1) : pull the cushion lock lever (2) up, then raise the rear of cushion. 2. Installation first insert the support lug on the front end of cu...

Page 38

(ii) rear fender 1. Disassembly 1- place vehicle on level ground. 2- disassemble the rear luggage carrier (1) and installing bushing (2) 3- disassemble the cushion (3) (see cush - ion disassembly in this section). 4- disconnect the negative wire (5) and positive wire (4) of battery. Caution: disconn...

Page 39

2. Installation reverse procedure for “disassembly”. Pay at - tention to the following points: 1- install: rear fender (1) bolt (2) (rear fender and frame). The torsion in 7n·m. Bolt (3) and rubber hood of protecting plate (rear fender and frame). The torsion is 7n·m. 2- install: a.Battery (1) b.Bat...

Page 40

(iii) fuel tank 1. Disassembly 1- place the vehicle on level ground. 2- remove the cushion (see “cushion disas - sembly” section) 3- remove the air hose on the fuel tank cover 4- remove: a.Bolt (2) , flat washer 30, installing bush - ing of upper cover of fuel tank, washer and rubber hood 2 of fuel ...

Page 41

2. Installation reverse procedure for “disassembly”. Pay close attention to the following points: 1- install the fuel tank (1) 2- connect a. Air inlet pipe (2) and hose (4) b. Supporting pad (3) of air pipe and air rub - ber pipe (4) caution: the convext part on the ring should be facing forward whe...

Page 42

(iv) front fender 1. Disassembly: 1- place the vehicle on level ground. 2- disassemble the front luggage carrier (1) 3- disassemble the front guarding plate (2) 4- cut off the connecting wire (1) of head - light (from connecting point). 5- disassemble the bumper (2) 6- disassemble the front fender (...

Page 43

2. Installation reverse procedure for “disassembly”. 1- install: a. Front fender (1) b. Bolt (2) . The fastening torque is 7n·m c. Bolt (3) , rubber hood of protecting plate. The fastening torque is 7n·m 2- install the bumper (1) . The fastening torque of bolt (bumper and frame) is 16n·m. 2- install...

Page 44: Vehicle Body

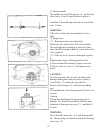

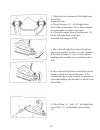

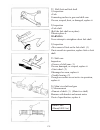

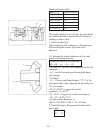

Section 3 maintenance and adjustment of vehicle body (i) wear inspection of front and rear brake 1.Check the front brake 1- stop the vehicle using the front brake 2- check: • brake pad (1) between caliper (2) and disc (3) • if pads are worn, replace. Refer to “front wheel and front brake” sec - tion...

Page 45

2. Adjustment adjusting procedure of the free clearance of right lever: • loosen the lock nut (1) , rotate the cable adjusting screw (2) clockwise to reduce the tension of front brake cable. • lift the front end from the ground, rotate the two front wheels. Apply brake to verify it is adjusted corre...

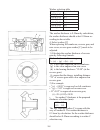

Page 46

2. Adjust • free clearance of left lever. • free clearance of rear brake pedal. Adjusting procedure: caution: before adjusting, depress the rear brake pedal 2-3 times. • loosen the locking nut (1) completely, and screw in the cable adjusting screw (2) completely. • loosen adjusting nut (3) of the re...

Page 47

(iv) position adjustment of steering lever • position adjusting procedure of steering lever. • place the vehicle on level ground. • change gears to 1st gear and pull the steering lever (1) to reverse gear position. • loosen the locking nut (2) • screw in or out the adjusting nut (3) of steering leve...

Page 48

(vi) replacing engine oil of rear driving gear case. 1. Place the vehicle on level ground. 2. Place an oil catcher under the rear driving gear case. 3. Remove: • lower cover of gear case • oil fillin screw plug • oil drain screw plug (1) drain out the engine oil of the rear driving gear case. 4. Che...

Page 49

(vii) rubber sleeve inspection of rear wheel fork check • rubber sleeve (1) if damaged or worn, replace it. Refer to chapter 3 section 6 “rear shock absorber and rear wheel fork”. (viii) inspection of steering system 1. Place the vehicle on level ground 2. Check: • clamp seat of steering column and ...

Page 50

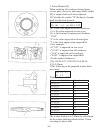

(ix) adjustment of toe-in on front wheels. 1. Rest the vehicle on level ground. 2. Measurement: • toe-in, adjust if not in specification. Adjustment steps for toe-in • mark the center of tire thread on both front wheels • lift the front end to keep force off wheels • point tires forward, measure the...

Page 51

(x) inspection of front/rear shock absorbers 1. Rest the vehicle on level ground 2. Inspection: • ball joint assy (1) (upper part of front shock absorber). If broken or damaged, replace the front shock absorber. • rear shock rod (2) (rear shock absorber) if broken or damaged, replace the rear shock ...

Page 52

(xii) inspection of tire warning: this vehicle is equipped with low pressure tires, so correct filling pressure and keeping the proper pressure is very important. • tire characteristics 1) quality charicteristics of tire will affect the driv - ing reliability of atv. The following types of tires are...

Page 53

1. Measurement • tire pressure (normal atmospheric temperature): if out of specification, adjust. Caution: • the manometer (1) is included with the tool kit (nver use high pressure). • if there is any dust or debris in the tire pressure manometer you will not receive a correct reading. Always take t...

Page 54: Electrical Appliance

(i) inspection of battery warning: the electrolyte is dangerous and includes sulphuric acid, so it is poisonous and corrosive. • please operate by the following steps: a. Avoid touching any part of your body with the electrolyte especially your eyes. B.Wear protective glasses when operating near bat...

Page 55

5. Inspection of battery if damaged, replace it 6. Installment of battery (3) 7. Connect • battery electrode (positive electrode (1) negative electrode (2) ) first connect the positive electrode (1) 8. Installment: a. Battery clamp plate (4) b. Cushion (ii) inspection of fuse caution: close the main...

Page 56

2. Replacement of bad/old fuse replacement steps: • cut off engine and circuit • install the new fuse. • start the power for electrical appliance inspection. • if the fuse is not responding check the system again (refer to “electrical appliance” of chapter 4) 3. Installment of fuse cover (iii) repla...

Page 57

6. Installment • lamp (1) caution: be sure that the projective part of the lamp (2) is engaged with the convex groove (3) on the light seat. Caution: never touch the glass part otherwise the lamp will loose illuminating value. If there are some oils on it clean off with cloth mixed with alcohol. 7. ...

Page 58: Engine

(i) adjustment of clutch adjustment steps: a. Loosen the locking nut (1) b. Turn the adjusting screw rod (2) counterclock - wise slowly up to be unable to turn, then turn 1/8 clockwise, and fasten the adjusting screw rod 2 to this position and tighten up the locking nut 1 with the torque of n ·m. Ca...

Page 59

3. Removal a. Air filter core (1) b. Foam supporting cylinder (2) caution: never start the engine without filter, otherwise the piston and cylinder will be overworn. 4. Inspection a. Air filter core (1) b. Foam supporting cylinder (2) if damaged replace it. 5. Clean the foam supporting cylinder. Cle...

Page 60

(iii) inspection of spark plug 1. Rest the vehicle on level ground and clean the spark plug with compressed air to avoid the dust entering the engine. 2. Remove the spark plug (1) the standard spark plug: dtrtc, if not correct, replace it. 3. Inspection of spark plug a. Electrode (1) worn or damaged...

Page 61

(iv) adjustment of idle speed 1. Rest the vehicle on level ground 2. Start the engine and warm it at idle speed of 1000-2000r/min, after several minutes, increase the engine speed to 4000-5000r/min. 3. Set the specified idle speed through adjusting the throttle adjusting screw (1) . Screw in to incr...

