- DL manuals

- Barco

- Projector

- FLM HD14

- Service Manual

Barco FLM HD14 Service Manual

Summary of FLM HD14

Page 1

Flm series service manual r59770072/00 19/03/2007.

Page 2

Barco nv events noordlaan 5, b-8520 kuurne phone: +32 56.36.89.70 fax: +32 56.36.88.24 e-mail: sales.Events@barco.Com visit us at the web: www.Barco.Com printed in belgium.

Page 3: Table Of Contents

Table of contents table of contents 1. Safety ................................................................................................................ 5 1.1 safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Table of contents 12. Uv filter............................................................................................................ 117 12.1 uv filter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5

Table of contents 24.3 light processor compartment fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244 24.3.1 remove of the top plate . . . . . . . ....

Page 6

Table of contents 4 r59770072 flm series 19/03/2007.

Page 7: 1. Safety

1. Safety 1. Safety about this chapter read this chapter attentively. It contains important information to prevent personal injury while servicing the flm projector. Fur- thermore, it includes several cautions to prevent damage to the flm projector. Ensure that you understand and follow all safety g...

Page 8

1. Safety 1.1 safety instructions w arning : before removing/replacing any projector components, turn off the main power switch and un- plug the main ac power cable. Safety instructions 1. Before returning an instrument to the customer, always make a safety check of the entire instrument, including,...

Page 9

1. Safety 4. Lamp explosion protection warning – the lamp in this projector operates with a high internal pressure and there is a slight risk that the lamp may explode, particularly if it is used beyond its rated life. Do not remove, install, or otherwise handle the lamp in any manner without first ...

Page 10

1. Safety 8 r59770072 flm series 19/03/2007.

Page 11: 2. General Info

2. General info 2. General info overview • location of modules • spare part kits r59770072 flm series 19/03/2007 9.

Page 12

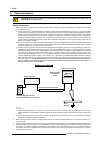

2. General info 2.1 location of modules convention - projector orientation front light processor side lamp side or input side rear image 2-1 projector orientation rear side and lamp side b a c e d f image 2-2 reference description a ir receiver b lamp power supply unit (lps) unit c lamp unit d catho...

Page 13

2. General info lamp side g h i j k image 2-3 reference description g backplane h signal distribution board i motor control board j switched mode power supply (smps) unit k formatter interface board r59770072 flm series 19/03/2007 11.

Page 14

2. General info light processor side - front side l m n o p q r s image 2-4 reference description l ir receiver m heat exchanger + fan n light processor assembly (light processor + light pipe) o anode fan p start pulse generator q cold mirror assembly r cold mirror fan s manometer + pressure vessel ...

Page 15

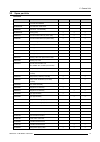

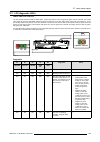

2. General info 2.2 spare part kits overview order number kit description flm r20+ flm hd18 flm hd14 b3245964dk fan axial 59ls 50$mdl x x x b3245651dk fan radial 24v 143d175cp x x x r848645k cold mirror + fan assembly x x x b4009521dk cooling pump x x x r9854470 front and bottom filters (6 pieces ea...

Page 16

2. General info order number kit description flm r20+ flm hd18 flm hd14 r764818k signal distribution board x x x r764822k start pulse generator x x x r764774k switched mode power supply x x x r764869k keypad unit x x x v322203k lcd panel 160x80 6h$led bl x x x b3722365k mains switch 35a ul/csa x x x...

Page 17: 3. Troubleshooting

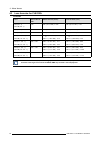

3. Troubleshooting 3. Troubleshooting about this chapter this chapter enumerates all possible error codes which can appear on the local lcd display of the flm projector. The code dis- played is preceded by a “ - ” sign in case of a warning or a “ + ” sign in case of a real error . Note that not all ...

Page 18

3. Troubleshooting 3.1 1000 → 1017 : lamp parameters related errors error 1000 → 1017 : “wrong lamp parameters” these error codes may appear during the start up of the projector. Situation solution wrong lamp house detected in lamp compartment of the projector. Replace the lamp house with a compatib...

Page 19: Flm

3. Troubleshooting 3.2 1692 → 1699 : formatter related errors error 1692 : “form. Pwrgood” situation solution formatter “power good" signal not ok. The local power supplies on the formatter interface board fails. The orange led “pwrgood” (ref a image 3-3 & image 3-4) on the formatter interface board...

Page 20: Flm Hd

3. Troubleshooting c a b flm hd image 3-4 status led’s of the formatter interface board (hd version). Visible trough the grid behind the front filter. A orange led “pwrgood” ok. B powergood status: led color = green “high”; yellow “low”; red “fail”. C fpga status: led color = green “normal”; yellow ...

Page 21

3. Troubleshooting error 1694 : “green form. Start failed” situation solution no communication with the formatter board of the green channel. The projector fails to start. • check if both wire units between the formatter interface board (fib) and the formatter board of the green channel are plugged ...

Page 22

3. Troubleshooting l1 l3 l5 l7 l2 l4 l6 image 3-6 status led’s of the fan & motor control board. Located behind the input cover. L1 green led “+30v”. L2 green led “+vmtr”. L3 green led “+vtec”. L4 green led “++5v”. L5 green led “+5v fib”. L6 green led “+5v pmp”. L7 red led “ error”. Error 1697 : “fo...

Page 23

3. Troubleshooting 3.3 2000 → 2808 : lamp power supply (lps) related errors see also chapter "lps diagnostic led’s", page 299, for more diagnostic information about the lps unit. Error 2000 : “no lps detected” situation solution no communication with the lamp power supply. • check if the grey wire u...

Page 24

3. Troubleshooting error 2001 : “mains voltage to low” situation solution the mains voltage applied to the “mains input” sockets of the lps module is to low. • check if the main power cables (image 3-9) are connected with the “mains input” sockets of the lps module. • check if the mains voltage appl...

Page 25

3. Troubleshooting error 2005 : “lamp stop failed” situation solution no communication with the lamp power supply. • switch off the projector. • reboot the projector. If problem remains, replace the lamp power supply. Error 2006 : “one lps down, reduced power” this is not a real error but a warning....

Page 26

3. Troubleshooting situation solution you can hear the spg module three times clicking in an attempt to ignite the lamp. The voltage on the “lamp out” pins of the lps module is first 140 volt during the attempt to ignite and then drops to 0 volt after a few minutes. Note : the ambient noise must be ...

Page 27

3. Troubleshooting error 2506 : “lamp ignition failed” the same troubleshooting checklist can be applied to as for error 2206. The only difference is that this error is generated by the lps unit with address 0x22. Error 2507 : “lamp voltage range” the same troubleshooting checklist can be applied to...

Page 28

3. Troubleshooting 3.4 4000 : incompatible hardware error error 4000 : “incompatible hardware” situation solution one or more parts of the projector are replaced with incompatible parts. • reinstall the original parts of the projector. Use only original barco spare parts for servicing. • if the prob...

