- DL manuals

- Baldor

- Servo Drives

- FP4 A02TB

- Installation & Operating Manual

Baldor FP4 A02TB Installation & Operating Manual - Section 1

Section 1

General Information

General Information 1-1

MN1276

Copyright Baldor

!

1999. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in

whole or in part, be copied or reproduced in any form without the prior written

consent of Baldor.

Baldor makes no representations or warranties with respect to the contents hereof

and specifically disclaims any implied warranties of fitness for any particular

purpose. The information in this document is subject to change without notice.

Baldor assumes no responsibility for any errors that may appear in this document.

Microsoft and MS--DOS are registered trademarks, and Windows is a trademark of

Microsoft Corporation.

UL and cUL are registered trademarks of Underwriters Laboratories.

CE Compliance

A custom unit may be required, contact Baldor. Compliance to Directive

89/336/EEC is the responsibility of the system integrator. A control, motor and all

system components must have proper shielding, grounding, and filtering as

described in MN1383. Please refer to MN1383 for installation techniques for CE

compliance. For additional information, refer to Sections 3 and 8 of this manual.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or

replace without charge controls and accessories which our examination proves to be

defective in material or workmanship. This warranty is valid if the unit has not been

tampered with by unauthorized persons, misused, abused, or improperly installed and

has been used in accordance with the instructions and/or ratings supplied. This warranty

is in lieu of any other warranty or guarantee expressed or implied. BALDOR shall not be

held responsible for any expense (including installation and removal), inconvenience, or

consequential damage, including injury to any person or property caused by items of our

manufacture or sale. (Some states do not allow exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply.) In any event, BALDOR’s

total liability, under all circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or replacements must be referred to

BALDOR with all pertinent data as to the defect, the date purchased, the task performed

by the control, and the problem encountered. No liability is assumed for expendable items

such as fuses.

Goods may be returned only with written notification including a BALDOR Return

Authorization Number and any return shipments must be prepaid.

Summary of FP4 A02TB

Page 1

Flex+drive servo control servo drive installation & operating manual 2/03 mn1276.

Page 2: Table Of Contents

Table of contents table of contents i mn1276 section 1 general information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ce compliance 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3

Ii table of contents mn1276 section 5 operation 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installing software on your pc 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Table of contents iii mn1276 section 7 specifications & product data 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Identification 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5

Iv table of contents mn1276.

Page 6: Section 1

Section 1 general information general information 1-1 mn1276 copyright baldor ! 1999. All rights reserved. This manual is copyrighted and all rights are reserved. This document may not, in whole or in part, be copied or reproduced in any form without the prior written consent of baldor. Baldor makes...

Page 7

1-2 general information mn1276 product notice intended use: these drives are intended for use in stationary ground based applications in industrial power installations according to the standards en60204 and vde0160. They are designed for machine applications that require variable speed controlled th...

Page 8

General information 1-3 mn1276 precautions: warning: do not touch any circuit board, power device or electrical connection before you first ensure that power has been disconnected and there is no high voltage present from this equipment or other equipment to which it is connected. Electrical shock c...

Page 9

1-4 general information mn1276 caution: suitable for use on a circuit capable of delivering not more than the rms symmetrical short circuit amperes listed here at rated voltage. Horsepower rms symmetrical amperes 1--50 5,000 caution: avoid locating control immediately above or beside heat generating...

Page 10: Section 2

Section 2 product overview product overview 2-1 mn1276 overview the flex+drive product is designed to serve the needs of machine designers and manufacturers. Baldor products have both ul and ce approvals. The flex+drive is a “flexible” versatile compact control for brushless servo motors. This digit...

Page 11

2-2 product overview mn1276 control inputs opto isolated inputs are single ended, user selectable and active high or low: enable machine input 1 quit machine input 2 fault reset machine input 3 home flag machine input 4 trigger control outputs one normally closed relay contact provides a dedicated “...

Page 12: Section 3

Section 3 receiving and installation receiving & installation 3-1 mn1276 receiving & inspection baldor controls are thoroughly tested at the factory and carefully packaged for shipment. When you receive your control, there are several things you should do immediately. 1. Observe the condition of the...

Page 13

3-2 receiving & installation mn1276 electrical installation all interconnection wires between the control, ac power source, motor, host control and any operator interface stations should be in metal conduits. Use listed closed loop connectors that are of appropriate size for wire gauge being used. C...

