- DL manuals

- Baotian

- Scooter

- BT49QT-7

- Service Manual

Baotian BT49QT-7 Service Manual

Summary of BT49QT-7

Page 1

Bt49qt-7&bt49qt-8 service manual jiangmen sino-hongkong baotian motorcycle industrial co., ltd.

Page 2: Contents

Contents chapter one maintenance of the motorcycle . Items of maintenance 1 . Periodic maintenance schedule and maintenance locations 1 . Maintenance specifications 4 . Throttle actuation inspection 5 . Air filter inspection and cleaning 6 . Rear brake fricition lining inspection 6 . Brake system in...

Page 3

1 chapter one maintenance of the motorcycle . Items of maintenance when the motorcycle is used, loosening of parts and mechanical wear inevitably occur to varied extents. Neglect of timely maintenance not only reduces its mechanical function, economic performance, stability and durability, but also ...

Page 4

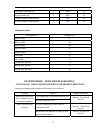

2 maintenance schedule time item mileage 1000km 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 engine oil new r 300km r r r r r r r r r r r engine oil strainer c c gasoline strainer r gear oil note 4 new r 300km r r throttle play a a a a carburetor i i c air filter note 3, 4 i r r y ...

Page 5

3 throttle grip actuation,play £ ¨ £ © oil tank brake oil level £ ¨ £ © front shock absorber damage,loosening £ ¨ £ © rear tire wear,damage,tire pressure £ ¨ £ © rear rim damage,oscillation £ ¨ £ © front rim damage,oscillation £ ¨ £ © front tire wear,damage,tire pressure £ ¨ £ © headlight beam adjus...

Page 6

4 . Maintenance specifications the basic methods of motorcycle maintenance include inspection, adjustment, tightening, lubrication, cleaning, supplementing and replacement, which constitute the main elements of maintenance. 1. Inspection inspection refers to basic inspecting operations in accordance...

Page 7

5 iv. Throttle actuation inspection inspect throttle grip for easy and smooth movement. Inspect throttle free travel. Free travel: 2-6mm the main adjusting position is beside the carburetor. Remove rear store case cover. Adjust by loosening the fastening nut and turning the adjusting nut. Fine adjus...

Page 8

6 2000-3000km and in dusty or rainy conditions strainer must be cleaned or replaced earlier. Remove 5 tightening bolts of air filter. Remove strainer cover. Take out the foam strainer. Immerse foam strainer in gasoline and wash it to remove dust and impurities by gripping and pressing. Press gasolin...

Page 9

7 * do not pull brake lever when brake caliper is removed so as to prevent jamming of brake block. If brake block is jammed, pry it with screwdriver and push piston back into caliper. Brake block replacement: brake block must be replaced when it is worn to the limit of use. * it is not necessary to ...

Page 10

8 inspect rear brake lever free travel. Free travel: 10-20mm turn adjusting nut to effect adjustment when free travel exceeds limit. Viii. Front and rear shock absorber inspection 1. Front shock absorber tighten front brake lever, press front shock absorber up and down and inspect actuation. Inspect...

Page 11

9 inspect wheel rim, remove rust stains and rubber chips. Deformation and fissures are causes of air leakage. Do not use wheel rims in the following cases: bruise of wheel rim face contacting tire bead ring exceeds 0.5mm in depth and 1.0mm in width. Tire inspection: inspect if there is fissure or ir...

Page 12

0 1 torques: front wheel nut 60n·m rear wheel nut 120n·m x. Steering stem inspection swing handlebar right and left to see if there is interference such as wire or other things. Turn front wheel to see that handlebar is easy in operation. In case of any difficulty in operation, inspect steering stem...

Page 13

1 1 ii. Precautions in operation removed washers, 0-rings, elastic retaining rings and split pins must be replaced with new ones. When mounting bolts, nuts and screws, proceed from trial tightening, from larger diameters to smaller diameters and inner ones to outer ones in a diagonally order. Tighte...

Page 14

2 1 wire bunches must be fixed away from turning or moving parts. Do not damage the covering of wire bunches. In case of wire bunch defects, remedy it with insulating bands. Wire bunches must not be covered with mounted parts. Do not twist or bend cables by force. Deformed or damaged cables would re...