Page 62

(vi) adjustment of speed limiter: the speed limiter can limit the throttle in full open - ing condition when the throttle grip is pulled to the max position, screwing the adjuster inward can stop increasing the speed. 1. Adjust speed limiting length (a) adjustment steps: a. Loosen the locking nut (1...

Page 63

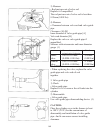

(vii) adjustment of valve clearance caution: the valve clearance should be adjusted only after the engine is cold, the valve clearance should be adjusted when the piston is at the end point posi- tion of compress stroke. 1. Removal: 1) rest the vehicle on level ground 2) remove a. Cushion (refer to ...

Page 64

B. Make the mark “t” on the rotor align with the mark on the crankcase. When aligned the piston ties in top dead center (tdc) c. Inspection of top dead center in pressure stroke: (i) when the mark (1) on the rotor is align with mark (2) on the crankcase, the two arms must be clear. (ii) if there is ...

Page 65

3. Installation: follow the opposite steps of “removal”. (1) mount: a. Valve cap (1) (side of outlet door) b. Valve cap (2) ( side of inlet door) caution: (i) project of valve cap (1) (2) should be up (3) (ii) check if the o-ring (4) is damaged, if so re - place immediately. Torque of valve cap: 10n...

Page 66

(ix) inspection of ignition timing notice: before you check the correct timed ignition, adjust the engine idle speed and free clearance of the throttle grip to the correct position. 1. Put the vehicle on level ground 2. Start the engine for pre-heating, and then stop the engine. 3. Mount the inducti...

Page 67

(x) measurement of compressive force caution: inadequate compressive force will reduce the en - gine performance. Before measuring the compressive force, the valve clearance should be adjusted first (refer to “adjust - ment of valve clearance” section). 1. Put vehicle on level ground 2. Take the spa...

Page 68

D. If pressure drops below min. Value: (i) drop some oil to active cylinder. (ii) measure the pressure again compressing force (the machine oil has been filled in the cylinder) compressure read reason read is higher piston or ring is than filling before worn/damaged read is equal when piston ring, t...

Page 69

B. Completely remove the dipstick (1) and clean it before inserting it back into the oil hole. C. Remove the dipstick (1) . Make certain that the oil level is between the max value (2) and min value (3) . D. Put some engine oil in to get te proper oil quantity if it was too small. See diagram to the...

Page 70

6. Inspection if o-ring (1) , compressor spring (2) , rough filter (3) , or fine filter (4) is damaged, it should be replaced. 7. Cleaning use cleanser to clean the compressor spring (2) , filter (3), filter net (4), crankcase filter plug (5), and filter nut cap (6) . 8. Slightly coat the o-ring wit...

Page 71

11. Mount dipstick 12. Stop pre-heating engine after 5 minutes or more. 13. Check the oil level and if it is leaking 14. Check oil flow inspection steps: a. Lightly loosen bolt (1) of cylinder head. B. Start engine for racing until oil runs from the oil tunnel. Stop the engine immediately if no mach...

Page 72

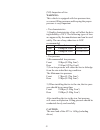

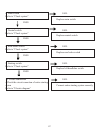

1. Driving gear case cover 2. O-ring 3. Oil seal 4. Bearing 5. Pad 6. Shift gear 7. Thrust plain pad 18. Trans. Shaft 19. Circlip 20. Rear joint 21. Bearing 22. Oil seal 23. Bearing 13. Bearing 14. Bearing gasket 15. O-ring 16. Bearing 17. Bushing 8. Bearing 9. Oil seal 10. Bearing 11. Main driving ...

Page 73

(i) trouble • trouble judging guidance performance possible reason 1. The vehicle appears to stop or there is irregular a. Damaged bearing axial run-out with an abnormal noise while the b. Improper clearance vehicle accelerates, decelerates, or is in idle state. C. Damaged gear (make sure not to con...

Page 74

It is necessary to check the rust of bearing if there is a great deal of metal or metal corpuscle on the oil draining screw plug so it does not cause a jam. Caution: it is normal for some metal corpuscle to be in the oil. 3. Check oil leakage check according to following procedures. A. Completely cl...

Page 75

(iv) disassembly warning: ensure that the vehicle does not turn over by firmly supporting it. 1. Drain the rear driving gear case oil refer to section 3, chapter 2, “replacement of engine oil of rear driving gear case” 2. Disassemble 1) cushion 2) rear luggage carrier 3) rear fender refer to “rear f...

Page 76

1. Disassembly a. Remove: bolt (1) m6 bolt (2) m8 caution: loosen each bolt by ¼ circle and remove bolts alternately. B. Disassemble: 1) rear driving gear case body (1) 2) annular gear pad 3) shift gear 4) thrust plain pad c. Disassemble: bearing gasket (transmission shaft-last grade) caution: on th...

Page 77

D. Disassemble with a soft hammer lightly tap the main driv - ing gear (1) and remove (with thrust pad (2) and bearing (3)) caution: remove the main driving gear first if it is nec - essary to replace the gear. Replace the original bearing thrust pad, do not reuse. E. Disassemble: 1) oil seal (1) 2)...

Page 78

(v) inspection 1. Replace the main driving gear and shift gear if there are any caving, scratches, or wearing on the gear teeth of bevel gear pair (1) 2. Check oil seal (2) 3. Check the o-ring (3) replace if damaged 4. Check the bearing (4) replace if damaged caution: (a) the bearing can be used rep...

Page 79

(vi) choice of main driving and shift gear pad 1. Main driving gear pad (1) choice: use “a” = (a) - (b) to work out main driving gear pad thickness (a) =84 +/- engraved number on main driving gear (b) =83.5 +/- engraved number on driving gear case body caution: the unit of numbers on the main drivin...

Page 80: -05

2. Choice of shift gear pad shift gear pad (1) choosing procedures: work out the pad thickness “b” from following formula “b”= (c) + (d) - ( (e) + (f) ) (c) =45.5 adds or subtracts the number en - graved on the driving gear case body. (d) =1 adds or subtracts the number engraved on the driving gear ...

Page 81

(vii) installation: reversal of “disassembly.” make sure to pay attention to the following points: 1. Install the needle bearing (small) on main driving gear: procedures: a. Warm the case body to 150°c b. Assemble the out circle of bearing with proper hold-down. C. Install the inner circle of the ne...

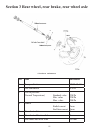

Page 82

Section 3 rear wheel, rear brake, rear wheel axle no. Item parameter 1 tire specification at22x10-10 2 rim dimension 8.5x10 3 tire air pressure (normal temperature) standard value min. Value max. Value 25kpa 22kpa 28kpa 4 runout radial runout end face runout 2mm 2mm 5 wear limit of tire 2mm 6 wear l...

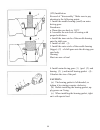

Page 83

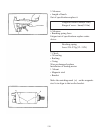

B. Right end of rear wheel 1 rear brake hub 2 brake shoe 3 bearing block 4 dust-proof seal 5 air pipe 6 rear brake cover assembly 7 rear brake cam shaft 8 brake indicating plate 9 rear brake arm assembly 82.

Page 84

(i) removal steps 1. Rest the motorcycle on a flat ground. Press the brake clip (1) . 2. Loosen the connecting nuts of front and rear wheels. 3. Stop up the front wheel with wood, then put a proper supporting article under the frame so as to lift the rear wheel and make the rear wheel leave the eart...

Page 85

8. Removal: (the ser. No. As shown on the drawing) (1) adjusting nut, pin and spring of rear brake arm and rear brake tension rod assy. 9. Removal: (2) rear brake cable (3) rear brake tension rod assy (4) air pipe of rear brake 10. Removal: (1) rear brake bearing block (2) rear brake hub 11. Removal...

