Presents your operators manual baldor generators 3815 oregon street oshkosh, wi 54902 phone: 920-236-4200 fax: 920-236-4219 form#: s-psg-002-91 revised: 2/25/02 c:\iso9001\forms\s-psg-00291.Msw effective: 5/3/01 standby permanent mount series generator.

Forward this manual contains the information you need to safely and efficiently operate your generator set. During the preparation of this manual every effort was made to ensure the accuracy of its contents. Never operate this generator set without first carefully reading this manual and observing a...

Ƈ place protective covers and guards over the rotating parts, if rotating parts such as the drive shaft, pulley, belt, etc. Are left exposed, they are potentially hazardous. Ƈ when cleaning, repairing or inspecting, make sure all moving parts have stopped. Ƈ prior to working on the generator set, di...

Ƈ never permit anyone to operate the generator set without proper instructions. Ƈ never allow children to operate the generator set. Ƈ children and pets must be kept away from the area of operation due to the possibility of burns from hot engine components or injury from any equipment the generator ...

Ƈ always treat the electrical circuits as if they were energized. Ƈ disconnect all leads plugged into the unit prior to working on it. Ƈ have the electrical circuits serviced only by qualified technicians. Ƈ inspect wiring frequently and replace frayed, broken or poor leads. Ƈ do not connect this un...

ż ż ż ż for gasoline or diesel powered generator sets ż ż ż ż Ƈ check all fuel supply piping and their connections on a monthly basis for fuel leaks. Ƈ use only approved piping and componentry in your fuel supply system. Ƈ a professional, experienced technician should only install the fuel supply sy...

Standby permanent- mount series generator table of contents item page voltage ratings: this informational page describes features and specifications for all standby permanent- mount series units. 1 electrical connection information: this information explains how to interface your generator with the ...

Baldor generator features ■ baldor generators are manufactured in a certified iso9001 facility located in oshkosh, wisconsin. ■ every generator is design, prototype, and production tested ■ brushless synchronous four-pole alternator ■ industrial grade exhaust silencer ■ engine block heater ■ baldor ...

Engine specifications engine data manufacturer perkins model 3.1524 cylinders 3 in-line cycle 4-stroke induction system natural displacement, l (cu. In.) 2.5 (152 cu. In.) bore and stroke 91.4 x 127.0 compression ratio 16.5:1 lubrication capacity 6.17 quarts cooling capacity (incl. Radiator) 11.85 q...

Baldor generator features ■ baldor generators are manufactured in a certified iso 9001 facility located in oshkosh, wisconsin ■ every generator is design, prototype, and production tested ■ brushless synchronous four-pole alternator ■ industrial-grade exhaust silencer ■ engine block heater ■ baldor ...

Engine specifications engine data manufacturer perkins model 1004-40t cylinders 4 in-line cycle 4-stroke induction system turbocharged displacement, l (cu. In.) 3.99 (243.5 cu. In.) bore and stroke 100.0 mm x 127.0 mm 3.94 x 5 compression ratio 17.25:1 lubrication capacity 8.4 liters (9 qts.) coolin...

Baldor generator features ■ baldor generators are manufactured in a certified iso 9001 facility located in oshkosh, wisconsin ■ every generator is design, prototype, and production tested ■ brushless synchronous four-pole alternator ■ industrial-grade exhaust silencer ■ engine block heater ■ baldor ...

Engine specifications engine data manufacturer perkins model 1004-40t cylinders 4 in-line cycle 4-stroke induction system turbocharged displacement, l (cu. In.) 3.99 (243.5 cu. In.) bore and stroke 100.0 mm x 127.0 mm 3.94 x 5 compression ratio 17.25:1 lubrication capacity 8.4 liters (9 qts.) coolin...

Baldor generator features ■ baldor generators are manufactured in a certified iso9001 facility located in oshkosh, wisconsin. ■ every generator is design, prototype, and production tested ■ brushless synchronous four-pole alternator ■ industrial grade exhaust silencer ■ engine block heater ■ baldor ...