Page 14

Receiving & installation 3-3 mn1276 figure 3-3 recommended system grounding (1 phase) for ul ac main supply safety ground driven earth ground rod (plant ground) l n earth route all 3 wires l, n, and earth (ground) together in conduit or cable. Note: wiring shown for clarity of grounding method only....

Page 15

3-4 receiving & installation mn1276 system grounding continued ungrounded distribution system with an ungrounded power distribution system it is possible to have a continuous current path to ground through the mov devices. To avoid equipment damage, an isolation transformer with a grounded secondary...

Page 16

Receiving & installation 3-5 mn1276 table 3-1 wire size and protection devices (for units with power supply) catalog number incoming power g contin o s inp t input wire gauge nominal input continuous output input breaker input fuse wire gauge nominal input voltage output amps (rms) breaker (a) time ...

Page 17

3-6 receiving & installation mn1276 figure 3-5 single phase ac power connections (fp1axxt & fp2axxt only) l1 l2 alternate * fuse connection note 1 l1 l2 l n * circuit breaker earth note 2 note 1 baldor control notes: 1. See “protection devices” described in this section. 2. Metal conduit or shielded...

Page 18

Receiving & installation 3-7 mn1276 figure 3-7 3 phase power connections (fp2axxs & fp4axxt only) l1 l2 l3 alternate * fuse connection note 1 l1 l2 l3 l1 l2 l3 * circuit breaker earth * components not provided with control. Note 2 baldor control note 1 a1 b1 c1 notes: 1. See protection device descri...

Page 19

3-8 receiving & installation mn1276 figure 3-9 connector locations (single phase controls) x6 - rs232 / 485 rs232 rs485 1 reserved 1 tx- 2 r x data 2 tx+ 3 t x data 3 rx+ 4 dtr 4 rx- 5 dgnd 5 dgnd 6 dsr 6 rts- 7 rts 7 rts+ 8 cts 8 cts+ 9 +5v 9 cts- x3 - control signals & digital i/o 1 cmd+ 2 cmd- 3 ...

Page 20

Receiving & installation 3-9 mn1276 figure 3-10 connector locations (three phase controls) x6 - rs232 / 485 rs232 rs485 1 reserved 1 tx- 2 r x data 2 tx+ 3 t x data 3 rx+ 4 dtr 4 rx- 5 dgnd 5 dgnd 6 dsr 6 rts- 7 rts 7 rts+ 8 cts 8 cts+ 9 +5v 9 cts- x3 - control signals & digital i/o 1 cmd+ 2 cmd- 3 ...

Page 21

3-10 receiving & installation mn1276 x1 motor connections motor connections are shown in figure 3-11 and figure 3-12. It is important to connect the motor leads u, v and w correctly at the x1 connector of the control. Incorrect wiring can cause erratic operation including moves at peak force until t...

Page 22

Receiving & installation 3-11 mn1276 figure 3-13 optional m-contactor connections u v w * rc device electrocube rg1781-3 u v w g 9 * m enable x3 * motor m m m * m-contactor to power source (rated coil voltage) m=contacts of optional m-contactor note: close “enable” after “m” contact closure. * optio...

Page 23

3-12 receiving & installation mn1276 x1 +24vdc logic supply for fpxaxxxx-xxx3 only. A separate 24vdc supply to the “logic power” input is required for operation. An external 24 vdc power source must be used. If bus power is lost, the logic circuits are still active if the 24vdc is present. This is i...

Page 24

Receiving & installation 3-13 mn1276 x3 digital inputs continued table 3-3 opto input signal conditions pin number signal name switch = closed (active) switch = open (not active) x3-9 enable drive enabled. Drive disabled. X3-10 ma i 3 machine input 3 = logical 1 machine input 3 = logical 0 x3-11 ma ...

Page 25

3-14 receiving & installation mn1276 x3 digital inputs continued figure 3-17 positioning mode timing diagram time trigger time ma i 1 - 4 t2 t4 t1 t3 time trajectory t5 t6 time motion ready = motion in process t7 see table 3-4. Table 3-4 process duration for resolver and encoder feedback time resolv...

Page 26

Receiving & installation 3-15 mn1276 factory installed settings absolute moves 15 predefined absolute moves have been programmed at the factory. These moves are defined in table 3-5. Table 3-5 machine inputs and position move definitions buffer machine inputs position speed acceleration buffer (move...

