- DL manuals

- Baldor

- Controller

- MDH1A05TB-RC23

- Installation manual

Baldor MDH1A05TB-RC23 Installation manual

Summary of MDH1A05TB-RC23

Page 1

Mintdrive ii servo & position control servo drive installation manual 01/07 mn1901.

Page 3

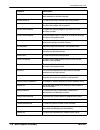

Contents i mn1901 contents 1 general information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 introduction 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 mintdrive ii features 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Ii contents mn1901 3.8 drive enable 3-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.8.1 drive enable - x3 3-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.8.2 drive enable - sw1 dip switch 3-32 . . . . . ....

Page 5

Contents iii mn1901 5.2.3 commissioning wizard 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2.4 using the commissioning wizard 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2.5 completing the commissioning wizard 5-7 . . . . . . ...

Page 6

Iv contents mn1901 8.1.11 relay / general purpose output (x3) 8-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1.12 serial rs232 interface (x6) 8-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1.13 serial rs485 interface (x6) 8-9 . . . . . . . . . ...

Page 7

Www.Baldormotion.Com general information 1-1 mn1901 lt0159a03 copyright baldor (c) 2006. All rights reserved. This manual is copyrighted and all rights are reserved. This document or attached software may not, in whole or in part, be copied or reproduced in any form without the prior written consent...

Page 8: Product Notice

Www.Baldormotion.Com 1-2 general information mn1901 product notice only qualified personnel should attempt the start-up procedure or troubleshoot this equipment. This equipment may be connected to other machines that have rotating parts or parts that are controlled by this equipment. Improper use ca...

Page 9

Www.Baldormotion.Com general information 1-3 mn1901 warning: be sure all wiring complies with the national electrical code and all regional and local codes. Improper wiring may result in unsafe conditions. Warning: the stop input to this equipment should not be used as the single means of achieving ...

Page 10

Www.Baldormotion.Com 1-4 general information mn1901 caution: avoid locating the drive in the vicinity of corrosive substances or vapors, metal particles and dust. Caution: do not connect ac power to the drive terminals u, v and w. Connecting ac power to these terminals may result in damage to the dr...

Page 11: 2.1 Mintdrive

Www.Baldormotion.Com introduction 2-1 mn1901 2.1 mintdrive ii features the mintdrive ii combines a powerful fully featured motion controller and brushless servo control into a compact package. This provides a flexible and powerful motion control solution for single axis rotary and linear positioning...

Page 12

Www.Baldormotion.Com 2-2 introduction mn1901 2.2 receiving and inspection when you receive your mintdrive ii , there are several things you should do immediately: 1. Check the condition of the shipping container and report any damage immediately to the carrier that delivered your mintdrive ii . 2. R...

Page 13

Www.Baldormotion.Com introduction 2-3 mn1901 2.3 units and abbreviations the following units and abbreviations are used in this manual: v volt (also vac and vdc) . . . . . . . . . . . . . . . W watt . . . . . . . . . . . . . . A ampere . . . . . . . . . . . . . . . Ω ohm . . . . . . . . . . . . . . ...

Page 14

Www.Baldormotion.Com 2-4 introduction mn1901.

Page 15: 3.1 Introduction

Www.Baldormotion.Com basic installation 3-1 mn1901 3.1 introduction you should read all the sections in basic installation to ensure safe installation. This section describes the mechanical and electrical installation of the mintdrive ii in the following stages: h location considerations h mounting ...

Page 16

Www.Baldormotion.Com 3-2 basic installation mn1901 h a serial cable. Note: the serial connector on the mintdrive ii (connector x6) can be configured as either rs232 or rs485 / rs422. Pin 9 is used to carry +8v for powering some baldor keypad peripherals. Ensure that pin 9 is not connected to earth/g...

Page 17

Www.Baldormotion.Com basic installation 3-3 mn1901 3.1.5 other information needed for installation this information is useful (but not essential) to complete the installation: h the data sheet or manual provided with your motor, describing the wiring information of the motor cables/connectors h know...

Page 18

Www.Baldormotion.Com 3-4 basic installation mn1901 3.2 mechanical installation and location requirements it is essential that you read and understand this section before beginning the installation. Caution: to prevent equipment damage, be certain that the input power has correctly rated protective d...

Page 19

Www.Baldormotion.Com basic installation 3-5 mn1901 h for effective cooling and maintenance, the mintdrive ii should be mounted on a smooth, non-flammable vertical surface. The power handling capability is affected by the temperature of the left side of the unit. H at least 50mm (2 in) top and bottom...

Page 20

Www.Baldormotion.Com 3-6 basic installation mn1901 3.2.2 dimensions h 1 h 2 h w d w 2 w 1 w 3 package size h only. W 4 package sizes e, g & h only: w 4 =9.5mm. All other sizes: w 4 = w 2 h 3 h 4 65mm front panel h 5 h 6 mounting keyhole and slot detail a b c a 5mm (package sizes e, g and h: 6.5mm) b...

Page 21: 3.3 Connector Locations

Www.Baldormotion.Com basic installation 3-7 mn1901 3.3 connector locations earth nc (nc) l ac line n ac neutral u motor u v motor v w motor w r1 regen resistor r2 (dynamic brake) - (nc) +24v customer 0v supplied 24v (mdhxxxxxx-xxx3 only) earth earth l1 ac phase 1 l2 ac phase 2 l3 ac phase 3 u motor ...

Page 22: 3.4 Power Connections

Www.Baldormotion.Com 3-8 basic installation mn1901 3.4 power connections this section provides instructions for connecting the ac power supply. It is important that you refer to the correct front panel for your mintdrive ii package. The installer of this equipment is responsible for complying with n...

Page 23

Www.Baldormotion.Com basic installation 3-9 mn1901 3.4.1 single-phase connection to package sizes a, b, c, d location connector x1 (mating connector: phoenix combicon mvstbw 2,5/9-st, 5mm pitch) part number mdh1a... Mdh2a... Nominal input voltage 115vac, 1Φ line to neutral (u.S. Single phase supply)...

Page 24

Www.Baldormotion.Com 3-10 basic installation mn1901 3.4.2 three-phase connection to package sizes e, g, h location connector x1a (mating connector: phoenix power combicon pc4/..-st- 7.62) part number mdh2a15... Mdh4a... Nominal input voltage 230vac, 3Φ line to line 230-460vac, 3Φ line to line range ...

