Summary of 7EM

Page 1

Instruction manual 1262-in-009-0-03 february 1998 model 7em.

Page 2

2 1/8 din, three digit display temperature controller model: 0 7 e m - 4 3 1 1 - 0 0 - 0 - 0 0 field. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 fields 1 through 4. Base 07em - controller field 5. Input 4 - tc types j, k, l and n; pt 100, 3 wire rtd note: all inputs are factory calibrated and selectable by...

Page 3

3 congratulations congratulations on your purchase of one of the easiest to configure controllers on the market. After a four step configuration procedure, your process will be up and running. Guide to simple set-up only four steps are required to set-up your controller: 1. Wire the instrument (page...

Page 4

4 caution: use wire suitable for 75 °c minimum contents 1/8 din, three digit display temperature controller .................................................. 2 mounting requirements ................................... 5 dimensions and panel cutout ......................... 6 wiring guidelines ........

Page 5

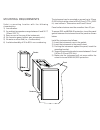

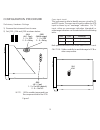

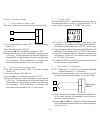

5 bracket panel gasket mounting requirements select a mounting location with the following characteristics: 1) low vibration. 2) an ambient temperature range between 0 and 50 °c (32 and 122 °f). 3) easy access to the rear of the instrument. 4) no corrosive gases (sulfuric gas, ammonia, etc.). 5) no ...

Page 6

6 89 mm 3.504 in 60 mm 2.362 in 125 mm 4.921 in 45 mm, -0, +0.6 mm 1.772 in, -0, +0.024 in 92 mm, -0, +0.8 mm 3.622 in, -0, +0.031 in 48 mm 1.890 in 96 mm 3.780 in 10 mm (0.394 in) dimensions and panel cutout.

Page 7

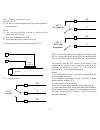

7 wiring guidelines terminal board note: control outputs 1 and 2 are protected by v aristor against an inductive load up to 0.5 amps. All other outputs, or external contacts in series with the instrument outputs, need an external snubber network (rc) across the terminals: c r in accordance with the ...

Page 8

8 rtd input 4 3 rtd 1 4 3 rtd 1 safety note: 1) do not run rtd wires with power cables. Notes: 1) ground shielded cable at one end only. 2) use the correct size copper wires. 3) the resistance of the 3 wires must be the same. 4) pay attention to line resistance: high line resistance (higher than 20 ...

Page 9

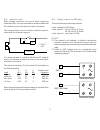

9 thermocouple compensating cable color codes. E l p u o c o m r e h t l a i r e t a m h s i t i r b 3 4 8 1 s b n a c i r e m a 1 . 6 9 c m i s n a n a m r e g 0 1 7 3 4 n i d h c n e r f 1 0 0 - 8 1 e f n t r e p p o c n a t n a t s n o c + - e t i h w e u l b e u l b + - e u l b d e r e u l b + -...

Page 10

10 a.2) current transformer input safety note: 1) do not run current transformer input wiring with ac power cables. Note: 1) the minimum active period to perform this measurement is 50 ms. 2) the input impedance is 10 Ω. 3) the maximum input current is 50 ma. This input measures the current used by ...

Page 11

11 b.2) inductive loads high voltage transients can occur when switching inductive loads. It is recommended to install an additional rc network across the internal contacts as shown. The same problem can occur when a switch is used in series with the internal contacts. L o a d c r p o w e r l in e i...

Page 12

12 f) power line wiring 12 13 power supply 100 to 240 vac rms (50/60 hz) or 24 vac/vdc n n l2 l1 r (s, t) r (s, t) safety notes: 1) do not run input wires with power cables. 2) permanently connected equipment must include a switch or circuit-breaker in the installation. Place it in close proximity t...

Page 13

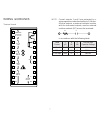

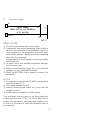

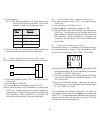

13 configuration procedure preliminary hardware settings 1) remove the instrument from its case. 2) set j303, j304 and j305 as shown below: j303 (al1, cool) 1 - 2 = out no (default) 2 - 3 = out nc j305 (main output) 1 - 2 = ssr 2 - 3 = relay j304 (al1, cool) 1 - 2 = ssr 2 - 3 = relay 1 3 note: j303 ...

Page 14

14 configuration key functions func = the new setting of the selected parameter is stored and the next parameter is displayed (in increasing order). Man = scrolls back through the parameters without storing the new setting. S = increases the setting of the selected parameter. T = decreases the setti...