Page 27

3-16 receiving & installation mn1276 x3 digital outputs - opto isolated outputs the control outputs are located on the x3 connector. A customer provided, external power supply must be used if digital outputs are to be used. The opto outputs provide status information and are not required for operati...

Page 28

Receiving & installation 3-17 mn1276 x6 rs232 / 485 connections rs232 a null modem cable (also called a modem eliminator cable) must be used to connect the control and the computer com port. This will ensure that the transmit and receive lines are properly connected. Either a 9 pin or a 25 pin conne...

Page 29

3-18 receiving & installation mn1276 rs485 standard rs485 connections are shown in figure 3-24. Maximum cable length is 3280 ft (1000m). Figure 3-23 9 pin rs-485 cable connections for ul installations 9 pin connector pin signal 1 tx- 2 tx+ 3 rx+ 4 rx- 5 dgnd control (dce) computer com port (dte) tx-...

Page 30

Receiving & installation 3-19 mn1276 figure 3-25 rs485 4 wire multi-drop for ul installations * terminating resistor t r is 120 w typical value. Only the pc and last control are terminated. Tx+ tx-- x6 host computer dgnd gnd tx+ tx-- shields dgnd gnd * rx+ rx-- dgnd gnd t r * t r tx+ tx- rx+ rx- rx+...

Page 31

3-20 receiving & installation mn1276 x7 simulated encoder output the control provides a simulated encoder output at connector x7. This output may be used by external hardware to monitor the encoder signals. It is recommended that this output only drive one circuit load (rs422 interface -- 28ls31 dev...

Page 32

Receiving & installation 3-21 mn1276 x8 resolver feedback the resolver connections are the standard feedback on flex+ drives and connections are made at the x8 connector as shown in figure 3-27. The resolver cable must be shielded twisted pair #22 awg (0.34mm 2 ) wire minimum. The cable must also ha...

Page 33

3-22 receiving & installation mn1276 x9 encoder w/hall tracks optional (option e) twisted pair shielded wire with an overall shield should be used. Figure 3-29 shows the electrical connections between the encoder and the encoder connector. Figure 3-29 encoder with hall tracks connections for ul inst...

Page 34: Section 4

Section 4 switch setting and start-up switch setting & start-up 4-1 mn1276 switch as1 settings monitor 7 8 off / on as1 6 5 4 3 2 1 note: as1--8 is shown in the “on” position (drive enabled). All other switches are shown in the “off” position. As1 switches are located on the front panel between x1 a...

Page 35

4-2 switch setting & start-up mn1276 setting of switches as1-5 to as1-8 the function of switches as1-5 to as1-8 are described in table 4-2. Table 4-2 as1-5 to as1-8 description switch function on off as1-5 not used as1-6 hold-position hold-position is active. Hold-position is not active as1-7 offset...

Page 36

Switch setting & start-up 4-3 mn1276 start-up procedure power off checks before you apply power, it is very important to verify the following: 1. Disconnect the load from the motor shaft until instructed to apply a load. If this cannot be done, disconnect the motor wires at x1-u, v and w. 2. Verify ...

Page 37

4-4 switch setting & start-up mn1276.

Page 38: Section 5

Section 5 operation operation 5-1 mn1276 installing software on your pc the setup software is windows--based. The servo control connects to a serial port on your pc. The setup wizard will guide you through the necessary steps to set--up your servo control. Online--help to each topic is available. Mi...

Page 39

5-2 operation mn1276 5. Select “binary transfers” from the settings pull down menu within terminal program. 6. Set the binary transfer protocol to xmodem/crc. 7. Close menu and save the settings. 8. Terminal communications settings are now complete. Windows 95 1. Power up the host and start windows ...

Page 40

Operation 5-3 mn1276 using the setup wizard the setup software wizard guides you through each step to set the basic parameters. This wizard is activated automatically after each start-up of the software. This automatic start of the wizard can be turned off. It can be activated (and reset to automati...

Page 41

5-4 operation mn1276 figure 5-1 flowchart of the setup wizard setup wizard auto tuning procedure sequence 1: motor and control general: -- app. Bus voltage --sim enc. Output motor: -- select the motor sequence 2: operating mode general: -- current -- velocity -- positioning download skip skip sequen...

