- DL manuals

- Baldor

- Controller

- VS1SM

- Installation & Operating Manual

Baldor VS1SM Installation & Operating Manual

Summary of VS1SM

Page 1

Installation & operating manual vs1sm single phase ac drive 10/07 mn761.

Page 2: Important:

Any trademarks used in this manual are the property of their respective owners. Important: be sure to check www.Baldor.Com for the latest software, firmware and drivers for your vs1 product. Also, you can download the latest version of this manual in adobe acrobat pdf format..

Page 3: Table Of Contents

Table of contents mn761 table of contents i chapter 1 introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 getting assistance from baldor 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Ii table of contents mn761 chapter 8 customizing for your application 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 9 troubleshooting 9-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Introduction

Mn760 quick start 1-1 chapter 1 introduction this manual is intended for qualified electrical personnel familiar with installing, programming, and maintaining ac drives. This manual contains information on: s installing and wiring the vs1sm drive s programming the drive s troubleshooting the drive 1...

Page 6

1-2 quick start mn760 warning: improper operation of control may cause violent motion of the motor shaft and driven equipment. Be certain that unexpected motor shaft movement will not cause injury to personnel or damage to equipment. Certain failure modes of the control can produce peak torque of se...

Page 7: 1.3

Mn760 quick start 1-3 1.3 quick start quick start guide is also available separately, see ms760. Figure 1‐1 power & motor terminal locations l1 l2 p p1 n u v w jumper bar vs1sm82/82-f, vs1sm83/83-f l1 l2 p p1 n u v w jumper bar vs1sm80p5/80p5-f, vs1sm81/81-f powerup procedure refer to chapter 3, 4 a...

Page 8

1-4 quick start mn760 figure 1‐2 input/output connections control i/o terminal strip p4 p5 vr v1 cm i am 30a30b30c moextgp24 p1 p2 cm p3 see mn761 for tightening torques np n pn p set the npn/pnp switch for desired mode. Npn mode pnp mode or shown with npn digital input connections tightening torque...

Page 9: 2.1

Mn761 general information and ratings 2-1 chapter 2 general information and ratings the vs1sm is a variable frequency pwm drive capable of operating in open- loop, v/hz (volts per hertz) mode and in a sensorless vector control (svc) mode. This chapter contains information about the vs1sm drive, incl...

Page 10

2-2 general information and ratings mn761.

Page 11: 3.1

Mn761 installing the drive 3-1 chapter 3 installing the drive this chapter provides information that must be considered when planning a vs1sm drive installation and provides drive mounting information and installation site requirements. 3.1 receiving & inspection when you receive your control, there...

Page 12: 3.3

3-2 installing the drive mn761 3.3.2 watts loss data refer to table 2‐1 for watts loss data. 3.3 cover removal to connect power and signal wires, the cover must be removed. Remove the cover as shown in figure 3‐2. 1. Gently press in the area labeled cover release shown in figure 3‐2. 2. Slide the co...

Page 13: Power Wiring

Mn761 power wiring 4-1 chapter 4 power wiring 4.1 overview of power connections the recommended grounding method is shown in figure 4‐1. Safety ground - (g) this is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joi...

Page 14: 4.2

4-2 power wiring mn761 4.2 power disconnect a power disconnect should be installed between the input power service and the drive for a fail safe method to disconnect power. The drive will remain in a powered‐up condition until all input power is removed from the drive and the internal bus voltage is...

Page 15

Mn761 power wiring 4-3 figure 4‐2 power terminal locations npn pnp power terminal strip l1 l2 p p1 n u v w jumper bar vs1sm82/82-f, vs1sm83/83-f l1 l2 p p1 n u v w jumper bar vs1sm80p5/80p5-f, vs1sm81/81-f see recommended tightening torques in table 4‐1. Figure 4‐3 input power connections l1 l2 l1 l...

Page 16: 4.5

4-4 power wiring mn761 figure 4‐4 motor connections * optional components not provided with control. Baldor control notes: 1. Metal conduit should be used. Connect conduits so the use of load reactor or rc device does not interrupt emi/rfi shielding. 2. See line/load reactors described previously in...

Page 17: Control Wiring

Mn761 control wiring 5-1 chapter 5 control wiring 5.1 control wiring overview analog and digital inputs and output terminals are shown in figure 5‐1 and described in table 5‐1. Figure 5‐1 control wiring terminal identification control i/o terminal strip p4 p5 vr v1 cm i am 30a 30b 30c mo extgp24 p1 ...