Page 29

3. Troubleshooting 3.5 4198 : pixel map related error error 4198 : “fpga-pmp init failed” situation solution the controller was unable to initialize the fpga of the pixel map processor (pmp). • reboot the projector. • if the problem persists, reinstall the pmp firmware using the projector toolset. •...

Page 30

3. Troubleshooting 3.6 5095 → 5098 : flash memory related errors error 5095 : “restoring unsuccessful” situation solution restoring the custom settings from the internal backup device has failed. • check if the latest projector software is installed. • reinstall the latest projector software. • if t...

Page 31

3. Troubleshooting 3.7 7658 → 7999 : temperature, fan & motor related errors error 7658 : “engine air temp short” this error may be preceded by a warning. This error can only appear on the flm hd series. Situation solution damaged insulation of the wire unit of the temperature sensor (ref e image 3-...

Page 32

3. Troubleshooting tb tg tr e h r g b bl fr image 3-11 sockets on the formatter interface board (fib) of the flm hd series r temperature sense red channel. G temperature sense green channel. B temperature sense blue channel. Bl temperature sense dmd water cooling blocks. Fr temperature sense dmd fro...

Page 33

3. Troubleshooting situation solution damaged insulation of the wire unit of the temperature sensor (ref b image 3-12), which measures the temperature of the water cooling block of the blue channel. When disconnecting the wire unit (ref b/bl image 3-11) of the temperature sensor from the formatter i...

Page 34

3. Troubleshooting situation solution interruption of the liquid cooling circuit. Check if the loop of the liquid cooling circuit is closed. The liquid cooling circuit of the light processor is mistakenly excluded from the main liquid cooling circuit. Reconnect the cooling circuit of the light proce...

Page 35

3. Troubleshooting situation solution damaged insulation of the wire unit of the temperature sensor (ref g image 3-14), which measures the temperature of the water cooling block of the green channel. When disconnecting the wire unit (ref g/bl image 3-11) of the temperature sensor from the formatter ...

Page 36

3. Troubleshooting situation solution the liquid cooling circuit of the light processor is mistakenly excluded from the main liquid cooling circuit. Reconnect the cooling circuit of the light processor with the pump and heat exchanger. Water cooling pump electrical disconnected. Check if the wire un...

Page 37

3. Troubleshooting error 7671 : “red block temp open” this error may be preceded by a warning. This error can only appear on the flm hd series. Situation solution wire unit (ref r/bl image 3-11) of the temperature sensor is disconnected from the formatter interface board (fib) plug in the wire unit ...

Page 38

3. Troubleshooting situation solution damaged insulation of the wire unit of the temperature sensor (ref h image 3-16), which measures the temperature of the common water cooling block of the heat pipes. When disconnecting the wire unit (ref h image 3-11) of the temperature sensor from the formatter...

Page 39

3. Troubleshooting situation solution the liquid cooling circuit of the light processor is mistakenly excluded from the main liquid cooling circuit. Reconnect the cooling circuit of the light processor with the pump and heat exchanger. Water cooling pump electrical disconnected. Check if the wire un...

Page 40

3. Troubleshooting situation solution damaged insulation of the wire unit of the temperature sensor (ref d image 3-17) which measures the temperature at the front of the dmd of the blue channel. When disconnecting the wire unit (ref b/fr image 3-11) of the temperature sensor from the formatter inter...

Page 41

3. Troubleshooting s s s s h image 3-18 heat pipes securing screws (e.G. Red channel) s screws. H heat pipe. Error 7687 : “blue front dmd temp low” this is a warning. This warning can only appear on the flm hd series. Situation solution the temperature on the front side of the dmd of the blue channe...

Page 42

3. Troubleshooting situation solution damaged wire unit of the temperature sensor which measures the temperature at the front of the dmd of the green channel. • repair the wire unit. • if not repairable, replace the light processor. Contact barco for further instructions to repair the malfunction li...

Page 43

3. Troubleshooting situation solution damaged insulation of the wire unit of the temperature sensor (ref d image 3-17) which measures the temperature at the front of the dmd of the red channel. When disconnecting the wire unit (ref r/fr image 3-11) of the temperature sensor from the formatter interf...

Page 44

3. Troubleshooting situation solution the temperature on the front side of the dmd of the red channel is low. If this warning persist, contact barco for further instructions. Error 7696 : “light pipe temp short” this error may be preceded by a warning. This error can only appear on the flm hd series...

Page 45

3. Troubleshooting sb ca sh sg sr pr db ls dg dr l image 3-20 sb wire unit of temperature sensor at the rear of the dmd of the blue channel. Sg wire unit of temperature sensor at the rear of the dmd of the green channel. Sr wire unit of temperature sensor at the rear of the dmd of the red channel. L...

Page 46

3. Troubleshooting situation solution disconnected wire unit. Reconnect the wire unit of the fan. Check if the wire unit of the fan is plugged into its socket on the backplane. Blocked fan. Unblock the fan. Ensure that the fan can turn freely. Damaged wire unit. Check if the wire unit of the fan is ...

Page 47

3. Troubleshooting situation solution the maximum allowed projector tilt range is exceeded. Place the projector within the maximum allowed tilt range. See owners manual for maximum tilt range. Error 7937 : “waterflow” no water flow detected. This error is not preceded with a warning. Situation solut...

Page 48

3. Troubleshooting situation solution lens is touching the sensor (pr) on the prism. Maximum lens shift position reached. Shift the lens upwards and/or to the left. Pr image 3-22 error 7940 : “5v pmp voltage high” this is a warning. Situation solution the +5 volt supply voltage for the pixel map pro...

Page 49

3. Troubleshooting situation solution the +5 volt supply voltage for electronics is too high. Replace the fan & motor control board. Error 7945 : “5v voltage low” this is a warning. Situation solution the +5 volt supply voltage for electronics is too low. Replace the fan & motor control board. Error...

Page 50

3. Troubleshooting situation solution the supply voltage “30v” from which all fan supplies are subdivided is too low. Replace the fan & motor control board. Error 7958 : “pump voltage high” this is a warning. Situation solution the supply voltage for the pump is too high. Replace the fan & motor con...

Page 51

3. Troubleshooting error 7966 : “fan 4 voltage high” this is a warning. Situation solution the supply voltage for the fan mounted on top of the cold mirror and the fan mounted on top of the heat exchanger is too high. Replace the fan & motor control board. Error 7967 : “fan 4 voltage low” this error...

Page 52

3. Troubleshooting situation solution the supply voltage for the fan which cools the cathode of the lamp is too high. The fan for the lamp cathode cooling is mounted between the lamp compartment and the input & communication unit. Replace the fan & motor control board. Error 7973 : “fan 1 voltage lo...

Page 53

3. Troubleshooting situation solution blocked high density filter of the heat exchanger. The other dmd temperatures are too high as well. Replace the blocked high density filter of the heat exchanger with a new high density filter. The liquid cooling circuit of the light processor is mistakenly excl...