Page 86

(ii) inspection steps: 1. Inspection when inspecting the real wheel, refer to “tire inspection”, “rim inspection” section of chap - ter 2. 2. Measurement: a: radial run-out of rim b: tire surface refer to “front wheel and front brake inspec - tion” section of this chapter 3. Inspection (1) rear whee...

Page 87

8. Inspection (the ser. No. As shown on the drawing) 1 inner surface of rear brake hub if there is some engine oil or scraped markings, remove it and treat it. The method of treat is as follows: removal of engine oil: clean with cloth dipped in volatile dilute or volatile solvent. Removal of scraped...

Page 88

13. Measurement the radial run-out of the piston (a) on the rear wheel axle, if out of specification, replace it. Attached: the radial run-out limit of rear wheel axle: 1.5mm warning: if the axle is bent, do not straighten it force - fully. 14. Inspection: (1) bearing on the rear wheel axle rotate t...

Page 89

(iii) installment steps: the reversal steps of “removal steps” are in - stallment steps. Pay attention to the following points when installing: 1. Lubrication part (1) oil seal lip of rear wheel axle. (2) bearing of rear wheel axle. The corresponding splint tooth of rear wheel axle. The lubrication ...

Page 90

5. Installment cam shaft of rear brake (1) indicating plate of brake (2) rear brake arm assy (3) caution: when installing the brake indicating plate (2) to rear brake cam shaft (1) , be sure to align the projective part (a) of brake indicating plate (2) with the concave part (b) of rear brake cam sh...

Page 91

8. Installment brake shoe assy 9. Lubrication dust-proof seal lubrication oil for dust-proof seal: lithium base grease. Warning the lubrication oil is not allowed to be used for brake shoe assy, the lithium base grease is used for rear brake hub splint groove. Warning: the lubrication oil is not all...

Page 92

15. Installment split pin 4x30 (1) caution: after fastening the torque, the nut on the rear axle is not allowed to be loose. If the nut con - cave groove is not aligned with the splint hole on the screw rod, align it by tightening up the nut. Warning: always use the new splint pin 16. Installment ri...

Page 93

(1) upper holder of steering bar (2) lower holder of steering bar (3) steering vertical column welding (4) steering vertical column holder (5) seal ring (6) bushing (7) clip assy (8) locking pad (9) steering tension rod ball pin assy (10) tension rod section 4 steering operation system 92.

Page 94

(i) removal steps of steering bar 1. Removal front luggage carrier bumper front fender refer to chapter 2, section 2 2. Removal main switch lock wire “neutral” indicating light wire “reverse” indicating light wire “high beam” indicating light wire clutch switch wire 3. Removal (1) front brake cable ...

Page 95

(ii) removal steps of steering vertical column welding 1. Plain move (1) the locking part of locking pad as shown 2. Removal (2) bolt m8x60 (3) locking washer (4) clip assy 3. Removal install the steering vertical column with split pin 2.5x24 nut m10 washer 10 4. Removal split pin 3.2x24 nut m12x1.2...

Page 96

(iii) inspection content 1. Check if the steering bar cracked, bent, or damaged. If it is, replace it. 2. Inspect the steering vertical column welding assy for any bends or damage. If there is, re - place it. Warning: in order to avoid decreasing the performance of the steering vertical column, do n...

Page 97

6. Adjustment assembly length of tension rod adjustment steps of tension rod assembly length 1- loosen the connecting nut [a] [b] 2-adjusting the assembly length of tension rod by rotating the tension rod. Attached: tension rod assembly length @: 297mm [a] right-handed thread [b] left-handed thread ...

Page 98

2. Lubricate the steering vertical column hold - er (1) and seal ring (2) during installation of the steering vertical column welding. 3. Installment install the seal ring (1) to the steering verti - cal column welding, then install bushing (2). Finally, install the steering vertical column holder (...

Page 99

7. Mounting split pin (1) caution: don’t loosen the nut after the torque is fixed. If the nut recess does not correspond with split pin hole on the double-screw bolt, tighten the nut to align them. Warning: always use new split pin 8. Tightening after mounting the washer, nut, split pin under the st...

Page 100

(v) installation steps of steering bar 1. Install the lower holding seat (1) , steering tube (2) and upper holding seat (3) . Warning: when tightening the bolt of holding seat, make sure clearance (b) is clear. Attached: bolt torque: 20nm 2. Install the throttle grip unit caution: the projection (1)...

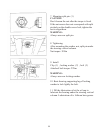

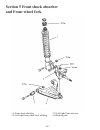

Page 101: And Front Wheel Fork

(1) front shock absorber (2) left/right front seat assy (3) left/right front wheel fork welding (4) bushing unit section 5 front shock absorber and front wheel fork 100

Page 102

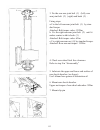

(i) disassembly: 1. Take off front luggage carrier, bumper, and front fender. Refer to the second section of chapter 2 disassemble the front wheel front brake hub, brake shoe unit, and front brake cap unit. Refer to “dischargement of front wheel and front brake” of this chapter 2. Take off split pin...

Page 103

7. Check the free clearance of left/right front wheel fork inspection step: a: check the parts (1) of left/right front wheel fork on the frame. If it is bent, cracked, or worn, repair or replace the frame. B: check the torque value of locking nut (2) on the left/right front wheel fork attached: nut ...

Page 104

(ii) inspection step 1. Check the front shock absorber. If there is leakage, replace it. Check the universal joint. If it is cracked or damaged, replace the front shock absorber. Check spring, if it is fatigued or damaged, re - place the front shock absorber. (when check - ing, move the spring up an...

Page 105

(iii) installment steps the opposite steps of “disassembly” are the mounting steps. The following must be paid attention to when mounting: 1. Lubricate the inner surface of bushing sub- assembly (1) . (lubrication oil is lithium base grease). 2. Fix nut (2) nut torque: 45nm caution: must ensure that...

Page 106

5. Mount the split pin (3) caution: don’t loosen the nut after marking the standard torque. If the recess on the nut does not corre - spond with split pin hole on the bolt, correct it by tightening the nut. Warning: must use new split pin. 6. Mount: front shock absorber (4) , front shock absorb - er...

Page 107

Caution: don’t loosen the nut after marking the standard torque. If the recess on the nut does not cor - respond with the split pin on the bolt, correct it by fixing the nut. Warning: must use new split pin (3) 10. Mount front brake cap assy, brake shoe assy, front brake hub, and front wheel. Refer ...

Page 108

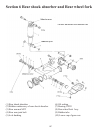

(1) rear shock absorber (2) rubber washer assy of rear shock absorber (3) rear arm nut m22 (4) rear arm joint bolt (5) axle bushing (6) oil sealing (7) bearing 30203 (8) rear wheel fork assy (9) rubber tube (10) lower cap of gear case section 6 rear shock absorber and rear wheel fork 107.

Page 109

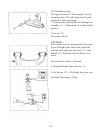

(i) disassembling steps 1. Take off left rear wheel, rear wheel joint plate, right rear wheel, rear brake hub, rear brake, and rear axle. Refer to “disassembly of rear wheel/rear brake and rear wheel axle” section in this chapter. 2. Take off lower cap (2) of gear case. 3. Take off the rear driving ...

Page 110

5. Take off nut (1) on the rear shock absorber, bolt (2), rear shock absorber (3) . 6. Take off rear brake tension spring (1) . 7. Take off dusty cap on rear arm axle. 8. Check the free clearance of rear wheel fork checking steps. A: check the torque value of rear arm joint bolt and the torque value...

Page 111

9. Take off rear bush (1) 10. Take off driving axle clamp assy (front) (1), rear arm nut (right side) and rear arm joint bolt. 11. Take off rear wheel fork assy (1) . (ii) checking steps 1. Check a: if rear shock absorber is leakage, if any, replace it. B: if rear shock absorber is bent or damaged, ...

