- DL manuals

- Baldor

- Inverter

- GLC10

- Installation & Operating Manual

Baldor GLC10 Installation & Operating Manual

Summary of GLC10

Page 1

Glc generator (gaseous liquid cooled) glc10, 15, 20, 25 30, 40, 45, 60, 65, 100 and 105 installation & operating manual 2/08 mn2408.

Page 2

Any trademarks used in this manual are the property of their respective owners. Warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. Warning: california proposition...

Page 3

Table of contents table of contents i mn2408 section 1 product safety information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety notice 1-1 . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Ii table of contents mn2408 section 4 operation 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Digital engine controller description 4-1 . . . . . . . . . . . . . ...

Page 5

Section 1 product safety information product safety information 1‐1 mn2408 safety notice be sure that you are completely familiar with the safe operation of this equipment. This equipment may be connected to other machines that have rotating parts or parts that are controlled by this equipment. Impr...

Page 6

1‐2 product safety information mn2408 this symbol is shown throughout the manual to indicate a connection to ground reference point. Symbols indicates a potentially hazardous situation which, if not avoided, could result in injury or death. Indicates a potentially hazardous situation which, if not a...

Page 7

Product safety information 1‐3 mn2408 operation warning statements continued warning: never connect or disconnect loads during operation. Always connect load circuits before starting the engine and use external branch disconnects etc. To switch loads on/off. Warning: be sure that you understand how ...

Page 8

1‐4 product safety information mn2408 warning statements continued installation warning: installation and servicing of batteries is to be performed or supervised by personnel knowledgeable of batteries and the required precautions. Keep unauthorized personnel away from batteries. Warning: disconnect...

Page 9

Product safety information 1‐5 mn2408 warning statements continued battery safety warning: installation and servicing of batteries is to be performed or supervised by personnel knowledgeable of batteries and the required precautions. Keep unauthorized personnel away from batteries. Warning: do not d...

Page 10

1‐6 product safety information mn2408 warning statements continued maintenance warning: before cleaning, inspecting, repairing or performing any maintenance to the generator set, always be sure the engine has stopped and that all rotating parts have also stopped. After stopping, certain components a...

Page 11

Section 2 general information general information 2‐1 mn2408 thank you for purchasing your baldor generator set. This manual contains information you need to safely and efficiently install and operate your generator set. During the preparation of this manual every effort was made to ensure the accur...

Page 12

2‐2 general information mn2408.

Page 13

General information 2‐3 mn2408 important be sure you are completely familiar with all safety instructions detailed in section 1 of this manual. Do not proceed if you are unsure of any detail. Contact your baldor distributor, they are experienced and are happy to assist you and to answer your questio...

Page 14

2‐4 general information mn2408 room location often a separate building located on the site away from the main building is the most simple and cost effective. Major considerations when housing the genset in a separate building are: s maintain the building at a satisfactory temperature year round (to ...

Page 15

General information 2‐5 mn2408 foundation design warning: an open bottom stationary engine generator set must be installed over noncombustible materials and shall be located such that it prevents combustible materials from accumulating under the generator set. Foundation checklist a. Evaluate if a s...

Page 16

2‐6 general information mn2408 s steel spring isolators are a very effective and commonly used. Steel spring isolators are typically 95-98% efficient (reduces the transmitted vibration 95-98%) while a pad type can be 75-88% efficient. Spring isolators also level the genset sub-base in the event the ...

Page 17

General information 2‐7 mn2408 designing an isolated foundation if the genset cannot be mounted directly on a floor slab, or if it is desirable to isolate it from the floor slab, then a separate foundation slab must be designed. A massive concrete foundation is not required. Outside dimensions of th...

Page 18

2‐8 general information mn2408 table 2‐1 approximate load bearing capacities of various soil types soil type safe bearing capacity lb per ft 2 kilo pascals hard rock - granite etc. 50,000 - 200,000 2,395 - 9,576 medium rock - shale etc. 20,000 - 30,000 958 - 1,436 hardpan 16,000 - 20,000 766 - 958 s...

Page 19

General information 2‐9 mn2408 exhaust system exhaust checklist a. Exhaust outlets are not located upwind or near any building air intakes. B. Flexible piping section is used at engine exhaust outlet. C. Exhaust piping material is adequate for expected service. D. Exhaust piping sizing is adequate t...