Page 18: 5.2

5-2 control wiring mn761 5.2 control input connections determine if you will use npn (factory setting) or pnp connections. Npn/pnp settings are shown in figure 5‐2. For npn, cm (common or ground) is used to switch the input signals. For pnp, p24 (+24vdc output) is used to switch the input signals. F...

Page 19

Mn761 control wiring 5-3 figure 5‐3 input connections forward run speed signal input (0-10vdc ) speed signal input (0-20ma) p1 p2 p3 p4 p5 p24 vr vi i cm reverse run output inhibit jog operation fault reset internal 10vdc power for potentiometer pnp 24vdc output common shown with npn digital input c...

Page 20: 5.3

5-4 control wiring mn761 5.3 control output connections the analog and digital outputs are shown in figure 5‐4. 1. Connect an external analog output device to am terminal and it's reference to cm. 2. The normally open and closed relay outputs can be connected to an external device, terminal 30b is t...

Page 21: Using The Keypad

Mn761 using the keypad 6-1 chapter 6 using the keypad 6.1 keypad overview operator controls are shown in figure 6‐1 and described in table 6‐1. The 5 way button that is used for parameter setting is only accessible when the cover is removed. Figure 6‐1 operator controls display stop/reset switch spe...

Page 22: 6.2

6-2 using the keypad mn761 figure 6‐2 alpha-numeric led characters 1 b l v 0 a k u 2 c m w 3 d n x 4 e o y 5 f p z 7 h r 8 i s 9 j t 6 g q 6.2 parameter groups to access the parameter groups the cover must be removed to allow access to the 5 way button. The 5 way button is used to navigate the param...

Page 23

Mn761 using the keypad 6-3 view the drive group parameters: when power is applied, the first drive group parameter is viewed. Action description display comments apply power power on display shows drive status. Speed reference is 0.0hz this is the first display within the drive group press the y key...

Page 24

6-4 using the keypad mn761 change accel time from 5.0 to 16.0 seconds: factory setting is 5.0 seconds. Action description display comments apply power press the y key accel parameter is displayed. Acceleration time. Press enter to view or change setting. Press enter to view/edit the right most digit...

Page 25

Mn761 using the keypad 6-5 change speed reference from 0.0 to 30.0hz: factory setting for keypad speed reference is 0.0hz. Action description display comments apply power press the a key twice to move 2 digits to the left the present value is 5 and we want it to be 6. Press the y key to increase the...

Page 26

6-6 using the keypad mn761 view the motor rpm on a 3 digit display: motor rpm in this example is 1730rpm action description display comments apply power speed reference is displayed 57.6hz press the y key until the rpm is displayed the next parameter is displayed. Press enter to view or change setti...

Page 27

Mn761 using the keypad 6-7 reset all parameters to factory settings: restoring factory settings (h93) will overwrite all parameter values. Action description display comments apply power press the " key to go to function group 2. The jump code in function group 2 press enter to edit the jump code. C...

Page 28

6-8 using the keypad mn761.

Page 29: Parameter Descriptions

Mn761 parameter descriptions 7-1 chapter 7 parameter descriptions 7.1 drive group parameter # access parameter name, value range, description and preset value rw speed reference (range: 0.00 to 400.00 hz) must be less than f21. The value of the speed reference command. The commanded speed (frequency...

Page 30: 7.1 Drive Group

7-2 parameter descriptions mn761 7.1 drive group continued parameter # access parameter name, value range, description and preset value rw preset speed 3 (range: 0-400 hz) must be less than f21. Sets preset speed 3 during operation. See also i30-i33. Preset value: 30.00 ro output current (range: n/a...

Page 31: 7.2

Mn761 parameter descriptions 7-3 7.2 function group1 parameter # access parameter name, value range, description and preset value rw jump code (range: 0-60) sets the parameter number to jump to within function group1. Allows quick access to a desired parameter. Preset value: 1 rw forward/reverse run...

Page 32: 7.2 Function Group1

7-4 parameter descriptions mn761 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw dc brake trigger (range: 0.0-60 hz) sets the frequency at which dc braking begins. Cannot be less than f23. Preset value: 5.00 parameter is only displayed wh...

Page 33: 7.2 Function Group1

Mn761 parameter descriptions 7-5 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw start speed (range: 0.1-10hz) sets initial speed of the inverter. Preset value: 0.50 rw speed high/low limit selection (range: 0=no, 1=yes) sets whether the ...

Page 34: 7.2 Function Group1

7-6 parameter descriptions mn761 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw volts/hz pattern (range: 0- linear. Maintains a linear volts/hz ratio from f23 to f22. 1- square. Maintains a squared volts/hz ratio. 2- user defined. Volts/...