Page 112

2. Check if the rear wheel fork assy is cracked, bent, and damaged. If any, replace it. Check if the rear wheel bush is cracked, bent, and damaged. If there is one of these problems, replace it. 3. Check the gear case lower cap. If there are any cracks, bends, or damage, replace this part. 4. Check ...

Page 113

Take off bearing (3) with usually bearing tool. The reverse step of “bearing and oil sealing replacing step” is the mounting step of new bearing and new oil sealing. Caution: use a pressure tooling (4) which is matched with outer diameter of bearing race (7) and oil sealing. Warning: don’t strike th...

Page 114

3. Fix the rear arm joint bolt (1) (left), rear arm joint bolt (2) (right) and bush (3) . Fixing steps: a: fix the left rear arm joint bolt (1) by stan - dard torque. Attached: bolt torque value: 130nm b: fix the right rear arm joint bolt (2) until it makes contact with its bush (3) . Attached: bolt...

Page 115

8. Mount the rear driving gear case sub-assem - bly (1) refer to “installation of rear driving gear case sub-assembly and driving shaft” section of this chapter. 9. Mount the rear wheel axle, rear brake hub, right rear wheel, rear wheel joint plate and left rear wheel. Refer to “installation of rear...

Page 116: Section 1 Electric Assembly

Chapter iv electric appliance section 1 electric assembly 1. Cdi assembly 15. Battery 2. Rectifier 22. Main switch lock 5. Safety. Starting relay 24. Neutral indicating assembly 6. Power off relay 26. Reverse indicator assembly 7. High voltage coil 28. High beam indicator assembly 11. Reverse switch...

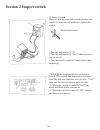

Page 117: Section 2 Inspect Switch

Section 2 inspect switch (i) inspect switch make certain the wire end is on the pocket mul - timeter. If there are any problems replace the switch pocket multimeter • turn the multimeter to “o” • turn the multimeter to “Ωx1” when inspecct - ing the circuit • turn the switch on and off many times whi...

Page 118

(ii) inspect the switch circuit refer to “inspect switch”. Inspect if the circuit between wire and wire end is on. If the contact is poor or the circuit is off-repair or replace 1 light switch 6 reverse switch 2 engine stop switch 7 neutral switch 3 starting switch 8 protecting device 4 main switch ...

Page 119

Section 3 check lamp (headlight) check the lamp condition 1. Remove the lamp caution: pay attention to support the lamp. Do not pull the lead wire, otherwise it will brake. Warning: when the headlight illuminates, remove your hand from the lamp, it will be very hot. Do not touch until it has cooled ...

Page 120

119.

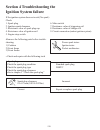

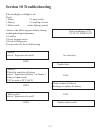

Page 121: Ignition System Failure

Section 4 troubleshooting the ignition system failure if the ignition system does not work (no spark) check: 1. Spark plug 2. Ignition spark clearance 3. Resistence value of spark plug cap 4. Resistence value of ignition coil 5. Engine stop switch •remove the following parts before trouble - shootin...

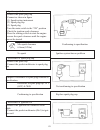

Page 122

2. Ignition spark clearance • remove the spark plug cap • connect as shown in figure (1) spark testing instrument (2) spark plug cap (3) spark plug • turn the main switch to the “on” position • check the ignition spark clearance • press the starting switch to start the engine. Increase the spark cle...

Page 123

• inspect if the resistence of primary coil con - forms to specification primary coil resistence at 20˚c(68˚f), 0.43~0.5Ω • connect the multitester (Ωx1k) to ignition coil • inspect if the second coil resistence conforms to specification secondary coil resistence at 20˚c(68˚f), 4.6~7.6kΩ pass 5. Eng...

Page 124

8. Resistence value of charge coil • remove the corresponding connector of charge coil from cable. • connect the multitester (Ωx100) to wire end of charge oil multitester pen (+) - yellow/green wire end(1) multiteser pen (-) - red wire end (2) inspect if the resistence value is not at the specificat...

Page 125

The starting circuit of this vehicle including starting motor, cut-off relay, rear brake switch and neutral switch. If the main switch is in position, the starting motor could be operated only at the following conditions: • driving device is in the neutral postion (neutral switch is closed) or • rea...

Page 126

Section 6 troubleshooting electric starting system if starting motor does not work • check 1. Safety 6. Main switch 2. Battery 7. Neutral switch 3. Starting motor 8. Rear brake switch 4. Cut-off relay 9. Starting switch 5. Starting relay 10. Circuit connection (entire startinf system) • remove the f...

Page 127

Operation 4. Power off relay • remove relay from cable • connect portable multitester (Ωx1) and bat - tery (12v) to end of wire on relay battery end (+) - red/white wire end (1) battery end (-) - green/yellow wire end (2) mutlitester pen (+) - red/white wire end (1) multitester pen (-) - blue/white ...

Page 128

6. Main switch refer to “check system” pass 7. Neutral switch refer to “check system” pass 8. Rear brake switch refer to “check system” pass 9. Starting switch refer to “check system” pass 10. Circuit connection • check the circuit connetion of entire starting sytem refer to “electric diagram” fail ...

Page 129: Section 7 Starting Motor

Section 7 starting motor sequence name of part qty remark starting motor disassembly starting motor wire starting motor connecting wire starting motor o-ring 1 1 1/1 remove the components according to sequence. 1 2 3 4 5 6 7 same disassembly as above bracket 1 washer/pad bracket 2 pad electrice brus...

Page 130

1. Check • reverser if dirty clean with #600 sand paper 2. Measure • reverser diameter (a) does not meet specification-change the starting motor outer diameter 28mm(1.10in) (wear range) 27mm(1.06in) 3. Measure • mica cut sheet (b) does not meet specification- scrape the mica with square scraper mica...

Page 131

5. Measure • length of brush out of specification-replace it length of brush:10mm(0.39in) range of wear: 6. Measure • brushing spring force fatigue/out of specifications-replace entire device brushing spring force:326~970g(3.2~3.8n) 7. Check • oil sealing • bushing • o-ring worn or damaged-replace i...

Page 132

Check: 1. Safety 4. Stator coil 2. Battery 5. Coupling of circuit 3. Charging voltage (entire charging system) • remove parts before maintenance 1) cushion • repair with special tools 1. Safety refer to “inspection of switch” pass 2. Battery • check the condition of battery refer to “inspection of b...

Page 133

• start engine and accelerate to 2000r/m charging voltage: 14-15v at 2000r/m use fully charged battery out of specification 4. Resistence value for stator coil • remove the lighting coil of ac magneto • connect pocket multimeter to stator coil (Ωx1) pocket multimeter (+) - white terminal 1 pocket mu...

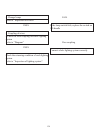

Page 134: Section 10 Troubleshooting

Section 10 troubleshooting if the headlight or taillight is out check: 1. Safety 4. Lamp switch 2. Battery 5. Coupling of wires 3. Main switch (entire lighing system) • remove the following parts before starting troublingshooting maintenance 1) cushion 2) front luggage carrier 3) front covering part...

Page 135

4. Change lamps refer to “inspection of switch” pass 5. Coupling of wires • check the wire coupling for entire lighting system refer to “diagram” pass check the returning condition of each lighting system. Refer to “inspection of lighting system”. Fail if the lamp switch fails, replace the switch on...

Page 136

Section 11 inspection of lighting system (ii) if headlight is out 1. Bulb and socket • check if the bulb and socket are correct pass 2. Voltage • connect the pocket tester (dc 20v) to the headlight a b multimeter (+) - green terminal (1) or yel - low terminal (2) multimeter (-) - black terminal (3) ...