Page 20

2‐10 general information mn2408 figure 2‐6 exhaust system calculations exhaust piping caution: the weight of the exhaust system must never be imposed on the turbo-charger outlet. Damage to the turbo-charger and other components may result. An exhaust system must withstand the vibration and thermal e...

Page 21

General information 2‐11 mn2408 transfer switch transfer switch checklist a. Locate transfer switch in a clean, dry place, near the emergency load. B. Provide a circuit breaker between the genset and the transfer switch. C. Put a flexible connection between the conduit and genset. D. Observe applica...

Page 22

2‐12 general information mn2408 6. Conduit, wire, circuit protective device sizes, insulation etc. Must conform to applicable local and national codes and regulations. 7. Be certain to seal around conduits that penetrate the walls of the genset room to reduce the amount of noise that is transmitted ...

Page 23

General information 2‐13 mn2408 battery charger an engine mounted alternator charges the batteries during engine operation. Standby gensets should include a solid state battery charger that is connected to utility power so the battery is charged continuously while the genset is not running. The batt...

Page 24

2‐14 general information mn2408.

Page 25

Section 3 receiving & installation receiving & installation 3‐1 mn2408 receiving & inspection when you receive your generator, there are several things you should do immediately. 1. Observe the condition of the shipping container and report any damage immediately to the commercial carrier that deliv...

Page 26

3‐2 receiving & installation mn2408 warning: an open bottom stationary engine generator set must be installed over noncombustible materials and shall be located such that it prevents combustible materials from accumulating under the generator set. Several other factors should be carefully evaluated ...

Page 27

Receiving & installation 3‐3 mn2408 secure the generator six (eight for the glc125) mounting bolts in the base frame secure the generator to the shipping pallet. Remove these bolts, lift the generator and remove the shipping pallet. Secure the generator to the concrete pad using 3 / 8 ″ anchor hardw...

Page 28

3‐4 receiving & installation mn2408 hot exhaust gasses warning: exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never breath exhaust fumes produced by a running engine. Only run the engine outdoors where ventilation is plentiful. Exhaust gases contain carbon monoxi...

Page 29

Receiving & installation 3‐5 mn2408 8. As much of the exhaust piping as possible should be located near the power ventilation exhaust. This will reduce the radiant exhaust heat inside the building. 9. Keep all fuel and its associated piping away from all components of the engine exhaust system. 10. ...

Page 30

3‐6 receiving & installation mn2408 installation the generator is completely assembled, tested and adjusted at the factory before it is shipped to you. The procedures presented in this manual are suggestions and it is the responsibility of the owner/operator to arrange for these procedures to be per...

Page 31

Receiving & installation 3‐7 mn2408 example: determining pipe size for natural gas a generator has a 16hp engine 60 feet from the supply. Determine the supply pipe size for natural gas fuel. 16 x 10,000 = 160,000 btu's / per hour for proper operation. 160, 000 1, 096 + 146cubicfeetperhour. From tabl...

Page 32

3‐8 receiving & installation mn2408 example: determining pipe size for lpv a generator has a 16hp engine 60 feet from the supply. Determine the supply pipe size for natural gas fuel. 16 x 10,000 = 160,000 btu's / per hour for proper operation. 160, 000 2, 516 + 63.5cubicfeetperhour. From table 3‐6, ...

Page 33

Receiving & installation 3‐9 mn2408 electrical connections class 1 wiring methods must be used for field wiring connections to terminals of a class 2 circuit. It is the responsibility of the owner/operator to arrange for these procedures to be performed by a licensed electrical contractor and ensure...

Page 34

3‐10 receiving & installation mn2408 transfer switch considerations the following are general considerations for the safe use of a transfer switch: 1. The transfer switch should be located inside the building near the main breaker box or the disconnect box. 2. The transfer switch must be kept away f...

Page 35

Receiving & installation 3‐11 mn2408 figure 3‐5 single phase connections from alternator (factory wired) ac power connections neutral connections ground connections load neutral ground customer connections bond jumper l1 l2 note: remove the bonding jumper to meet local codes if required. Figure 3‐6 ...

Page 36

3‐12 receiving & installation mn2408 battery charger considerations 1. Mount the battery charger on the generator or as close to the generator as possible. 2. If you mount the battery charger inside the building, mount it near the main breaker box or disconnect box. 3. If you mount the battery charg...