Page 25

Www.Baldormotion.Com basic installation 3-11 mn1901 3.4.3 input power conditioning baldor drives are designed for direct connection to standard single and three-phase lines (depending on model) that are electrically symmetrical with respect to earth/ground. Certain power line conditions must be avoi...

Page 26

Www.Baldormotion.Com 3-12 basic installation mn1901 note: power to single phase models may be derived by connecting two phases of an appropriate three-phase supply (l1 and l2 for example). When supplying ac power in this way, the voltage between the two phases must not exceed the rated input voltage...

Page 27

Www.Baldormotion.Com basic installation 3-13 mn1901 3.4.6 wire sizes and protection device ratings table 2 describes the wire size to be used for power connections and the ratings of the protection devices. Incoming power c t l n b nominal input continuous output d-type input time delay minimum cata...

Page 28

Www.Baldormotion.Com 3-14 basic installation mn1901 3.4.7 external customer supplied 24v control supply depending on model (catalog numbers mdhxxxxx-xxx3) a 24vdc control supply must be provided to power the control electronics. This is useful for safety reasons where ac power needs to be removed fr...

Page 29: 3.5 Motor Connections

Www.Baldormotion.Com basic installation 3-15 mn1901 3.5 motor connections the motor can be connected directly to the mintdrive ii or through a motor contactor (m-contactor). Location connector x1 / x1a part number mdh1a... Mdh2a... Mdh2a15... Mdh4a... Nominal output voltage 160vdc 320vdc 320vdc 565/...

Page 30

Www.Baldormotion.Com 3-16 basic installation mn1901 3.5.1 motor circuit contactors if required by local codes or for safety reasons, an m-contactor (motor circuit contactor) may be installed to provide a physical disconnection of the motor windings from the mintdrive ii (see section 3.5). Opening th...

Page 31

Www.Baldormotion.Com basic installation 3-17 mn1901 3.5.3 motor cable pin configuration - baldor linear motors the following table shows the core colors used in a typical baldor linear motor cable set, part number ay1763a00: signal name motor cable wire color motor u black motor v red motor w white ...

Page 32

Www.Baldormotion.Com 3-18 basic installation mn1901 3.5.5 thermal switch connection you might wish to wire the motor’s thermal switch contacts (normally closed), using a relay, to a digital input on connector x3 (see section 4.3.1). Using the workbench v5 digital i/o tool, the input can be configure...

Page 33

Www.Baldormotion.Com basic installation 3-19 mn1901 3.5.6 motor brake connection you might wish to wire a motor’s brake, via relays, to digital outputs on connector x3 (see section 4.3.1). This provides a way for the mint program to control the motor’s brake. A typical circuit is shown in figure 10....

Page 34

Www.Baldormotion.Com 3-20 basic installation mn1901 3.6 regeneration resistor (dynamic brake resistor) the 2.5a and 5a mintdrive ii both have an internally fitted regeneration resistor *. For 7.5a, 15a, 20a and 27.5a mintdrive ii , an external regeneration resistor must be installed to dissipate exc...

Page 35: 3.7 Feedback Connections

Www.Baldormotion.Com basic installation 3-21 mn1901 3.7 feedback connections two feedback options are available for use with linear and rotary motors - commutating encoder or resolver. Confirm the catalog number of your mintdrive ii (see section 2.2.1) to ensure you are wiring the correct feedback d...

Page 36

Www.Baldormotion.Com 3-22 basic installation mn1901 3.7.1 resolver option - x8 the resolver connections are made using the 9-pin d-type male connector x8. Twisted pair cables must be used for the complementary signal pairs e.G. Sin+ and sin-. The overall cable shield (screen) must be connected to th...

Page 37

Www.Baldormotion.Com basic installation 3-23 mn1901 3.7.1.1 resolver cable pin configuration figure 12 shows the pin configuration for a typical baldor resolver feedback cable, part number cbl025sf-r1. Signal name mintdrive ii x8 pin motor / cable pin baldor resolver cable internal wire colors ref+ ...

Page 38

Www.Baldormotion.Com 3-24 basic installation mn1901 3.7.2 encoder option - x8 the encoder connections (abz channels and hall signals) are made using the 15-pin d-type female connector x8. Twisted pair cables must be used for the complementary signal pairs e.G. Cha+ and cha-. The overall cable shield...

Page 39

Www.Baldormotion.Com basic installation 3-25 mn1901 3.7.2.1 encoder cable pin configuration - rotary motors figure 14 shows the pin configuration for a typical baldor encoder feedback cable, part number cbl025sf-e1. Signal name mintdrive ii x8 pin motor / cable pin baldor encoder cable internal wire...

Page 40

Www.Baldormotion.Com 3-26 basic installation mn1901 3.7.2.2 encoder cable connections - linear motors cha+ cha- chb+ chb- +5v dgnd 1 6 2 7 3 8 11 x8 encoder feedback chz+ (index) chz- (index) 4 5 9 14 10 15 13 hall u+ hall u- hall w+ hall w- hall v+ hall v- 12 (nc) hall feedback connect overall shie...

Page 41

Www.Baldormotion.Com basic installation 3-27 mn1901 3.7.3 endat (absolute encoder) option - x8 the absolute encoder interface supports both incremental and absolute (multi and single turn) feedback using sincos technology. It is possible to read and write information to the encoder. The absolute enc...

Page 42

Www.Baldormotion.Com 3-28 basic installation mn1901 3.7.3.1 absolute encoder cable pin configuration figure 14 shows the pin configuration for a typical baldor absolute encoder feedback cable, part number cbl025sf-d1. Signal name mintdrive ii x8 pin motor / cable pin baldor endat cable internal wire...

Page 43

Www.Baldormotion.Com basic installation 3-29 mn1901 3.7.4 hiperface (absolute encoder) option - x8 the hiperface absolute encoder interface supports both incremental and absolute (multi and single turn) feedback using sincos technology. It is possible to read and write information to the encoder. Th...

Page 44

Www.Baldormotion.Com 3-30 basic installation mn1901 3.7.4.1 absolute encoder cable pin configuration figure 14 shows the pin configuration for a typical baldor absolute encoder feedback cable, part number cbl025sf-d1. Signal name mintdrive ii x8 pin motor / cable pin baldor hiperface cable internal ...

