Baldor FLEXIDYNE 11C Instruction Manual

INSTRUCTION MANUAL

FOR

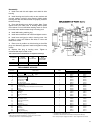

FLEXIDYNE

®

Couplings

Sizes 9C and 11C

WARNING

: Because of the possible danger to persons(s) or property from accidents which may result from the improper use of products, it is

important that correct procedures be followed. Products must be used in accordance with the engineering information specified in the catalog.

Proper installation, maintenance and operation procedures must be observed. The instructions in the instruction manuals must be followed.

Inspections should be made as necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety

devices or procedures as may be desirable or as may be specified in safety codes should be provided, and are neither provided by Baldor

Electric Company Automaton nor are the responsibility of Baldor Electric Company. This unit and its associated equipment must be installed,

adjusted and maintained by qualified personnel who are familiar with the construction and operation of all equipment in the system and the

potential hazards involved. When risk to persons or property may be involved, a holding device must be an integral part of the driven

equipment beyond the speed reducer output shaft.

www.baldor.com www.ptplace.com www.dodge-pt.com www.reliance.com

Baldor Electric Company Headquarters

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.648.5792, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

DODGE/Reliance Division

6040 Ponders Court, Greenville, SC 29615-4617 U.S.A., Ph: (1) 864.297.4800, FAX: (1) 864.281.2433

IM499872

04/07 Copyright © 2007 Baldor Electric Company All Rights Reserved. Printed in USA.

This material is not intended to provide operational instructions. Appropriate instruction

manuals and precautions should be studied prior to installation, operation or maintenance of

equipment.