Page 37

Receiving & installation 3‐13 mn2408 battery connections the generator may be shipped with no battery installed. Procedure: the correct type battery must be installed in the battery compartment provided, see table 3‐7. Installation and servicing of batteries is to be performed or supervised by perso...

Page 38

3‐14 receiving & installation mn2408 post installation checks when the initial installation is complete, these checks must be performed before starting the engine. These checks are not required before each start, only after the initial installation. 1. Generators that have been in transit or storage...

Page 39

Receiving & installation 3‐15 mn2408 post installation checks continued 22. With the engine running, several checks must be made: a. Verify there are no fuel leaks. If a fuel leak is detected, stop the engine immediately (move the master control switch to the “stop” position) and repair the leak bef...

Page 40

3‐16 receiving & installation mn2408.

Page 41

Section 4 operation operation 4‐1 mn2408 digital engine controller description em0046a21 (mrs17) figure 4‐8 operator control panel stop manual run display menu group led indicators operating modes and horn & fault reset note: the operator control panel is equyipped with a heater element that allows ...

Page 42

4‐2 operation mn2408 digital engine controller description em0046a21 (mrs17) continued operating mode press mode or to scroll though the list of operating modes: off, manual and automatic. The control mode is shown in the highlighted area at the top of the display, figure 4‐9. When the desired contr...

Page 43

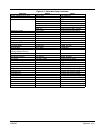

Operation 4‐3 mn2408 digital engine controller description em0046a21 (mrs17) continued table 4‐9 manual mode sequence description menu status condition of transition action next state main measurement ready start request prestart on, prestart time counter started prestart rpm > 2 or oil pressure det...

Page 44

4‐4 operation mn2408 alarms following alarms are available: sensor fail (fls) see table 4‐10 sensor fail is detected when measured value is 6% out of selected sensor characteristic. Sensor fail is indicated by ##### symbol instead measured value. Warning (wrn) see table 4‐10 when warning comes up, o...

Page 45

Operation 4‐5 mn2408 inputs and outputs any binary input or output can be configured to any controller terminal inputs are bi1 - bi6, outputs are bo1 - bo6) or changed to different function by liteedit software. There is fixed 1 sec delay when any binary input is configured as protection. Table 4‐11...

Page 46

4‐6 operation mn2408 analog inputs three analog inputs for resistive sensor 0 to 2400 ohms measuring are available on il controller. Use liteedit software to modify configuration. The analog inputs values assignment (ai1 = oil press, ai2 = water temp, ai3 = fuel level) is fix. It is possible to conf...

Page 47

Operation 4‐7 mn2408 table 4‐15 engine setpoints start rpm “firing” speed when il controller stops cranking (starter goes off). Step: 1% of nominal rpm; range: 5 - 50 % starting poil when reached controller stops cranking (starter goes off). Step: 0,1 psi; range: -100 - 10000 note: there are three c...

Page 48

4‐8 operation mn2408 table 4‐15 engine setpoints continued cooling time runtime of the unloaded gen-set to cool the engine before stop. Step: 1s; range: 0 - 3600 s aftercooltime runtime of engine after cooling pump. Binary output cooling pump is closed when the engine starts and opens aftercool time...

Page 49

Operation 4‐9 mn2408 table 4‐17 generator protect setpoints overload threshold for generator overload (in % of nominal power) step: 1% of nominal power; range: 0 - 200% overload wrn threshold for generator overload warning (in % of nominal power) step: 1% of nominal power; range: 0 - 200% overload d...

Page 50

4‐10 operation mn2408 table 4‐18 sensor spec setpoints calibr ai1,ai2, ai3 calibrating constant to adjust the measured value of il analog inputs. Physical dimension of calibrating constant is corresponding to analog input. Step: 1; range: -1000 to +1000 anout-kw/20ma conversion coefficient from gen-...

Page 51

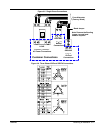

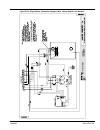

Operation 4‐11 mn2408 digital engine controller description em0046a21 (mrs17) continued figure 4‐11 controller connection diagram oil pressure w a ter temp fuellevel rpm load e m e rge ncy s t op r e m o te sstar t/sto p di ese l /gasengin e start er battery - + fu el so len o id generator binaryout...

