- DL manuals

- Banner

- Barcode Reader

- TCNM AD/EX

- Instruction Manual

Banner TCNM AD/EX Instruction Manual

Summary of TCNM AD/EX

Page 1

Tcnm ad/ex barcode scanner instruction manual original instructions 174476 rev. A 28 january 2014.

Page 2: Contents

Contents 1 safety and compliance notices ....................................................................................... 4 2 installation ..................................................................................................................... 6 2.1 package contents ................

Page 3

14 glossary .....................................................................................................................55 tcnm ad/ex barcode scanner.

Page 4

1 safety and compliance notices warning: not to be used for personnel protection never use this device as a sensing device for personnel protection. Doing so could lead to serious injury or death. This device does not include the self-checking redundant circuitry necessary to allow its use in person...

Page 5

Communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. 1 power supply this product is intended to be installed by qualified personnel only. This accessory device...

Page 6: 2 Installation

2 installation 2.1 package contents verify that the barcode reader and all the parts supplied with the equipment are present and intact when opening the packaging; the list of parts includes: • barcode reader with cable • quick start guide • barcode test chart • geniusplus cd-rom • replicate serial ...

Page 7

23.3* 0.92 14 0.55 84 3.31 4 0.16 10 .3 0. 41 40 1. 57 0. 41 10 .3 40 1 .57 14.7 0.58 m 4 n° 4 1.29 32.7 mm inch 68 2.68 4 6 1.81 * the quote refers to the scan line figure 1. Overall dimensions 9 4.2 7.8 20° 2.5 73 4 2 r 4 0 4.2 90° 30 13.8 1 7. 5 2 .5 23 units in mm 4.2 n° 2 1 x 4 5° n° 2 figure 2...

Page 8: Cover Screws

Skew tilt skew pitch figure 3. Positioning with mounting bracket at 10° angle 2.2.2 mounting the deflection mirror (option) the tcnm-acm-102r accessory is a 102° deflection mirror that can be mounted to a barcode scanner. Install the deflection mirror as follows: 1. Make sure the device is not power...

Page 9: Laser Beam

5. Tighten the two cover screws. Figure 5. Mounting tcnm-acm-102r deflection mirror the reading position with respect to the scanner is shown below. Laser beam 102° ± 2° figure 6. Tcnm-acm-102r laser beam output position 2.2.3 positioning the barcode scanner is able to decode moving barcode labels a...

Page 10

Ensure at least 10° minimize tilt angle minimize pitch angle s t p skew angle figure 7. Skew, tilt, and pitch angles the skew angle is represented by the value s shown. Position the reader to assure at least 10° for the skew angle. This avoids the direct reflection of the laser light emitted by the ...

Page 11: 3 Introduction

3 introduction 3.1 product description the barcode laser scanner satisfies the most advanced needs of a wide range of users. It has been developed focusing on the realistic requirements of its target market. The outstanding result is an extremely compact, cost-effective, and easy- to-use industrial ...

Page 12

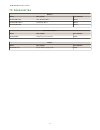

Version max code resolution (mm (mils)) max code resolution (scans/s) 12x0 0.20 (8) 500 to 800 12x4 0.15 (6) 800 to 1000 22x0 0.15 (6) 500 to 800 22x4 0.12 (5) 800 to 1000 version reading distance 12x0 40 mm (1.6 in) - 300 mm (11.8 in) on 0.50 mm (20 mils) codes 12x4 50 mm (1.8 in) - 310 mm (11.8 in...

Page 13: 4 Default Settings

4 default settings 1. On-line operating mode (1 input, active closed) 2. Code label settings #1 = read code 39, variable length, up to 60 characters (match string rule) 3. Code label settings #2 = read i 2 of 5 of 8 characters (match string rule) 4. Code label settings #3 = read code 128, variable l...

Page 14: 5 Rapid Configuration

5 rapid configuration 5.1 step 1 – connect the system note: this section illustrates a standalone application. For a pass-through installation, refer to the appropriate section. For complete scanner configuration using the geniusplus configuration program, refer to the context-sensitive help on-line...