Page 35: 7.2 Function Group1

Mn761 parameter descriptions 7-7 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw user v/f frequency 4 (range: 0-400hz) sets frequency 4 in user defined v/f pattern. See also f38. Cannot be greater than f21. Preset value: 60.00 parameter i...

Page 36: 7.2 Function Group1

7-8 parameter descriptions mn761 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw electronic thermal level for 1 minute (range: 50-150%) sets the maximum continuous motor current allowed for 1 minute as a % of h33. Cannot be less than f52....

Page 37: 7.2 Function Group1

Mn761 parameter descriptions 7-9 7.2 function group1 continued parameter # access parameter name, value range, description and preset value rw stall prevent (range: 0- no stall prevention. 1- during acceleration. Accel is stopped when motor current > f60. 2- during constant run: motor decels when mo...

Page 38: 7.3

7-10 parameter descriptions mn761 7.3 function group2 parameter # access parameter name, value range, description and preset value rw jump code (range: 1-95) sets the parameter number to jump to within function group2. Allows quick access to a desired parameter. Preset value: 1 ro fault history 1 (r...

Page 39: 7.3 Function Group2

Mn761 parameter descriptions 7-11 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw skip frequency high limit 1 (range: 0-400hz) sets the upper limit of frequency range 1 to skip. Preset value: 15.00 parameter is only displayed when h10=1. ...

Page 40: 7.3 Function Group2

7-12 parameter descriptions mn761 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw auto restart (range: 0- off. Motor will not start immediately when fault condition is reset. 1- on. Motor will start acceleration when fault condition is re...

Page 41: 7.3 Function Group2

Mn761 parameter descriptions 7-13 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw i gain during speed search (range: 0-9999) sets the pi controller integral gain used during speed search. Preset value: 1000 rw restart attempts (range: 0-1...

Page 42: 7.3 Function Group2

7-14 parameter descriptions mn761 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw load inertia rate (range: 0- load inertia rate is less than 10 times that of motor inertia 1- load inertia rate is approximately 10 times the motor inertia....

Page 43: 7.3 Function Group2

Mn761 parameter descriptions 7-15 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw proportional (p) gain for pid (range: 0-999.9%) sets the p gain for the pid controller. If p gain is set to 50%, 50% of the error value will be output. Pres...

Page 44: 7.3 Function Group2

7-16 parameter descriptions mn761 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw speed reference for accel/decel (range: 0- f21 (max speed). Accel/decel time is the time to reach max speed from 0 hz or 0hz from max speed. 1- delta speed....

Page 45: 7.3 Function Group2

Mn761 parameter descriptions 7-17 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw monitoring item (range: 0- output voltage [v] 1- output power [kw] 2- torque [kgf-m]) selects the item to be monitored/displayed in vol parameter. Preset va...

Page 46: 7.3 Function Group2

7-18 parameter descriptions mn761 7.3 function group2 continued parameter # access parameter name, value range, description and preset value rw second motor stall prevention level (range: 30-150%) sets the current level that activates stall prevention for the second motor during accel, constant, or ...

Page 47: 7.4

Mn761 parameter descriptions 7-19 7.4 i/o group parameter # access parameter name, value range, description and preset value rw jump code (range: 0-63) sets the parameter number to jump to within i/o group. Allows quick access to a desired parameter. Preset value: 1 rw filter time constant for v0 in...

Page 48: 7.4 I/o Group

7-20 parameter descriptions mn761 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw i input minimum current (range: 0-20ma) sets the minimum current of the i input. Preset value: 4.00 rw speed corresponding to i12 (range: 0-400hz) sets the minimu...

Page 49: 7.4 I/o Group

Mn761 parameter descriptions 7-21 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw programmable digital input terminal p1-p5 definition (range: 0- forward run. 1- reverse run. 2- output inhibit. 3- fault reset. 4- jog. 5- speed select1. 6- speed...

Page 50: 7.4 I/o Group

7-22 parameter descriptions mn761 7.4 i/o group continued figure 7‐4 p5 (jog) frequency f20 run command (fx) p1 p5 cm fx : t1 = 0 jog t5=4 5 = speed select 1 - (see figure no tag) 6 = speed select 2 - (see figure no tag) 7 = speed select 3 - (see figure no tag) used to select preset speed 1 - 7 comb...

Page 51: 7.4 I/o Group

Mn761 parameter descriptions 7-23 7.4 i/o group continued figure 7‐6 p1 p2 p8 cm fx : t1=0 rx : t2=1 3- wire :t8=17 fx rx frequency p8 (3- wire) t 18 = external trip - a (n.O.): normally open contact input. When a digital input is set to “ext trip-a” is on (closed), the drive displays the fault and ...

