- DL manuals

- Ballu

- Air Conditioner

- BSGI 09

- Service Manual

Ballu BSGI 09 Service Manual

Summary of BSGI 09

Page 1

As-09(12)ur4svnvg service manual 编号:xm00009562 编制:项目组长李本卫 校对:电控于心艳张永良 结构卢瑞艳 系统李本卫 审核 1:杜建伟 审核 2:赵可可 审核 3:殷显鑫 审核 4:陆汉宁 批准:王剑锋 海信科龙空调有限公司 2010 年 03 月.

Page 2

Table of contents page 1.operating range 1 2.specification 2 2-1 unit specifications 2 2-2 major component specifications 3 2-3 other component specifications 4 3.outlines and dimensions 6 3-1 indoor 6 3-2 outdoor 7 4.refrigerant flow diagram 8 4-1 refrigerant flow diagram 8 4-2 evacuation procedure...

Page 3

9-2 outdoor 41 10.parts list 45 10-1 indoor 45 10-2 outdoor 47.

Page 4

1 1 . . O o p p e e r r a a t t i i n n g g r r a a n n g g e e a a s s - - 0 0 9 9 ( ( 1 1 2 2 ) ) u u r r 4 4 s s v v n n v v g g temperature indoor air intake temp. Outdoor air intake temp maximum 32℃ d.B./23℃ w.B. 43 ℃ d.B./26℃ w.B. Cooling minimum 21℃ d.B./15℃ w.B. 21 ℃ d.B./15℃ w.B. Maximum 27...

Page 5

2 2 . . S s p p e e c c i i f f i i c c a a t t i i o o n n s s 2-1. Unit specifications note :test conditions: model function cooling heating cooling heating power supply a.C 220v/50hz btu 9000 11000 11000 11500 capacity kw 2.65 3.25 3.2 3.37 dehumidification l /h 1.0 —- 1.0 —- capacity air flow m ...

Page 6

2 2 . . S s p p e e c c i i f f i i c c a a t t i i o o n n s s 2-2. Major component specifications 2-2-1.Indoor fan motor electric performance parameter motor model rgp18 rated power source 220v 50hz phases/poles 1/4 rated load output(w) 16 rated speed(r/min) 1330 ambient temperature( ) ℃ -5℃~+43℃....

Page 7

2 2 . . S s p p e e c c i i f f i i c c a a t t i i o o n n s s 2-3. Other component specifications 2-3-1. Inductance electric performance parameter inductance model - rated power source - loop winding rated current - rated current(a) filter winding rated current - loop winding rated inductance - ra...

Page 8

2 2 . . S s p p e e c c i i f f i i c c a a t t i i o o n n s s 2-3-5. Overload protection electric performance parameter model int11l-3979 reset temperature( ) ℃ 95±5℃ trip temperature( ) ℃ 115±3℃ 5 bsgi 09(12).

Page 9

3 3 . . O o u u t t l l i i n n e e s s a a n n d d d d i i m m e e n n s s i i o o 3-1. Indoor 23mm 631mm 94mm 750mm 65mm 250m m 190mm 50mm 50mm 50m m 3-2.Outdoor 6 bsgi 09(12).

Page 10

3 3 . . O o u u t t l l i i n n e e s s a a n n d d d d i i m m e e n n s s i i o o 443 240 245 240 6 715 48 2 31 0 134.5 19 narrow tube service valve Φ9.52( ) wide tube service valve Φ6.0( ) 68 87 >40cm >25cm >1 0 c m >5cm 7 bsgi 09(12).

Page 11

4 4 . . R r e e f f r r i i g g e e r r a a n n t t f f l l o o w w d d i i a a g g r r a a m m 4-1. Refrigerant flow diagram : indoor outdoor evaporator condenser check valve ass'y compressor capillary(shot tube throttle valve ) remark: cooling cycle remark: heating cycle 4-2. Evacuation procedures...

Page 12

4 4 . . R r e e f f r r i i g g e e r r a a n n t t f f l l o o w w d d i i a a g g r r a a m m evacuation procedures connect the refrigerant pipes (both the liquid and gas pipes) between the indoor and the outdoor units. Remove the service port cap of the stop valve on the side of the outdoor unit ...

Page 13

4 4 . . R r e e f f r r i i g g e e r r a a n n t t f f l l o o w w d d i i a a g g r r a a m m max. Refrigerant piping length models refrigerant piping max. Length: m a piping size (od) : mm length of connecting pipe : m gas liquid indoor unit outdoor unit models indoor unit outdoor unit max. Heigh...

Page 14

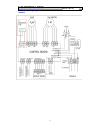

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 5-1.Electrical wiring diagrams 1.Indoor 11 bsgi 09(12).

Page 15

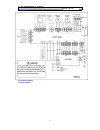

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 12 2.Outdoor 5-2. Electric control 1.Indoor control bsgi 09(12).

