- DL manuals

- Baldor

- Controller

- VS1MX

- Installation & Operating Manual

Baldor VS1MX Installation & Operating Manual

Summary of VS1MX

Page 1

04/13 installation & operating manual mn762 vs1mx ac extreme duty microdrive.

Page 2

Any trademarks used in this manual are the property of their respective owners. Important: be sure to check www.Baldor.Com for the latest software, firmware and drivers for your vs1mx product. Also you can download the latest version of this manual in adobe acrobat pdf format..

Page 3

I mn762 chapter 1 introduction 1.1 getting assistance from baldor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 1.2 safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Ii mn762 chapter 6 using the keypad 6.1 keypad overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 6.2 keypad display parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5

Iii mn762 appendix e rs485/modbus protocol e.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1 e.2 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

Iv mn762.

Page 7: Chapter 1

Introduction 1-1 mn762 chapter 1 introduction this manual is intended for qualified electrical personnel familiar with installing, programming, and maintaining ac drives. This manual contains information on: • installing and wiring the vs1mx drive • programming the drive • troubleshooting the drive ...

Page 8

1-2 introduction mn762 warning: the motor shaft will rotate during the autotune procedure. Be certain that unexpected motor shaft movement will not cause injury to personnel or damage to equipment. Warning: medical device/pacemaker danger - magnetic and electromagnetic fields in the vicinity of curr...

Page 9

Introduction 1-3 mn762 1.3 quick start (quick start guide ms762 is also available separately.) figure 1-1 power & motor terminal locations see recommended tightening torques in table 4-1. L1/l l2/n l3 l1/l l2/n l3 size a size b & c + size a, b, c (vs1mx10ps5 shown as an example) size a, b, c (vs1mx2...

Page 10

1-4 introduction mn762 figure 1-2 input connections red blu yel grn wht blk front panel speed pot front panel fwd-o-rev switch 1 2 3 4 5 vs1mx tightening torque = 3.5 lb-in (0.4nm) +24vdc reference forward (digital in1) 6 7 reverse (digital in2) digital in3 / analog in2 +10vdc pot reference analog i...

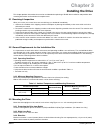

Page 11: Chapter 2

General information and ratings 2-1 mn762 chapter 2 general information and ratings the vs1mx is an adjustable frequency pwm drive operating in v/hz (volts per hertz) mode. This chapter contains information about the vs1mx drive, including how to identify the drive. 2.1 identify the drive by model n...

Page 12

2-2 general information and ratings mn762 2.3 vs1mx ratings, model numbers and frame sizes table 2-1 drive ratings hp model number kw model number hp kw current (amps) frame watts loss input output 110-115v +/-10% 1-phase input, 230v 3-phase output vs1mx10p5 --- 0.5 --- 10.1 2.3 a 45 vs1mx11 --- 1 -...

Page 13: Chapter 3

Installing the drive 3-1 mn762 chapter 3 installing the drive this chapter provides information that must be considered when planning a vs1mx drive installation and provides drive mounting information and installation site requirements. 3.1 receiving & inspection when you receive your control, there...

Page 14

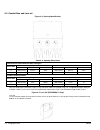

3-2 installing the drive mn762 3.4 cover removal to connect power and signal wires, the cover must be removed as shown in figure 3-1. Figure 3-1 cover removal press in (cover release) then lift cover to remove. Remove 2 screws then left the white cover to remove. Figure 3-2 nema 12 / ip55 mounting h...

Page 15

Installing the drive 3-3 mn762 figure 3-3 nema 4x / ip66 mounting hole locations a b1 c b a1 i j a2 stop reset start prog ent table 3-3 nema 4x / ip66 dimensions frame a a1 a2 b b1 i Φ j Φ c (depth weight in mm in mm in mm in mm in mm in mm in mm in mm lb kg a 9.13 232 7.44 189 0.98 25 6.34 161 5.85...

Page 16

3-4 installing the drive mn762 3.5 conduit size and lock off figure 3-4 opening identification b a c table 3-4 opening dimensions cable gland recommended hole sizes and types: frame size opening a and c knock out b diameter ul gland size metric gland size diameter ul gland size metric gland size a ....

