- DL manuals

- Bally

- Chiller

- 1000

- Installation And Operation Manual

Bally 1000 Installation And Operation Manual

Summary of 1000

Page 1

1 installation and operation manual northwind blast chiller models: 500 and 1000 1-800-24 bally bally refrigerated boxes, inc. Www.Ballyrefboxes.Com im-359-11 2011© bally refrigerated boxes, inc ..

Page 2

2 introduction read entire manual before beginning installation! • there are 9 steps to the installation process. This manual gives you a correct sequence to follow as you prepare for and carry out installation. • prior to the day you make the installation, be sure to review the tool list and parts ...

Page 3

3 table of contents title page number introduction 1 tool list 4 parts list 4 step 1 – locating the blast chiller 5 step 2 – panel preparation 5 step 3 – erection of vertical panels 6 step 4 – installation of ceiling panels 7 step 5 – secure all panel sections 8 step 6 – installation of the controll...

Page 4

4 note: 012993’s are sometimes left out (see chapter. 6.3).

Page 5

5 bally northwind tool list two people are required to assemble a bally northwind. The following list will assist you on the tools necessary in the assembly process. 1. Caulk gun (tube type) 2. Utility knife (for foam insulation) 3. Foaming kit (in the general miscellaneous box*) 4. Speed lock wrenc...

Page 6

6 1. Locating the blast chiller 1.1. Using a chalk line and a carpenter’s square, locate on the building floor, the exact dimensions of the blast chiller as shown in the supplied print. After marking the exterior rectangular dimensions, measure inward 4” around the perimeter to form an interior rect...

Page 7

7 3. Erection of vertical panels 3.1 before attempting to erect any prefab sections, familiarize yourself with the following chapters in the standard installation manual (im-268-11, revised 2011): • page 4, section 1 • page 5, section 2 operation of the bally speed-lok • page 7, section 3 bally boxe...

Page 8

8 3.3 on each panel, check for proper alignment and level. Leveling can be accomplished by placing wooden shims under the vertical panels (cross- reference im-268-11, section6). 3.4 remove the shipping strap attached to the bottom of the door opening. When attaching the door, hold a level on the fac...

Page 9

9 5. Secure all panel sections 5.1 after all speed-loks are secured, install access hole plug buttons to all speed-lok locations. 5.2 anchor both sides of the doorframe inside the box to the floor with “l” braces with 5/16” expansion bolts and 5/16”hex head self-tapping screws with shoulders to the ...

Page 10

10 deflecting the flow of air from the fan frame assembly to the coil frame assembly. Prior to installing, prepare 1/8” pilot holes and use ¾” stainless steel, self-tapping, phillips head sheet metal screws. Some tall (over 106”) boxes may not have ceiling deflectors. Check the packing list for pn 0...

Page 11

11 7.3 installing the fan frame assembly 1. First remove the fan guard. 2. Install the frame in the appropriate side and screw the back braces to the side wall using the same stainless steel sheet metal screws. 3. Plug in the air probe (see connector at top of picture). 4. Install the two shorter si...

Page 12

12 7.5 installing the plenum supports and plenum 1. At this point, the front plenum support, fan seal strip, and coil top trim should be in place. Adjust the side pieces so that they match the front in height (usually 78”). Interior plenum supports on both sides of the interior wall of a nw1000. The...

Page 13

13 *the priority should be in that order, if the coil top trim holes won’t match up when the plenum is screwed to the front, unscrew the coil frame from the wall and shift it over until it fits. The fan trim piece can shift side to side with respect to the frame, and you can redrill the holes in the...

Page 14

14 operations manual bally northwind blast chiller models: 500 and1000 introduction • before turning the controller on, take the time to ensure that all wire connections are secure and correctly matched according to the color code set for them. • also, inspect all of the external wiring, making sure...

Page 15

15 1. The control panel the first pushbutton located to the right is the manual on/off power switch for the blast chiller. The red pushbutton to the left of the on/off is used to silence the alarm buzzer. On the face of the input screen you see nine buttons; left / right on the left hand side of the...

Page 16

16 3.2 the display screens in automatic: • while in automatic, you can push the up and down arrows on the display to page through information appropriate for this mode. • when the automatic mode begins, you will see the word “auto” and the product temperature in large numbers, so you can see it from...

Page 17

17 4. Defrost • actually a lot of our customers don’t use defrost. They’ll run the unit for three to six hours a day, and for the rest of the time it will remain idle. The temperature in the unit comes up above freezing and whatever ice is on the evaporator coils will thaw and drain from the unit be...

Page 18

18 5. Manual mode in manual mode, you can leave out the product probe that auto mode requires. Instead of inserting the probe, you program the chiller to chill for a certain length of time. While running in manual mode, yet prior to the time ending, it will behave as it does when in auto mode when t...

Page 19

19 7. Maintenance items for bally northwind blast chillers 7.1 maintenance points • probe plugs the temperature probes are low voltage circuits that are routed through plugs at the top of the coil frame and behind the fan frame. If you start getting erroneous probe readings, use a light abrasive pad...

Page 20

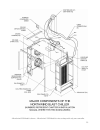

20 a northwind 500 model is shown. A northwind 1000 model is twice as deep with only one controller..