Page 16

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 13 2.Outdoor control bsgi 09(12).

Page 17

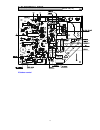

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 14 out ipm: bsgi 09(12).

Page 18

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 15 bsgi 09(12).

Page 19

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 1. The parameter of outdoor compressor temperature sensor: (r 0 =187.25k±6.3%;r 100 =3.77k±2.5k;b=3979±1%) t(℃ ) r(kΩ ) v(v) dec hex t(℃ ) r(kΩ ) v(v) dec hex t(℃ ) r(kΩ ) v(v) dec hex -30 966.1 0.1014 5 5 26 55.46 1.3252 68 44 82 6.662...

Page 20

5 5 . . E e l l e e c c t t r r i i c c a a l l d d a a t t a a 2. The parameter of the coil and indoor and outdoor sensor : (r 0 =15k±2%;b=3450±2%) t(℃) r(kΩ) v(v) dec hex t(℃) r(kΩ) v(v) dec hex t(℃) r(kΩ) v(v) dec hex -30 67.94 0.3235 16 10 18 6.962 2.0151 103 67 66 1.297 3.9186 200 c8 -29 64.25 ...

Page 21

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l 6-1. Major general technical parameters 6-1-1 conditionings for operation: ambient temperatures: (-15 - +45 ℃), relative humidity (45 - 85%). 6-1-2 remote receiver distance: 8 m. 6-1-3 remote receiver angle: less than 80 degrees. 6-1-4 temperat...

Page 22

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l switch for 5 seconds, the buzzer rings for 3 times and the controller starts in the trial operation. The trial operation is the forced cooling with the indoor fan speed being set at high speeds, the flaps sweeping and the air conditioner’s oper...

Page 23

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l receiving a signal from the remote controller. If the air conditioner has not received a signal from the remote controller when the set time is up, it will turn off automatically. 6-3-3-3 neither the turning on nor turning off operation will ca...

Page 24

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l a. When t room – t set > 3℃, it will be changed to the cooling mode; b. When t room – t set < -3℃, it will be changed to the heating mode; c. When these conditions are not met, it will remain in the previous run mode. When the temperature setti...

Page 25

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l t room -t set indoor fan speed t room -t set ≤2 0 c low 2 0 c room -t set 0 c medium t room -t set ≥4 0 c high 6-3-7-4 prevention against condensation and insufficient heat exchange at the low indoor fan speed. When the indoor fan speed is set ...

Page 26

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l when the compressor is turned off in the heating run, the indoor fan does not stop at once, but until the indoor evaporator temperature is below 23 0 c, but for 30 seconds at the latest. When the compressor is turned off in the heating run, the...

Page 27

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l dehumidifying area ii: the compressor stops for 5 minutes and operators for 5 minutes at the lowest frequency. Dehumidifying area iii: the compressor stops. 6-3-10 air blowing mode the outdoor unit does not work while the indoor fan runs with t...

Page 28

6 6 . . C c o o n n t t r r o o l l m m o o d d e e l l starts to operate, the indoor unit supplies the outdoor unit (except for the ventilation mode). If the eeprom data is read correctly after turning on the power, the indoor unit’s beeper rings one time, or if it is not the case the beeper will r...

Page 29

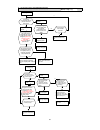

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g 7-1. Trouble alarm trouble list indication on the outdoor unit when the compressor is interrupted, the outdoor leds are used to indicate the troubles listed below: symbols for indicator lights: ★: on Ο: flashing ×: off led1 led2 led...

Page 30

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g 6 over and under-voltage control 33 room temperature sensor in trouble 7 communication trouble 34 indoor coil temperature sensor in trouble 8 current overload control 36 communication between the indoor and outdoor in trouble 9 maxi...

Page 31

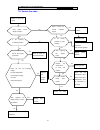

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g 7-2. Service flow chart switch on the power supply no no yes no no yes no yes yes yes no yes no check the first and secondary voltage. The first voltage:220v the secondary voltage: *c15:12v cn4(1,2terminal):5v are the wires poorly c...

Page 32

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g yes error code 34 indoor coil sensor trouble error code 33 indoor temperature sensor replace the indoor pcb board does the resistance of thermistor have the characteristics on part 6-3 take out from cn6 ,measure the resistance of th...

Page 33

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g 30 error code 39 indoor fan motor trouble is indoor fan motor running? Set the air conditioner operate in fan mode does fan motor stop with the remote controller check the connector of indoor motor does the socket cn1(1-3) of indoor...

Page 34

7 7 . . T t r r o o u u b b l l e e s s h h o o o o t t i i n n g g 31 error code 36 communication trouble are all the lead wires connected between indoor and outdoor unit? Connect the indoor and outdoor unit again according to the wiring diagram is there power output between indoor t/b 1 and 2 ac22...