Page 15

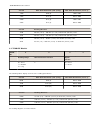

Tcnm-acbb1 terminal block connectors i2a input 2 a (polarity insensitive) id-net ™ i2b input 2 b (polarity insensitive) ref network reference –v power reference – inputs id+ id-net ™ network + shield id– id-net ™ network – shield network cable shield main interface rs232 rs485 full- duplex rs485 hal...

Page 16

25-pin d-sub male connector pinout pin name function 11 o2+ output 2 + 12 o2– output 2 – 20 rx auxiliary rs232 rx 21 tx auxiliary rs232 tx 23 id+ id-net ™ network + 24 id– id-net ™ network – 14, 15, 16, 17 nc not connected 25-pin d-sub male connector pinout pin name rs232 rs485 full-duplex rs485 hal...

Page 17

2. When mounting the barcode scanner, take into consideration these three ideal label position angles: skew 10° to 30°, tilt 0° and pitch 0°. Ensure at least 10° minimize tilt angle minimize pitch angle s t p skew angle figure 11. Skew, tilt, and pitch angles 3. Refer to the reading diagrams to dete...

Page 18

5.3.1 auto learn if you are configuring your scanner using smart-teach, you must start with the auto learn procedure. 1. Hold the smart-teach push button pressed until the learn led is on. 2. Release the button to enter the auto learn function. The reader begins to automatically detect and recognize...

Page 19

5.3.3 reset scanner to factory default (optional) to reset the scanner to the factory default values, hold down the smart-teach push button while powering up the scanner. At the end of the procedure (about 5–6 seconds), the configuration and environmental parameters are reset, and all leds blink sim...

Page 20

1. Click create new to create a new configuration a. Select a barcode and drag it into one of the slots at the bottom. Click next to configure the selected barcode(s) on the following screen(s). B. Select operating mode and click next. On line operating mode requires the reader to be connected to an...

Page 21

2. After defining the parameter values, the following window appears allowing you to complete the reader configuration as follows: • save the configuration to disk • switch to advanced mode • send the configuration to the scanner 3. After sending the configuration to the scanner, click next. You hav...

Page 22

5.5 step 5 – test mode use a code suitable to your application to test the system. 1. To enter test mode, hold down the smart-teach push button until the test led is on. 2. Once entered, the bar graph on the five leds is activated and if the scanner starts reading barcodes, the bar graph shows the g...

Page 23

6 advanced scanner configuration the advanced selection is available when starting the geniusplus application and is designed for expert users to complete a more detailed scanner configuration. By choosing this option it is possible to start a new scanner configuration or to open and modify an old o...

Page 24

Note: the smart-teach functions do not work if the motor or laser are turned off, see troubleshooting on page 50 for details. 6.1.1 diagnostic indication the status and ready leds blink simultaneously to signal the presence of a failure. Diagnostic message transmission on interfaces can be enabled t...

Page 25

Setup learn test ready good trigger com status green green yellow yellow red figure 15. Release button to enter autosetup setup learn test ready good trigger com status green green yellow yellow red figure 16. Release button to exit 6.1.2 test mode function in test mode, the bar graph on the five le...

Page 26

Note: the autosetup function does not modify the programmed barcode symbologies. If needed, the autolearn function can be performed after autosetup. 6.1.2 reset scanner to factory default see reset scanner to factory default (optional) on page 19. Tcnm ad/ex barcode scanner 26.

Page 27

7 tcnm-acbb1 electrical connections all laser barcode scanners are equipped with a cable terminated by a 25-pin male d-sub connector for connection to the power supply and input/output signals. We recommend making system connections through a tcnm-acbb1 connection box because they offer the advantag...

Page 28

Main interface rts tx– rtx– cts 5 rx– sgnd sgnd sgnd note: to avoid electromagnetic interference when the scanner is connected to a tcnm-acbb1 connection box, verify the jumper positions in the tcnm-acbb1. 7.1 power supply supply 10 to 30v dc power to the scanner through the tcnm-acbb1 spring clamp ...

Page 29

Tcnm-acbb1 function cts clear to send sgnd signal ground it is always advisable to use shielded cables. The overall maximum cable length must be less than 15 m (49.2 ft). Sgnd rxd txd cts rts user interface sgnd tx rx rts cts scanner the rts and cts signals control data transmission and synchronize ...