Page 54

3. Troubleshooting situation solution the wire units of two peltier elements (tec) or there respective temperature sensors (ntc’s) have been swapped. While the temperature of one dmd is too high, the other will most likely be too low. Check if the wire units of all peltiers (tec) and all temperature...

Page 55

3. Troubleshooting situation solution malfunction tec of the involved dmd. Use the “diode test” of a multi-meter to check out the tec. Polarity doesn’t matter. The tec is not ok in case the measured value is higher then 0,01 volt. Remove the light processor from its compartment and replace the malfu...

Page 56

3. Troubleshooting situation solution disconnected wire unit. Reconnect the wire unit of the fan. Blocked fan. Unblock the fan. Ensure that the fan can turn freely. Damaged wire unit. Check if the wire unit of the fan is not damaged. Repair if possible, otherwise replace with new one. Fan end of lif...

Page 57

3. Troubleshooting 3.8 8000 → 8001: shutter related errors error 8000 : “opening shutter failed” this is a warning. Situation solution disconnected wire unit of the shutter motor reconnect the wire unit (ref sh image 3-23 and image 3-20) of the shutter motor with the formatter interface board (fib) ...

Page 58

3. Troubleshooting 3.9 8002 : lamp eeprom error error 8002 : “lamp eeprom” this is a warning. Situation solution the projector is unable to read out the lamp eeprom during the start up of the projector. Place a new lamp house in the projector. 56 r59770072 flm series 19/03/2007.

Page 59

3. Troubleshooting 3.10 9198 → 9398: cpu related errors error 9198 : “scaler pixel clock too high” situation solution bandwidth or refresh rate of input source too high. Apply another source to the projector. Error 9199 : “scaler init failed” situation solution the initialization of the scaler on th...

Page 60

3. Troubleshooting 3.11 10498 : input module related error error 10498 : “unsupported module” situation solution input slot contains an input module which is not supported by the projector due to obsolete firmware. Replace the unsupported input module with a supported version. 58 r59770072 flm serie...

Page 61: 4. About Lenses

4. About lenses 4. About lenses about this chapter this chapter gives an overview of the different lenses, lens formulas and the procedure how to install a new lens. Overview • available lenses • lens selection • lens formulas for flm r20+ • lens formulas for flm hd projectors • lens installation • ...

Page 62

4. About lenses 4.1 available lenses available lenses for the flm projector the tld and the tld hb (high brightness) lens series can be used on the flm projector. Note that there is no physical difference on the outside between the tld and the tld hb lenses with corresponding focal length. The tld h...

Page 63

4. About lenses 4.2 lens selection how to select the right lens for your application ? 1. Determine the required screen width (sw). 2. Determine the position of the projector in the projection room with regard to the screen and measure the projector-screen distance (pd). 3. Use the lens formulas to ...

Page 64

4. About lenses 4.3 lens formulas for flm r20+ formulas lens throw ratio for flm metric formulas (meter) inch formulas (inch) tld (0.8 : 1) tld hb (0.8 : 1) 0.75 pd = (0.77 x sw ) + 0.05 pd = (0.77 x sw ) + 1.97 tld (1.2 : 1) 1.1 pd = (1.11 x sw ) - 0.01 pd = (1.11 x sw ) - 0.39 tld+(1.2:1) 1.2 pd= ...

Page 65

4. About lenses 4.4 lens formulas for flm hd projectors formulas lens throw ratio for flm hd metric formulas (meter) inch formulas (inch) tld (0.8 : 1) tld hb (0.8 : 1) 0.7 pd = (0.71 x sw ) + 0.05 pd = (0.71 x sw ) + 1.97 tld (1.2 : 1) 1.1 pd = (1.03 x sw ) - 0.01 pd = (1.03 x sw ) - 0.39 tld+(1.2:...

Page 66

4. About lenses 4.5 lens installation how to install a lens into the projector lens holder ? 1. Remove the foam rubber in the opening of the lens holder if not removed yet. 2. Take the lens assembly out of its packing material and remove the lens caps on both sides. 3. Place the lens holder in the “...

Page 67

4. About lenses image 4-11 8. Check if the lens is really secured by trying to pull the lens out of the lens holder. C aution : never transport the projector with a lens mounted in the lens holder. Always remove the lens before transporting the projector. Neglecting this can damage the lens holder a...

Page 68

4. About lenses 4.6 lens removal how to remove a lens from the projector lens holder ? 1. Support the lens with one hand while you unlock the lens holder by sliding the lock handle towards the “unlocked” position as illustrated. Image 4-12 2. Gently pull the lens out of the lens holder. Image 4-13 i...

Page 69: 5. Carrying Handle

5. Carrying handle 5. Carrying handle about this chapter this chapter describes how to replace the bottom carrying handle and how to mount an extra carrying handle on top of the projector. Parts location a b c d image 5-1 a rugged carrying handle. B adjustable feet. C integrated safety chain. D mova...

Page 70

5. Carrying handle 5.1 replacement of the bottom carrying handle necessary tools 8 mm allen key. How to replace the bottom carrying handle? 1. Turn the projector upside down. 2. Remove the bottom carrying handle by releasing the four hexagon socket head screws (h). H w image 5-3 3. Install the new c...

Page 71

5. Carrying handle 5.2 installing the carrying handle on top of the projector necessary tools 8 mm allen key. Necessary parts • 4 adapted spacers. • 4 hexagon socket head bolts m10 x 30. • 4 washers. How to install the carrying handle on top of the projector? 1. Remove all three eyebolts on top of t...

Page 72

5. Carrying handle f w image 5-8 note: the hexagon bolts which fasten the bottom carrying handle are longer then the hexagon bolts (m10 x 30) which fasten the top carrying handle. 70 r59770072 flm series 19/03/2007.

Page 73: Covers

6. Removal and installation of projector covers 6. Removal and installation of projector covers about this chapter most maintenance and servicing procedures demand removing one or more of the projector covers to gain access to the parts to maintain or to service. To avoid redundancy, all procedures ...

Page 74

6. Removal and installation of projector covers 6.1 removal of the front cover necessary tools 7 mm flat screw driver. How to remove the front cover of the projector ? 1. Remove the lens. See chapter "lens removal", page 66. 2. Remove the rubber dust ring from the lens holder. See image 6-1. 3. Rele...

Page 75

6. Removal and installation of projector covers 6.2 removal of the side cover c aution : remove the side cover of the projector only in a clean and dust free area. Never remove the side cover in an area which is subject to airborne contaminants such as that produced by smoke machines or similar. Nec...

Page 76

6. Removal and installation of projector covers 6.3 removal of the lamp cover w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools 7 mm flat screw driver. How to remove the lamp cover of the projector ? 1. Release the two captive screws at the top...