Page 15

15 p11 alarm 2 operating mode and reset of hbd alarm not available when p10 = 0 and p16 = off.. H.A = high alarm (outside band) with automatic reset. L.A = low alarm (inside band) with automatic reset. H.L = high alarm (outside band) with manual reset. L.L = low alarm (inside band) with manual reset...

Page 16

16 p15 setpoint for the soft start function setpoint, in engineering units, of the “soft start” function (output power limiting). At instrument start up, if the measured value is lower than the programmed setpoint, the instrument will automatically enable the output limiter (see olh parameter), an...

Page 17

17 p23 automatic modification of relative cooling gain available only when p4 = hc. Off = autotuning (smart at) does not modify “relative cooling gain.” on = autotuning modifies “relative cooling gain.” p24 output maximum rate of change sets the maximum rate of change of the power output. P24 is p...

Page 18

18 setpoint access when the device is in the auto mode and the “normal display mode,” the setpoint can be directly accessed and modified. 1) press the s or t key (and hold for 3 seconds); the setpoint will start to change. 2) once the desired setting is reached, wait 3 seconds before pressing a key ...

Page 19

19 operating parameters from the “normal operating mode,” press the func key. The lower display will show the code while the upper display shows the setting or the status (on or off) of the selected parameter. Press the s or t key to change the setting. Press the func key again and the instrument st...

Page 20

20 error messages overrange or underrange and sensor break indications this device is capable of detecting process variable faults (overrange, underrange or sensor break). An overrange condition will appear as: an underrange condition will appear as: a sensor break will be signalled as: - for tc inp...

Page 21

21 - the instrument is set for heating/cooling and an underrange is detected, then out 1 turns on and out 2 turns off. Error messages on powerup, the instrument performs a self-diagnostic test. When an error is detected, the lower display shows an “err” indication while the upper display shows the c...

Page 22

22 default configuration parameters the configuration parameters can be loaded with predetermined default values. These are the settings loaded into the instrument prior to shipment from the factory. To load the default values proceed as follows: a)open switch v2 (see configuration procedure figure ...

Page 23

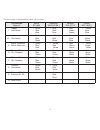

23 default configuration parameter list: table 1 table 2 parameter european usa p1 1 9 p2 0°c 0°f p3 400°v 999°f p4 h h p5 rel rel p6 air air p7 1 1 p8 ha ha p9 off off p10 0 0 p11 ha ha p12 off off p13 0 0 p14 0 0 p15 0 0 p16 off off p17 10 amps 10 amps p18 0 0 p19 rev rev p21 dir dir p22 dir dir p...

Page 24

24 specifications general case: dark grey polycarbonate. Self-extinguishing degree v-0 according to ul94. Front protection: designed and tested for ip65 and nema 4x. Installation: panel mounting by means of brackets. Rear terminal block: 21 screw terminals with safety rear cover. Dimensions: 48 x 96...

Page 25

25 note: for tc inputs, the minimum span is 300 °c or 600 °f, which makes it possible to increase the sensitivity of the control parameters. Current transformer input for out 1 heater breakdown detection (optional) this feature allows measurement of the load current by means of a current transformer...

Page 26

26 calibration procedure calibration parameters are logically divided into groups of two parameters each - minimum range value and maximum range value. A calibration check is provided after entering the values of each group. A calibration check can be initiated without making an entry: press the fun...

Page 27

27 rj cold junction compensation note: make sure “tl” and “th” are correctly calibrated before attempting “rj” calibration. A)measure the temperature close to terminals 1 and 3 using an appropriate instrument, as shown below. 1 3 measuring device + - b) wait a few minutes to allow temperature stabil...

Page 28

28 d) after a few seconds, start calibration by pressing the func key. The decimal point of the least significant digit will light to indicate the instrument is performing the calibration. When calibration is complete, the instrument will proceed to the cold junction compensation check. Rj. Cold jun...

Page 29

29 this completes the calibration procedure. To enter the configuration procedure press the s key, the display will show “cnf”. If configuration and calibration are complete, switch the instrument off and close the switch v2 (see configuration procedure figure 2). Al current transformer minimum rang...

Page 30

30 maintenance 1. Disconnect the power from the power supply terminals and relay output terminals. 2. Remove the instrument from its case. 3. Using a vacuum cleaner or a compressed air jet (max. 3 kg/cm 2 ) remove dust and dirt which may be present on the louvers and on the internal circuits, being ...

Page 31

31 notes....

Page 32

Eurotherm/barber-colman 741-f miller drive leesburg, va 20175 telephone: +1 703 443 0000 facsimile: +1 703 669 1300 email: info@eurotherm.Com copyright © 1998 barber-colman company..