Page 17: Chapter 4

Power wiring 4-1 mn762 chapter 4 power wiring 4.1 overview of power connections the recommended grounding method is shown in figure 4-1. 4.1.1 safety ground - (g) this is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girde...

Page 18

4-2 power wiring mn762 4.3 protective devices recommended fuse sizes are based on the following: 115% of maximum continuous current for time delay. 150% of maximum continuous current for fast or very fast action. Note: these recommendations do not consider harmonic currents or ambient temperatures g...

Page 19

Power wiring 4-3 mn762 4.4.4 optional dynamic brake hardware size b & c controls if optional db resistor is to be used, connect it to the + and br terminals, (see figure 4-2). Dynamic brake (db) hardware must be installed on a flat, non-flammable, vertical surface for effective cooling and operation...

Page 20

4-4 power wiring mn762 unexpected faults may occur due to excessive charging current required for motor cable capacitance. If you use long motor leads and experience unexpected trips due to current overload conditions and are not sure how to correctly size and connect the optional load reactors, ple...

Page 21: Chapter 5

Control wiring 5-1 mn762 chapter 5 control wiring 5.1 control board connections analog and digital input and output connections are made at the control wiring terminals shown in figure 5-1. Control wire connections can be made using shielded twisted pair #18 awg (0.8mm2) wire minimum. The cable must...

Page 22

5-2 control wiring mn762 5.2 rj45 communication connection the rj45 data port can be used as either a rs485 serial modbus interface or to connect the optional remote keypad (vs1st-rkey3) and/or copycat loader (vs1st-ccl). Serial modbus networks use the rs485 pin connection; see appendix e for the co...

Page 23

Control wiring 5-3 mn762 6. Close the control switch, terminals 1-2. The drive is now ‘enabled’ and the output frequency/speed are controlled by the potentiometer. The display shows zero speed in hertz ( .) with the potentiometer turned to minimum. 7. Turn the potentiometer to maximum. The motor...

Page 24

5-4 control wiring mn762.

Page 25: Chapter 6

Using the keypad 6-1 mn762 chapter 6 using the keypad 6.1 keypad components this chapter provides an overview of the integrated keypad and how to use it to program the vs1mx drive. The controls are shown in table 6-1. Table 6-1 operator interface description key name description display 6 digit seve...

Page 26

6-2 using the keypad mn762 6.2 keypad display parameters the following display values can be viewed from the keypad while operating the drive. 6.2.1 default configuration speed and amps can be displayed by the drive in its default configuration. Press the ent/prog key momentarily to toggle between h...

Page 27

Using the keypad 6-3 mn762 6.2.3 custom display unit parameter p-23 is used to configure the display and show custom units based on the scale factor assigned. When a value other than zero is assigned to p-23, a new display is enabled in operational mode. If p-04=0, p-23 will scale units in hertz, an...

Page 28

6-4 using the keypad mn762 6.3 using the rev/0/fwd selector switch (switched version only) by adjusting the parameter settings the vs1mx can be configured for multiple applications and not just for forward or reverse. This could typically be for hand/off/auto applications (also known as local/remote...

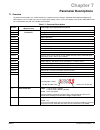

Page 29: Chapter 7

Parameter descriptions 7-1 mn762 chapter 7 parameter descriptions 7.1 overview parameters p00 through p-45 are presented in this chapter and each setting is explained. Selecting p00 and pressing ent/prog accesses a read-only menu to monitor internal drive values. Once in the display view, the up and...

Page 30

7-2 parameter descriptions mn762 number name (display level) value range, description and preset value p-03 motor rated frequency range: 25 to 500 hz preset: 60 hz (display shows ) rated frequency of the motor (listed on the nameplate). Adjusting the voltage / frequency (v/f) if motor instabili...

Page 31

Parameter descriptions 7-3 mn762 number name (display level) value range, description and preset value p-08 speed reference source range: 0-12 preset: 0 sets the digital inputs configuration. The operation of p-08 changes depending on the value of p-07. Refer to table 8-1, table 8-2, table 8-3, and ...