Page 45: 3.8 Drive Enable

Www.Baldormotion.Com basic installation 3-31 mn1901 3.8 drive enable location connector x3, pins 7 & 9 (mating connector: phoenix mini-combicon mc 1.5/20-st-3,5) name drive enable input voltage +24vdc (±20%) to enable the mintdrive ii and allow motion, three actions are necessary: h a customer suppl...

Page 46

Www.Baldormotion.Com 3-32 basic installation mn1901 3.8.2 drive enable - sw1 dip switch to enable the mintdrive ii the front panel dip switch 8 must be set to on. This switch provides a local enable/disable switch that can be useful during testing. The state of the drive enable dip switch is display...

Page 47: 3.9 Dip Switches - Sw1

Www.Baldormotion.Com basic installation 3-33 mn1901 3.9 dip switches - sw1 various functions of the mintdrive ii can be controlled by the front panel sw1 dip switches. Location switch block sw1 switch function 1 8 2 4 node number selection (serial and fieldbus networks) 3 2 node number selection (se...

Page 48

Www.Baldormotion.Com 3-34 basic installation mn1901 if switches 1-4 are all in the off position, the mint node keyword can be used to set the node number. Workbench v5 (see section 5.2) reads the mintdrive ii node number (during the scan process) and then uses it to direct commands to the mintdrive ...

Page 49

Www.Baldormotion.Com basic installation 3-35 mn1901 3.9.6 switches 9 and 10 - rs232/rs485 select switch 9 is reserved for baldor keypad selection. Switch 10 selects rs232 communications (off) or rs485/rs422 (on) the next time the mintdrive ii is power-cycled. 3.9.7 factory settings if switches 1-4 a...

Page 50

Www.Baldormotion.Com 3-36 basic installation mn1901 3.9.8 preventing a program running at startup if switches 5 and 9 are set to on and switch 8 is set to off, any program already in the mintdrive ii that contains an auto command will be prevented from running automatically at startup. On 5 reapply ...

Page 51: 4.1 Introduction

Www.Baldormotion.Com input / output 4-1 mn1901 4.1 introduction this section describes the various digital and analog input and output capabilities of the mintdrive ii , with descriptions of each of the connectors on the front panel. The following conventions will be used to refer to the inputs and ...

Page 52

Www.Baldormotion.Com 4-2 input / output mn1901 4.2.1 analog input - x3 (demand) location connector x3, pins 1-3 (mating connector: phoenix mini-combicon mc 1.5/20-st-3,5) name ain0 mint keyword adc.0 description single ended or differential input. Common mode voltage range: ±10vdc. Resolution: 14-bi...

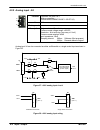

Page 53

Www.Baldormotion.Com input / output 4-3 mn1901 ain0 (adc.0) x3 ain0 (adc.0) 1 2 3 x3 ain0- differential connection single ended connection ain0+ 1 2 3 ain0+ gnd figure 25 - ain0 analog input wiring ain0 1kΩ, 0.25w potentiometer (adc.0) 2 1 x3 1.5kΩ, 0.25w 0v +24vdc 3 figure 26 - typical input circui...

Page 54

Www.Baldormotion.Com 4-4 input / output mn1901 4.2.2 analog input - x4 location connector x4, pins 2 & 3 (mating connector: phoenix mini-combicon mc 1.5/6-st-3,5) name ain1 mint keyword adc.1 description single ended or differential input. Common mode voltage range: ±10vdc. Resolution: 14-bit with s...

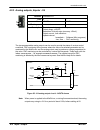

Page 55

Www.Baldormotion.Com input / output 4-5 mn1901 ain1 1kΩ, 0.25w potentiometer (adc.1) 3 2 x4 1.5kΩ, 0.25w 0v +24vdc 6 figure 29 - typical input circuit to provide 0-10v (approx.) input from a 24v source.

Page 56

Www.Baldormotion.Com 4-6 input / output mn1901 4.2.3 analog outputs, bipolar - x4 location connector x4 pins 4 5 name aout0 aout1 mint keyword auxdac.0 auxdac.1 description two independent assignable outputs. Output range: ±10vdc. Resolution: 8-bit with sign (accuracy ±78mv). Output current: 1ma max...

Page 57: 4.3 Digital I/o

Www.Baldormotion.Com input / output 4-7 mn1901 4.3 digital i/o the mintdrive ii provides as standard: * h 8 general-purpose inputs on connector block x3 h 3 general-purpose outputs on connector block x3 h 1 relay / general-purpose output on connector block x3 a digital input can be used to support m...

Page 58

Www.Baldormotion.Com 4-8 input / output mn1901 4.3.1 digital inputs - x3 location connector x3 pin name mint keyword 9 drive enable - 10 din0 inx.0 11 din1 inx.1 12 din2 inx.2 13 din3 inx.3 14 din4 inx.4 15 din5 inx.5 16 din6 inx.6 17 din7 inx.7 description eight general-purpose optically isolated a...

Page 59

Www.Baldormotion.Com input / output 4-9 mn1901 4.3.2 cref and digital inputs pin 7 (cref) controls the sense of all the digital inputs (x3 pins 9 to 17) and should be permanently wired, dependent on the user requirements: active high: connect 0v to pin 7. The digital inputs will be active when a vol...

Page 60

Www.Baldormotion.Com 4-10 input / output mn1901 capture. To prevent subsequent inputs causing the captured value to be overwritten, the interrupt is latched in software. It is necessary to clear the latch before subsequent interrupts can be detected. See the mint help file. Both inputs are fitted wi...

Page 61

Www.Baldormotion.Com input / output 4-11 mn1901 4.3.4 digital outputs - x3 location connector x3 pin name mint keyword 18 dout0 outx.0 19 dout1 outx.1 20 dout2 outx.2 description three general-purpose optically isolated digital outputs. Output current: 50ma maximum each output update interval: immed...

Page 62

Www.Baldormotion.Com 4-12 input / output mn1901 4.3.5 relay output / digital output - x3 location connector x3, pins 4 (+) & 5 (-) name general purpose relay mint keyword relay / outx.3 description relay switch contacts controlled by mint, rated at 1a, 30vdc. Update interval: immediate the factory p...