Page 35

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s 8-1. Check refrigerant system test system flow conditions: compressor is running. ① ② the air condition should be installed in good ventilation. Tool: pressure gauge technique: see feel test ① ① ① see---tube defrost. Fee...

Page 36

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s 33 cooling mode test system pressure.Does the low pressure normal at service part ? The pressure on the high side. The pressure on the low side. Recharge refrigerant after air purging with the vacuum pump.Does the low pr...

Page 37

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s 8-2.Check parts unit 1. Indoor fan motor .Motor examine and repair circuit diagram 34 test in resistance. Tool: multimeter. Test the resistance of the main winding. The indoor fan motor is fault if the resistance of main...

Page 38

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s 3. Compressor 1. Coil resistance::0.744Ω (at 20 ) ℃ 2. Compressor examine and repair. Dc inverter controller & r u ( ) s v ( ) t w ( ) overload protection power test in resistance. Tool: multimeter. Test the resistance o...

Page 39

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s test in resistance. Tool: multimeter. Test the resistance of “load” port. The filter is fault if the resistance of winding 0(short circuit)or∞(open circuit) 7. Stepper motor test in resistance. Tool: multimeter. Test the...

Page 40

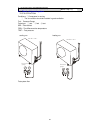

8 8 . . C c h h e e c c k k i i n n g g c c o o m m p p o o n n e e n n t t s s fuse fig.2 2. Capacitor remove the lead wires from the capacitor terminals, and then place a probe on the capacitor terminals as shown in fig.3.Observe the deflection of the pointer, setting the resistance measuring rang...

Page 41

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 38 9-1.Indoor 1. . . ' remove the installation plate take out the screw of the installation plate and remove the installation plate. 2 remove the mounting plate take out the mounting plate . 3 remove ...

Page 42

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 39 4 take out the 4 screws of the grille and remove the grille. Grille and remove the grille. ) screws 4 1 3 and evaporator ass y take out the room temperature sensor and coil sensor on the evaparator...

Page 43

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 40 then remove the evaporator. Evaporator. 6 remove the indoor cross flow fan and fan motor 1 take out the 2 screws of the cover and remove the cover of the bearing housing. . - ) 2 take out the 3 scr...

Page 44

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 41 1.Remove the top panel the front panel 1)take out the 8 screws of the top panel and remove the top panel. 8 screws top panel 2. Remove the front panel 1)take out the 9 screws of the top panel and r...

Page 45

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 42 2) take out the 11 screws of the side panel and remove the side panel. 11 screws side panel 4. Take out the 2 screws and remove the electrical control box . 2 screws electrical box filter 5. Remove...

Page 46

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 43 6.remove the partition plate 1) take out the 3 screws and remove the partition palte。 2)take out the 4 screws and remove the inductance。 3 screws 4 screws on the partiton partiton plate bsgi 09(12).

Page 47

9 9 . . D d i i s s a a s s s s e e m m b b l l y y i i n n s s t t r r u u c c t t i i o o n n s s 44 7.Check up the other parts of the outdoor units. 1)check-up the condenser ass’y. 2)check-up the compressor ass’y. 3)check-up the base ass’y. 4)check-up the 4 way valve,capillary tube and check valv...

Page 48

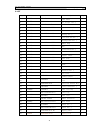

1 1 0 0 . . P p a a r r t t s s l l i i s s t t 10-1.Indoor 1. Parts 45 bsgi 09(12).

Page 49

1 1 0 0 . . P p a a r r t t s s l l i i s s t t 46 2. List key no. No. Part no. Description q’ty 1 1359354 g1k30/r00.02-01 front panel 1 2 1320776 k33b10003 air filter ass’y 2 3 1359347 g1k30/r00.02-02 grill ass'y 1 4 1203331 rza-2-2219-043-xx-0 evaporator bracket 1 5 1336907 k37320147 evaporator as...

Page 50

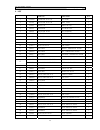

1 1 0 0 . . P p a a r r t t s s l l i i s s t t 10-2. Outdoor 1. Parts 27 32 31 30 29 28 26 25 24 23 21 20 19 16 7 6 5 4 3 22 18 17 15 14 12 13 11 1 2 8 9 10 33 34 47 bsgi 09(12).

Page 51

1 1 0 0 . . P p a a r r t t s s l l i i s s t t 48 2. List key no. No. Part no. Part name q'ty 1 12768461 w1b0d/r00.02.01-02 fan guard 1 2 1247907 w1e0l/r00.02.01-00 front panel 1 3 1313821 dg22z1-20 propellor fan 1 4 1335251 k1b310136 fan motor assy 1 5 1308210 w1e0l/r00.02-05 fan supporter 1 6 137...