- DL manuals

- Banner American

- Laminator

- Easy-Lam II

- Operating Instructions Manual

Banner American Easy-Lam II Operating Instructions Manual

Summary of Easy-Lam II

Page 2: Table of Contents

Table of contents important safety messages and electrical safeguards……………………3-4 introduction………………………………………………………………….5 specifications………………………………………………………………..5 initial setup……………………………………………………………….6-8 Ø unpacking……………………………………………………………6 Ø components………………………………………………………….6 • motor switch……...………...

Page 3: Electrical Safeguards

3 important safety messages and electrical safeguards for your protection, do not connect the laminator to electrical power or attempt to operate it until you have read these instructions completely. Keep these instructions in a convenient location for future reference. This instruction manual and l...

Page 4

4 plug into an outlet, contact a qualified electrician to have a suitable outlet installed. Ø do not leave the laminator power on overnight. Unplug the laminator at the end of the day. Ø unplug the laminator before moving it or when it is not in use for an extended period of time as a precaution aga...

Page 5: Introduction

5 introduction congratulations on your purchase of the easy-lam ii roll laminator. This unit is designed to provide years of trouble-free service. The easy-lam ii will accept rolls of laminating film up to 27” wide in both 1.5 and 3 mil thicknesses. Paper and card stock up to 1/16” (1.6mm) thick may...

Page 6: Initial Setup

6 initial setup unpacking before unpacking the unit, inspect the shipping container for signs of damage. Notify the carrier and your dealer immediately if any damage is noted. Caution! The laminator weighs approximately 91 lbs. Use two people when removing the laminator from the shipping container. ...

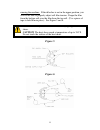

Page 7: Figure 1

7 figure 1.

Page 8: Heater Switch

8 heater switch this switch turns power on and off to the top and bottom heat shoe. (switch will light up in the “on” position). Heat indicator light this light goes on when the heat switch is first turned on and then remains on until the heat shoe reaches the operating temperature. After that point...

Page 9: Figure 2A

9 figure 2a threading laminating film these instructions apply to poly-in film rolls (shiny side out, dull side in). 1. For the top supply roll, place the mandrel ends into the slots on the top of the laminator. If you are facing the front of the laminator, the film should unwind toward you from the...

Page 10: Figure 3

10 figure 3 2. Pull 6”-12” of film from the top roll. Pass the film under the idler bar and safety shield, and over the heat shoes. Make sure the shiny side of the film is against the shoes. See figure 5 and 6. 3. For the bottom supply roll, remove the feed table. Place the mandrel ends into positio...

Page 11: Figure 5

11 running the machine. If the idler bar is not in the upper position, you will not be able to properly adjust roll film tension. Drape the film from the bottom roll over the film from the top roll. (use a piece of tape to hold film in place). See figure 5 and 6. Note: the shiny side of the film mus...

Page 12

12 5. Turn the motor switch to the “on” position to start the rollers. 6. Push a piece of thin letter-sized cardboard against the film so that it is centered between the two heat shoes. Push the cardboard and film into the nip rollers. See figure 5. 7. When the feed card has completely exited the pu...

Page 13: Figure 7

13 counterclockwise to decrease) until the film passes over the top heat shoe without wrinkles and the web between the laminating and pull rollers is tight. Note: this adjustment should require only a slight turn. If increased too much, you may stall the drive motor. Figure 7 5. If necessary, locate...

Page 14: Laminating

14 3. Turn the knob clockwise to increase and counterclockwise to decrease the temperature. If reducing the temperature, wait several minutes for the heat to drop to the desired operating temperature. When increasing temperature, the indicator lamp will come on as the laminator is heating up and go ...

Page 15: Troubleshooting

15 note: you may want to run a test lamination first, as any item that passes between the heat shoes will be laminated and cannot be recovered until it exits the rear of the laminator. 7. Additional items may be fed in sequence, keeping enough distance between sheets for trimming. 8. After the last ...

Page 16

16 action: check the thickness of item to be laminated. Maximum thickness is 1/16” (1.6mm). Clean heat shoes of residual adhesive. Refer to the maintenance section for cleaning instructions. Problem: plastic is not bonding to the item or to itself at the edges. Action: make sure heat shoes and rolle...

Page 17: Maintenance

17 maintenance this section contains instructions for cleaning and maintaining your laminator. These procedures should be performed at regular intervals to help ensure the trouble-free operation of your laminator. Cleaning the heat shoes and laminator rollers the heat shoes and laminating rollers sh...

Page 18: Removing Wrap-Arounds

18 removing wrap-arounds when laminating with thinner gauges of films, there is the possibility of the film wrapping around the pull rollers. Refer to cleaning the heat shoes and laminating rollers in order to remove a wrap-around. If the film cannot be pulled out of the back of the machine, leave t...

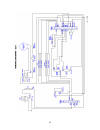

Page 19: Parts List and Illustrations

19 parts list and illustrations this section contains reference drawings and parts list to assist you when ordering parts for your laminator. The drawings show only those parts that may be replaced by the dealer. Item part no. Description quantity 1 10091 c-clip, 15/16” dia 4 2 10092 bushing, 5/8 x ...

Page 20: Item

20 item part no. Description quantity 37 1182 fuse, 15amp, mda-15 1 38 1242 heater, tubular, easy-lam ii 4 39 10415 relay, solid state, 25 amp 1 40 10358 sprocket, motor, easy-lam ii 1 41 2801 sprocket, 22t, steel 1 42 10371 sprocket, 25b21, .625 bore 1 44 10232 switch, motor reverse, 1 easy-lam ii ...

Page 21

21.

Page 22

22.

Page 23

23.

Page 24

24.