Page 63: 4.4 Other I/o

Www.Baldormotion.Com input / output 4-13 mn1901 4.4 other i/o 4.4.1 encoder output - x7 location connector x7 pin name 1 cha+ 2 chb+ 3 chz+ 4 (nc) 5 dgnd 6 cha- 7 chb- 8 chz- 9 (nc) description encoder output on a 9-pin female d-type connector this output can be used for position feedback to a host ...

Page 64

Www.Baldormotion.Com 4-14 input / output mn1901 1 6 3 8 5 2 7 1 6 3 8 5 2 7 mintdrive ii x7 nextmove bx ii encoder input connect overall shield to connector backshells. Cha+ cha- chb+ chb- chz+ chz- dgnd baldor cable parts cbl0xxmf-e3b are recommended (where xx represents a choice of available lengt...

Page 65

Www.Baldormotion.Com input / output 4-15 mn1901 4.4.2 master (auxiliary) encoder input - x9 location connector x9 pin encoder name pulse & direction name 1 cha+ pulse+ 2 chb+ direction+ 3 chz+ - 4 (nc) - 5 dgnd - 6 cha- pulse gnd 7 chb- direction gnd 8 chz- - 9 +5v out - description optically isolat...

Page 66

Www.Baldormotion.Com 4-16 input / output mn1901 cha+ cha-- chb+ chb-- +5v dgnd 1 6 2 7 3 8 9 5 x9 chz+ chz -- twisted pairs connect overall shield to connector backshells. Connect internal shields to dgnd. Master encoder figure 39 - differential encoder connections 4.4.2.1 dual encoder feedback the ...

Page 67

Www.Baldormotion.Com input / output 4-17 mn1901 4.4.3 serial port - x6 location connector x6 pin rs232 name rs485 / rs422 name 1 (nc) (nc) 2 rxd rx- (input) 3 txd tx- (output) 4 (nc) (nc) 5 0v gnd 0v dgnd 6 (nc) (nc) 7 rts tx+ (output) 8 cts rx+ (input) 9 (do not connect! See caution below) descript...

Page 68

Www.Baldormotion.Com 4-18 input / output mn1901 4.4.4 using rs232 cable caution: the serial connector on the mintdrive ii (x6) can be configured as either rs232 or rs485 / rs422. Pin 9 is used to carry +8v for powering certain baldor keypad peripherals. Ensure that pin 9 is not connected to earth/gr...

Page 69

Www.Baldormotion.Com input / output 4-19 mn1901 4.4.5 multidrop using rs485 / rs422 cable multidrop systems allow one device to act as a ‘network master’, controlling and interacting with the other (slave) devices on the network. The network master can be a controller such as a mintdrive ii , a host...

Page 70

Www.Baldormotion.Com 4-20 input / output mn1901 4.4.6 connecting baldor hmi operator panels baldor hmi operator panels use a 15-pin male d-type connector (marked plc port), but the mintdrive ii connector x6 is a 9-pin male d-type connector. If you do not require hardware handshaking then use the con...

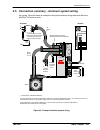

Page 71

Www.Baldormotion.Com input / output 4-21 mn1901 4.5 connection summary - minimum system wiring as a guide, figure 45 shows an example of the typical minimum wiring required to allow the mintdrive ii to control a motor. Com ii host pc ac power filter l n pe l n e motor power u v w motor feedback seri...

Page 72: 4.6 Option Connectors

Www.Baldormotion.Com 4-22 input / output mn1901 4.6 option connectors if there are additional connectors on the front panel of your mintdrive ii that have not been described in previous sections, these are part of a factory fitted option. You will need to refer to the extra manual supplied with your...

Page 73: 5.1 Introduction

Www.Baldormotion.Com operation 5-1 mn1901 5.1 introduction before powering the mintdrive ii you will need to connect it to the pc using a serial cable and install the supplied pc software workbench v5. This software includes a number of tools to allow you to configure, tune and program the mintdrive...

Page 74

Www.Baldormotion.Com 5-2 operation mn1901 5.1.3 starting the mintdrive ii if you have followed the instructions in the previous sections, you should now have connected all the power sources, your choice of inputs and outputs and the serial cable linking the pc with the mintdrive ii . 5.1.4 prelimina...

Page 75

Www.Baldormotion.Com operation 5-3 mn1901 5.1.6 offset tuning (optional) if the mintdrive ii will be using analog input 0 (ain0) as a demand reference input (or for any other purpose) you may wish to perform offset tuning before continuing. The purpose of offset tuning is to remove dc offset voltage...

Page 76: 5.2 Workbench V5

Www.Baldormotion.Com 5-4 operation mn1901 5.2 workbench v5 workbench v5 is a fully featured application for programming and controlling the mintdrive ii . The main workbench v5 window contains a menu system, the toolbox and other toolbars. Many functions can be accessed from the menu or by clicking ...

Page 77

Www.Baldormotion.Com operation 5-5 mn1901 5.2.2 starting workbench v5 1. On the windows start menu, select programs, workbench v5, workbench v5. Workbench v5 will start, and the tip of the day dialog will be displayed. You can prevent the tip of the day dialog appearing next time by removing the che...

Page 78

Www.Baldormotion.Com 5-6 operation mn1901 3. In the select controller dialog, go to the drop down box near the top and select the pc serial port to which the drive is connected. If you are unsure which pc serial port is connected to the drive, select scan all serial ports. Click scan to search for t...

Page 79

Www.Baldormotion.Com operation 5-7 mn1901 5.2.3 commissioning wizard each type of motor and drive combination has slightly different performance characteristics. Before the mintdrive ii can be used to control the motor accurately, the mintdrive ii must be “tuned”. This is the process where the mintd...

Page 80

Www.Baldormotion.Com 5-8 operation mn1901 5.2.6 performing a test move this section tests the basic operation of the drive and motor. 1. Check that the drive enable button is pressed (down). 2. In the toolbox, click the edit & debug icon. 3. Click in the command window. 4. Type: jog.0 = 10 this will...