Page 42

Operation 5-5 mn1276 set up software opening menu. Click next to go to the set up software. If you have already set up the parameters and saved them to a file, click finish then load the parameter file using the file ( open selection. Start by selecting the motor and control and these parameters wil...

Page 43

5-6 operation mn1276 there are 7 parts to the setup procedure: motor select your motor from the list. First, select the general “motor type”. Then select your specific “motor id”. All of the parameters will be entered if your motor is on the list. If your motor is not on the list, you must define a ...

Page 44

Operation 5-7 mn1276 after the motor and control are selected, click the general menu and note that the values are filed in. Operating mode select the operating mode of the control. Choices are: 1. Current mode 2. Velocity mode 3. Positioning (15 preset point to point moves) click “download” when fi...

Page 45

5-8 operation mn1276 current parameter nominal and peak current values are automatically entered for the motor type. For manual tuning only, set the control current limit value to a percentage of the continuous current rating. For example, if your control is rated for 5a continuous current and you d...

Page 46

Operation 5-9 mn1276 positioning there are two ways to start a move: software triggered or hardware triggered. Software triggered (refer to section 3 for information on how to setup a move). Motion trigger dwell time 1. From the main menu select “setup ) operation mode”. 2. Click on “positioning tab...

Page 47

5-10 operation mn1276 home starts a search for the machines absolute zero position. When home is found, the control will hold the position at absolute zero. There are three homing types: index channel, capture and actual position. Index channel causes the motor shaft to rotate to a predefined home p...

Page 48

Operation 5-11 mn1276 drift if you know the input offset value of the control, you may enter the value manually. Otherwise, you may initiate automatic offset tuning and let the control measure and set this value. Click “download” when finished. Figure 5-7 drift parameter screen autotune you may manu...

Page 49

5-12 operation mn1276 main menu choice descriptions file open a new editor window. Open an existing editor window. Close the active editor window. Close all editor windows. Save the active editor window to a file. Save the active editor window to a new file name . Save all editor windows. Print the ...

Page 50

Operation 5-13 mn1276 tuning allows manual or automatic tuning to remove offset drift. Allows manual or automatic tuning of velocity control parameters. Watch show or hide the “symbols list bar”. Show or hide the “system parameters bar”. Show or hide the “system status bar”. Gather and plot motor da...

Page 51

5-14 operation mn1276 alphabetic glossary listing of keywords. Search for help based on a keyword. Get help for a specific topic. Starts the setup wizard to configure a motor and control. Software version and release information. Plc program at the main menu, select “functions” then “plc”. See figur...

Page 52: Section 6

Section 6 troubleshooting troubleshooting 6-1 mn1276 overview the system troubleshooting procedures involves observing the status of the “ready” led, the “db on” led and the “monitor” 7 segment display. The tables in this section provide information related to the indications provided by these devic...

Page 53

6-2 troubleshooting mn1276 table 6-1 operating mode indications continued ready monitor status cause red a eeprom checksum error. The personality must be downloaded to eeprom and reset the control. If problem remains, contact baldor. Red c velocity data in the eeprom failed. The velocity data must b...

Page 54: Section 7

Section 7 specifications & product data specifications & product data 7-1 mn1276 identification flex +drive fp --r enclosure type t= panel mount w/internal power supply p= panel mount w/external power supply s = panel mount w/internal power supply (suitable for sharing with other controls). Servo co...

Page 55

7-2 specifications & product data mn1276 specifications description unit fpx a02t fpx a05t fpx a07t fpx © a02s fpx © a05s fpx © a010s fpx © a015s input voltage range nominal minimum maximum vac 115 / 230 92 / 184 132 / 265 input frequency hz 50/60 " 5% nominal output bus nominal (@ 115 / 230 input) ...

Page 56

Specifications & product data 7-3 mn1276 specifications continued description unit fp4 a02tb fp4 a05tb fp4 a07tb fp4 a15tr fp4 a20tr fp4 a27tr input voltage range nominal minimum maximum vac 460 @ 60hz / 400 @ 50hz 400 / 360 528 / 480 input frequency hz 50/60 " 5% nominal output bus nominal (@ 400 /...

