- DL manuals

- Baotian

- Scooter

- BT125T-2

- Service Manual

Baotian BT125T-2 Service Manual

Summary of BT125T-2

Page 1

Bt125t-2 service manual jiangmen sino-hongkong baotian motorcycle industrial co., ltd.

Page 2

Contents chapter one maintenance of the motorcycle Ⅰ. Items of maintenance 1 Ⅱ. Periodic maintenance schedule and maintenance locations 1 Ⅲ. Maintenance specifications 4 Ⅳ. Throttle actuation inspection 5 Ⅴ. Air filter inspection and cleaning 6 Ⅵ. Brake system inspection, adjustment and replacement ...

Page 3

Chapter one maintenance of the motorcycle Ⅰ. Items of maintenance when the motorcycle is used, loosening of parts and mechanical wear inevitably occur to varied extents. Neglect of timely maintenance not only reduces its mechanical function, economic performance, stability and durability, but also t...

Page 4

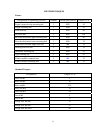

1. Maintenance schedule maintenance schedule time item mileage 1000km 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 new r engine oil r r r r r r r r r r r 300km engine oil strainer c c gasoline strainer r new r gear oil note 4 r r 300km throttle play a a a a carburetor i i c note 3,...

Page 5

2. Maintenance locations throttle grip actuation,play £ ¨ £ © oil tank brake oil level £ ¨ £ © front shock absorber damage,loosening £ ¨ £ © front rim damage,oscillation £ ¨ £ © front tire wear,damage,tire pressure £ ¨ £ © headlight beam adjustment £ ¨ £ © rear shock absorber damage,loosening £ ¨ £ ...

Page 6

Ⅲ. Maintenance specifications the basic methods of motorcycle maintenance include inspection, adjustment, tightening, lubrication, cleaning, supplementing and replacement, which constitute the main elements of maintenance. 1. Inspection inspection refers to basic inspecting operations in accordance ...

Page 7

Iv. Throttle actuation inspection inspect throttle grip for easy and smooth movement. Inspect throttle free travel. Free travel: 2-6mm the main adjusting position is beside the carburetor. Remove rear store case cover. Adjust by loosening the fastening nut and turning the adjusting nut. Fine adjustm...

Page 8

Ⅴ. Air filter inspection and cleaning after a certain mileage, dust and impurities will gather in air filter case and strainer, which will clog strainer pores and reduce inlet of air and thus lead to excessive concentration of mixed gas and reduce the performance of engine. That’s why the strainer m...

Page 9

* do not pull brake lever when brake caliper is removed so as to prevent jamming of brake block. If brake block is jammed, pry it with screwdriver and push piston back into caliper. Brake block replacement: brake block must be replaced when it is worn to the limit of use. * it is not necessary to re...

Page 10

2. Rear brake (disk brake) remove the bolts linking brake caliper and rear brake mounting board. Remove brake caliper. * do not pull brake lever when brake caliper is removed so as to prevent jamming of brake block. If brake block is jammed, pry it with screwdriver and push piston back into caliper....

Page 11

Ⅶ. Front and rear shock absorber inspection 1. Front shock absorber tighten front brake lever, press front shock absorber up and down and inspect actuation. Inspect front shock absorber to see if there is leakage of oil and if there is damage or loosening. 2. Rear shock absorber press rear shock abs...

Page 12

Z damage due to forced dismounting z fissure extending to frame z abnormal inner lining z tire groove wear: front wheel rear wheel z punctured or otherwise damaged tire flank inspect tire pressure by means of a tire pressure gauge * tire pressure should be inspected when the motorcycle is in a cold ...

Page 13

Chapter two maintenance information i. Frame number and engine number location ii. Precautions in operation z removed washers, 0-rings, elastic retaining rings and split pins must be replaced with new ones. Z when mounting bolts, nuts and screws, proceed from trial tightening, from larger diameters ...

Page 14

Z before connecting connectors, confirm that they are free from breakage, bending, over length or loosening. Z connectors must be inserted home. When connecting connectors with locks, confirm that their locks are fastened. Confirm that the wires are not loose. Z confirm that connectors’ plastic slee...