Page 81: 5.3 Further Configuration

Www.Baldormotion.Com operation 5-9 mn1901 5.3 further configuration workbench v5 provides a number of tools, each of which has an icon on the left of the screen. Click once on an icon to select the tool. Three of the main tools used for tuning and configuring the mintdrive ii are briefly described h...

Page 82

Www.Baldormotion.Com 5-10 operation mn1901 5.3.1.2 fine-tuning - speed tab the speed tab allows you to set speed loop gains and perform test moves. The commissioning wizard may have already set some of these values, depending on the type of system selected on the mode screen. Enter new values in the...

Page 83

Www.Baldormotion.Com operation 5-11 mn1901 5.3.2 parameters tool the parameters tool can be used to setup many important parameters, such as a scaling factor for the feedback input, and the action to take when errors occur. 1. Click the parameters icon in the toolbox on the left of the screen. The m...

Page 84

Www.Baldormotion.Com 5-12 operation mn1901 5.3.3 digital i/o tool the digital i/o tool allows you to define how each digital input and output will be triggered and if it is to be assigned to a special function, for example the forward limit or stop input. 1. Click the digital i/o icon in the toolbox...

Page 85: 6.1 Introduction

Www.Baldormotion.Com preset moves & plc task 6-1 mn1901 6.1 introduction two of the important features introduced on the mintdrive ii are preset moves and the plc task. Basic operation of these two features are described in the following sections. 6 preset moves & plc task 6.

Page 86: 6.2 Preset Moves

Www.Baldormotion.Com 6-2 preset moves & plc task mn1901 6.2 preset moves the standard mintdrive ii can store 16 preset moves. If the can & auxiliary i/o option is fitted, 256 preset moves can be stored. Presets can be selected and triggered using software (workbench v5 or a mint program) or by using...

Page 87

Www.Baldormotion.Com preset moves & plc task 6-3 mn1901 6.2.2 testing a preset move for testing, workbench v5 can be used to trigger the preset moves. 1. At the bottom of the presets window, ensure that the software option is checked. This means that workbench v5 will be used to control the preset m...

Page 88

Www.Baldormotion.Com 6-4 preset moves & plc task mn1901 6.2.3.1 configuring digital inputs to control presets the default combination of digital inputs used for triggering presets is 6, 7, 0 and 1 to select the preset, and 5 to trigger the preset. However, this combination can be changed to use any ...

Page 89

Www.Baldormotion.Com preset moves & plc task 6-5 mn1901 2. At the bottom of the digital i/o window, click in the preset inputs drop down box and select the number of inputs to be used for preset selection. For example, if the application requires only four different preset moves, choose 2. This mean...

Page 90

Www.Baldormotion.Com 6-6 preset moves & plc task mn1901 6.2.4 controlling preset moves additional options are available to control the operation of preset moves. Dwell time can be used to set a delay period between the triggering of a preset move and its commencement. If the wait for idle option is ...

Page 91: 6.3 Plc Task

Www.Baldormotion.Com preset moves & plc task 6-7 mn1901 6.3 plc task the plc task is a special task that can be set up to monitor various events and act upon them if they become true. In workbench v5, the plc task tool allows you to enter conditional statements that respond to the events by performi...

Page 92

Www.Baldormotion.Com 6-8 preset moves & plc task mn1901 6.3.2 enabling and downloading the actions individual actions can be enabled by clicking in the appropriate check box in the enable column. When the plc task is activated, only those actions that have been enabled will be evaluated. 1. Set the ...

Page 93

Www.Baldormotion.Com preset moves & plc task 6-9 mn1901 6.3.3 testing the plc task there is no way to test the plc task other than causing the required conditions to occur. For example, if you have an action that is triggered by the condition digital input 0, then activating digital input 0 will cau...

Page 94

Www.Baldormotion.Com 6-10 preset moves & plc task mn1901.

Page 95: 7.1 Introduction

Www.Baldormotion.Com troubleshooting 7-1 mn1901 7.1 introduction this section explains common problems that may be encountered, together with possible solutions. 7.1.1 problem diagnosis if you have followed all the instructions in this manual in sequence, you should have few problems installing the ...

Page 96: 7.2 Mintdrive

Www.Baldormotion.Com 7-2 troubleshooting mn1901 7.2 mintdrive ii indicators 7.2.1 status display the status led display indicates general mintdrive ii status information. Some characters will flash to indicate an error. Drive / comms watchdog. Interprocessor communications failure. This is potential...

Page 97

Www.Baldormotion.Com troubleshooting 7-3 mn1901 overtemperature. The temperature of the drive or motor has exceeded a trip level (see mint keyword temperaturelimitfatal ) or the motor overtemperature trip input has been activated (see mint keyword motortemperatureinput). Drive enabled. The drive is ...

Page 98

Www.Baldormotion.Com 7-4 troubleshooting mn1901 preset jog. The drive is jogging. The jog was triggered from a preset jog table. Overspeed. The measured speed of the motor has exceeded the trip level defined by drivespeedfatal. Check that the trip level is set to a suitable value for your applicatio...

Page 99

Www.Baldormotion.Com troubleshooting 7-5 mn1901 7.2.2 db on (regeneration) led the front panel db on led indicates regeneration activity. Yellow power is being dissipated into the regeneration resistor off no regeneration is occurring. 7.2.3 communication problem check status display is blank check ...

Page 100

Www.Baldormotion.Com 7-6 troubleshooting mn1901 7.2.4 power on problem check the status display is showing a flashing symbol with a static decimal point. The mintdrive ii has detected a motion error. Use the error log tool to view a list of recent errors, or click the error button on the motion tool...

Page 101: 8.1 Introduction

Www.Baldormotion.Com specifications 8-1 mn1901 8.1 introduction this section provides technical specifications for the various mintdrive ii models. 8 specifications 8.

Page 102

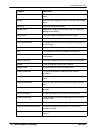

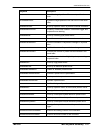

Www.Baldormotion.Com 8-2 specifications mn1901 8.1.1 ac input power and motor output - single-phase models 115vac (catalog number mdh1...) unit 2.5a 5a 7.5a nominal input voltage vac 115 minimum input voltage (recommended / absolute) 97 / 75* maximum input voltage 125 nominal input current @ maximum...