Engine specifications engine data manufacturer perkins model 1004-40tw cylinders 4 in-line cycle 4-stroke induction system turbocharged displacement, l (cu. In.) 3.99 (243.5 cu. In.) bore and stroke 100.0 mm x 127.0 mm 3.94 x 5 compression ratio 17.3:1 lubrication capacity 8.5 liters (9 qts.) coolin...

Baldor generator features ■ baldor generators are manufactured in a certified iso9001 facility located in oshkosh, wisconsin. ■ every generator is design, prototype, and production tested brushless synchronous four-pole alternator industrial grade exhaust silencer engine block heater baldor gensets ...

Engine specifications engine data manufacturer perkins model 1006-6t cylinders 6 in-line cycle 4-stroke induction system turbocharged displacement, l (cu. In.) 5.99 (365.0 cu. In.) bore and stroke 100.0 mm x 127.0 mm 3.94 x 5.0 compression ratio 17.3:1 lubrication capacity 16.1 liters (17.0 qts.) co...

Baldor generator features ■ baldor generators are manufactured in a certified iso9001 facility located in oshkosh, wisconsin ■ every generator is design, prototype, and production tested ■ brushless synchronous four-pole alternator ■ industrial grade exhaust silencer ■ engine block heater ■ baldor g...

Engine specifications engine data manufacturer perkins model 1006-6ta cylinders 6 in-line cycle 4-stroke induction system turbocharged - aftercooled displacement, l (cu. In.) 5.99 (365.0 cu. In.) bore and stroke 100.0 mm x 127.0 mm 3.94 x 5.0 compression ratio 17.3:1 lubrication capacity 19.0 liters...

Standby permanent - mount series generator electrical connection information high voltage may be present at receptacles and load studs while engine is operating - danger of electrical shock is present. Use extreme care. Voltage is present at the 120v/15 amp convenience receptacle only when generator...

Connection information your new pow'r gard generator has all interconnecting wiring terminated at a junction box. All wiring will be clearly labeled as being load, remote start contacts and ac input terminals and are to be connected as described below. Load - these connections are rated and sized ac...

Standby permanent mount series generator generator mounting requirements the generator set must be secured to a solid surface, which is non-combustible. A concrete floor is typical of this application. Wood floors should be prepared in accordance with local and state requirements for the load, heat ...

Engine cooling air the air, which will cool the engine, must be brought in from outside the building. A forced airflow of sufficient cubic feet per minute (cfm) will prevent the incoming cooling air from mixing with the air inside the building and eventually overheating and damaging the engine. To d...

When discharging the heated cooling air or the hot exhaust gases out through the side of the building or compartment please contact your local building inspector to find out what is necessary for your application to prevent a fire from occurring. You must clean and inspect both the exhaust fan and i...

If you are using a remote muffler it should be mounted as close to the engine as possible, since it will clog with carbon if it's operating temperature is too low. If you are using a remote muffler a flexible coupling of 12" or more must be installed between the exhaust line and the manifold to abso...

When discharging the heated cooling air or the hot exhaust gases out through the side of the building please contact your local building inspector to find out what is necessary for your application to meet local building code requirements. Keep all fuel and its associated piping away from all compon...

Building ventilation as hot air rises you must provide some type of power ventilation at the highest possible point of the building to permit the accumulating hot air to escape. This will help to prevent engine damage and it will help to eliminate hot restart problems. An electric powered exhaust fa...

Exhaust requirements while it is important to supply the proper amount of clean air to the cylinder, it is equally important to discharge the gases of combustion. If these gases remain in the cylinder, the next cycle cannot burn the fuel completely. This condition results from excessive backpressure...

Figure 6-2: double thimble - wall outlet details exhaust piping thru walls and roofs always check local and state laws pertaining to hot gas pipes before making plans for running exhaust piping thru walls or roofs. If the exhaust pipe must pass thru combustible walls or roofs, use an exhaust thimble...

Figure 6-3 — double thimble - roof outlet details a rain shield must be included above the thimble as shown in figure 6-3. The rain cap as shown on the end of the exhaust pipe is recommended only in areas not subject to freezing temperatures. In an area where freezing is common, extend the exhaust p...