Page 77

6. Removal and installation of projector covers 6.4 removal of the input cover w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools 7 mm flat screw driver. How to remove the input cover of the projector ? 1. Release the two captive screws at the t...

Page 78

6. Removal and installation of projector covers 6.5 removal of the back cover w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools 7 mm flat screwdriver. How to remove the back cover from the projector 1. Release the two captive screws at the bott...

Page 79

6. Removal and installation of projector covers 6.6 removal of the top cover to remove the top cover, first all side covers must be removed. How to remove the top cover from the projector 1. Turn out the 3 eye bolt (a). A a a b image 6-11 top cover removal 2. Remove the front interlocking adapter (b...

Page 80

6. Removal and installation of projector covers 6.7 installation of the top cover how to install the top cover 1. Place the cover on the projector so that the holes matches the fixation holes in the frame. B b b a image 6-12 mount top cover 2. Push the interlocking adapter (a) on its place, turn in ...

Page 81

6. Removal and installation of projector covers 6.8 installation of the back cover necessary tools 7 mm flat screwdriver. How to install the back cover of the projector? 1. Check if the lps module is correctly installed. 2. Install the back cover of the projector doing the following: a) bring the ba...

Page 82

6. Removal and installation of projector covers 6.9 installation of the front cover necessary tools 7 mm flat screw driver. How to install the front cover of the projector ? 1. Check if the front filter is present. 2. Ensure that no lens is mounted. 3. Install the front cover of the projector doing ...

Page 83

6. Removal and installation of projector covers 6.10 installation of the side cover necessary tools 7 mm flat screw driver. How to install the side cover of the projector ? 1. Check if the bottom and top filters are present. 2. Check the pressure indicated on the internal manometer of the liquid coo...

Page 84

6. Removal and installation of projector covers 6.11 installation of the lamp cover necessary tools 7 mm flat screw driver. How to install the lamp cover of the projector ? 1. Install the lamp cover of the projector doing the following: a) bring the lamp cover towards its final position (a), b) then...

Page 85

6. Removal and installation of projector covers 6.12 installation of the input cover necessary tools 7 mm flat screw driver. How to install the input cover of the projector ? 1. Install the input cover of the projector doing the following: a) bring the input cover towards its final position (a), b) ...

Page 86

6. Removal and installation of projector covers 84 r59770072 flm series 19/03/2007.

Page 87: 7. Dust Filters

7. Dust filters 7. Dust filters about this chapter this chapter contains detailed information about the replacement of the dust filters. The flm projector has three high density filters which can easily be replaced. One at the front side, one at the bottom side (under the heat exchanger) and one at ...

Page 88

7. Dust filters 7.1 replacement of the dust filter on the front side necessary parts new hepa dust filter for the front side (r9854470). How to replace the hepa dust filter on the front side of the projector ? 1. Remove the front cover of the projector, see "removal of the front cover", page 72. 2. ...

Page 89

7. Dust filters 7.2 replacement of the dust filter on the bottom side necessary parts • new hepa dust filter for the bottom side (r9854480). • 2.5 mm allen key. How to replace the hepa dust filter on the bottom side of the projector ? 1. Remove the side cover of the projector, see "removal of the si...

Page 90

7. Dust filters 7.3 replacement of the dust filter on the top side necessary parts new hepa dust filter for the top side (r9854480). How to replace the hepa dust filter on the top side of the projector ? 1. Remove the side cover of the projector, see "removal of the side cover", page 73. 2. Remove t...

Page 91: 8. Lamp And Lamp House

8. Lamp and lamp house 8. Lamp and lamp house about this chapter this chapter describes how to replace a complete lamp house and it gives also the procedure to realign the z-axis of the lamp to optimize the light output. Image 8-1 c aution : never attempt to disassemble the lamp from its housing or ...

Page 92

8. Lamp and lamp house 8.1 removal of the lamp house w arning : this procedure may only be performed by qualified technical service personnel. C aution : never attempt to disassemble the lamp from its housing or to dispose of it. Return it to barco. Due to its high internal pressure, the lamp may ex...

Page 93

8. Lamp and lamp house 8.2 installation of the lamp house w arning : this procedure may only be performed by qualified technical service personnel. C aution : never attempt to disassemble the lamp from its housing or to dispose of it. Return it to barco. Due to its high internal pressure, the lamp m...

Page 94

8. Lamp and lamp house while starting up the projector, the electronics detect if a lamp is installed. If no lamp is installed, it is not possible to start up the projector. 92 r59770072 flm series 19/03/2007.

Page 95

8. Lamp and lamp house 8.3 realignment of the lamp in its reflector why realigning the lamp ? With longer run times, the light output of the lamp will decrease, which results in a lower light output on the screen. This light output decrease can be compensated by readjusting the z-position of the lam...

Page 96

8. Lamp and lamp house 94 r59770072 flm series 19/03/2007.

Page 97

9. Input & communication unit 9. Input & communication unit about this chapter this chapter describes how to replace the complete input & communication unit or one of its input modules. Hot swapping of this unit is not allowed. Projector must be switched off. Parts 1 2 3 4 5 6 7 image 9-1 1 lcd pane...

Page 98

9. Input & communication unit 9.1 removal of the input & communication unit w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools 7 mm flat screw driver. How to remove the input & communication unit from the projector ? 1. Ensure that no cables are...

Page 99

9. Input & communication unit 9.2 installation of the input & communication unit w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools 7 mm flat screw driver. How to install the input & communication unit of the projector ? 1. Ensure that the proje...

Page 100

9. Input & communication unit 9.3 removal of an input module the procedure below is applicable to all input modules of the input & communication unit of the projector. Necessary tools phillips screw driver ph1. How to remove an input module out of the input & communication unit of the projector ? 1....

Page 101

9. Input & communication unit 9.4 installation of an input module the procedure below is applicable to all input modules of the input & communication unit of the projector. Necessary tools phillips screw driver ph1. How to install an input module into the input & communication unit of the projector ...

Page 102

9. Input & communication unit 100 r59770072 flm series 19/03/2007.

Page 103

10. Light processor + light pipe assembly 10. Light processor + light pipe assembly about this chapter this chapter describes briefly the functionality of the light processor and light pipe and the procedures which must be followed to replace this unit. Functionality the light processor and light pi...

Page 104

10. Light processor + light pipe assembly 10.1 diagnostics troubleshooting of the light processor + light pipe the are several reasons why removal or replacing of the light processor is required. Nevertheless, try to avoid unnecessary removal of the light processor. The list below gives an overview ...

Page 105

10. Light processor + light pipe assembly 10.2 removal of the light processor c aution : remove the light processor of the projector only in a clean and dust free area. Never remove the side cover in an area which is subject to airborne contaminants such as that produced by smoke machines or similar...

Page 106

10. Light processor + light pipe assembly image 10-3 4. Uncouple the cooling circuit from the light processor by unplugging the two valved fittings as illustrated. One valved fitting is located in the tube coming from the pump and leading to the light processor and the other valved fitting is locate...