Page 32

7-4 parameter descriptions mn762 number name (display level) value range, description and preset value p-17 analog input format (analog input 1) range: u 0 - 10 b 0 - 10 a 0 - 20 t 4 - 20 r 4 - 20 t 20 - 4 r 20 - 4 preset: u 0 - 10 sets the analog input for voltage or current operation and the range...

Page 33

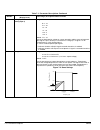

Parameter descriptions 7-5 mn762 number name (display level) value range, description and preset value p-19 energy savings range: 0=disabled 1=enabled preset: 0 when enabled, automatically reduces applied motor voltage on light load. Minimum value is 50% of nominal. Figure 7-3 energy saving adjustme...

Page 34

7-6 parameter descriptions mn762 number name (display level) value range, description and preset value p-24 analog/digital output function select range: 0 to 9 preset: 8 digital output mode 0: drive enabled 4: motor speed >= limit 1: drive healthy 5: motor current >= limit 2: motor at target speed 6...

Page 35

Parameter descriptions 7-7 mn762 number name (display level) value range, description and preset value p-30 analog input offset range: -500.0 to 500.0% preset: 0.0 amount of offset for analog input level. Resolution of 0.1%. P-31 brake after stop range: 0 to 60.0 seconds preset: 0.0 sets the amount ...

Page 36

7-8 parameter descriptions mn762 number name (display level) value range, description and preset value p-35 serial comms address range: adr: 0 (disable) to 63 preset: adr: 1 sets a unique drive address for communication network modbus enable / baudrate select range: op-bus, 9.6, 19.2, 38.4, 57.6, 11...

Page 37

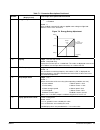

Parameter descriptions 7-9 mn762 number name (display level) value range, description and preset value p-43 user pi feedback select range: 0 to 2 preset: 0 0: 2nd analog input 1: 1st analog input 2: motor load current this parameter selects the feedback signal source. Note: parameter setting is igno...

Page 38

7-10 parameter descriptions mn762.

Page 39: Chapter 8

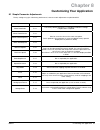

Customizing your application 8-1 mn762 chapter 8 customizing your application 8.1 simple parameter adjustments factory settings may give satisfactory performance, however certain adjustments may be beneficial. Adjustment parameter parameter name motor rated volts p-01 the factory default setting p01...

Page 40

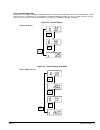

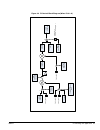

8-2 customizing your application mn762 8.2 analog and digital input configurations parameters p-07 and p-08 can be set to allow various operating modes. Following are settings for these parameters. 8.2.1 terminal strip mode (p-07 = 0) table 8-1 parameter p-08 control of digital inputs when p-07=0 p-...

Page 41

Customizing your application 8-3 mn762 figure 8-1 terminal mode example wiring 1 2 3 4 5 6 7 1 2 3 4 5 6 7 1 2 3 4 5 6 7 t3 t4 0 0 1 0 0 1 1 1 speed preset 1 preset 2 preset 3 preset 4 1 2 3 4 5 6 7 1 2 3 4 5 6 7 + - 1 2 3 4 5 6 7 terminal mode p07 = 0, p08 = 0 terminal mode p07 = 0, p08 = 1 termina...

Page 42

8-4 customizing your application mn762 8.2.2 keypad mode (p-07 = 1 or 2) table 8-2 parameter p-08 control of digital inputs when p-07=1 or 2 p-08 digital in 1 (term. 2) digital in 2 (term. 3) digital in 3 (term. 4) analog in 1 (term. 6) 0, 1, 5, 8-12 open stop open keypadspeedref open keypadspeed re...

Page 43

Customizing your application 8-5 mn762 8.2.3 modbus control mode (p-07 = 3 or 4) table 8-3 parameter p-08 control of digital inputs when p-07=3 or 4 p-08 digital in 1 (term. 2) digital in 2 (term. 3) digital in 3 (term. 4) analog input 1 (term. 6) 0, 2, 4-5, 8-12 open stop open no effect open no eff...