Page 103

Www.Baldormotion.Com specifications 8-3 mn1901 8.1.2 ac input power and motor output - 230v three-phase models 230vac 50/60hz (catalog number mdh2a15...) unit 15a nominal input voltage vac 230 minimum input voltage (recommended / absolute) 184 / 75* maximum input voltage 253 nominal input current @ ...

Page 104

Www.Baldormotion.Com 8-4 specifications mn1901 8.1.3 ac input power and motor output - 230-460v three-phase models 230-460vac 50/60hz (catalog number mdh4...) unit 2.5a 5a 7.5a 15a 20a 27.5a nominal input voltage vac 230-460 minimum input voltage (recommended / absolute) 180 / 75* maximum input volt...

Page 105

Www.Baldormotion.Com specifications 8-5 mn1901 8.1.4 customer supplied 24vdc supply input 24vdc (catalog number mdhxxxxx-xxx3) unit 2.5a 5a 7.5a 15a 20a 27.5a nominal input voltage vdc 24 minimum input voltage 20.4 maximum input voltage 28.8 maximum ripple % ±10 maximum continuous current @24vdc a 1...

Page 106

Www.Baldormotion.Com 8-6 specifications mn1901 230vac three-phase models (catalog number mdh2a15...) unit 15a switching threshold vdc on: 376, off: 365 nominal power (10% power cycle) kw 1.0 peak power (10% power cycle) kw 15 maximum regeneration switching current a rms 40 maximum load inductance μh...

Page 107

Www.Baldormotion.Com specifications 8-7 mn1901 8.1.7 analog input (x4) all models unit all models type differential common mode voltage range vdc ±10 common mode rejection db 40 input impedance kΩ >5 input adc resolution bits 14 (includes sign bit) equivalent resolution mv ±1.2 sampling interval sof...

Page 108

Www.Baldormotion.Com 8-8 specifications mn1901 8.1.9 digital inputs (x3) all models unit all models type opto-isolated dc inputs input voltage (active high) nominal minimum vdc 24 12 input voltage (active low) nominal maximum vdc 0 2 input current (approximate, per input) ma 5 sampling interval ms 2...

Page 109

Www.Baldormotion.Com specifications 8-9 mn1901 8.1.11 relay / general purpose output (x3) all models unit all models contacts normally closed contact rating (resistive) 1a @ 30vdc or 0.5a @ 125vac maximum carrying current a 2 maximum switching power 62.5av, 30w maximum switching voltage 250vac, 220v...

Page 110

Www.Baldormotion.Com 8-10 specifications mn1901 8.1.15 resolver feedback option (x8) catalog numbers mdhxxxxxx-rxxxx unit all models resolution set automatically by software bits 14 resolver winding ratio 0.5 mintdrive ii resolver input accuracy counts ±3 typical accuracy using baldor bsm series res...

Page 111

Www.Baldormotion.Com specifications 8-11 mn1901 8.1.18 hiperface (absolute encoder) feedback option (x8) catalog numbers mdhxxxxxx-hxxxx unit all models absolute encoder input hiperface sin/cos differential inputs and data input operating modes single or multi-turn. 512 or 1024 sin/cos cycles per tu...

Page 112

Www.Baldormotion.Com 8-12 specifications mn1901 8.1.21 environmental all models unit operating temperature range °c °f minimum maximum derate +0 +40 2.5% / °c between 40°c and 50°c (max) +32 +104 2.5% / 1.8°f between 104°f and 122°f (max) storage temperature range -25 to +70 -13 to +158 humidity % 1...

Page 113: A.1 Introduction

Www.Baldormotion.Com accessories a-1 mn1901 a.1 introduction this section describes accessories and options that you may need to use with your mintdrive ii . Shielded (screened) cables provide emi / rfi shielding and are required for compliance with ce regulations. All connectors and other component...

Page 114

Www.Baldormotion.Com a-2 accessories mn1901 a.1.2 motor power cables cable cable assembly baldor catalog length cable rated current cable assembly description baldor catalog number m ft power cable: no connectors cbl050-501 available by the meter or on 100m drum. 12 amps power cable assembly: ce sty...

Page 115

Www.Baldormotion.Com accessories a-3 mn1901 a.1.4 resolver feedback cables this table lists part numbers of baldor resolver feedback cables for use with the mintdrive ii : cable assembly description catalog number length cable assembly description catalog number m ft resolver feedback cable: no conn...

Page 116

Www.Baldormotion.Com a-4 accessories mn1901 a.1.5 encoder / hall feedback cables this table lists part numbers of baldor encoder feedback cables for use with the mintdrive ii : cable assembly description baldor catalog number length cable assembly description baldor catalog number m ft encoder feedb...

Page 117

Www.Baldormotion.Com accessories a-5 mn1901 a.1.7 feedback cable part numbers a description of a baldor feedback cable catalog number is shown here, using the example number cbl025sf-r1: meaning alternatives cbl the item is a cable - 025 indicates the length, in this example 2.5 meters various: see ...

Page 118

Www.Baldormotion.Com a-6 accessories mn1901 a.1.8 emc filters ac filters remove high frequency noise from the ac power supply, protecting the mintdrive ii . These filters also prevent high frequency signals from being transmitted back onto the power lines and help meet ce requirements. To select the...

Page 119

Www.Baldormotion.Com accessories a-7 mn1901 l k j h g f e d c b a dimensions mm (inches) dimension fi0014a00 fi0015a00 fi0015a02 a 85 (3.35) 113.5 (4.47) 156 (6.14) b 54 (2.13) 57.5 (2.26) c 40 (1.57) 46.6 (1.83) d 65 (2.56) 94 (3.70) 130.5 (5.14) e 75 (2.95) 103 (4.06) 143 (5.63) f 27 (1.06) 25 (0....

Page 120

Www.Baldormotion.Com a-8 accessories mn1901 b d a c mounting keyhole and slot detail a b c a 5.5mm b 11mm c 10mm d 5mm a d dimensions shown as: mm (inches). A c f e dimensions mm (inches) dimension fi0029a00 a 255 (10.04) b 100 (3.94) c 244.5 (9.63) d 70 (2.76) e 40 (1.57) f 20 (0.79) figure 50 - fi...

Page 121

Www.Baldormotion.Com accessories a-9 mn1901 a.1.9 regeneration resistors some mintdrive ii models (2.5a and 5a) are fitted with an internal regeneration resistor (see sections 2.2.1 and 8.1.5). Additional (external) regeneration resistors can be fitted to these models using the r1 and r2 pins of con...