Page 15

Specified torques frame: designations of tightening positions number thread specification torques: n·m engine suspension lug mounting nut 1 m10 45 engine mounting nut 1 m10 45 front axle nut 1 m12 60 rear axle nut 1 m16 120 rear shock absorber upper mounting bolt 1 m10 40 rear shock absorber lower m...

Page 16

Chapter three body troubleshooting section one body common troubles and trouble detection body part common troubles and possible causes are as follows: troubles causes details (reference) over tightening of handlebar adjusting nut handlebar rotation not easy (strenuous turning or unstable tightness)...

Page 17

Chart continued troubles causes details (reference) worn seal ring of brake caliper piston viscous or worn brake caliper piston inability of brake caliper normal sliding worn main cylinder piston seal ring feeble brake lever viscous or worn main cylinder piston contaminated main cylinder clogged nar...

Page 18

Chart continued troubles causes details (reference) bent front axle, incorrect wheel mounting roundness error of wheel rim deformation of wheel rim deviation of motorcycle direction (inclining to roadside) refer to “front wheel service” inadequate tire pressure deformed wheel rim loose front wheel b...

Page 19

Section two detailed description of body parts troubles precautions in operation: z forced mounting or dismounting of body cover parts will cause damage to claws and slots of corresponding hoods. Z when mounting body cover parts, be sure to align the corresponding parts of hoods. Z when mounting bod...

Page 20

Axle bending inspection place axle on a v-seat and measure with a dial gauge. The dial gauge indicates a 1/2 bending value. Limit of use: replace if >0.2mm. Wheel rim oscillation inspection measure oscillation value on a correcting bench. Limit of use: replace if >2.0mm. Traverse direction: replace ...

Page 21

Mount spacer. Drive in right bearings. Z bearings must be driven in parallel. Z dust cover must be driven in with the face out. Apply grease to new dust cover lip. Mount front axle bush. Oil reservoir cover front wheel mounting mount brake disc, tighten brake disc mounting bolts. Torque: 27n·m sprea...

Page 22

The specification of brake oil is indicated on the reservoir cover. Place diaphragm. Connect a transparent hose to exhaust valve. Grip brake lever fast and open exhaust valve 1/2 turn to let out air and lock exhaust valve. Repeat this operation till no bubbles are exhausted from brake oil passage. Z...

Page 23

Remove brake light switch and brake lever. Remove retaining ring from main cylinder. Z use special retaining ring remover when removing retaining ring. Remove piston cover, piston and spring. Clean oil reservoir and piston with pure brake oil. Z do not effect cleaning with gasoline as it is corrosiv...

Page 24

Remove 4 pieces of bolts on the upper part of front shock absorber. Remove shock absorber. Inspection inspect if there is oil leakage in front shock absorber, if there is deformation of shock absorber arm and if there is damage or loosening of any part. Mounting mount front shock absorber on front f...

Page 25

Remove front axle nut; remove front wheel. Remove front shock absorber, front fender (the mounting screws is inside the fender) etc. Remove steering stem from head tube. The removing of the bottom bearing cup, bearing top and bearing set is the same as the removing of the upper series. Front fender ...

Page 26

Mount front fender on steering stem. Mount front wheel. Mount front shock absorber and other parts. Apply grease to top bearing cup and bearing top. Mount in order upper bearing cup, bearing ball set and upper bearing top on the upper part of steering stem and fasten them. Torque: 15 n·m turn front ...

Page 27

Mounting mount handlebar on steering stem guide tube, setting bolt and nut. Torque: 45 n·m mount rear brake main cylinder and fasten bolts. Mount left handlebar switch and fasten screws. Torque: 9 n·m mount front brake main cylinder and fasten bolts. Mount right handlebar switch and fasten screws. T...

Page 28

Remove the bolts linking brake caliper and rear brake mounting board. Remove rear brake caliper. Remove rear axle nut. Remove rear brake mounting board and bush. Remove rear wheel. Remove 3 mounting bolts of brake disc. Remove brake disc. Rear wheel oscillation inspection measure oscillation value o...

Page 29

Vii. Rear brake service (disk brake) the service of the rear brake is the same as the front brake. Viii. Rear shock absorber service dismounting remove motorcycle body covering parts. Remove mounting bolt connecting rear shock absorber and motorcycle frame, bolt connecting rear shock absorber and en...