Page 107

10. Light processor + light pipe assembly image 10-5 6. Place the light processor, which includes the fib, on a stable table. R59770072 flm series 19/03/2007 105.

Page 108

10. Light processor + light pipe assembly 10.3 installing the light processor necessary tools • 5 mm flat screw driver. • 10 mm nut driver. How to install the light processor of the flm projector ? 1. Hold the light processor by the handles and gently slide the light processor into the compartment o...

Page 109

10. Light processor + light pipe assembly 3. Fasten the two captive screws at the right side of the light processor as illustrated. Use a 5 mm flat screw driver. Caution: prior to screwing ensure the reference blocks are pushed well up against there respective reference surfaces. Use your screw driv...

Page 110

10. Light processor + light pipe assembly image 10-9 5. Check the pressure indicated on the internal manometer of the liquid cooling circuit, "flm liquid cooling circuit", page 153. Barco provides a liquid cooling refill kit for the flm projector. See "flm liquid cooling circuit", page 153 for furth...

Page 111: 11. Integration Rod

11. Integration rod 11. Integration rod about this chapter this chapter describes briefly the functionality of the integration rod, how to diagnose the integration rod, how to replace this rod and how to adjust it. Functionality the integration rod is made of fused silica and is approximately 13 cen...

Page 112

11. Integration rod overview • rod diagnostic • removal of the integration rod assembly • installing a new integration rod assembly • adjusting the integration rod 110 r59770072 flm series 19/03/2007.

Page 113

11. Integration rod 11.1 rod diagnostic general due to bad environmental conditions the integration rod may become contaminated with grease, dust, dirt or other particles, which will burn into the rod and cause permanent damage. As a result spots may become visible in the projected image on the scre...

Page 114

11. Integration rod 11.2 removal of the integration rod assembly to remove the integration rod assembly from the light pipe the light processor unit has to be removed from the projector first. C aution : all servicing to the light processor unit has to be done in a dust free area. Use compressed air...

Page 115

11. Integration rod 11.3 installing a new integration rod assembly necessary tools • compressed air. • 2 mm allen key. • 2,5 mm allen key. Necessary parts integration rod assembly. How to install a new the integration rod assembly ? 1. Removing the mask (m) from the integration rod by releasing the ...

Page 116

11. Integration rod a a image 11-10 8. Install the mask (m) and cooling block as illustrated. Use for that two washers (w) and two hexagon screws (s) which you removed in step one. Use a 2,5 mm allen key. Caution: ensure that the mask (m) is placed in portrait like the entrance of the integration ro...

Page 117

11. Integration rod 11.4 adjusting the integration rod to adjust the integration rod you have to remove the side cover (light processor side) first. Necessary tools 2 mm allen key. How to adjust the integration rod of the flm projector? 1. Check if the set screws a and b are aligned. If not see proc...

Page 118

11. Integration rod image 11-14 7. Fasten the set screw b which you released in step 3. 8. Loosen the two set screws a as illustrated. Use a 2 mm allen key. A a image 11-15 9. Gently rotate the adjustment ring d until the projected light beam matches the projected outline of the dmd’s. Note: no spot...

Page 119: 12. Uv Filter

12. Uv filter 12. Uv filter about this chapter this chapter describes how to replace the uv filter inside the projector. About the uv filter visible light goes through this uv filter. Uv light and ir light is reflected towards the cold mirror. The following type of uv filters can be found in the flm...

Page 120

12. Uv filter 12.1 uv filter replacement to replace the uv filter you have to remove the lamp cover and lamp house first. Necessary tools 2,5 mm allen key. How to replace the uv filter? 1. Turn out the 4 screws (3 when rounded type). Image 12-2 uv filter replacement 2. Take off the metal frame. Imag...

Page 121: 13. Cold Mirror Assembly

13. Cold mirror assembly 13. Cold mirror assembly about this chapter this chapter describes how to replace the cold mirror and top fan as complete assembly. It also describes the necessary adjustments for the cold mirror. Functionality the cold mirror reflects the visible light and absorbs the infra...

Page 122

13. Cold mirror assembly 13.1 diagnostic general the easiest way to check the condition of the cold mirror is by removing the lamp unit. See owners manual of the projector for the lamp removal procedure. When the lamp unit is removed, the cold mirror becomes visible at the end of the lamp compartmen...

Page 123

13. Cold mirror assembly 13.2 removal of the cold mirror assembly w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools • allen key 3 mm • flat screwdriver 7 mm how to remove the cold mirror assembly? 1. Remove the lamp door and the opposite side c...

Page 124

13. Cold mirror assembly image 13-3 remove cover plate 5. Turn out both screws 1 and slide the connector a little backwards. 1 1 2 2 3 3 image 13-4 cold mirror assembly removal 6. On the same plate, turn out both indicated screws 2. 7. At the left side of the cold mirror assembly, turn out both indi...

Page 125

13. Cold mirror assembly image 13-5 remove of cold mirror r59770072 flm series 19/03/2007 123.

Page 126

13. Cold mirror assembly 13.3 mounting the new cold mirror + fan assembly w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools • allen key 3 mm • flat screwdriver 7 mm how to mount 1. Insert the assembly in the projector and make the electrical co...

Page 127

13. Cold mirror assembly 3 4 2 2 1 1 image 13-7 secure assembly 3. In the depth, turn in both indicated screws 2. 4. Place the connector on its place. Turn in the upper screws 3. 5. Push the lower screws 4 first through the eye of the ground wire and then turn it in. 6. Insert the cover plate and tu...

Page 128

13. Cold mirror assembly image 13-8 mount cover plate 7. Reinsert the lamp house and close the lamp door. 126 r59770072 flm series 19/03/2007.

Page 129

13. Cold mirror assembly 13.4 adjusting the cold mirror w arning : this procedure may only be performed by qualified technical service personnel. Necessary tools • wrench 10 mm • wrench 7 mm or nut driver 7 mm • light meter how to adjust the cold mirror? 1. Place the light meter in the center of the...

Page 130

13. Cold mirror assembly 8. Reinstall the side cover. 128 r59770072 flm series 19/03/2007.

Page 131: 14. Lens Holder

14. Lens holder 14. Lens holder about this chapter this chapter describes how to replace the complete lens holder with build in motors for lens manipulation and the adjustment pro- cedure. Functionality next to securing the lens, the lens holder makes it possible to shift, tilt and swing the lens pl...

Page 132

14. Lens holder 14.1 removing the lens holder to remove the lens holder you have to remove the lens, the front cover, the side cover and the light processor first. Necessary tools • side cutter. • 5,5 mm nut driver. • 3 mm allen key. How to remove the lens holder ? 1. Remove the plastic cable ties f...

Page 133

14. Lens holder f image 14-4 r59770072 flm series 19/03/2007 131.

Page 134

14. Lens holder 14.2 installing the lens holder necessary tools • 5,5 mm nut driver. • 3 mm allen key. Necessary parts two cable ties. How to install the lens holder ? 1. Release the two screws (c), which fasten the mid position switch (s) to the projector chassis and position the switch as illustra...