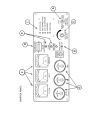

Control panel operation and function a. Master control switch - this switch controls the starting and stopping of the engine via the engine control logic circuitry. With this switch in the “manual” mode, the engine will start and run immediately after a 10 - 20 second time delay. Caution: please not...

The hour meter accumulates and displays the total running time of the generator set. E. Voltage adjust - the rheostat allows the user to “fine tune” the generator set’s voltage output. It is normally used to adjust output voltage after switching the output of the generator set to a different voltage...

Operation - pre-start procedure 1. Fill system fuel tank with clean, fresh diesel fuel. Wipe up any and all fuel spillage 2. Fill engine crankcase to full mark with clean, fresh lubricating oil per attached engine operating guide. 3. Radiator coolant should be checked at the beginning of each day an...

Operation the prime mover utilized in this power generating system is controlled via an engine control module. Starting is accomplished by commanding the control to "start" the engine. This command can be given by a number of controls; the operator control mounted on the front panel. The remote cont...

3. Overspeed adjustment (os) - over frequency overspeed protection is provided by a frequency sensing network within the controller. The trip point of the frequency network is adjustable via a rheostat located on the top of the controller at the right hand side. Clockwise (cw) rotation increases the...

Troubleshooting - generator as with any machine, trouble may develop in electrical generators. It may be due to long service or neglect of regular maintenance. Servicing, and checking. Should trouble develop, the following instructions will be helpful in tracing the cause and making repairs. Speed d...

Low voltage (continued) cause check and remedy high resistance connections- make better connection electrically and connections will be warm or hot mechanically. Shorted field. Test field coils for possible short by checking resistance with an ohmmeter or resistance bridge. Return rotor assembly to ...

Overheating (continued) cause check and remedy high room temperature. Improve ventilation. Insufficient circulation. Provide cross-ventilation. Low power factory. Reduce inductive loads or install power factor improvement capacitors. Unbalanced load the load on each leg should be as evenly balanced ...

Troubleshooting - engine code list of possible causes 1. Battery capacity low. 33. Piston rings not free or are worn or broken. 2. Bad electrical connections. 34. Valve stems and/or guide worn. 3. Fault in starter motor. 35.West type air cleaner too full or wrong oil used. 4. Fault in starter motor....

Limited warranty unless otherwise provided, baldor generators are warranted against defects in baldor workmanship and materials for a period of time as set forth in the warranty period chart on the following page. All warranty claims must be submitted to a baldor generator repair facility prior to t...

Warranty period generator series labor* parts portable products (premier, powerchief, dg series, k series) 1 year 3 years towable products (ts) 1 year or 3,000 hours whichever comes first 3 years or 3,000 hours whichever comes first 3600 rpm standby systems (some ae models) 1 year or 1,000 hours whi...

Limitations: baldor generators is not responsible for the repair of generators required because of normal wear, accident, misuse, abuse, improper installation, lack of maintenance, unauthorized modifications or improper storage. Normal wear: this warranty will not cover repair where normal use has e...

For standby, automatic emergency and prime power generators it is required that both sides of this form be filled out completely, signed where indicated and returned to baldor generators within 30 days of initial start-up and test. It is your responsibility to insure that copies are distributed to: ...

Pre start-up check list start-up procedure no freight damage (components tight, straight, etc.). Check that all applicable warning decals are in their proper place and are legible. Proper belt alignment and tensions. The ats engine start wires and other dc wires, if any, must be properly connected. ...

3518 oregon street oshkosh wi 54902 phone: 920-239-4200 fax: 920-236-4219 baldor generators firmly believes proper installation along with proper maintenance are critical factors in assuring proper, dependable, safe and long term operation. The checklist was developed for making sure your installati...

California proposition 65 warning engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects, and other reproductive harm. California proposition 65 warning diesel engine exhaust and some constituents are known to the state of california to ca...

Service is just a phone call away: 800-872-7697 www.Baldor.Com/products/generators.Asp 3815 oregon street oshkosh wi 54902 phone: (920) 236-4200 fax: (920) 236-4219.