Page 44

8-6 customizing your application mn762 figure 8-3 pi control mode example wiring 1 2 3 4 5 6 7 + - 1 2 3 4 5 6 7 + - 1 2 3 4 5 6 7 + - terminal mode p07 = 5, p08 = 0 terminal mode p07 = 5, p08 = 1 terminal mode p07 = 5, p08 = 3 +24v output +24v output +24v output o: stop (disable) c: run (enable) o:...

Page 45

Customizing your application 8-7 mn762 figure 8-4 pi control block diagram (when p-08 ≠ 9) 6 an al og in pu t 1 p- 42 pi d ig ita l r ef er en ce p- 41 pi r ef er en ce se le ct 6 an al og in pu t 1 4 an al og in pu t 2 m ot or l oa d c ur re nt p- 43 fe ed ba ck r ef er en ce se le ct + - p g ai n ...

Page 46

8-8 customizing your application mn762 figure 8-5 pi control block diagram (when p-08 = 9) p- 42 pi d ig ita l r ef er en ce 6 an al og in pu t 1 4 an al og in pu t 2 p- 08 = 9 fe ed ba ck r ef er en ce se le ct + - p g ai n p -3 8 i g ai n p -3 9 p0 0- 03 sp ee d r ef er en ce pi o ut pu t 0 to p -...

Page 47: Chapter 9

Troubleshooting 9-1 mn762 chapter 9 troubleshooting the vs1mx continuously monitors its status and operation. When a fault occurs, the event and drive status is captured to help you troubleshoot problems. The following are designed to help in troubleshooting: • leds on the keypad indicate status (st...

Page 48

9-2 troubleshooting mn762 table 9-1 fault descriptions and corrective actions fault code description corrective action default parameters loaded press stop key, drive is ready to configure for particular application. Output over current condition. Excess load on the motor. Over temperature on the he...

Page 49: Appendix A

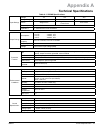

Technical specifications a-1 mn762 appendix a technical specifications table a-1 vs1mx specifications input ratings voltage 115 230 460 voltage range 99-126 198-264 342-528 phase single phase single phase and three phase three phase frequency 50/60hz ±5% impedance 1% minimum from main connection out...

Page 50

A-2 technical specifications mn762.

Page 51: Appendix B

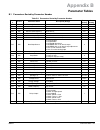

Parameter tables b-1 mn762 appendix b parameter tables b.1 parameters sorted by parameter number table b-1 parameters sorted by parameter number param # access parameter name description (range) factory setting user setting p00 ro read only parameters 1-20 p01 rw motor rated volts 0, 20-250vac or 0,...

Page 52

B-2 parameter tables mn762 param # access parameter name description (range) factory setting user setting p24 rw analog/digital output digital output mode 0: drive enabled 1: drive healthy 2: motor at target speed 3: drive tripped 4: motor speed >= limit 5: motor current >= limit 6: motor speed 7: m...

Page 53: Appendix C

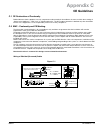

Ce guidelines c-1 mn762 appendix c ce guidelines c.1 ce declaration of conformity baldor indicates that the products are only components and not ready for immediate or instant use within the meaning of “safety law of appliance”, “emc law” or “machine directive”. The final mode of operation is define...

Page 54

C-2 ce guidelines mn762 c.3 emc installation options when installed for class a or class b operation, the control is compliant with en55011 (1991)/ en55022 (1994) for radiated emissions as described. C.4 grounding for wall mounting (class a) also see chapters 4 and 5 top cover must be installed. • a...

Page 55

Ce guidelines c-3 mn762 c.7 emc wiring technique figure c-2 1 cabinet the drawing shows an electroplated zinc coated enclosure, which is connected to ground. This enclosure has the following advantages: - all parts mounted on the back plane are connected to ground. - all shield (screen) connections ...

Page 56

C-4 ce guidelines mn762 a) all metal conducting parts of the enclosure must be electrically connected to the back plane. These connections should be made with a grounding strap from each element to a central grounding point. [1] b) keep the power wiring (motor and power cable) and control wiring sep...