Page 52

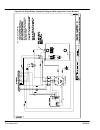

4‐12 operation mn2408 digital engine controller description em0046a21 (mrs17) continued figure 4‐12 controller connection diagram load e m e rge ncy s t o p r e m o te s star t/sto p di ese l /gasengin e start er battery - + fu el so len o id generator g binaryoutputs starter l1 l2 l3 n prestart pe ...

Page 53

Operation 4‐13 mn2408 operator control panel (microprocessor engine controller only) the operator control panel is shown in figure 4‐13. Warning: never connect this generator to any buildings electrical system unless a licensed electrician has installed an approved transfer switch. The national elec...

Page 54

4‐14 operation mn2408 operator control panel continued auto switch - when pushed, initiates automatic operation of the engine (generator set). Starting and stopping of the engine is controlled by a remote contact (transfer switch). When the remote start signal is removed the engine will continue to ...

Page 55

Operation 4‐15 mn2408 5. When the cool down time delay period expires (typically 5 minutes), the controllers run output will be immediately terminated which will initiate the engine to stop. Automatic fault shutdown when a fault circuit is programmed as a shutdown, the engine will immediately stop w...

Page 56

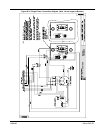

4‐16 operation mn2408 when the controller is applied in an auto mains failure (amf) application with a transfer switch, it must be wired as shown in figure 4‐14. Programmable output #3 must be selected for utility ready to load and programmable output #4 must be selected for gen ready to load. After...

Page 57

Operation 4‐17 mn2408 no load test to allow a timed no load test of the engine/generator set while using the amf control application, a digital input contact from an external timer must be programmed for no load test the sequence of operation for a no load test condition is as follows: 1. With the u...

Page 58

4‐18 operation mn2408 figure 4‐15 engine controller inputs & outputs.

Page 59

Operation 4‐19 mn2408 analog faults eight analog fault inputs are user programmable for 12 fault conditions. Each analog fault input requires a specific analog signal type. Fault name fault action inputs signal low engine temperature alarm engine temperature high engine temperature #1 alarm engine t...

Page 60

4‐20 operation mn2408 output contacts all output contacts are non-powered (i.E. Dry contacts) and are rated 10a/240vac, 8a/28vdc resistive (3a inductive, 0.4pf). Output contacts are not fused therefore external overcurrent protection (maximum 10a) is required for all control circuits using these con...

Page 61

Operation 4‐21 mn2408 display modes the controller is in the display mode at all times except when in the programming mode. The display screens and menus may be selected by pressing the enter or exit keys to access operating status display, fault display, timer countdown, generator ac metering or pr...

Page 62

4‐22 operation mn2408 timer countdown timer countdown menus are automatically displayed when a specific time delay function occurs during a control sequence. When a time delay begins, the lcd display will show the time delay function name (i.E. Engine start delay) and the current time remaining in t...

Page 63

Operation 4‐23 mn2408 generator ac metering the controller is in the display mode at all times except when in the programming mode. The display screens and menus may be selected by pressing the enter or exit keys to access operating status display, fault display, timer countdown, generator ac meteri...

Page 64

4‐24 operation mn2408 engine parameter display two engine operating parameter screens are provided. Battery voltage/engine speed (tachometer) battery speed 27.0 vdc 1800 rpm battery displays battery voltage in dc volts. The voltage is displayed with a resolution of 1/10 of a volt. Speed displays eng...

Page 65

Operation 4‐25 mn2408 navigation hints programming parameters are displayed in the same order as the programming sheets (see figures 4‐17 to 4‐20). To skip over parameters that do not require changes, push and hold the enter push-button until the desired parameter is displayed. The exit push-button ...

Page 66

4‐26 operation mn2408 main menu loop continued loss of speed signal select the desired action (i.E. Alarm or shutdown) when a loss of speed signal is detected during operation. Note: a loss of speed signal must be detected for longer than 2 seconds to initiate the desired action. Common fail for “no...

Page 67

Operation 4‐27 mn2408 digital fault menu loop the controller's digital fault settings are described as follows: caution: the digital fault label selection must agree with the external control wiring prior to energizing the controller. Failure to do so may cause severe equipment damage. Digital fault...

