Installation and operating instructions intended for other than household use model: vh1828g retain this manual for future reference oven must be kept clear of combustibles at all times this equipment has been engineered to provide you with year-round dependable service when used according to the in...

Table of contents section item page 1 safety precautions 3 2 general information 3 3 receiving 5 4 location & minimum clearances 6 5 installation 6 6 stacking 7 7 electrical connections 7 8 gas connections 8 9 system check 9 10 initial startup 10 11 shutdown 11 12 special features 12 13 cleaning 12 ...

! Warning: this symbol refers to a potential hazard or unsafe practice, which could result in serious injury or death. ! ! ! Danger: this symbol warns of imminent hazard which will result in serious injury or death. ! ! Caution: this symbol refers to a potential hazard or unsafe practice, which may ...

! ! Warning: never clean any electrical unit by immersing it in water. Turn off before cleaning surface. ! ! Warning: an earthing cable must connect the appliance to all other units in the complete installation and from there to an independent earth connection. ! ! Warning: shock hazard - de-energiz...

! ! Notice: instructions to be followed if anyone smells gas should be posted in a prominent place. These may be obtained from the gas supplier. ! ! Warning: post in a prominent location instructions to be followed in the event you smell gas. Obtain these instructions from your local gas supplier. !...

6 4. Location and minimum clearances adequate air space must be provided for the proper venting of the rear exhaust air and provision made for venting of cooking vapors. The conveyor oven must be installed in a well-ventilated area. Note: attached rear rubber bumpers must not be removed and can cont...

Your conveyor oven(s) can be stacked up to (3) high. Each unit is built exactly the same, so it does not matter in which order they are stacked. For stacking of (2) units, remove the legs from the second (upper) unit prior to mounting on top of the bottom unit. For stacking of (3) units, it is prefe...

8. Gas connections the 1828g conveyor oven can be ordered either as natural gas or liquid propane gas. A) only a qualified gas appliance installer should make gas connections. B) the 1828g is supplied with a ½” npt inlet pipe only. The installer must supply an approved external gas pressure regulato...

9. System check a) insure that the conveyor belt assembly is installed correctly, with the drive-shaft pin fitting firmly into the coupling that protrudes from the power control box gearmotor output shaft. Visually check that the belt is flat and parallel to the countertop surface. If the belt is no...

Open the front door and verify the proper orientation of the upper air return shield. C) the plenum fingers are identical, so any finger can be mounted in any location. D) close the front door into the front opening, sealing the cooking chamber closed. Secure the (4) outer side panels to the main fr...

1) flip on the main switch. The switch should light up when on ( ), and be dark when off( ). Normal warm-up time is 30-40 minutes for maximum temperature. Lower temperature settings will take less time. 2) set the temperature controls to max (full clockwise rotation). The indicator lights will illum...

12. Special features 13. Cleaning your new conveyor oven has been built with numerous enhancements to add flexibility and simplicity to your cooking operation. A. Independent top and bottom heat. Different temperature settings can be set for both top and bottom heat zones. B. Variable-speed conveyor...

Conveyor beltassembly plenum fingers 1. Conveyor belt still mounted in oven: using a plastic abrasive pad, wipe the conveyor belt in a back-and-forth motion to remove baked-on product. Wipe clean with a hot, damp cloth. 2. Conveyor belt removed from oven: using a plastic abrasive pad, wipe the con...

14. Operator maintenance warning danger disconnect the power supply before servicing or cleaning the oven. Serious injury, including death, may occur if contact is made with incoming power. Caution if fuse bad, replace only with identical fuse. Do not substitute higher value fuses, as this may nulli...

Periodically check the tension of the conveyor belt.Adjust tension using the adjustment slots at the left end of the conveyor. Proper tension can be measured by the following: 6 from the left end of the conveyor, place fingers beneath belt and lift upwards. The belt should lift a maximum of 1 1/2,...

Gas control box with main on/off switch hinged front door product flow power control box 4 10 16 18. Conveyor belt speed calibration the conveyor belt requires calibration to properly align the speed control knob on the gas control box. Calibration is done by timing the belt as it passes between two...

E. Using a black marking pen, mark any belt link near the outer edge. Using a stopwatch, check the time it takes for this link to move between the timing marks. Repeat this procedure several times until the distance is traveled in 90 seconds (recommended calibration interval), which equals a 6- minu...

19. Troubleshooting guide the problem the cause the solution belt master link(s) missing, broken, or installed incorrectly. Oven doesn't start conveyor belt doesn't move, or it moves unevenly. Unexpected speed changes. Drive sprockets worn out, missing, or mis- aligned belt loose. Drive sprockets no...

