Summary of NC250

Page 1

0

Page 2: User’S Safety Statement

1 user’s safety statement dear customer, please don’t ride the motorcycle before you are not reading this handbook or unknown this motorcycle performance, also don’t borrow to anybody who don’t know how to use. Driver’s attention: 1、before driving ① check motorcycle condition careful,don ’t ride if ...

Page 3

2 the company reserves it’s rights to make any changes due to product updates。 introduction 1、resume ………………………………………………………………………………………p 2~p 7 2、maintenance …………………………………………………………………………………p8~p33 3、e lertr ical sch ema tics ………………………………………………………………p34 4、product warranty description …………………………………………………...

Page 4

3 cooling system description………1-6 maintenance regulation 1. Must to use this company or this company recommend spare parts or lubricants;not to suits to this company designing parts or lubricants ,may damage the vehicle . 2. Should use the metric tool, bolt, nuts and screws to maintain vehicle, it ...

Page 5

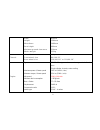

4 wi d t h h e i g h t w h e e l b a s e s e a t h e i g h t m i n i m u m g r o u n d c l e a r a n c e w h o l e we i g h t 8 3 0 m m 1 2 8 0 m m 1 4 8 6 m m 9 6 0 m m 3 1 0 m m 1 3 5 k g c h a s s i s m a t e r i a l f r o n t wh e e l s i z e r e a r w h e e l s i z e a l l o y 8 0 / 1 0 0 - 2 1...

Page 6

5 lubricating system and pump type ignition advance angle valve clearance(cold) spark plug type measurement net weight transmission type pressure splash btdc 12° [3000r/min] intake valve: 0.03 mm exhaust valve: 0.05mm; chamr10n rg6yc 370mm×315mm×415 mm 30 kg chain reduction ratio clutch type gearshi...

Page 7

6 starting performance ≤15 s l u b ricat io n s ystem i t e m s e n g i n e l u b r i c a t o i l c a p a c i t y 1 6 0 0 m l o i l b r a n d : apl sj sae10w-40 f u el s ystem i t e m s d e s c r i p t i o n oil brand 97# c a p a c i t y 8 . 0 l ta n k c a p a c i t y 1 . 4 l c o o lin g s ystem i t...

Page 8

7 st a n d a r d c o o l a n t c o n c e n t r a t i o n m i x e d 1 : 1 w i t h d i s t i l l e d w a t e r f ro n t w h eel /s u sp en sio n / op erate sp eci fica tio n i t e m s st a n d a r d m a i n t e n a n c e l i m i t e d c o o l i n g wh e e l p r e s s i o n 3 2 / 2 . 2 5 ( p s i / b a ...

Page 9

8 vo l t a g e ( 2 0 0 / 6 8 0 f ) f u l l y c h a r g e d 1 3 . 0 - 1 3 . 2 v ig n it io n s ys tem i t e m s d e s c r i p t i o n sp a r k p l u g st a n d a r d c h a m p i o n r g 6 y c 2. Maintenance first: maintance date………………………………2-9 fourteenth: engine oil/oil filter………2-23 second: techniqu...

Page 10

9 tenth: spark plug………………………2-19 twenty-third: rocker arm/vibration coupling……2-31 eleventh: radiator coolant……………2-19 twenty-fourth: wheels/tires………………2-32 twelfth: cooling system…………………2-20 twenty-fifth: front tube bearing………… … 2-33 thirteen: valve clearance/decompression device system…2-21 first...

Page 11

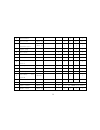

10 second: technique maintenance i:check and clean,adjust,if necessary lubricate or replace c:clean r:replace a:adjust l:lubricate frequency items no matter which one first time to maintain trip distance or date first minutes 100 600 1200 1800 2400 received kilometers 150 1000 2000 3000 4000 note mo...

Page 12

11 * accelerator i i air filter (note 1) c c c c crankcase breather pipe (note 2) i i i i spark plug i i i i * air valve i i i i i machine oil r r r r r oil filter r r r r r * decompression device i i i i i * idling i i i i i coolant fluid (note 3) i r * cooling system i i i i i * secondary air syst...

