- DL manuals

- bannerman

- Trimmer

- BW2015-M

- Operations & Parts Manual

Bannerman BW2015-M Operations & Parts Manual

Summary of BW2015-M

Page 1

Bannerman line trimmer bw2015-m operation & parts manual read the following instructions before use..

Page 2: Model

Dear owner, welcome to bannerman, the home of sports turf magic. Your new bw2015 commercial line trimmer is designed to meet your trimming requirements. The ease of operation and low maintenance will give you many trouble free hours of operation. Please make certain that you read and understand the ...

Page 3: Warranty Statement

Warranty statement bannerman ltd. Warranties all bannerman bw2015 commercial line trimmer’s that have been registered in our system. By receiving the warranty card & declaration or delivery card completely filled out, via post, fax, or email within 15 days of date of sale for registration, or warran...

Page 4

Safety warnings and definitions understanding signal words and follow safety instructions safety alert symbol – this is the safety alert symbol. When you see this symbol in this manual, be alert and avoid personal injury. When accompanied by the words “caution” and “warning”, it calls your attention...

Page 5: Safety Rules

Safety rules read the operator’s manual carefully. Be familiar with the controls and the proper use of the unit, and how to turn off, and unhook the harness quickly in an emergency. Warning: to avoid serious injury there is a great risk to eyes from thrown objects. Always wear proper eye protection....

Page 6: Precautions

Precautions warning: to avoid serious injury never allow children to operate or play with the machine. Never allow anyone to use this machine without proper instruction. Warning: to avoid serious injury keep people out of the danger zone. This is a circle of 15 meter radius around the unit and opera...

Page 7: Strictly No Fire

Strictly no fire warning: to avoid serious injury always handle gasoline with care. It is highly flammable. Always stop the engine to refuel. Do not refuel a hot engine. Wait until the engine has cooled down. Do not remove the fuel cap when the engine is still warm or running. Eliminate all sources ...

Page 8: Checks Before Starting

Checks before starting adjust the handle to a position for comfort and keeping a good balance is recommended. Make sure that the unit is assembled properly. If using the shoulder strap that is provided with this unit, balance the unit as recommended by adjusting the position of the clamp on the shaf...

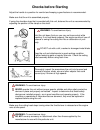

Page 9: Cautions During Operation

Cautions during operation note: if necessary to cut where people or cards could be hit by thrown, cut at a reduced (slow) throttle speed to reduce the speed of the cutting head. Warning: to avoid serious injury shut down immediately if the unit starts to shake or vibrate. This could be a sign of dan...

Page 10: Cautions After Operation

Warning: to avoid serious injury blade thrust may when the spinning blade contacts a solid object in the critical area. A dangerous reaction may occur causing the entire unit and operator to be thrust violently. This reaction is called blade thrust. As a result, the operator may lose control of the ...

Page 11: Technical Data

Names and specifications for each part technical data drive system: auto centrifugal clutch spiral bevel gear reduction ratio: 14:19 rated cutter edge rotation speed (rpm): 4,300 to 6,500 direction of blade rotation: left (top view) throttle lever: fixed type vibration dampener: genuine vibration da...

Page 12

Caution: instructions which, if not followed, could result in mechanical damage or failure. Note: the fuel mixture for the mitsubishi engine is 50:1 only use premium two-stroke engine oil that is formulated for modern, high performance, air- cooled two-stroke engines. Oil specification jaso service ...

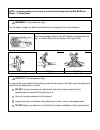

Page 13: Installations

Installations installing the engine - fasten the engine together with the fuel tank facing down. Be sure to fasten the engine mounting bolts uniformly and secure. Installing the throttle lever and connecting the throttle cable - insert the throttle cable through the cable passage in the main grip. E...

Page 14

Installing the blade (optional equipment) - install the parts in the following order: holder a – blade holder b. Make sure that the blade’s direction of rotation is orientated properly before installing the blade. Use an “l” wrench to prevent holder a from spinning and tighten the blade fastening nu...

Page 15: Working Methods

Working methods nylon cutter pull out the cord of the nylon cutter by 12 to 15 cm. Warning: to avoid serious injury use only nylon line. Do not use any type of blade for edging or scalping. Always check that there is a safe distance between the cutting device and your feet. Blade bw-lh-10 line head ...

Page 16

Note: to ensure safety, be sure not to cut wood and twigs with the bw-bb brush blade – 4 tooth blade. Warning: to avoid serious injury for the sake of safety the blade used shall be one designed by this manufacturer. Since rotary blades rotate in the left direction (as seen from the top), it is more...

Page 17: Inspection and Maintenance

Setting of the rotary blade root of a blade shall be rounded by a round file. Inspection and maintenance inspect and maintain satisfactory for achieving a longer life of the equipment and nice safe work. After work is finished, remove holder a, and take off the scraps and grass inside it and wipe it...

Page 18: Inspection Table

Inspection table items for inspection and maintenance inspection and maintenance period before work after work every 25 hours every 100 hours inspection of cutters * inspection of clamping bolts of gear case * inspection of safety guard * inspection of bolts * inspection of main pipe * * cleaning of...

Page 19: Throttle Cables

Bw-2010 gear case & driving apparatus reference no. Part no. Description qty. 1 n71008-320 gear case assembly 1 2 n17730-189 maine pipe 1 3 n64011-250 main shaft 1 4 n71012-145 hanger band assembly 1 5 n36001-110 main grip 1 6 n68013-136 spring 2 7 n71010-263 clutch case assembly 1 8 n0416n0620 sock...

Page 20: Bw-2015-M Handle & Fitting

Bw-2015-m handle & fitting reference no. Part no. Description qty. 1 n71011-153 handle joint assembly 1 2 n51009-143 handle joint a 1 3 n51010-146 handle joint b 1 4 n51013-122 handle joint c 1 5 n0412n0615 socket screw (6mm x 25mm) 6 6 n61023-192 sleeve 1 7 n71038-171 guard band set 1 8 n0412n0515 ...