Page 57

7-4 specifications & product data mn1276 24vdc logic power input (option fpxaxxxx--xxx3 only) description unit fpx a02t fpx a05t fpx a07t fpx a02s fpx a05s fpx a10s fpx a15s input voltage (maximum ripple = " 10%) vdc 20 -- 30 input current @ 24vdc a rms 0.55 -- 0.8 ¡ 1.4 power on surge current (24vd...

Page 58

Specifications & product data 7-5 mn1276 encoder input (handwheel or feedback) description unit all signal type rs422 operating mode a / b quadrature maximum input frequency khz 125 cycle time msec 1 serial interface (option fpxaxxxx--xx2x) description unit all communication type rs232c (not galvani...

Page 59

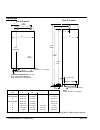

7-6 specifications & product data mn1276 dimensions 7.70 ' (195.5mm) 6.81 ' (173mm) a 0.12 (3.0) w 0.2 (5.2) dia. 4 places 1.57 ' (40mm) size a, b and c size e, g and h 14.05 (357) 15.14 (385) 15.75 (400) depth size e, g and h = 10.4 (265) 0.3 (8.0) 0.25 (6.5) dia. 3 places a clearance requirements ...

Page 60: Section 8

Section 8 ce guidelines ce guidelines 8-1 mn1276 ce declaration of conformity baldor indicates that the products are only components and not ready for immediate or instant use within the meaning of “safety law of appliance”, “emc law” or “machine directive”. The final mode of operation is defined on...

Page 61

8-2 ce guidelines mn1276 using ce approved components will not guarantee a ce compliant system! 1. The components used in the drive, installation methods used, materials selected for interconnection of components are important. 2. The installation methods, interconnection materials, shielding, filte...

Page 62

Ce guidelines 8-3 mn1276 emc installation instructions to ensure electromagnetic compatibility (emc), the following installation instructions should be completed. These steps help to reduce interference. Consider the following: $ grounding of all system elements to a central ground point $ shielding...

Page 63

8-4 ce guidelines mn1276 input signal cable grounding cable 1 2 3 7 9 10 11 control x3 simulated encoder output cable grounding cable 1 6 2 7 3 8 11 13 control x7 to controller resolver cable grounding cable 1 6 2 7 3 8 5 control x8 1 2 3 4 5 6 resolver connector housing connection of shields to ana...

Page 64: Section 9

Section 9 accessories and options accessories & options 9-1 mn1276 cables shielded (screened) cable provides emi / rfi shielding and are required for compliance to ce regulations. All connectors and other components used must be compatible with this shielded cable. Motor power cable cable rated c rr...

Page 65

9-2 accessories & options mn1276 resolver feedback cable motor type cable assembly baldor catalog number length motor type cable assembly description baldor catalog number feet meters resolver feedback cable assembly threaded connector (standard-metric style) cbl015sf--alm cbl030sf--alm cbl046sf--al...

Page 66

Accessories & options 9-3 mn1276 for package size e, g and h (model t -- 3 phase required for fp4xx) filter type rated volts rated amps @ 40 # c leakage current ma weight lbs (kg) baldor no. Fn 3258 - 30 - 47 480 30 184.7 2.64 (1.2) asr30521 fn 3258 - 7 - 45 480 7 172.4 0.11 (0.5) asr30522 d ac filt...

Page 67

9-4 accessories & options mn1276 regeneration resistor some controls are shipped with an internal regen resistor. If an internal resistor is not present, a regeneration resistor should be installed to dissipate energy during braking if a fault “1” (over-voltage) occurs. Baldor catalog number control...

Page 68

Accessories & options 9-5 mn1276 can bus (optional -- not available for controls with encoder feedback) controls that are supplied with the can bus option have two additional connectors, x10 and x11 (conform to ds102, version 2.0). These are shown in figure 9-1. Can is a factory installed option. Fi...

Page 69

9-6 accessories & options mn1276 figure 9-2 can bus interconnections flex control x10 x11 x10 x11 terminate the last drive x10-7 x10-2 x11-7 x11-2 x10-3 x10-7 x10-2 x10-3 x11-7 x11-2 x10-3 gnd can_l can_h 120 w 120 w terminate the master can_l can_h gnd can_l can_h gnd can_l can_h gnd can_l can_h ca...

Page 70

Accessories & options 9-7 mn1276 index range the index range from 0x1000 to 0x100d is valid. The following index ranges are important: 0x1400 1st pdo receive (communication) 0x1402 2nd pdo receive (communication) 0x1600 1st pdo receive (mapping) 0x1602 2nd pdo receive (mapping) 0x1800 1st pdo transm...