Page 15

3 1 handlebar mounting nut 1 m10 45 upper bearing top 1 m25 2.5 exhaust muffler connector nut 2 m6 12 exhaust muffler mounting bolt 2 m8 35 standard torques: n : s e u q r o t s n o i t a n g i s e d ·m bolt, nut m5 5 bolt, nut m6 10 bolt, nutm8 21.5 bolt, nut m10 35 bolt, nut m12 55 screw m5 4 scre...

Page 16

4 1 over tightening of steering stem top ball bearing retainer damaged or broken ball bearing reduced tire air refer to “front wheel service”, “rear wheel service” imbalance of right and left shock absorbers refer to “front shock absorber service” bent front fork refer to “front fork service” deflec...

Page 17

5 1 inability of brake caliper normal sliding worn main cylinder piston seal ring viscous or worn main cylinder piston contaminated main cylinder clogged narrow brake system clogged narrow liquid passage viscous worn brake caliper inability of brake caliper normal sliding worn seal ring of brake cal...

Page 18

6 1 bent front axle, incorrect wheel mounting roundness error of wheel rim deformation of wheel rim inadequate tire pressure refer to “front wheel service” deformed wheel rim loose front wheel bearing poor tire front wheel oscillation poor axle locking refer to “front wheel service” soft front shock...

Page 19

7 1 remove front axle nut, brake calipers, front absorbers connecting bolt and remove brake calipers, front shock absorber, transmission gear box, front axle bush and the small bush, remove front axle. Remove front wheel. Remove brake disc mounting bolts. Remove brake disc. Axle bending inspection p...

Page 20

8 1 front wheel bearing inspection remove front wheel bearing and dust cover. Turn bearing inner race to inspect sliding. Replace it with a new one in case of no sliding or damage or loosening of outer race. Front wheel bearing replacement dismounting: remove front wheel bearing by means of a bearin...

Page 21

9 1 torque: 60n·m mount brake caliper as specified. Ii. Front brake service (disk brake) brake oil replacing prevent dust or water from entering brake system. Do not use brake oils of different specifications or impure brake oils. Prevent brake oil from dripping onto rubber, plastic or painted parts...

Page 22

0 2 main brake oil tank dismounting and mounting dismounting remove each 2 bolts and screws of front part and rear part of head cover. Remove front part and rear part of head cover. Exhaust brake oil from front brake system. Pull out brake switch plug from main cable. Remove bracket bolts from handl...

Page 23

1 2 mount spring, piston, retaining ring and piston cap. Piston cup cannot be used inside out. Apply grease to brake lever axis pin. Mount brake lever and brake switch. Mount main cylinder, main cylinder bracket and lock them. Mount brake oil pipe. Connect brake light switch cable with switch. Mount...

Page 24

2 2 iv. Front fork service dismounting remove motorcycle body covering parts. Remove nut and blot from handlebar; remove handlebar. Remove steering stem setting nut. Remove upper bearing cup, upper bearing top and bearing set. Remove front axle nut; remove front wheel. Remove front shock absorber, f...

Page 25

3 2 inspect for completeness of bearing balls and if there is, effect replacement with new ones. Inspect for proper tightness of steering stem and if not, effect adjustment and fasten it. Inspect for correct position of bearing cup and bearing top and if not, effect correct mounting. Bearing cup and...

Page 26

4 2 remove 2 screws of left handlebar switch. Remove left handlebar switch. Remove left grip from handlebar. Remove front brake main cylinder. Remove connectors of right handlebar switch. Remove 2 screws of right handlebar switch. Remove right handlebar switch. Remove throttle cable from throttle gr...

Page 27

5 2 remove 2 connecting nuts and 2 mounting bolts of exhaust muffler. Remove exhaust muffler. Remove rear axle nut and rear axle. Rear wheel oscillation inspection measure oscillation value on a correcting bench. Limit of use: longitudinal >2.0 mm traverse >2.0 mm mounting mount rear wheel and faste...

Page 28

6 2 limit of use: Ø111mm, effect replacement if the limit is exceeded. Rear brake block replacement remove rear brake block and return spring as a whole and replace them with new ones. See that no grease is with brake block friction surface. Rear brake disassembling remove rear brake adjusting nut, ...

Page 29

7 2 mount brake swing arm pin and rear brake cable. Mount return spring of brake cable with the spring aligned with the recess hole of left crankcase cover. Mount adjusting nut. Adjust brake system. Viii. Rear shock absorber service dismounting remove motorcycle body covering parts. Remove 2 mountin...

Page 30

8 2.