Page 137

(ii) if taillight is out 1. Bulb and socket • check if the bulb and socket are correct pass 2. Voltage • connect the pocket tester (dc 20v) to the taillight terminal multimeter (+) - blue terminal (1) multimeter (-) - black terminal (2) • turn main switch to “on” position •turn lamp switch to “low” ...

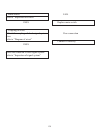

Page 138: Section 12 Troubleshooting

Section 12 troubleshooting (i) if indicator lamp is out check: 1. Safety 4. Coupling of wires 2. Battery (whole signal system) 3. Front switch • remove the following parts before trouble - shooting 1) cushion 2) front frame 3) front pedal • use specific tools for troublshooting 1. Safety refer to “i...

Page 139

3. Main switch refer to “inspection of switch” pass 4. Coupling of wires • check the coupling of whole signal system wires refer to “diagram of wires” pass check the condition of each signal system refer to “inspection of signal system” fail replace main switch poor connection connect it correctly 1...

Page 140

Section 13 inspection of signal system (i) if the neutral indicator lamp is out 1. Bulb and socket •check if the bulb and socket circuit b are correct. Pass 2. Neutral switch • refer to “inspection of switch” pass 3. Voltage • connect pocket tester (dc 20v) to the tail - lamp terminal pocket tester ...

Page 141

(ii) if the reverse indicator lamp is out 1.Bulb and socket • check if the bulb and socket are in good condition. Pass 2. Reverse switch • refer to “inspection of switch” pass 3. Voltage • connect pocket multimeter (dc 20v) to the taillight terminal multimeter (+) - brown terminal (2) multimeter (-)...

Page 142

(iii) if the hb indicator light is out 1. Bulb and socket •check if the bulb and socket circuit b are correct. Pass 2. High or low beam switch • refer to “inspection of switch” pass 3. Voltage • connect pocket tester (dc 20v) to the tail - lamp terminal pocket tester (+) - brown terminal (1) pcoket ...

Page 143: Chapter V Engine

(i) remove the engine from finished atv 1. Remove • cushion • front luggage carrier • front bumper • front fender • rear luggage carrier • rear fender the disassembling method refers to “fender, fuel tank disassembly” of chapter ii. 2. Oil draining screw out oil draining screw plug. Drain off the lu...

Page 144

2) remove • connecting plate of starting motor (2) • starting motor (3) 6. Rear brake cable and footrest 1) remove • adjusting nut (1) • pin (2) • spring (3) • rear brake cable and tension rod (4) (remove from rear brake arm) 2) remove • left footrest (1) • shift pedal (2) • supporting rod of front ...

Page 145

8. Rear diving unit and rocker (rear wheel fork and shock absorber) 1) remove • remove the air (1) (gear case of last grade and rear brake hub) from the clip on the frame • fix the front wheel and raise up the rear wheel (place the supporter on the frame) 2) remove • bolt (1) (upper end of the rear ...

Page 146

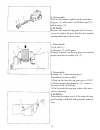

(ii) disassembly of engine 1. Remove • hand starting unit (1) 2. Remove • screw (1) (2) (3) • reverse controlling bar unit (4) • washer pay attention not to lose washer 3. Remove • sprocket cabinet cover (1) 4. Remove • spark plug (1) • upper valve cap (intake) (2) • lower valve cap (exhaust) (3) 1 ...

Page 147

5. Remove • chain tensioner (2) caution: before removing the chain tensioner, loosen the screw (1) firstly. 6. Remove • bolt (1) • timing sprocket (2) caution: • when loosening the bolt, it is needed to fix the hand starting ratchet (4) • use a wire to hold chain so the timing chain does not drop in...

Page 148

9. Remove • screw (1) (cylinder body) • cylinder body assy (2) • cylinder body pad (3) • location pin (4) • o-ring (5) 10. Remove • circlip (1) • piston pin (2) • piston unit (3) caution: • before disassembling the piston pin circlip, cover the crankcase with a clean cloth to avoid the circlip sudde...

Page 149

13. Remove • gasket of left crankcase cover (1) • location pin (2) • intermediate gear shaft (3) • washer (4) • duplex intermediate gear (5) (starting motor) 14. Remove • magneto (1) caution: disassemble the magneto rotator with special tool. 15. Remove • semicircle key (1) • electric starting gear ...

Page 150

18. Remove • screw (1) (rear driving cover) • rear driving cover (2) 19. Remove • output shaft unit (1) • location pin (2) 20. Remove • output shaft assy (1) • bearing (2) • washer (3) • forward gear (4) 21. Remove • fine filter cover of engine oil (1) • fine filter of engine oil (2) • o-ring (3) • ...

Page 151

23. Remove • main clutch nut (2) caution: loosen the locking pad (1) before removing the nut, and fix the main clutch shoe (3), then remove the nut. 24. Remove • locking pad (1) • main clutch shoe unit (2) • washer (3) • main clutch housing unit (4) • washer (5) caution: the two grooves (1) on auxil...

Page 152

27. Remove • nut (2) (clutch hub assy) caution: slap the locking washer (1) flat before removing the nut. Must fix the clutch hub assy (3) with special tool when screwing the nut. 28. Remove: • locking washer (1) • clutch hub assy (2) • friction washer (3) • clutch piece (4) • compressing plate (5) ...

Page 153

31. Remove: • shift lever unit (1) • washer (2) • limit torsion spring (3) • limit lever unit (4) caution: pull the limit lever unit and shift lever unit along the arrow direction, then you can remove them from the star-shaped gear. 32. Remove • star-shaped gear (1) (on shift cam) caution: • the loc...

Page 154

34. Remove • locking washer (1) • balance shaft gear (2) • flat key (3) 35. Remove •all the closing case screw. Caution: loosen and remove every screw ¼ circle with phillipshead screwdriver. 36. Remove • left crankcase (1) • location pin (2) caution: • disassemble the left crankcase with crankcase s...

Page 155

38. Remove • main shaft assy and driving shaft unit (1) • washer (2) (driving shaft unit) 39. Remove • circlip (1) • balance shaft driving gear (2) • crankshaft (3) • semicircle key (4) caution: •press out the crankshaft with pressure device. 40. Remove • stop plate (2) • pressing plate (3) caution:...

Page 156

42. Remove • rocker shaft (1) • air intake and exhaust rocker (2) caution: • screw the slip hammer assy into rocker shaft, then pull out the rocker. 43. Remove • valve lock clip (1) caution: • disassemble the valve lock clip with valve spring compressing device. 44. Remove • valve spring cover (1) •...

Page 157

47. Remove • coiling spring (1) •coiling spring backboard (2) • driving plate assy (3) • left side cover assy (4) 48. Remove • pressure plate (1) caution: • remove the screw with impact screwdriver 49. Remove • bearing (1) • washer (2) 50. Remove • circlip (1) • rear joint (2) caution: the disassemb...

Page 158

51. Remove • nut • washer • front joint caution: clamp the front joint with gymbal, then loosen the nut. 52. Remove • output shaft (1) • connecting jaw (2) 53. Remove • inner-hexagon screw bushing (1) • bearing (3) • washer caution: use inner-hexagon screw bushing wrench 54. Remove • irregular left ...

Page 159

55. Remove • nut • bearing caution: use inner-hexagon screw bushing wrench 56. Remove • reverse fork shaft (1) • reverse fork (2) • steel ball (3) • compressing spring (4) caution: when disassembling the reverse fork shaft, the steel ball is easy to roll out. Make sure not to lose it. 57. Remove • c...

Page 160

1. Cylinder cover 1) clean • carbon deposit use circular scraper (1) caution: please do not use sharp tool to avoid scraping • nut of spark plug • valve seat ring • bottom face of cylinder 2) measure • flatness of cylinder cover bottom face recorrect the bottom face or replace if unqualified flatnes...