Conveyor belt doesn't move, or it moves unevenly. Unexpected speed changes. Blower motor(s) "jammed" blower motor(s) "stalled" (not running when main switch on) if all previous tests verify power and control to gearmotor, replace gearmotor. 4. Verifywire connectors from power supply to gearmotor (2 ...

The problem the cause the solution 1. Locate the two temperature controls mounted with power control box on the hinged door, near the cooling fan. Verify that all connections and connectors are properly fastened and tight. Power should be connected to terminals labeled 120 & vac com. 2. Locate the t...

The problem the cause the solution 21 burner(s) do not light oven not hot enough (continued) check the following items first: 1. Gas supply connected. 2. Shut-off valve open. 3. Pressure regulator set correctly. The following diagnostics testing can only be performed by an authorized service agent. ...

20. Temperature control conversion chart - ohms to degrees the temperature sensor (probe) that is supplied with this conveyor oven is an rtd type, which yields an output based on ohms of resistance. This particular rtd device has a linear resistance curve that produces a very predictable amount of r...

Vh 1828g electrical schematic 115vac, 50/60hz, 1 phase 21. Electrical schematic & wiring diagram 23 u4182q f1 10 am p 18g aw hit e. 18g a.B lack f1 up pe r te mp co nt ro l low er te mp con tr ol co nt ro l bo x cooli ng fa n l o bl ac k wh ite mai n sw itch (o n ) (o ff ) up pe r bu rn er assemb ly...

Vh 1828g wiring diagram 115vac, 50/60hz, 1 phase u4182q cooling fan in gas box 4 5 2 1 3 upper temperature adjustment potentiometer 11 10 9 8 7 6 lower temperature adjustment potentiometer black bla ck 19 13 19 11 18 14 16 12 - wh ite ++ - 41 39 46 44 + black ( 2 ) red gearmotor power supply - + out...

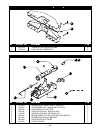

Item p/n description quan item p /n description quan 22. Parts lists & exploded views figure “a” e xternal covers figure “b” conveyor assembly 1 2 3 8 9 10 8 8 8 9 10 7 6 5 4 3 2 1 1 2 5 6 7 8 11 10 9 8 7 6 5 4 3 2 1 11 10 1 2 3 4 5 6 7 8 9 10 4 2 1 12 1 12 4 2 1 1 b6343k b6342k q1499a s6266u b6335k...

Figure “e” v h s eries ovens o nly figure “c” blower motor cover assembly figure “f” plenum “finger” assembly figure “d” b lower assembly item p/n description quan item p/n description quan item p/n description quan item p/n description quan 1 2 3 4 5 6 1 2 3 4 5 6 all component s shown all componen...

Item p/n description quan figure g main power control box 3-pi ece asse mbl y 1 2 3 4 11 17 18 19 21 20 23 24 25 18 17 16 7 8 9 1 2 3 4 5 6 11 10 24 23 22 26 21 20 19 15 14 13 12 25 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1...

26 item p/n description quan figure h gas control box 3- pie ce as se mb ly 1 2 3 4 6 8 9 10 11 13 14 15 16 17 19 21 22 25 12 18 17 16 7 8 9 1 2 3 4 5 6 11 10 24 23 22 21 20 19 15 14 13 12 25 plug-in harness -not shown- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 1 1 1 2 2...

Part number part number description description quan quan figure i cool-down thermostat, elements, switch & probe figure j gas burner assembly item item 1 2 1 2 2 2 m1518a temperature sensor probe m1534a cool-down thermostat 2 1 2 3 6 7 8 9 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 b6318u l5106a n5876...

Part number description quan figure k gas manifold system item see figure "l" 1 2 2 1 see figure l 1 2 1 1 r5877a r5878a upper gas manifold tube lower gas manifold tube part number description quan figure l gas valve assembly item 1 2 3 4 2 2 2 2 r3225a r3227p n3068p r3226a gas valve assembly,...

31 what is covered this warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser providing that: * the equipment has not been accidentally or intentionally damaged, altered or misused; * the equipment is properly installed, adjusted, operated a...

F. Bakers pride bakers pride oven co., inc. 30 pine street new rochelle, ny 10801 +1 (914) 576-0200 phone (800) 431-2745 us & canada +1 (914) 576-0605 fax www.Bakerspride.Com webaddress info@bakerspride.Com e-mailaddress 32.