Page 71

9-8 accessories & options mn1276 the default baud rate is set to 125 kbit/second and the node_id is the drive address+1 (as1 switches 1 to 4). Note: every drive, connected to one can bus system must have a different node_id. After power up you will receive an emergency message with two data bytes (0...

Page 72

Accessories & options 9-9 mn1276 to read a parameter from the drive: 0x40 ind_lo ind_hi sub xxx xxx xxx xxx d0 d1 d2 d3 d4 d5 d6 d7 drive pc master 0x60 ind_lo ind_hi sub 0x00 0x00 0x00 0x00 id = 0x600 + node_id id = 0x580 + node_id where: x don’t care id identifier 0x hexadecimal data format d0 - d...

Page 73

9-10 accessories & options mn1276 identifiers and object list the distribution of the identifiers of the supported objects conforms to can open (ds301, v 3.0, s. 8--12). Message / object function code cob - identifier services nmt services 0 0 (broadcast) start_remote_node stop_remote_node pre-opera...

Page 74

Accessories & options 9-11 mn1276 expedited domain download and initiate domain download 7..5: ccs 001 scs 011 expedited domain download request confirm domain protocols initiate domain download request confirm ccs 001 scs 011 4: x x x x 3..2:n (0 or n) x x x 1:e 1 x 0 x 0:s s x s x = 1.Byte =22, 2x...

Page 75

9-12 accessories & options mn1276 segmented domain upload 7..5: ccs 001 scs 000 upload domain segment request confirm domain protocols end of upload domain segment request confirm ccs 011 scs 000 4: t 0 / 1 0 / 1 0 / 1 0 / 1 3..1:n x n x n 0:c x 0 x 1 = 1.Byte =60 / 70 =0e / 1e =60 / 70 =0x / 1x 5 u...

Page 76

Accessories & options 9-13 mn1276 object dictionary (can - version: 23310d) index (hex) object used 0000 not used 0001 -- 001f static data types object_unsigned8 0005 0020 -- 003f complex data types 0040 -- 005f manufacturer specific data types 0060 -- 007f “device profile specific static data types...

Page 77

9-14 accessories & options mn1276 continued index (hex) object used pdo mappable parameters (2080 -- 2093): manufact_pos manufact_abs_pos manufact_vel manufact_vel_command manufact_control_command manufact_torque_command manufact_pos_command read only: manufact_com_actu manufact_com_actv manufact_co...

Page 78

Accessories & options 9-15 mn1276 subindexes to index 2010 (cur. Commands) ascii command subindex read/write (rw), read only (ro), write only (wo) (entries) 0x00 ro cur.Actv 0x01 ro cur.Actu 0x02 ro reserved 0x03 cur.Ipeak 0x04 rw cur.Inom 0x05 rw reserved 0x06 reserved 0x07 reserved 0x08 cur.Tofr 0...

Page 79

9-16 accessories & options mn1276 subindexes to index 2012 (hw. Commands) ascii command subindex read/write (rw), read only (ro), write only (wo) (entries) 0x00 ro hw.Grfx 0x01 rw hw.Grsh 0x02 rw hw.Plcgear 0x03 rw hw.Res 0x04 rw hw.Type 0x05 rw subindexes to index 2013 (pos. Commands) ascii command...

Page 80

Accessories & options 9-17 mn1276 subindexes to index 2015 (drv. Commands) ascii command subindex read/write (rw), read only (ro), write only (wo) (entries) 0x00 ro drv.Busapp 0x01 rw drv.Busov 0x02 rw drv.Busv 0x03 rw drv.I2t 0x04 rw drv.Id 0x05 rw drv.Idx 0x06 rw drv.Inom 0x07 rw drv.Ipeak 0x08 rw...

Page 81

9-18 accessories & options mn1276 subindexes to index 2018 (mot. Commands) ascii command subindex read/write (rw), read only (ro), write only (wo) (entries) 0x00 ro mot.Abspos 0x01 ro mot.Acc 0x02 rw mot.Vel 0x03 rw reserved 0x04 mot.Type 0x05 rw mot.Dwell 0x06 rw mot.Inccw 0x07 rw mot.Incw 0x08 rw ...