Page 122

Www.Baldormotion.Com a-10 accessories mn1901.

Page 123: B.1 Introduction

Www.Baldormotion.Com control system b-1 mn1901 b.1 introduction the mintdrive ii can be configured for four basic control modes to suit the particular application. The choice of mode is defined using the commissioning wizard or the mint keyword config. See the mint help file for details. The four co...

Page 124

Www.Baldormotion.Com b-2 control system mn1901 b.1.2 positioning system without speed controller setting config to _cftorque_servo configures the mintdrive ii to act as a different type of positioning system, as shown in figure 53. Here, the speed controller is not present and the position controlle...

Page 125

Www.Baldormotion.Com control system b-3 mn1901 b.1.3 speed amplifier setting config to _cfvelocity configures the mintdrive ii as a speed amplifier, as shown in figure 54. Here, a speed reference obtained from a specified source (e.G. A mint program, the workbench v5 command window, the analog deman...

Page 126

Www.Baldormotion.Com b-4 control system mn1901 b.1.4 torque amplifier setting config to _cftorque configures the mintdrive ii as a torque amplifier, as shown in figure 55. Here, a torque reference obtained from a specified source (e.G. A mint program, the workbench v5 command window, the analog dema...

Page 127

Www.Baldormotion.Com control system b-5 mn1901 b.2 control system operation the following sections describe the operation of the position, speed and torque controllers. B.2.1 position controller the position controller, shown below, is a typical proportional + integral + derivative (pid) controller,...

Page 128

Www.Baldormotion.Com b-6 control system mn1901 b.2.2 speed controller the speed controller, shown in figure 57, is also a pid controller. Gains are set using the mint keywords kvprop, kvint and kvderiv. The speed is compared with the measured speed and the error is fed into the pid control calculati...

Page 129

Www.Baldormotion.Com control system b-7 mn1901 b.2.3 torque controller and feedback the torque controller, shown in figure 58, is a pi controller. Gains are set using the mint keywords kiprop and kiint. The torque demand is scaled into a current demand. This is compared with the measured current, ob...

Page 130

Www.Baldormotion.Com b-8 control system mn1901.

Page 131: C.1 Introduction

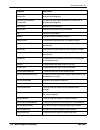

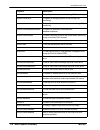

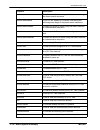

Www.Baldormotion.Com mint keyword summary c-1 mn1901 c.1 introduction the following table summarizes the mint keywords supported by the mintdrive ii . Note that due to continuous developments of the mintdrive ii and the mint language, this list is subject to change. Check the latest mint help file f...

Page 132

Www.Baldormotion.Com c-2 mint keyword summary mn1901 keyword description adcmax sets the upper analog limit value for the specified analog input. Adcmin sets the lower analog limit value for the specified analog input. Adcmode to set the analog input mode. Adcmonitor specifies the analog inputs that...

Page 133

Www.Baldormotion.Com mint keyword summary c-3 mn1901 keyword description auxencoderzlatch to read the state of the auxiliary encoder’s z latch. Axiserror to read back the motion error. Axismode to return the current mode of motion. Axisposencoder to select the source of the position signal used in d...

Page 134

Www.Baldormotion.Com c-4 mint keyword summary mn1901 keyword description busprocessdataout- interval to define the update interval for information sent in process data telegrams. Busprocessdataout- parameter to define the associated parameter for items sent in process data telegrams. Busreset resets...

Page 135

Www.Baldormotion.Com mint keyword summary c-5 mn1901 keyword description capturepretrigger- duration sets the duration of the pre-trigger phase. Captureprogress returns the progress of the pre-trigger or post-trigger capture phase. Capturestatus returns the progress of the capture. Capturetrigger to...

Page 136

Www.Baldormotion.Com c-6 mint keyword summary mn1901 keyword description dacmonitoraxis to specify which axis to monitor during dac monitoring. Dacmonitorgain to specify a multiplying factor for use during dac monitoring. Dacmonitormode to specify which axis parameter to monitor during dac monitorin...

Page 137

Www.Baldormotion.Com mint keyword summary c-7 mn1901 keyword description drivepeakcurrent reads the peak current rating of the drive. Drivepeakduration reads the duration for which peak drive current can be sustained. Driveratedcurrent reads the continuous current rating for the drive. Drivespeedfat...

Page 138

Www.Baldormotion.Com c-8 mint keyword summary mn1901 keyword description fastauxencoder to return the instantaneous auxiliary encoder value that was recorded on the fast interrupt. Fastauxlatch to read the auxiliary encoder fast interrupt latch. Fastauxlatchdistance to specify the distance over whic...

Page 139

Www.Baldormotion.Com mint keyword summary c-9 mn1901 keyword description folerrorfatal to set the maximum permissible following error before an error is generated. Folerrormode to determine the action taken on the axis in the event of a following error. Folerrorwarning sets the following error thres...

Page 140

Www.Baldormotion.Com c-10 mint keyword summary mn1901 keyword description homebackoff to set the home back-off speed factor. Homecreepspeed to set the creep speed for homing moves. Homedecel to set the deceleration rate for the homing profile. Homeinput to set a digital input to be the home switch i...

Page 141

Www.Baldormotion.Com mint keyword summary c-11 mn1901 keyword description idletime to specify the period for which the axis must meet its idle conditions before becoming idle. Idlevel reads or sets the idle velocity limit. Imask to mask off mint events in0 .. Inx. In to read the state of all the inp...

Page 142

Www.Baldormotion.Com c-12 mint keyword summary mn1901 keyword description kint to set the servo loop integral gain. Kintlimit to restrict the overall effect of the integral gain kint. Kintmode to control when integral action will be applied in the servo loop. Kiprop to set the proportional gain used...

Page 143

Www.Baldormotion.Com mint keyword summary c-13 mn1901 keyword description loaddamping to define the equivalent viscous damping coefficient for the motor and load. Loadinertia to define the combined inertia of the motor and load. Looptime to set the servo loop update interval in microseconds. Masterc...