Page 57: Appendix D

Options and kits d-1 mn762 appendix d options and kits d.1 remote keypad option the vs1mx remote keypad can be panel mounted for remote control or display of the drive. The remote keypad comes with a standard 3.0 meter cable. Table d-1 remote keypad catalog number description vs1st-rkey3 vs1st and v...

Page 58

D-2 options and kits mn762 vs1mx dynamic braking resistors vs1mx frame b and c drives include built-in braking transistors to aid in applications requiring the ability to stop rapidly. The brake resistor must be mounted and secured in place. Two wires connect to the + and br terminals on the power s...

Page 59: Appendix E

Rs485/modbus protocol e-1 mn762 appendix e rs485/modbus protocol e.1 introduction the vs1mx ac drive is supplied with imbedded rs-485 communications that supports the modbus-r tu protocol. This allows the user to set up a multi-drop communications network between multiple vs1mx drives and a plc or h...

Page 60

E-2 rs485/modbus protocol mn762 e.2 installation 1. Connect the rs485 communication line to rj45 connector, (see figure e-1). 2. Check the connections and turn on the inverter. 3. Table e-1 documents the parameters within the vs1mx that are related to communications: table e-1 communication paramete...

Page 61

Rs485/modbus protocol e-3 mn762 e.6 communication specifications table e-4 communication specifications communication speed 9600, 19200, 38400, 57600, 115200 bps selectable control procedure asynchronous communication system communication half duplex characters (data bits) ascii (8 bit) start bits 1...

Page 62

E-4 rs485/modbus protocol mn762 e.7.1 register descriptions read and write registers register 1: drive command 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 high byte low byte bit 0: run/stop command: set to 1 to enable the drive. Set to 0 to stop the drive. Bit 1: fast stop request. Set to 1 to enable driv...

Page 63

Rs485/modbus protocol e-5 mn762 register 17: drive type this register gives drive internal type code. Register 20: analog input 1 value this register gives drive analog input 1 value after scaling and offset control. Value 4096 = 100%. Register 21: analog input 2 value this register gives drive anal...

Page 64

E-6 rs485/modbus protocol mn762 adr description data range data format 145 analog input format (analog in 1) 0-6 0: 0-10v 1: b 0-10v 2: 0-20ma 3: t 4-20ma 4: r 4-20ma 5: t 20-4ma 6: r 20-4ma 146 voltage boost 0-200 100 = 10.0% 147 energy savings 0, 1 0: disable 1: enable 148 trip log last four trips...

Page 65

Rs485/modbus protocol e-7 mn762 adr description data range data format 163* serial comms address [parsing - lower byte] 0-63 drive comms address modbus enable / baudrate select [parsing - lower nibble; upper byte] 1-6 1 = optibus (or mxstbus) fixed baudrate 2 = 9.6k 3 = 19.2k 4 = 38.4k 5 = 57.6k 6 =...

Page 66

E-8 rs485/modbus protocol mn762 e.7.2 drive error codes 0x00 no trip 0x01 brake circuit over current (short circuit) 0x02 brake circuit overload 0x03 drive output over current 0x04 motor overload 0x05 power stage trip 0x06 dc bus over voltage trip 0x07 dc bus under voltage trip 0x08 over temperature...

Page 67

Baldor sales offices ohio (continued) cleveland 8929 freeway drive macedonia, oh 44056 phone: 330-468-4777 fax: 330-468-4778 oklahoma tulsa 5555 e. 71st st., suite 9100 tulsa, ok 74136 phone: 918-366-9320 fax: 918-366-9338 oregon portland 12651 se capps road clackamas, or 97015 phone: 503-691-9010 f...

Page 68

© baldor electric company mn762 all rights reserved. Printed in usa. 04/13 !762-0413* p.O. Box 2400, fort smith, ar 72902-2400 u.S.A., ph: (1) 479.646.4711, fax (1) 479.648.5792, international fax (1) 479.648.5895 baldor - dodge 6040 ponders court, greenville, sc 29615-4617 u.S.A., ph: (1) 864.297.4...