Page 135

14. Lens holder d e image 14-7 4. Place the mid position switch (s) into position as illustrated. Make sure that the vertical movements of the lens holder (g) will press the knob without touching the housing of the switch (s). S g image 14-8 5. Fasten the mid position switch with two screws (n) as i...

Page 136

14. Lens holder image 14-10 the lens holder has to be adjusted after installation. 134 r59770072 flm series 19/03/2007.

Page 137

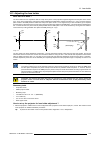

14. Lens holder 14.3 adjusting the lens holder what has to be done ? The lens holder has to be adjusted so that the “sharp focus plane” of the projected image falls together with the plane of the screen (fp1 → fp2). This is achieved by changing the distance between the dmd plane and the lens plane (...

Page 138

14. Lens holder screen pd = 1,5 m screen image 14-12 2. Remove the front cover, side cover and top cover of the projector. See owners manual of the projector for detailed cover removal procedures. 3. Install a tld hb zoom lens 1.6 - 2.0 : 1. See owners manual for detailed lens installation instructi...

Page 139

14. Lens holder f f f image 14-15 4. Adjust the screw of the lens holder tilt mechanism until the mid top and mid bottom of the projected pattern is most sharp on the screen. Use a 5,5 mm nut driver or a flat screw driver. Tip: use a white paper to search for the “sharp focus plane” at the top or bo...

Page 140

14. Lens holder 138 r59770072 flm series 19/03/2007.

Page 141

15. Vertical and horizontal shift motors 15. Vertical and horizontal shift motors about this chapter this chapter describes how to replace the vertical and horizontal shift motors inside the lens holder. Image 15-1 order information order number description b3580251k motor dc 12v d17 + 134:1 for ver...

Page 142

15. Vertical and horizontal shift motors 15.1 removing the vertical shift motor before you can start with the removal of the motor, the lens holder must be built out, see "removing the lens holder", page 130 for more explanation on how to build out. Necessary tools • allen key 3 mm • allen key 2.5 m...

Page 143

15. Vertical and horizontal shift motors a b c d e f g h i image 15-3 5. Disassemble everything mounted on the axe (components b to f). 6. Turn out both screws g. 7. Turn out the axe fixation screw h. 8. Slide out the axe i. 9. Take out the motor unit. Turn out both screws on the motor unit and remo...

Page 144

15. Vertical and horizontal shift motors image 15-4 removing motor image 15-5 motor assembly 142 r59770072 flm series 19/03/2007.

Page 145

15. Vertical and horizontal shift motors 15.2 mounting a new vertical shift motor necessary tools • allen key 3 mm • allen key 2.5 mm • allen key 2 mm • allen key 1.5 mm how to mount 1. Fixate the small plate with 2 screws on the motor. Fold the wires in the same direction of the rounded side of the...

Page 146

15. Vertical and horizontal shift motors g f e d d c a b image 15-8 mount assembly 4. Turn the first squared nut c on the axe until the middle of the axe. Then slide both washers d on the axe with the spherical side towards each other. Continue with the connection piece e and finally, turn again a s...

Page 147

15. Vertical and horizontal shift motors d b c a image 15-9 fixate mechanism 7. Turn in screw b and fasten the screw at the back side of the block (c). Make sure that both block on the axe are parallel with each other. 8. Guide all cables in the groove, place the cover plate (d) on its place and tur...

Page 148

15. Vertical and horizontal shift motors 15.3 removal of the horizontal lens motor before you can start with the removal of the motor, the lens holder must be built out, see "removing the lens holder", page 130 for more explanation on how to build out. Necessary tools • allen key 3 mm • allen key 2....

Page 149

15. Vertical and horizontal shift motors d d f e image 15-11 remove axe 4. Take part of the lens holder in position f and pivot it upward until the horizontal motor and axes parts become free. 5. Disassemble the motor axe as follow: - remove first square nut a - slide off the interconnection piece b...

Page 150

15. Vertical and horizontal shift motors image 15-13 remove motor image 15-14 148 r59770072 flm series 19/03/2007.

Page 151

15. Vertical and horizontal shift motors 15.4 mounting the new horizontal lens motor necessary tools • allen key 3 mm • allen key 2.5 mm • allen key 2 mm • allen key 1.5 mm how to mount 1. Fixate the small plate with 2 screws on the motor. Fold the wires in the same direction of the rounded side of ...

Page 152

15. Vertical and horizontal shift motors f e d d c a b image 15-17 4. Turn the first squared nut c on the axe until the middle of the axe. Then slide both washers d on the axe with the spherical side towards each other. Continue with the connection piece e (as shown in the drawing) and finally, turn...

Page 153

15. Vertical and horizontal shift motors image 15-19 cover plate insert the lens holder in the projector, see "installing the lens holder", page 132 for a detailed description. Then, reinstall all covers and insert the lens. R59770072 flm series 19/03/2007 151.

Page 154

15. Vertical and horizontal shift motors 152 r59770072 flm series 19/03/2007.

Page 155

16. Flm liquid cooling circuit 16. Flm liquid cooling circuit about this chapter this chapter describes how to diagnoses and to maintain the liquid cooling circuit of the flm projector. W arning : all procedures in this chapter may only be performed by “qualified service technicians” . W arning : al...

Page 156

16. Flm liquid cooling circuit c aution : to avoid damage to the connector seal, always depress the connector tab of the female valved fitting prior to inserting the male valved fitting. 154 r59770072 flm series 19/03/2007.

Page 157

16. Flm liquid cooling circuit 16.1 safety w arning : hazardous product: blue antifreeze diluted 1,2 ethanediol (1/3 ethanediol – 2/3 demi water). Not for household use. Keep out of reach of children. Harmful by oral intake. Avoid exposure to pregnant women. Avoid contact with eyes, skin and clothin...

Page 158

16. Flm liquid cooling circuit 16.2 introduction functionality much heat has to be extracted from the dmd’s and from the light pipe entrance during operation of the projector. The liquid cooling circuit takes care of this. The liquid cooling circuit is a closed loop of flexible tubing comprising of ...

Page 159

16. Flm liquid cooling circuit 16.3 diagnostics general over extended periods there may be small losses of pressure in the liquid cooling system of the projector. It is therefor recommended to check the pressure at regular intervals. In case the pressure drops below 0,5 bar it is recommended to rest...

Page 160

16. Flm liquid cooling circuit possible cause solution none of the wire units of the peltier elements or there respective temperature sensors (ntc’s) are connected. Check if the wire units of all peltiers and all temperature sensors (ntc’s) are plugged in there respective connector sockets on the in...

Page 161

16. Flm liquid cooling circuit 16.4 pressure verification of the liquid cooling circuit how to check the pressure of the liquid cooling circuit inside the projector ? 1. Remove the side cover of the projector, see "removal of the side cover", page 73. 2. Check the pressure indicated on the internal ...