Page 144

Www.Baldormotion.Com c-14 mint keyword summary mn1901 keyword description motorlinearencoder- resolution to set the resolution of the encoder on a linear motor. Motorlinearpolepitch to set or read the distance between north poles on a linear motor. Motorls to set or read the motor leakage inductance...

Page 145

Www.Baldormotion.Com mint keyword summary c-15 mn1901 keyword description moveoutx to load a change of state for a specific digital output into the move buffer. Movepulseoutx to load a pulsed change of state for a specific digital output into the move buffer. Mover to set up a positional move to a r...

Page 146

Www.Baldormotion.Com c-16 mint keyword summary mn1901 keyword description phasesearchcurrent to select amount of current applied to the motor during the phase search sequence. Phasesearchmode to turn on the ‘debounce’ controller used during the initial alignment stage of the phase search sequence. P...

Page 147

Www.Baldormotion.Com mint keyword summary c-17 mn1901 keyword description postarget to read the target position of the current positional move. Postargetlast to read the target position of the last move in the move buffer. Presetcancel to set up a preset ’move’ to perform a cancel command. Presetdwe...

Page 148

Www.Baldormotion.Com c-18 mint keyword summary mn1901 keyword description pulsecounter to return the value of the pulse input counter. Pulsedirmode to set the control mode for the step (pulse) & direction digital inputs. Pulseoutx to activate a digital output for a specified number of milliseconds. ...

Page 149

Www.Baldormotion.Com mint keyword summary c-19 mn1901 keyword description remoteobjectstring to access ‘vis-string’ entries in the object dictionary of any canopen node present on the network. Remoteout to control the state of digital outputs on a remote can node. Remoteoutbank to read the state of ...

Page 150

Www.Baldormotion.Com c-20 mint keyword summary mn1901 keyword description sentineltriggervalue to read the ’lowval’ or ’highval’ parameter used by a sentinel channel. Serialbaud to set the baud rate of the rs232 / rs485/422 port. Sextant to read the current sextant value for a motor using hall senso...

Page 151

Www.Baldormotion.Com mint keyword summary c-21 mn1901 keyword description suspend to pause the current move. Systemdefaults to reset parameter table entries to their default values and erase the mint program, nvram and error log. Systemseconds to set or read a programmable system lifetime counter fo...

Page 152

Www.Baldormotion.Com c-22 mint keyword summary mn1901 keyword description userparameter to provide access to user-programmable parameters stored in eeprom. Userpositionunits to define a text description for the user unit. Usertimeunits to define a text description for the user time unit. Vel to retu...

Page 153: D.1 Introduction

Www.Baldormotion.Com ce guidelines d-1 mn1901 d.1 introduction this section provides general information regarding recommended methods of installation for ce compliance. It is not intended as an exhaustive guide to good practice and wiring techniques. It is assumed that the installer of the mintdriv...

Page 154

Www.Baldormotion.Com d-2 ce guidelines mn1901 d.1.2 declaration of conformity ec declaration of conformity date: 01/06/02 ref: de00011-001 manufacturer: baldor uk limited address: mint motion centre, hawkley drive, bristol distribution centre, bristol, bs32 0bf, united kingdom this is to certify tha...

Page 155

Www.Baldormotion.Com ce guidelines d-3 mn1901 d.1.3 use of ce compliant components the following points should be considered: h using ce approved components will not guarantee a ce compliant system! H the components used in the drive, installation methods used, materials selected for interconnection...

Page 156

Www.Baldormotion.Com d-4 ce guidelines mn1901 d.1.5 emc installation suggestions to ensure electromagnetic compatibility (emc), the following installation points should be considered to help reduce interference: h earthing/grounding of all system elements to a central earth/ground point (star point)...

Page 157

Www.Baldormotion.Com ce guidelines d-5 mn1901 d.1.6 wiring of shielded (screened) cables remove the outer insulation to expose the overall shield. Clamp should provide 360° contact with the cable. Or flat or p-type conductive clamp figure 59 - earthing/grounding cable shields cable 1 6 2 7 3 8 mintd...

Page 158

Www.Baldormotion.Com d-6 ce guidelines mn1901.

Page 159

Index mn1901 a abbreviations. See units and abbreviations absolute encoder cable, 3-28, 3-30, a-4 endat option, 3-27 hiperface option, 3-29 specification, 8-10, 8-11 accessories, a-1 emc filters, a-6 feedback cables, a-3, a-4 motor power cables, a-2 regeneration resistors, a-9 analog i/o, 4-1 analog...

Page 160

Index mn1901 cable, 3-25, a-4 endat. See absolute encoder hiperface. See absolute encoder option, 3-24 specification, 8-10 endat. See absolute encoder environmental location, 3-4–3-5 specification, 8-12 f factory fitted options, a-1 factory settings, 3-35 fast inputs, x3 - din4/5, 4-9 features, 2-1 ...

Page 161

Index mn1901 p plc task, 6-7 defining conditions, 6-7 enabling and downloading, 6-8 saving conditions, 6-9 testing, 6-9 power 24v control supply, 3-14 connections, 3-8 disconnect and protection devices, 3-11 input conditioning, 3-11 input cycling, 3-11, 7-1 sources, 3-1 supply filters, 3-12, a-6 pre...

Page 162

Index mn1901 u units and abbreviations, 2-3 w wire sizes, 3-13 workbench v5, 5-4 commissioning wizard, 5-7 digital i/o tool, 5-12 fine-tuning tool, 5-9 help file, 5-4 other tools and windows, 5-12 parameters tool, 5-11 starting, 5-5.

Page 163

Comments mn1901 if you have any suggestions for improvements to this manual, please let us know. Write your comments in the space provided below, remove this page from the manual and mail it to: manuals baldor uk ltd mint motion centre 6 bristol distribution park hawkley drive bristol bs32 0bf unite...

Page 164

Www.Baldormotion.Com comments mn1901 thank you for taking the time to help us..

Page 166

Printed in uk e baldor uk ltd lt0159a03 europe (southern) baldor asr ag, switzerland tel: +41 52 647 4700 fax: +41 52 659 2394 europe baldor asr gmbh, germany tel: +49 (0) 89 905 080 fax: +49 (0) 89 905 08491 australia australian baldor pty ltd tel: +61 2 9674 5455 fax: +61 2 9674 2495 mexico baldor...