Page 161

3) measure • rod part run-out of valve rod replace it if unqualified the rod part run-out of valve rod is less than 0.03mm (0.0012in) 4) measure • clearance between valve rod and valve guide pipe clearance=[a]-[b] inner diameter of valve guide pipe [a] valve rod diameter [b] replace the valve or val...

Page 162

3) install • circlip (1) • valve guide pipe (2) use the installing and disassembling device of valve guide pipe 4) ream the inner diameter of valve guide pipe to get proper valve rod clearance. Caution: regrind the valve race after installing valve guide pipe 4. Valve race 1) clean • carbon deposit ...

Page 163

• press the valve on the valve race through valve guide pipe to leave clear trace on the valve. • remove the valve from cylinder cover • when the valve contacts with valve race, the reddle is marked on the valve from valve race. Then can measure the contacting width of valve and valve race. Contacti...

Page 164

The contacting part [b] is in the middle of valve face. But the width is too narrow reamer assy of valve rale result use reamer 45˚ get unified contacting width 1.0mm (0.04in) the contacting part [c] is too narrow, and on the upper edge of valve face reamer assy of valve rale result reamer 35˚ make ...

Page 165

• paint molybdenum disulfide oil on the valve rod part. • place the valve in to the cylinder cover • rotate the valve to grind in with seat fully on the valve face, then clean the dirt • repeat procedure until the contacting width of valve face and valve seat caution: in order to get the best grindi...

Page 166

2) measure • installing pressure of valve spring if unqualified, replace the inner and outer spring totally. 6. Seal check of valve 1) installation of valve lubricate • valve rod part (1) • valve rod oil seal (2) install • valve spring seat (1) (lower part) • oil seal of valve rod (2) • valve (3) • ...

Page 167

Caution: must install the long pitch end of all valve spring upward 2) check the valve seal if there is leakage on the valve face, repair again and regrind or replace the valve and regrind. Inspecting procedure of valve seal • inject the clean solvent (1) into intake way and exhaust way respectively...

Page 168

Limit value “a” of limit value“b” distribution cam of distribution cam intake 36.437mm 30.031mm cam (1.435 in) (1.182 in) exhaust 36.482mm 30.152mm cam (1.436 in) (1.187 in) 8. Valve rocker and rocker shaft 1) check • rocker hole • contacting surface with distribution cam if ever worn, replace it 2)...

Page 169

• subtract the outer diameter of rocker shaft from inner diameter of valve rocker hole to calculate clearance. Clearance between rocker hole and shaft= (a) - (b) inner diameter of valve rocker hole (a) outer diameter of rocker shaft (b) replace a set if unqualified clearance between rocker shaft and...

Page 170

2) check flexibility of chain tensioner checking procedure • press the tensioner pushing rod lightly with finger, and rotate it clockwise with thin screwdriver to screw it in. • press the pushing rod lightly with finger and remove screwdriver, then the pushing rod screws out stably • if the operatio...

Page 171

If out of specification, rebore or replace the cylinder and piston (replace in a set) • measure the diameter “p” of piston lower part with micrometer, (b) is the measuring position (b) is 4mm away from piston bottom (0.16 in) piston lower part diameter “p” standard 70.92~70.97mm (2.792~2.794in) if o...

Page 172

Clearance between piston ring and ring groove standard limit first 0.03~0.07mm 0.12mm ring (0.001~0.003 in) (0.005in) second 0.02~0.06mm 0.12mm ring (0.008~0.024in) (0.005in) 2) measurement: • closed clearance of piston ring • install the piston ring to the cylinder, pull forward about 20mm (0.8in),...

Page 173

Piston pin 1) inspection • if the color is changed, or indent is found, replace piston pin, then inspect to lubrication system. 2) measurement: • outer diameter (a) (piston pin) out of specification, replace it outer diameter (piston pin): 15.991~16.00mm (0.6296~0.6299 in) 3) measurement: • inner di...

Page 174

16. Crankshaft 1) measurement • dimension a of crankshaft assy if out of specification replace it or repair it dimension of crankshaft assy 55.95-56.00mm(2.203-2.205 in) • runout c if out of specification, replace it or repair it runout limit c1: 0.03mm (0.0012 in) c2: 0.06mm (0.0024 in) • side clea...

Page 175

Main points of reassembly of crankshaft: the oil traces on crankshaft (1) and crank pin (2) should be connected correctly, the malposi - tion of two oil traces should be within 1mm (0.04 in) 17. Driving gear of balance shaft and gear of balance shaft inspection: • driving gear of balance shaft (1) •...

Page 176

• inspection • bolt (1) (overrunning clutch) • loosen then replace with new one and apply fastening agent caution: fastening torgue of bolt (overrunning clutch) is 30nm(3.0m·kg22yd·pound) apply the fastening agent on the bolt 19. Main clutch clutch case 1) inspection: • clutch case assy (1) (inner s...

Page 177

Clutch hub assy and pressing plate inspection • tooth groove on the clutch hub (1) • tooth groove on the pressing plate (2) if there is scraped, worn, or damaged, replace the clutch hub or pressing plate. Friction plate 1) inspection • friction plate (1) if damaged, worn replace a set of friction pl...

Page 178

Clutch spring 1) inspection • clutch spring if worn or damaged, replace it 2) measurement • freelength of clutch spring (a) if out of specification replace set of springs min limit of clutch spring length 32.9mm (1.30 in) clutch operating rocker assy inspection • operation rocker assy (1) • adjustin...

Page 179

22. Shift fork and fork shaft 1) inspection: • fork connecting surface to gear and shift cam if worn, scraped, bent, or damaged, replace it. 2) inspection • fork shaft (roll the fork shaft on a plane) if bent replace it. Warning: never attempt to straighten a bent fork shaft 3) inspection • movement...

Page 180

2) inspection • gear (refer to shift mechanism and output gear (2)) • engaging jaw position if cracks, damage, wear, replace it. Caution: when replacing the output gear, be sure to adjust the adjusting washer of output gear. 3) inspection • movement of gear (shift mechanism) if not smooth in operati...

Page 181

27. Bearing and oil seal 1) inspection • bearing if jammed in operation or there are pits and damage, replace it. 2) inspection • oil seal if damaged or worn replace it. 28. Circlip and washer inspection: • circlip • washer if damaged, loose, or bent, replace it. 29. Crankcase 1) clean crankcase wit...

Page 182

30. Hand operated mechanism 1) inspection • inspection (1) if cracked, bent, or damaged, replace it. • driving jaw (2) • compressing spring (3) • torsion spring (4) (driving jaw position) wear/cracks/damage, replace it. 2) inspection: • rolling spring (1) (starting) wear/cracks/damage, replace it. •...

Page 183

4) inspection • reverse fork (1) if wear/abrasion/bend/damage is found on the surface connecting with connecting jaw and reverse operating shaft, replace it. • compressing spring (2) if the elasticity is lost, or worn, replace it • steel ball (3) if wear, damage, or scratch marks are found, replace ...

Page 184

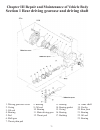

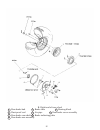

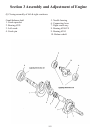

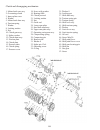

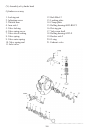

(i) closing assembly of left & right crankcase crank/balance shaft 1. Crank sprocket 2. Bearing 6305 3. Left crank 4. Crank pin section 3 assembly and adjustment of engine 5. Needle bearing 6. Connecting lever 7. Right crank assy 8. Bearing 6306/c4 9. Bearing 6304 10. Balance shaft 183.