Page 162: Out

16. Flm liquid cooling circuit 16.5 draining the liquid cooling circuit in case of part replacement, consider only draining that part of the circuit which contains the defect part. E.G. In case of pump replacement; it is preferred to bypass the engine circuit. This to exclude the engine from the pro...

Page 163: Out

16. Flm liquid cooling circuit out no out image 16-6 draining circuit, excluding light processor circuit 3. Fill the syringe with air. Press in the valve of the male fitting when extracting air. Image 16-7 4. Couple the air filled syringe to the inlet of the cooling circuit and force air into the ci...

Page 164: Out

16. Flm liquid cooling circuit in out image 16-8 draining complete cooling circuit out in image 16-9 draining cooling circuit, excluding light processor circuit 5. Disconnect the syringe from the cooling circuit and repeat from step 3 until all cooling liquid is drained. 162 r59770072 flm series 19/...

Page 165: Out

16. Flm liquid cooling circuit 16.6 filling the liquid cooling circuit this procedure can only be used to fill an empty (drained) cooling circuit. Necessary tools • half a meter of plastic tube with male valved fitting. • half a meter of plastic tube with female valved fitting. • syringe connected w...

Page 166: Out

16. Flm liquid cooling circuit out no out image 16-12 filling part of cooling liquid circuit, light processor excluded 3. Fill the syringe with cooling liquid as follows: a) couple the female (f) fitting of a plastic tube to male (m) fitting of the syringe and emerge the tube end. Make sure that the...

Page 167: Out

16. Flm liquid cooling circuit a b c d e f m f image 16-13 4. Couple the filled syringe to the inlet of the cooling circuit and press the cooling liquid inside the circuit. Caution: position the empty bottle above the liquid circuit (on top of projector). In out a b image 16-14 filling complete cool...

Page 168: Out

16. Flm liquid cooling circuit a b in out image 16-15 filling part of cooling liquid circuit, light processor excluded 5. Disconnect the syringe from the cooling circuit and repeat from step 3 until cooling liquid comes out the exit side of the cooling circuit. 166 r59770072 flm series 19/03/2007.

Page 169: Out

16. Flm liquid cooling circuit 16.7 refreshing the liquid cooling circuit over time the cooling liquid may show deterioration and hence less effective cooling characteristics. To main- tain sound cooling properties, we advise annual replacement of the cooling liquid. Necessary tools • half a meter o...

Page 170: Out

16. Flm liquid cooling circuit 3. Fill a plastic tube, which contains a male fitting, with cooling liquid as follows: a) connect a tube, which contains a male (m) fitting, to the male (m) fitting of the syringe using a female/female (f) adapter. B) emerge the tube end and make sure that the piston o...

Page 171

16. Flm liquid cooling circuit 5. Activate the “refill mode” in the “service” menu of the projector. As a result the pump starts and the fresh cooling liquid in the bottle is sucked into the cooling circuit while the old cooling liquid is pressed out of the circuit into the empty bottle. Note: make ...

Page 172

16. Flm liquid cooling circuit 16.8 expelling air from the liquid cooling circuit necessary tools • half a meter of plastic tube with male valved fitting. • half a meter of plastic tube with female valved fitting. • bottle with cooling liquid (minimum 1/3 liter). • syringe equipped with male valved ...

Page 173: Out

16. Flm liquid cooling circuit in out image 16-25 5. Activate the “refill mode” in the “service” menu of the projector. As a result the pump starts and the cooling liquid in the bottle is sucked into the cooling circuit while air bubbles are pressed out of the circuit. Note: the pump cycle will now ...

Page 174

16. Flm liquid cooling circuit 16.9 pressurizing the liquid cooling circuit before pressurizing the liquid cooling circuit ensure that the circuit is filled with cooling liquid and that all air bubbles are expelled. C aution : this procedure is only valid in case the liquid cooling circuit is calibr...

Page 175

16. Flm liquid cooling circuit a b c d e f m f image 16-30 3. Couple the syringe to the inlet of the cooling circuit and press the cooling liquid inside the circuit until the manometer indicates 1 bar pressure. Ensure that no air bubbles are injected into the circuit. Caution: maximum 1 bar of press...

Page 176

16. Flm liquid cooling circuit check within 24 hours whether the pressure has stabilized close to 1 bar. If not, search for leakage. 174 r59770072 flm series 19/03/2007.

Page 177

16. Flm liquid cooling circuit 16.10 calibrating the liquid cooling circuit to check if the pressure vessel is correctly calibrated you may connect the syringe with the cooling circuit and measure the amount of liquid that is automatically expelled. The pressure would have dropped from 1 to 0 bar. T...

Page 178

16. Flm liquid cooling circuit a) couple the female (f) fitting of a plastic tube to male (m) fitting of the syringe and emerge the tube end. Make sure that the piston of the syringe is completely pressed in. B) extract cooling liquid into the syringe by pulling out the piston. C) turn the syringe u...

Page 179

16. Flm liquid cooling circuit a) first empty the syringe but make sure that the tube of the syringe remains filled with cooling liquid. B) couple the syringe (plunger completely pressed in) with the inlet of the cooling circuit. Keep holding the syringe vertical with the outlet downwards. C) releas...

Page 180

16. Flm liquid cooling circuit 178 r59770072 flm series 19/03/2007.

Page 181: 17. Heat Exchanger

17. Heat exchanger 17. Heat exchanger about this chapter this chapter describes who to replace a heat exchanger. Functionality the heat collected, via the cooling circuit in the different parts inside the projector is extracted to the ambient in the heat exchanger. Image 17-1 order info order number...

Page 182

17. Heat exchanger 17.1 removing the defective heat exchanger necessary tools • 2,5 mm allen key. • 7 mm wrench. • universal plier. How to remove the heat exchanger? 1. Uncouple the cooling circuit from the heat exchanger and from the engine (to exclude the engine cooling circuit from the complete c...

Page 183

17. Heat exchanger image 17-4 5. Drain the cooling circuit. Exclude the light processor circuit. Note: the procedure for draining is described in the service manual and in the installation manual included in the kit of the heat exchanger. 6. Pull out the complete assembly. Image 17-5 remove assembly...

Page 184

17. Heat exchanger 17.2 disassembling the heat exchanger assembly how to disassemble 1. Remove both indicated clips (1 & 3) with a universal plier. Push both clip tongs to each other in order to open the clip and move the clip away from the hose (when releasing the both clip tongs, it camps again. 1...

Page 185

17. Heat exchanger a b image 17-8 disassembling heat exchanger a dust filter assembly b heat exchanger fan assembly 4. Loosen on both sides the nuts holding the dust filter assembly to the heat exchanger. R59770072 flm series 19/03/2007 183.