Page 68

4‐28 operation mn2408 span calibration energize the generator supply voltage to the controller at nominal level. Note: it may be necessary to program the optional under and over voltage shutdowns as alarms to ensure the generator will continue to operate during calibration. Caution must be taken to ...

Page 69

Operation 4‐29 mn2408 engine temperature & oil pressure calibration to accurately calibrate the controller's temperature sensor, an external temporary engine mounted temperature gauge is required. The external temperature gauge should be connected as close as possible to the temperature sender. To a...

Page 70

4‐30 operation mn2408 figure 4‐16 configuration data sheet j j j j j j j j j.

Page 71

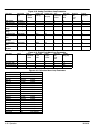

Operation 4‐31 mn2408 figure 4‐17 main menu loop parameters parameter setting range system voltage (line to line) xxxxx vac 120-15000v ac system frequency 50hz/60hz toggle between 50/60 hz system phases 1 phase/3 phase toggle between 1 & 3 phase neutral connected toggle between yes/no voltage sensin...

Page 72

4‐32 operation mn2408 figure 4‐18 analog fault menu loop parameters fault name input analog type fault e=enable d=disable setpoint level (pick-up) setpoint level (drop-out) action s=shutdown a=alarm alarm latch y=yes n=no bypass on start y=yes n=no transient delay (sec) under voltage ac voltage e* s...

Page 73

Operation 4‐33 mn2408 figure 4‐21 engine control connections 1 2 3 4 5 6 7 8 9 10 11 12 17 16 15 14 13 38 37 grd cr mp2 mp1 19 18 24 23 b - b + + - crank run 25 26 27 28 29 30 31 32 33 34 24 35 36 22 21 20 programmable contact #4 programmable contact #3 programmable contact #2 programmable contact #...

Page 74

4‐34 operation mn2408.

Page 75

Section 5 troubleshooting and maintenance troubleshooting and maintenance 5‐1 mn2408 maintenance this manual contains only very minimal engine maintenance instructions. Refer to the engine manufacturer's owner's manual for specific engine maintenance instructions for your generator set. Any maintena...

Page 76

5‐2 troubleshooting and maintenance mn2408 problems and solutions some of the more common problems are listed in table 5‐1. This information is intended to be a check or verification that simple causes can be located and fixed. It is not an exhaustive “how to” for all types of problems. Procedures t...

Page 77

Troubleshooting and maintenance 5‐3 mn2408 table 5‐2 troubleshooting guide (digital controller only) problem possible cause remedy controller does not power up even with correct dc power applied wiring mistake overload condition check that there are no wiring errors/short circuits connected to the c...

Page 78

5‐4 troubleshooting and maintenance mn2408 note: see engine controller manual for additional information. Table 5‐3 troubleshooting guide (analog controller only) problem possible cause remedy controller cannot be “reset” engine not stopped controller not in off mode verify the engine is at a comple...

Page 79

Appendix a options & accessories options & accessories a‐1 mn2408 battery charger btcgr6 battery charger - 12 volt / 6 amp float. Includes 6 ft power cord with grounding plug for ac input power and 4 ft power cord with ring terminals for dc output. Ul listed. Btcgr10a battery charger - 12 volt /10 a...

Page 80

A‐2 series glc mn2408 battery heaters battery heater (bthtr81) - 120 volt / 80 watt. Includes 6 ft power cord. Installation considerations: shore power must be available (120vac or 240vac) to power the battery heater and other components that may be installed). Shore power outlets or wiring must be ...

Page 81

Options & accessories a‐3 mn2408 engine block heater installation considerations: shore power must be available (120vac or 240vac) to power the block heater and other components that may be installed). Shore power outlets or wiring must be located close to block heater. Figure a‐3 catalog # g10a blo...

Page 82

A‐4 series glc mn2408 silencers refer to enclosure procedure to install silencer when enclosure is present. Industrial silencer for open skid mount units - provides silenced exhaust for up to 11 dba sound attenuation. Kit includes engine adapters, flex pipe, clamps, silencer, and rain cap. Critical ...

Page 83

Options & accessories a‐5 mn2408 fuel strainers & fuel lines a fuel strainer and flexible fule line can be installed at the fuel pressure regulator to make connection to the fuel main shutoff valve easier. Either 1-1/4” or 2” fittings may be specified. Figure a‐5 fuel strainer and flex fuel line con...