Page 82: Appendix A

Appendix a manual tuning manual tuning a-1 mn1276 tuning this appendix presents guidelines for manual tuning the control. Tuning is necessary, since a various loads (friction and inertia) will effect the drive response. Response may be defined as the time required for the drive to reach speed. Vario...

Page 83

A-2 manual tuning mn1276 there are 7 parts to the setup procedure: motor select your motor from the library. First, select the general motor type. Then select your specific motor. All of the parameters will be entered if your motor is on the list. If your motor is not on the list, you may define a m...

Page 84

Manual tuning a-3 mn1276 after the motor and control are selected, click the general menu and note that the values are filed in. Operating mode select the operating mode of the control. Choices are: 1. Current mode 2. Velocity mode 3. Positioning (15 preset point to point moves) click “download” whe...

Page 85

A-4 manual tuning mn1276 current parameter nominal and peak current values are automatically entered for the motor type. For manual tuning only, set the control current limit value to a percentage of the continuous current rating. For example, if your control is rated for 5a continuous current and y...

Page 86

Manual tuning a-5 mn1276 drift if you know the input offset value of the control, you may enter the value manually. Otherwise, you may initiate automatic offset tuning and let the control measure and set this value. Click “download” when finished. Figure a-8 drift parameter screen manual tuning the ...

Page 87

A-6 manual tuning mn1276 pole placement pole placement provides a “no--overshoot response” when tuned for the correct inertia. This is the easiest and recommended method of adjustment. Inertia click in the “load” block and enter the value in kg--cm 2 . The range is from 0 to 133 kg--cm 2 . If the in...

Page 88

Manual tuning a-7 mn1276 pi compensation pi method of adjustment allows adjustment of the acceleration ramp time and overshoot values. If “pi” compensation is selected, you would enter values for gv--gain and gvi--gain. Select pi compensation instead of pole placement on the menu shown in figure a-9...

Page 89

A-8 manual tuning mn1276 gv--gain this is the “proportional gain” of the velocity loop. It controls the gain of the velocity loop by adjusting the controls response to the error. The error is the difference between the commanded and actual velocity. The higher the gain, the smaller the difference (o...

Page 90

Manual tuning a-9 mn1276 plotting of move at any time after the setup parameters are downloaded to the control, you may proceed to the plotting routine. Plot allows you to verify that the parameter values you entered provide adequate system response. In this section, you will inform the software wha...

Page 91

A-10 manual tuning mn1276 pulse follower applications (only used in “pulse follower” applications). Choose tuning select the “manual tune” method as shown in figure shown in figure a-9. Position parameters click on the “position parameters” button. You will see parameters as shown in figure a-13. Se...

Page 92: Appendix B

Appendix b command set command set b-1 mn1276 flex -- ascii -- command -- set general flex controls use the rs232 communication port (optional rs485) as the interface. This document describes existing flexdrive/flex+drive ascii terminal commands for setup and control of the servo drive. There are th...

Page 93

B-2 command set mn1276 upon receiving a command, the controller answers by sending the function parameter and variable list. General purpose commands are not prefixed. These commands only consist of the command identifier and therefore need the general structure “command identifier” [“delimiter”]“pa...

Page 94

Command set b-3 mn1276 start--up with terminal communication and command examples 1. Select the correct com port nr. And set the following at your pc: -- baud rate: 9600 -- protocol (hardware, xon/xoff, none): off -- data length: 8 bit --stop bit: 1 --parity: none 2. Set the control address. The add...

Page 95

B-4 command set mn1276 general settings system constants command description range common lev i levii sys.Power queries dip switch id, (see drv.Id) x sys.Fback queries system feedback (encoder / resolver)as defined by altera 0:1 x sys.Info queries firmware version with naming and ascii letters x ¡ s...

Page 96

Command set b-5 mn1276 additional system parameters (mostly sys.* prefixed) velocity feedback parameters: command description units range default e 2 / par. Set mtr.Rpls resolver number of poles -- 1 : 65535 e / p sys.Encres queries / updates encoder feedback resolution for encoder motors (in pulses...

Page 97

B-6 command set mn1276 plc parameters: command description units range default e 2 / par. Set plc.Line defines plc statement :if [input]=true, then [action] set/started, with sytax plc.Line [num] [action] [input] [num] [action] -- plc line number, and string parameter for plc action, fixed to line n...