Page 30

7.2.2 rs485 full-duplex interface the rs485 full-duplex (5 wires + shield) interface is used for non-polled communication protocols in point-to-point connections over longer distances (maximum of 1200 m / 3940 ft) than those acceptable for rs232 communications or in electrically noisy environments. ...

Page 31

7.3 auxiliary rs232 interface the auxiliary serial interface is used exclusively for rs232 point-to-point connections. The parameters relative to the aux interface (baud rate, data bits, etc.) as well as particular communication modes such as local echo can be defined using the geniusplus utility pr...

Page 32

7.4 inputs there are two opto-coupled polarity insensitive inputs available on the scanner: input 1 (external trigger) and input 2, a generic input. The electrical features of both inputs are: maximum voltage: 30v dc maximum current: 12 ma (scanner) + 12 ma (tcnm-acbb1) an anti-disturbance filter is...

Page 33

External trigger input connections using external power pulled down to external input device reference input signal pnp photocell figure 21. Pnp external trigger using external power pulled up to external input device power input signal npn photocell figure 22. Npn external trigger using external po...

Page 34

Input 2 connections using external power pulled down to external input device reference input signal input device figure 25. Pnp input 2 using external power pulled up to external input device power input signal input device figure 26. Npn input 2 using external power 7.4.1 code verifier if the barc...

Page 35

Output connections using barcode scanner power power to output output device signal output device reference output device figure 27. Open emitter output using barcode scanner power power to output device output device reference output device output signal figure 28. Open collector output using barco...

Page 36

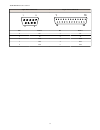

9-pin male connector 25-pin male connector 1 5 9 6 13 25 14 1 pin name pin name 2 rx 3 rx 3 tx 2 tx 5 gnd 7 gnd 7 rts 4 rts 8 cts 5 cts tcnm ad/ex barcode scanner 36.

Page 37: 8 Typical Layouts

8 typical layouts the following typical layouts refer to system hardware configurations. Dotted lines in the figures refer to optional hardware configurations within the particular layout. These layouts also require the correct setup of the software configuration parameters. 8.1 point-to-point in a ...

Page 38

8.2 pass-through mode host 1 2 3 3 1 device#1 3 main serial interface (rs232 only) auxiliary serial interface (rs232) external trigger (for on-line mode) 2 1 device#2 device#n 2 power figure 32. Pass-through layout pass-through mode allows two or more devices to be connected to a single external ser...

Page 39: 9 Reading Features

9 reading features 9.1 advanced code reconstruction the traditional way of barcode reading could be called “linear reading”. In this case, the laser beam crosses the barcode symbol from its beginning to its end as shown in the following figure: laser beam figure 33. Linear reading in advanced code r...

Page 40

Figure 35. Acr readable codes acr is disabled by default but can be enabled for the following code types: • code 25 interleaved • code 39 family • codabar • gs1 databar • code 128/ean128 • ean/upc (without add-ons) • code 93 • gs1 databar expanded 9.1.1 important advanced code reconstruction reading...

Page 41

The decoder will be able to read the label with a tilt angle between + α max and – α max as shown in the following figure: conveyor laser beam no read no read - + 0 ° ok ok ok ok ok no read = max figure 37. Reading zones with α max note: although tilt angles of 45° can be obtained, barcode scanners ...

Page 42

Code resolution (mm) conveyor speed (m/s) 45° max 30° max 0.5 0.75 1 0.5 0.75 1 0.50 31 33 35 21 23 25 table 6: code 128 - ean 128 code resolution (mm) conveyor speed (m/s) 45° max 30° max 0.5 0.75 1 0.5 0.75 1 0.20 12 15 18 9 11 14 0.35 22 25 28 13 16 19 0.50 25 27 30 17 20 23 9.2 linear code readi...

Page 43

Direction of code movement at ls speed laser beam barcode scanner lh figure 38. "step-ladder" scanning mode for example: tcnm-ex (800 scans/sec.) for a 25 mm high code moving at 1250 mm/s performs: [(25 ÷ 1250) × 800] – 2 = 14 effective scans tcnm-ad (500 scans/sec.) for a 25 mm high code moving at ...