Page 185

Shift gear mechanism 1. Bearing 6202 2. Washer 3. 1st gear of driven gear assy 4. 5th gear of driven gear 5. Circlip 6. Inner spline washer 7. 3rd gear of driven gear 8. 4th gear of driver gear 9. Circlip 26 10. Inner spline washer 11. 2nd gear of driven gear 12. Driving shaft assy 13. Fork 2 14. Fo...

Page 186

1. Installment: • crankshaft (1) (install to right crankcase) caution: when installing the crankshaft, fasten the connecting rod to the installing hole of cylinder with hand. 2. Installment spindle assy and driving shaft assy (1) 3. Installment: • balance shaft (1) • fork 1 (2) • fork 2 (3) • fork 3...

Page 187

4. Applying: • seal agent (1) apply the seal agent on the closing surface of left crankcase. Seal agent: letai 518 anaerobic plane seal glue. 5. Installment: • locating pin (1) 6. Install the left crankcase to the right crank - case. Beat with soft hammer slightly. Caution: before installing the clo...

Page 188

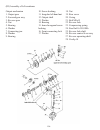

(ii) assembly of right crankcase shift shaft, balance shaft gear, lubrication system. 1. Oil pump 2. Oil pump gear assy 3. Driving pin 4. Oil pump pad 5. Screw m6x20 6. Oil rough filter 7. Compressing spring 8. O-ring 9. Oil drain plug 10. Woodruff key 11. Driving gear of balance shaft 12. Circlip 2...

Page 189

Clutch and disengaging mechanism 1. Main clutch case assy 2. Overruning clutch 3. Inner spline cover 4. Washer 5. Main clutch shoe assy 6. Tension spring 7. Washer 8. Locking washer 9. Nut 10. Clutch gear assy 11. Spline washer 12. Clutch drum assy 13. Friction plate 14. Clutch plate 15. Pressure pl...

Page 190

1. Balance shaft gear and driving gear 1) installment: • woodruff key (1) • driving gear of balance shaft (2) • circlip (3) caution: use the gear puller. 2) installment: • balance shaft gear (1) (be driven) • flat key (2) caution: the mark (3) of driving gear should align with the mark (4) of driven...

Page 191

2. Shift shaft and oil pump 1) installment: • star gear (1) • locating pin (2) (long) • shift pin (3) (short) caution: install the locating pin (2) (long) to the filt - ing mark (4) position. 2) installment: • star gear (install to shift cam) caution: the hole of shift cam should be aligned with the...

Page 192

6) apply engine oil • 4-stroke engine oil (apply the parts inside the oil pump) 7) installment: • oil pump seat (1) • outer rotor (2) • inner rotor (3) • locating pin (4) • oil pump gear assy (5) • driving pin (6) • oil pump cover (7) • screw (8) 8) applying engine oil • 4-stroke engine oil (apply t...

Page 193

4. Main, vice clutch 1) installment: • clutch gear assy (secondary) • spline washer (2) 2) installment: • friction plate (1) • clutch plate (2) (install the clutch hub (3)) caution: install the clutch plate and friction plate to the clutch hub alternately, from friction plate to friction plate. 3) i...

Page 194

6) bend the locking plate (5) of locking washer. 7) installment: • clutch spring (1) • pressure cover (2) • bearing (3) • clutch post rod (4) 8) installment: • output gear (1) • nut (2) 60 nm caution: be sure to use new nut. 9) tighten up: • nut (2) caution: fasten the clutch hub of vice clutch, and...

Page 195

11) installment: • washer (1) • main clutch case assy (2) • washer (3) • clutch shoe assy (4) caution: • there are two indents (1) on the vice clutch case. When installing the main clutch case, one of the indents should align with the main clutch gear (2) . 12) installment: • locking washer (1) • nu...

Page 196

5. Clutch disengaging mechanism and right case cover 1) installment: • lower cam plate (1) • steel ball stand assy (2) • upper cam plate assy (3) • compressing spring (4) caution: • the locating notch of lower cam plate should align with convex block of shift shaft • the locating notch of upper cam ...

Page 197

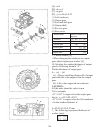

(iii) assembly of left crankcase output mechanism 1. Output gear 2. Forward gear assy 3. Reverse gear 4. Nut 5. Bearing 6. Washer 7. Connecting jaw 8. Washer 9. Bearing 18. Nut 19. Rear cover 20. O-ring 21. Bolt m8x15 22. Reverse fork 23. Compressing spring 24. Steel ball 6.35g100b 25. Reverse fork ...

Page 198

Electric starting system 1. Circlip 12 2. Washer 3. Wheel axle 4. Double wheel 5. Woodruff key 6. Washer 7. Electric starting gear assy 8. Electric starting clutch 9. Roller 10. Spring cover 11. Spring 12. Timing chain 13. Up guide plate assembly 14. Magneto rotor 15. Magneto starter 16. Left crankc...

Page 199

1. Reverse operation system 1) mount: • reverse operation shaft (1) • operation plate (2) • reverse control lever (3) • circlip (4) mount the above on the rear driving cover. 2) mount: • compressing spring (1) (on reverse gear fork (4)) • steel ball (2) caution: mount a positioning set pin into the ...

Page 200

2. Output shaft assy 1) mount: • bearing (to rear cover) • nut collar caution: use the nut collar spanner to tighten the collar. 3) mount: • washer • reverse gear • compromise left-turning nut caution: • fasten the compromise left-turning nut by counterclockwise direction, because it is left- turnin...

Page 201

7) mount: • output shaft • connecting claw • front splice • washer • nut 8) fasten • nut (5) caution: • fix the front splice with universal joint holder and connect the locking nut. • apply the thread fastening agent on the nut when mounting it. 9) mount: • rear joint and driving fork. Mounting step...

Page 202

3. Mount: • locating pin (1) • washer (2) • bearing (3) • forward shift gear assy (4) • output shaft assy (5) caution: apply grease on o-ring (6) 4. Coat: • sealing agent (coat on the matching surface of rear driving cover.) • brand of sealing agent is 518 anaerobic seal - ing gum or equal substitut...

Page 203

7. Electric starting system 1) mount: • timing chain (1) • up guide plate (2) caution: tighten the shaft wire of timing chain to avoid dropping it into the crankcase. 2) mount: • washer (1) • electric starting gear assy (2) • woodruff key (3) • magnets rotor (4) caution: • clean the conical part of ...

Page 204

4) mount: • left crankcase cover (1) • fasten screw (8 pieces 7nm) 5) mount: • starting click pulley assy (1) caution: • fix the click pulley with rotor seat and tighten the bolt • before mounting the starting click pulley, apply grease on oil sealing and o-ring (3). (iv) selection and installation ...

Page 205

[a] =a-b [b] =d-c-e-f [c] =d-g-h-i [d] =j+c-e-b-k-l-0.25 (1) left crankcase (2) output gear (3) forward shift gear (4) output shaft (5) reverse gear (6) rear cover 2. Choose washer [a] • when changing the crankcase or output gear, adjust output gear washer [a] 10 calculate the washer thickness of ou...

Page 206

Washer selection table the washer thickness is 0.57mm, by calculation, the washer thickness should select 0.60mm ac - cording to above table. 3. Select washer [b] when replacing left crankcase or forward gear, the forward gear washer [b] needs to be adjusted. 1) calculate the washer thickness of for...

Page 207

Washer selection table the washer thickness is 0.54mm by calculation, the washer thickness should select 0.50mm ac - cording to above table. 4. Select washer [c] when replacing left crankcase, reverse gear, and rear cover, reverse gear washer [c] needs to be adjusted. 1) calculate the washer thickne...

Page 208

5. Select washer [d] when replacing left crankcase forward gear, reverse gear, rear cover and output shaft, washer [d] of output shaft needs to be adjusted. 10 calculate the washer “d” thickness of output shaft by following formula washer thickness of output shaft: [d]= (d) + (j) - (e) -b-k-1-0.25 (...