Page 98

Command set b-7 mn1276 oci interface parameters: command description units range default significant e 2 / par. Set can.Bd (the range check is: invalid execute context.) it should be: “range error” hz 10 : 1000 ok can.Id (the range check is: invalid execute context.) -- 1 : 127 ok digital interface ...

Page 99

B-8 command set mn1276 system variables general variables: command description units range default e 2 / par. Set drv.Life drive life time. Hrs unsign.Word e / -- sys.Stts queries system status as a double word, where word high word is drive address (set by dip switches) low word: bit array “or”ed w...

Page 100

Command set b-9 mn1276 x1 possible faults -- continued x1 fault display description 12 “fault_relay” when fault relay is closed. Displays ’9’. 13 “eaf” n.I 14 “missing int” n.I 15 “power_id” drv.Id != sys.Power. Displays small ’u’. 16 “cw_ccw” both limit switches are on. Displays ’l’. 17 “design_fai...

Page 101

B-10 command set mn1276 queries of system variables, status, faults single values: command description units range default e 2 / par. Set actu cur.Actu query for actual current u 0.01 a -- / -- actv cur.Actv query for actual current v 0.01 a -- / -- anain sys.Anain query for analog input mv -- / -- ...

Page 102

Command set b-11 mn1276 memory related methods (queries / modifications): ram related: command description parameter range bdump gets hexadecimal memory dump in bytes memory address unsign.Int. Bmemh query / update memory byte in hex memory address unsign.Int. Bmemd query / update memory byte in dec...

Page 103

B-12 command set mn1276 sys.Mod 0: current mode parameters: command description units range default e 2 / par. Set cur.Bemf back emf voltage compensation, in percentage of nominal motor value ke. % 80 : 120 100 e / p cur.Ipeak queries / updates application peak current in percentage of drv.Ipeak % 0...

Page 104

Command set b-13 mn1276 sys.Mod 1 & sys.Mod 3 velocity mode parameters: command description units range default e 2 / par. Set vel.Acc queries /updates velocity acceleration limits ( time to max. Velocity ). Rpm/ms 0 : 7500 e / p vel.Adzon queries / updates min. Velocity in rpm rpm 0 : max_rpm e / p...

Page 105

B-14 command set mn1276 jog parameters: command description units range default e 2 / par. Set jog.Time jog time in milliseconds ms 3432448 e / -- jog.Type 0 -- continuos, 1 -- step, 2 -- square wave -- 0 : 2 e / -- jog.Vel jog velocity in rpm, limited to maximum velocity vel.Mxrpm. Vel.Mxrpm e / --...

Page 106

Command set b-15 mn1276 position controller position controller parameters: command description units range default e 2 / par. Set pos.Ffa queries/updates acceleration ff factor unsigned integer ranged 0..100 -- 25 : 100 e / p pos.Fftype queries / updates ff type with position controller redesign 0 ...

Page 107

B-16 command set mn1276 sys.Mod 2: pulse follower (handwheel respectively pulse/direction) parameters: command description units range default e 2 / par. Set hw.Grfx queries/updates mantissa hw gear parameter, negative value means negative gear. --32767 : 32767 e / p hw.Grsh queries/updates shift hw...

Page 108

Command set b-17 mn1276 4.4.3sys.Mod 3: ptp mode parameters: command description units range default e 2 / par. Set mot.Acc motion acceleration and deceleration rpm / 10ms 1 : 65535 23 e / p mot.Buf with parameters [line] [position] [velocity] [acceleration], the motion buffer is initialized line by...

Page 109

B-18 command set mn1276 homing parameters: command description units range default e 2 / par. Set hom.Acc queries / updates home acceleration rpm / 10ms 1 : 65535 e / p2 hom.Vel queries / updates homing velocity rpm --2500 : 2500 e / p2 hom.Type queries / updates home type: 1 -- zero is found by hom...

Page 110

Baldor electric company p.O. Box 2400 ft. Smith, ar 72902--2400 (479) 646--4711 fax (479) 648--5792 www.Baldor.Com ! Baldor electric company mn1276 printed in uk 2/03 ch tel: +41 52 647 4700 fax:+41 52 659 2394 d tel: +49 89 90 50 80 fax:+49 89 90 50 8491 uk tel: +44 1454 850000 fax:+44 1454 850001 ...