Page 84

A‐6 series glc mn2408 e-stop e-stop switch kit - mounts to baldor supplied enclosure to provide easy access to shut down engine with the press of a button. Connects to remote run terminals on genset. Must be adapted for remote mounting when used with open skid mount units. Figure a‐6 1 3 installatio...

Page 85

Options & accessories a‐7 mn2408 remote annuciators remote annunciator - for use with mec2 controller. Provides remote anunciation of faults and generator status. Up to 20 individual fault conditions are remotely monitored utilizing both visual led lights & audible alarm annunciation. Lamp test and ...

Page 86

A‐8 series glc mn2408 radiator duct flange radiator duct flange for open skid mount - provides easy connection to air ducting to carry away hot air from engine radiator. Duct flange mounts to front of engine radiator. Add 3” to length. Figure a‐9 table a‐1 mounting dimensions generator a b c glc10-2...

Page 87

Options & accessories a‐9 mn2408 enclosures weather resistant enclosure - heavy-duty 12 gauge hot rolled steel with welded corners and baked powder coat finish. Fasteners are zinc chromate plated and the locking latches are chrome plated on the lift off access doors. Silencer is mounted on top of re...

Page 88

A‐10 series glc mn2408.

Page 89

Appendix b series glc information & wiring diagrams series glc b‐1 mn2408 glc circuit breaker & electrical data circuit breaker size qty per phase min wire gauge osh plant ampacity @125c 15 1 #16 1 - #8 epdm per phase 90 20 1 #16 1 - #8 epdm per phase 90 30 1 #14 1 - #8 epdm per phase 90 40 1 #12 1 ...

Page 90

B‐2 series glc mn2408 figure b‐11 customer interface connection diagram mec20 mec2.

Page 91

Series glc b‐3 mn2408 figure b‐12 customer interface (w/o breaker) power connection diagram.

Page 92

B‐4 series glc mn2408 figure b‐13 single phase - (w/o breaker) connection diagram.

Page 93

Series glc b‐5 mn2408 figure b‐14 single phase - one breaker connection diagram.

Page 94

B‐6 series glc mn2408 figure b‐15 single phase - two breaker connection diagram.

Page 95

Series glc b‐7 mn2408 figure b‐16 single phase connection diagram (wire 1/0 and larger w/breaker).

Page 96

B‐8 series glc mn2408 figure b‐17 single phase connection diagram (wire 1/0 and smaller w/breaker).

Page 97

Series glc b‐9 mn2408 figure b‐18 single phase connection diagram (wire 1/0 and smaller w/o breaker).

Page 98

B‐10 series glc mn2408 figure b‐19 single phase connection diagram (wire larger than 1/0 w/o breaker).

Page 99

Series glc b‐11 mn2408 figure b‐20 three phase connection diagram.

Page 100

B‐12 series glc mn2408 figure b‐21 three phase connection diagram with pmg.

Page 101

Series glc b‐13 mn2408 figure b‐22 three phase connection diagram (wire 1/0 and larger).

Page 102

B‐14 series glc mn2408 figure b‐23 three phase connection diagram (wire larger than 1/0 w/breaker).

Page 103

Series glc b‐15 mn2408 figure b‐24 three phase connection diagram (wire 1/0 and smaller w/breaker).

Page 104

B‐16 series glc mn2408 figure b‐25 three phase connection diagram (wire larger than 1/0 w/o breaker).

Page 105

Series glc b‐17 mn2408 figure b‐26 three phase connection diagram (wire 1/0 and smaller w/o breaker).

Page 106

B‐18 series glc mn2408 figure b‐27 control box connections with mec20 controller.

Page 107

Series glc b‐19 mn2408 figure b‐28 control box connections with mec20 controller & governor.

Page 108

B‐20 series glc mn2408 figure b‐29 control box connections with mec2 controller.

Page 109

Series glc b‐21 mn2408 figure b‐30 engine wiring, woodward 4.3l gm.

Page 110

B‐22 series glc mn2408 figure b‐31 engine wiring, woodward 5.7l gm.

Page 111

Series glc b‐23 mn2408 figure b‐32 engine wiring, woodward 8.1l gm.

Page 112

B‐24 series glc mn2408.

Page 113

Baldor district offices.

Page 114

© baldor electric company mn2408 all rights reserved. Printed in usa 2/08 warning: california proposition 65 warning: engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. Warning: california proposition 65 wa...