Page 13

12 brake block i i i i brake system i i i i i * lights i i clutch system i i i i i side stay i i * f/r damping i i * nuts 、 bolts 、 fasteners i i i * * wheels/tires i i i i i * * front tube bearing i i i 9. * please go to our authorized dealers for repair, unless the owners have special tools and ma...

Page 14

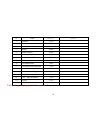

13 items frequency notes about 2.5 hours abouy 7.5 hours about 15.0 hours about 22.5 hours about 30 hours accelarator i choke valve i air filter (note 1) c crankcase breather pipe i spark plug i coolant fluid (note 2) i valve/decompression device (note 4) i machine oil (note 3) i r oil filter (note ...

Page 15

14 drive chain rotor i active/driven sprocket i brake fluid (note 2) i brake block i brake system i clutch system (note 5) i control cable i,l exhaust pipe/silencer i f/r damping i rear fork/ rocker arm l front shock absorber oil (note 3) r nuts、bolts、fastener i wheels/tires i front tube bearing i t...

Page 16

15 3、if replace the clutch plate and baffle ,should replace the transmission oil . Fourth: additional items should be changed frequently engine items reasons remarks cylinder head gasket clutch pressure plate head gasket right side cover sealing leakage of a crush abrasion or rust leakage damage as ...

Page 17

16 front covering parts front and rear fender clutch handle/stay brake handle kick start bar handlebar the throttle handle grip shift lever brake pedal chain adjuster/bolts air filter damage damage excessive gap or damage excessive gap or damage excessive gap or damage deformation or fissure damage ...

Page 18

17 sixth: oil filter mesh disassemble fuel tank: first drop the oil into container, remove the tubing,bolts and oil switch, then clean the oil filter ,ensure the o-ring in a good condition and install it to oil switch ,re-install in reverse order with the disassemble, install the fuel tank (make sur...

Page 19

18 seventh: accelerator operation check the throttle grip, it should be rotate smoothly and freely return; check the throttle cable, if it ’s ageing or damage should be replaced; if throttle operate not smoothly should lubricate the cable;the free rotation distance of adjust throttle grip is in 3-5m...

Page 20

19 nineth: air cleaner open the air cleaner side cover, remove the retaining bolts.Remove the filter element from bracket, put it into clean cleaner to wash, and then get it from that cleaner to the hot soup-sudz to wash; clean the air filter inner room to ensure there is no mess; when the air clean...

Page 21

20 tenth: spark plug disassembly disassemble fuel tank, remove the spark plug cover from cylinder head, disassemble spark plug,and check it to see if it is damage (see figure 10-1).(before disassemble,use the compression air to clean the spark plug, ensure there is no mess enter the combustor.) acco...

Page 22

21 eleventh: radiator coolant check the coolant level before start the engine or after the engine flameout 5 minutes, if can ’t see the liquid surface,please add the recommended coolant; remove the cover, add the mixed liquid which mixed with distilled water and antifreeze 1:1,the distance from liqu...

Page 23

22 thirteenth: valves clearance check valves clearance disassemble cylinder head cover; check and adjust the valve clearance after the engine is cooled; disassemble crankcase cover and o-ring.(see the figure 13-1) rotating the magnator mark on clockwise direction to make it with the left crankcase c...

Page 24

23 intake side: put the feeler gague between the rocker arm stud and valve, measure the intake side valve clearance intake valve clearance : 0.03mm (figure 13-3) exhaust valve side: put the feeler gague between the rocker arm stud and valve,measure the exhaust side valve clearance exhaust valve clea...

Page 25

24 install the crankshaft hole cap and screw it to the special torque. Torque:15n.M fourteenth:engine oil / oil filter oil surface inspection starting engine idling 3 minutes, waiting 3 minutes after the engine flameout . Put the motorcycle vertical support in the horizontal plane, if the oil horizo...