Page 52: 7.4 I/o Group

7-24 parameter descriptions mn761 7.4 i/o group continued figure 7‐8 set frequency frequency p8 operation command frequency p8 operation command 24 = accel/decel disable: disables the acceleration or deceleration ramp while the digital input is closed, holding the reference at its last value. See fi...

Page 53: 7.4 I/o Group

Mn761 parameter descriptions 7-25 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw input terminal status display (range: n/a) displays the on/off status of each digital input. Preset value: n/a on of f p1 p2 p3 p4 p5 example: p1, p3, p4 are on a...

Page 54: 7.4 I/o Group

7-26 parameter descriptions mn761 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw accel time 2 (range: 0-6000sec) sets the acceleration time for preset speed 2. Preset value: 4.0 rw decel time 2 (range: 0-6000sec) sets the deceleration time for...

Page 55: 7.4 I/o Group

Mn761 parameter descriptions 7-27 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw analog output function (range: 0-3) 0- output frequency. (range=min to max frequency). 1- output current. (range 0- 150%). 2- output voltage. (range 0-282vac). 3-...

Page 56: 7.4 I/o Group

7-28 parameter descriptions mn761 7.4 i/o group continued parameter # access parameter name, value range, description and preset value rw fault relay output (range: 0- none 1- at low voltage trip. 2- all trips other than low voltage. 3- all trips. 4- when setting h26 [number of auto-restart tries] 5...

Page 57

Mn761 customizing for your application 8-1 chapter 8 customizing for your application.

Page 58

8-2 customizing for your application mn761.

Page 59: Troubleshooting

Mn761 troubleshooting 9-1 chapter 9 troubleshooting the vs1pf constantly monitors operating status and provides the following means to determine drive status and to troubleshoot problems that may occur: s leds on the drive s fault codes displayed on lcd display s drive monitor and status parameters ...

Page 60

9-2 troubleshooting mn761 table 9-1 fault code description continued display function description / cause. Cause remedy low voltage output turns off when the dc link voltage is less than 180v. Line voltage is low. Insufficient line capacity. Increase line voltage. Check the ac line voltage at full r...

Page 61: Technical Specifications

Mn761 technical specifications a-1 appendix a technical specifications all specifications are subject to change without notice. Input ratings voltage 230 voltage range 190-253 phase single phase frequency 50/60hz ±5% impedance 1% minimum from mains connection output ratings horsepower 0.5-3 hp @ 230...

Page 62

A-2 technical specifications mn761 keypad display display 2 line by 15 character lcd keys 9 key membrane with tactile response functions output status monitoring digital speed control parameter setting and display diagnostic and fault log display motor run and jog local/remote toggle led indicators ...

Page 63: Parameter Tables

Mn761 parameter tables b-1 appendix b parameter tables refer to chapter 7..

Page 64

B-2 parameter tables mn761 b.1.1 basic parameters continued.

Page 65: Ce Guidelines

Mn761 ce guidelines c-1 appendix c ce guidelines c.1 ce declaration of conformity baldor indicates that the products are only components and not ready for immediate or instant use within the meaning of “safety law of appliance”, “emc law” or “machine directive”. The final mode of operation is define...

Page 66

C-2 ce guidelines mn761 emc installation options when installed for class a or class b operation, the control is compliant with en55011 (1991)/ en55022 (1994) for radiated emissions as described. Grounding for wall mounting (class a) also see chapters 4 and 5. Top cover must be installed. S a single...

Page 67

Mn761 ce guidelines c-3 emc wiring technique 1 cabinet the drawing shows an electroplated zinc coated enclosure, which is connected to ground. This enclosure has the following advantages: - all parts mounted on the back plane are connected to ground. - all shield (screen) connections are connected t...

Page 68: C.3

C-4 ce guidelines mn761 c.3 emc installation instructions to ensure electromagnetic compatibility (emc), the following installation instructions should be completed. These steps help to reduce interference. Consider the following: s grounding of all system elements to a central ground point s shield...

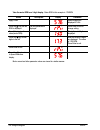

Page 69: Baldor District Offices

Baldor district offices.

Page 70: Baldor Electric Company

All rights reserved. Printed in usa 10/07 baldor electric company world headquarters p.O. Box 2400 fort smith, ar 72901-2400 (479) 646-4711 fax (479) 648-5792 www.Baldor.Com e 2007 baldor electric company mn761.

Page 71

Series vs1sm single phase ac contr ol mn761.