Page 44

Laser beam barcode scanner fw lw figure 39. "picket-fence" scanning mode for example: tcnm-ex (800 scans per sec), for a 100 mm wide code moving in a point where the reading field is 200 mm wide at a 2000 mm/s speed, performs: [((200 – 100) ÷ 2000) × 800] – 2 = 38 effective scans tcnm-ad (500 scans ...

Page 45

Version reading distance 12x0 40 mm (1.6 in) - 300 mm (11.8 in) on 0.50 mm (20 mils) codes 12x4 50 mm (1.8 in) - 310 mm (11.8 in) on 0.50 mm (20 mils) codes 22x0 30 mm (1.2 in) - 90 mm (3.5 in) on 0.30 mm (12 mils) codes 22x4 30 mm (1.2 in) - 90 mm (3.5 in) on 0.30 mm (12 mils) codes refer to the di...

Page 46

Tcnm-ex-0200 (short reading range) tcnm-ex-1200 (medium reading range) optic version = linear code = interleaved 2/5 or code 39 pcs = 0.90 pitch angle = 0° skew angle = 10° tilt angle = 0° code resolution 6 = high reading conditions 6 = standard scan speed 6 = 800 scans/sec optic version = linear co...

Page 47

9.4.2 reading diagrams (tcnm-ad models) tcnm-ad-1200 (standard resolution) tcnm-ad-2200 (high resolution) tcnm-ad-1204 (standard resolution) tcnm-ad-2204 (high resolution) note: (0,0) is the center of the laser beam output window. Tcnm ad/ex barcode scanner 47.

Page 48

Conditions optic version = linear code = interleaved 2/5 or code 39 pcs = 0.90 pitch angle = 0° skew angle = 15° tilt angle = 0° reading conditions 7 = standard scan speed 7 = 500 scans/sec 7 parameter selectable in geniusplus. Tcnm ad/ex barcode scanner 48.

Page 49: 10 Maintenance

10 maintenance dust, dirt, and debris on the window may alter the reading performance. Clean the laser beam output window periodically for continued correct operation of the reader; clean frequently in particularly dirty environments. Warning: clean the window of the laser barcode scanner when the s...

Page 50: 11 Troubleshooting

11 troubleshooting 11.1 general guidelines when wiring the device, pay careful attention to the signal name (acronym) on the tcnm-acbb1 spring clamp connectors. If you are connecting directly to the scanner's 25-pin connector, pay attention to the pin number of the signals. If you need information a...

Page 51

Problem solution communication: device is not transmitting anything to the host • is the serial cable connected? • is the correct wiring respected? • are serial host settings equivalent to the serial device setting? • if using tcnm-acbb1, make sure that the rs485 termination switch is positioned to ...

Page 52: 12 Specifications

12 specifications sensor input power supply voltage: 10–30v dc power consumption: maximum 0.5 to 0.17 a; 5 w serial interfaces main serial interface: sw programmable: rs232; rs485 fd and hd baud rate: 1200 to 115200 auxiliary: rs232 baud rate: 1200 to 115200 id-net ™ : rs485 half-duplex baud rate: u...

Page 53

10 acr readable. Tcnm ad/ex barcode scanner 53.

Page 54: 13 Accessories

13 accessories mirrors name description part number tcnm-acm-102r 102° reading mirror 90823 tcnm-acm-om110 oscillating mirror 90825 tcnm-acm-000a 90822 connection boxes name description part number tcnm-acbb1 compact connection box 90828 cables name description part number tcnm-ad-cab 25-pin cable, ...

Page 55: 14 Glossary

14 glossary a acr (advanced code reconstruction) this powerful code reconstruction technology considerably increases the code reading capability in the case of damaged or very tilted barcodes. Aperture term used on the required cdrh warning labels to describe the laser exit window. B barcode a patte...

Page 56

I interface a shared boundary defined by common physical interconnection characteristics, signal characteristics and meanings of interchanged signals. L led (light emitting diode) a low power electronic device that can serve as a visible or near infrared light source when voltage is applied continuo...

Page 57

Scanner a device that examines a printed pattern (barcode) and either passes the uninterpreted data to a decoder or decodes the data and passes it onto the host system. Serial port an i/o port used to connect a scanner to your computer, identifiable by a 9-pin or 25-pin connector. Signal an impulse ...