Page 209

6. Installation of adjusting washer 1) washer a mount • washer a (1) • bearing (2) caution: this step is carried out before assembly with closing case. Mount: • clamp plate (1) caution: this step is carried out before assembly with case. 2) washer b mount: • forward gear (1) • washer b (2) • bearing...

Page 210

3) washer c mount: • washer • reverse gear • special-shaped left-handed nut caution: • the special-shaped left-handed nut left-handed thread, so tighten it in counter clockwise direction. • use special-shaped nut wrench 4) washer d mount: • washer • bearing (2) • bushing (3) caution: • use inner all...

Page 211

(v) assembly of cylinder head cylinder cover assy 1. Locking nut 2. Adjusting screw 3. Throttle arm 4. Arm axle 1 5. Valve locking 6. Valve spring cover 7. Valve recoil sealing 8. Valve spring 9. Valve outer spring 10. Valve spring seal 11. Inlet valve 12. Bolt m6x12 13. Locking plate 14. Clamp plat...

Page 212

Cylinder head 1 1. Cylinder head cover assy 2. Steel wire circlip 3. Throttle guide tube 4. Bolt 95026-06010 5. Washer 6. Shock absorbing block 7. Cylinder cover washer assy 8. Locating pin 99510-14016 9. Locating pin 10. Oil sealing 11. Canopy nut 12. Washer 25. O-ring 26. Screw m6x18-06025 29. Cha...

Page 213

Cylinder head 2 1. Cylinder body assy 2. Screw m6 x 25-10.9 3. Cylinder body washer 4. Locating pin 99530-14016 5. O-ring 6. Piston ring 1 7. Piston ring 2 8. Oil ring subassembly 9. Circlip 10. Piston 11. Piston pin 12. Double end bolt 211.

Page 214

1. Mount: • double end bolt (1) 2. Mount: • piston (1) • piston pin (2) • circlip (3) caution: • arrow (4) on the piston must point to the forward engine • before mounting the piston pin, cover crankcase hole with cleaning towel or clothes for avoiding circlip and other small parts dropping into cra...

Page 215

6. Mount: • cylinder (1) • tighten bolt (cylinder ) temporarily caution: • when pressing the piston ring with one hand, assemble the cylinder with the other. • the timing chain should through the bending locking end (2) of chain chamber. 7. Lubricate: • valve rocker • rocker shaft • lubrication oil ...

Page 216

10. Mount: • valve cam caution: the driving pin on the end of valve cam must align to the timing mark on the cylinder cover. 9. Mount: • bearing (1) (to valve cam) • bearing (2) (to valve cam) caution: the bearing (1) with oil sealing is toward out when assembling it, and the bearing (2) with dust c...

Page 217

14. Mount: • lower guide plate (1) • oil sealing (2) • locating pin (3) • cylinder cover washer assy (4) • cylinder head (5) • washer (7) • cylinder head nut (6) • washer (8) • screw (9) caution: • apply 4-stroke engine oil on the washer (7) 15. Fasten the bolt and nut according to the order in the ...

Page 218

• turn the crank until the mark tdc (3) is correspondence with the mark on the crankcase cover (4) . • mount the timing chain to the timing sprocket pulley. • mount the timing sprocket pulley to the cam - shaft for ensuring the mark of timing sprocket pulley (5) is correspondence with the mark (2) o...

Page 219

• insert the small screwdriver into the groove of tension rod and turn the screwdriver clock - wise. A the same time press tension rod until the screwdriver can’t be turned. • hold the screwdriver at this position, and mount the tensioner assy (2) (with washer) on the cylinder, then turn the locking...

Page 220

20. Mount: • valve cover (1) (mount o-ring in the sealing groove of throttle cover first) • valve cover (2) (mount o-ring in the sealing groove of throttle cover first) • spark plug (3) caution: check the o-ring. If it is deformed or damaged, replace it. 21. Mount: • sprocket chamber cover (1) (moun...

Page 221

(vi) manual starting mechanism and others starting system (manual) 1. Left side cover assy 2. Guy 3. Starting lever 4. Starting lever cover 5. Washer 6. Coil spring backboard assy 7. Driver disc assy 8. Torsion spring 9. Drive jaw 10. Circlip 11. Screw pin 12. Guide plate 13. Pressure spring 219.

Page 222

1. Mount: • coil spring backboard assy caution: hang the coil spring hook hanger (2) into the split of spring backboards, and wind the coil spring in counterclockwise. 2. Install: • washer (1) • coil spring backboard assy (2) caution: end of the coil spring is hung on the inner race of left side–cov...

Page 223

6. Mount: • torsion spring (starting ratchet pawl) (1) • starting ratchet pawl (2) • hog ring (3) • compress spring (4) • guide plate (5) • screw pin (6) caution: when mounting torsion spring (starting ratchet pawl), make the end (7) of torsion spring align to groove a on the drive disc. 7. Turn the...

Page 224

9. Mount: • washer (1) • washer (2) • reverse lever system (4) caution: coat sealing gum on the bolt (3) 10. Mount: • manual starting system (1) (vii) reverse procedure for “engine assembly” caution: support motorcycle firmly to avoid turning over. 1. Mount: • engine mount the engine from right side...

Page 225

3. Mount: • drive assy of rear wheel and rear wheel fork assembly steps: 10 lubricate following parts before mounting the rear wheel fork • bearing (1) • oil sealing (2) • bushing (3) • coupling bolt of rear arm (4) • spline of drive shaft (5) • spline of main drive gear (6) lubrication oil: lithium...

Page 226

7. Fasten: • bolt (1) (installation position of engine -- rear lower) • bolt (2) (installation position of engine -- rear lower) • bolt (3) (installation position of engine -- front) • bolt (4) (installation position of engine -- top) • coupling bolt of rear arm (5) (rear arm shaft -- left) • coupli...

Page 227

10. Connect: • spark plug terminal • cdi magneto terminal (1) • “reverse” switch terminal (2) • “neutral” switch terminal (3) • breather tube (4) (crankcase) • brake cable (5) refer to “diagram of vehicle” in section 6 of chapter 1 11. Mount: • starting motor (1) • coupling plate (2) of staring moto...

Page 228

16. Mount: • exhaust pipe (1) • silencer (2) 17. Fill oil: • crankcase total:2.2l refer to relevant part in section 5 of chapter 2. 18. Adjust: • free clearance of plunger (clutch) 19. Adjust: • position of drive selection lever refer to relevant part in section 5 of chapter 2 20. Adjust: • idle spe...

Page 229

• wrong spark plug heat value • inefficient spark plug cap (2) ignition coil • primary coil/secondary coil is broken or shortened • inefficient high voltage wire • ignition coil is broken (3) cdi magneto system • cdi is failure • coil is failure • charging coil is failure • woodruff key is bad (4) s...

Page 230

(1) carburetor • wrong needle valve position • main jet is clogged or loosened • fuel is deteriorated or polluted • wrong float chamber oil level (2) air filter • core of air filter is clogged (iv) shifting trouble 1. Shifting difficulty refer to “slipping of clutch” and “ablation of clutch” in this...

Page 231

(2) fuel system • main jet of carburetor is wrong • improper oil level • core of air filter is clogged (3) cylinder system • serious carbon disposition (4) engine oil • improper oil level • improper oil toughness • poor oil quality (5) brake • brake is stagnant (viii) brake trouble troubles: poor br...

Page 232

• improper installation of steering pillar bearings • holding seat of steering pillar or sealing ring is damaged • rod is bent • spherical connection is bent (3) wheel tire • uneven pressure on two sides of tire • wrong tire pressure • uneven tire wear (4) front/ rear tire • deformed rim • loosen be...