Page 26

25 viscosity:sae 10w-40 fuel capacity:1.6l(figure14-2) engine oil and oil filter replacement remove the engine cover, starting engine idling 3 minutes, waiting 3 minutes after engine flameout. Put motorcycle vertical support in the horizontal plane, stop the engine, remove the oil nut off(figure 14-...

Page 27

26 this menthod can drop the engine oil completely remove the bolts, oil filter cover and o-ring( figure 14-5 ) remove the oil filter(figure14-6) , install the engine oil drain screw, use the special torque 20n.M to tightening the engine drain bolt(figure 14-3). Figure14-6 figure14-5.

Page 28

27 notes:if install the oil filter anti-direction,it will seriously damage the engine, grease engine oil on the new o-ring, put it on the oil filter cover, install the oil filter cover tightening the bolt. Put the recommended machine oil enter engine : re-check the engine oil level(see figure 14-1) ...

Page 29

28 sixteenth: drive chain drive chain relaxation tests put the vehicle on the workbench, make the rear wheel off ground . (when engine working, please don ’t check and adjust drive chain) review the middle of the chain, measure the chain relaxation on this. ( s e e f i g u r e 1 6 ) chain relaxation...

Page 30

29 notes: if chain slider was abrade, the chain will abrade rocker, destroy the chain and rocker. Check the chain guide and slider, to see if these are rank well 、abrade or damaged. ( f i g u r e 1 7 - 2 ) if damaged or abraded,replace the chain guide. If the slider was wear to the special wear mark...

Page 31

30 the chain and sprocket should be in good condition,otherwise it will wear the new chain quickly. Check the bolts and nuts on the drive and driven sprockets. If there is any loose, tighten them. Torque:drive sprocket bolts:31n.M driven sprocket nuts:32n.M twentieth: brake fluid notes: the spilling...

Page 32

31 front brake: turn the hand lever to make the inspection line with the fluid level at the same line,check the front brake fluid level. (figure 20-1) if the fluid level is closed to the horizontal line, check the brake block, to see if this was wear. Rear brake: put the motorcycle upright on the ho...

Page 33

32 twenty-first: brake blocl wear check the brake block ,to see if it was wear. If any one brake plate was wear to the wear limited mark bottom, please replace the brake block . Maintenance limited:1.0mm twenty-second: brake system front brake hand lever inspection loosing the locknut to roll the ad...

Page 34

33 brake pedal height loosen the locknut and roll the pedal height to adjust bolt. Adjust the brake pedal height to 79.6mm or what you need height.(figure22-2) twenty-third: rocker arm/ rocker arm fork put the support under engine, make the rear wheel off ground. Catch the rocker arm, shaking left a...

Page 35

34 (figure 24-1) catch the rocker arm, shaking the rear wheel to check if there is something wrong with rear wheel bearing., (figure 24-2) inspect wheel to see if there is split, nails or other damage, inspect the cold tires pressure carefully(it should be measure when tires cold) (figure 24-3) tire...

Page 36

35 torque: front wheel rim:3.68n.M rear wheel rim:3.7n.M cycle valve nut:13n.M twenty-fifth: front tube bearing put the support under engine, make the front wheel off ground. Inspect the direction hand lever to see if turning left and right flexible.(ensure the main wire harness is not interference ...

Page 37

36 4、 maintenance warranty instruction.

Page 38

37 dear user: thanks for using our vehicle nc250 type, in order to protect your benefits, please read this manual instruction and according to it to use. After-sale service 一、 because of this vehicle nc250 special performance, from the purchase date,it will be free to repair or replace the bad quali...

Page 39

38 will not include the free after-sale service; user should on schedule to maintain and the service station should record the maintanace report actually, if don’t have this report, it’s not suit to the warranty condition. Shandong asiawing motors co.,ltd address:taian city, shandong province pc:271...

Page 40

39 no. Name quantity remarks 1 handbar 1 set 2 front wheel assy 1 set 3 packing list detail: (1) battery 1 piece (2) battery cable tie 1 piece (3) headlamp assy 1 set (4) headlamp install bolts 1 set (5) rear lamp assy 1 set (6) front brake shield 1 pair (7) front brake shield install bolts 1 set (8...