Page 186

17. Heat exchanger 17.3 assembling the new heat exchanger how to assemble 1. Place the fan assembly on the heat exchanger and secure by fastening the four nuts (2 on each side). A b image 17-9 assembling heat exchanger 2. Place the heat exchanger and fan assembly on the dust filter assembly and secu...

Page 187

17. Heat exchanger 6. Secure with a clip (4). Push both clip tongs together and slide the clip on the hose. Release the tongs and it clamps automatically. Take care not to bend the soft copper tubes of the heat exchanger while sliding the hoses onto r59770072 flm series 19/03/2007 185.

Page 188

17. Heat exchanger 17.4 mounting the heat exchanger assembly into the projector necessary tools • 2,5 mm allen key. • 7 mm wrench. • universal plier. How to mount heat exchanger assembly into the projector? 1. Slide the heat exchanger assembly into the projector. Make sure the guides match the groov...

Page 189

17. Heat exchanger 4. Couple up the hose coming from the light pipe entrance to the heat exchanger. Caution: to avoid damage to the connector seal, always depress the connector tab of the female valved fitting prior to inserting the male valved fitting. After installation of the heat exchanger you h...

Page 190

17. Heat exchanger 188 r59770072 flm series 19/03/2007.

Page 191: 18. Cooling Pump

18. Cooling pump 18. Cooling pump about this chapter this chapter describes how to clean a jammed pump and also how to replace a defective cooling pump completely. In most cases it will be sufficient to clean the pump instead of replacing it with a new one. Image 18-1 as the cooling circuit has to b...

Page 192

18. Cooling pump 18.1 maintaining the cooling pump about this chapter this chapter describes how to maintain the cooling pump. What can happen due to crystallization inside the pump, the rotor can be jammed. This crystallization can be easily remove and the pump can be reused again. First always dra...

Page 193

18. Cooling pump 18.1.1 opening the cooling pump and rotor movement necessary tools • allen key 3 mm (best with ball point) • phillips head screwdriver • cloths how to open the cooling pump 1. After the pump cooling circuit is drained, remove the 4 screws on the pump body. Image 18-2 remove pump cov...

Page 194

18. Cooling pump 18.1.2 cleaning pump what can happen due to crystallization inside the pump, the rotor can be jammed. This can be removed with a cloth or a cotton swab. Necessary tools • cloth • cotton swab how to clean the pump 1. Slide out the rotor. 2. Clean both side of the rotor with a cloth. ...

Page 195

18. Cooling pump 18.1.3 closing the pump necessary tools phillips head screwdriver how to close the pump 1. Slide the pump cover with hose on the pump body. Make sure the sealing ring is not damaged and is on its place. Image 18-5 closing pump 2. Turn in the 4 screws. Tip: to optimize the sealing an...

Page 196

18. Cooling pump 18.2 cooling pump body replacement about this chapter this chapter describes how to replace the pump body just by draining the cooling circuit and without cutting hoses. Order info order number description quantity b4009521dk cooling pump 1 note : you have to order a complete coolin...

Page 197

18. Cooling pump 18.2.1 removing the pump body before removing the pump you have to drain the cooling circuit first. Necessary tools • allen key 3 mm (best with ball point) • phillips head screwdriver • cloths how to remove the body 1. Disconnect the pump electrically. Image 18-6 electrical disconne...

Page 198

18. Cooling pump 18.2.2 mounting the new pump body necessary tools • allen key 3 mm (best with ball point) • phillips head screwdriver how to mount 1. Remove the pump cover of the new pump. 2. Place the new pump body on the seating of the pump and turn in the 3 bolts. 3. Check if a rotor is inserted...

Page 199

18. Cooling pump 18.3 cooling pump replacement about this chapter this part describes how to replace the complete cooling pump. Order info order number description quantity b4009521dk cooling pump 1 overview • removing the pump • mounting the new pump r59770072 flm series 19/03/2007 197.

Page 200

18. Cooling pump 18.3.1 removing the pump before removing the pump you have to drain the cooling circuit first. Necessary tools • knife • allen key 3 mm • universal plier how to remove the pump 1. Disconnect the pump electrically. Image 18-8 electrical disconnection 2. Cut both hoses (1, 2) just nex...

Page 201

18. Cooling pump image 18-10 note: it is almost impossible to remove first the clip and then to pull off the hose. 3. Turn out both bolts (3) securing the pump to the seating of the pump. 4. Take out the pump. R59770072 flm series 19/03/2007 199.

Page 202

18. Cooling pump 18.3.2 mounting the new pump necessary tools • allen key 3 mm • universal plier how to mount the pump 1. Place the pump on its seating (a,1) 4 2 3 5 6 7 1 1 a b c image 18-11 pump mounting 2. Secure by turning both bolts. 3. Mounting the hose coming from the light processor. First, ...

Page 203

18. Cooling pump 5. Slide the clip over the connection and tighten the clip (b4). 6. Mounting the hose coming from the pressure vessel. First, slide a clip over the hose end (c5). 7. Push the hose end as far as possible on the input nipple of the pump (c6). 8. Slide the clip over the connection and ...

Page 204

18. Cooling pump 202 r59770072 flm series 19/03/2007.

Page 205: 19. Shutter Replacement

19. Shutter replacement 19. Shutter replacement about this chapter this chapter describes how to replace the shutter. Functionality a shutter is used to shut out the light when the projector is switched to pause or to standby. Image 19-1 order info order number description r849151k flm shutter assem...

Page 206

19. Shutter replacement 19.1 shutter replacement to replace the shutter you have to remove the light processor out of its compartment first. Necessary tools 2,5 mm allen key. How to replace the shutter? 1. Disconnect the shutter. Image 19-2 shutter connection 2. Turn out both indicated screws securi...

Page 207

19. Shutter replacement 3. Take off the shutter assembly. 4. Place the new shutter on its place so that the fixation holes match the holes in the light assembly. Image 19-4 mounting shutter 5. Turn in both screws. 6. Reinstall the connection. R59770072 flm series 19/03/2007 205.

Page 208

19. Shutter replacement 206 r59770072 flm series 19/03/2007.

Page 209

20. Formatter interface board 20. Formatter interface board about this chapter this chapter describes how to replace the formatter interface board (fib) from the light processor unit. Mh 1 c 223 j903 edge c831 r620 r 972 d1 c403 c 711 r2 c 400 c 302 m 113 r500 r402 c503 r 623 r 607 r 902 r 702 c 300...

Page 210

20. Formatter interface board 20.1 removing the fib to remove the formatter interface board (fib) you have to remove the light processor unit out of its compart- ment first. Necessary tools torx screwdriver tx10 how to remove the formatter interface board ? 1. Remove the indicated screws (9x) securi...

Page 211

20. Formatter interface board 20.2 mounting a new fib necessary tools torx screwdriver tx10 how to mount the new fib 1. Position the new fib in the box and turn in the 7 fixation screws. 2. Insert all cable. The black cables are marked with colored cable tie. Insert in the corresponding socket. Guid...

Page 212

20. Formatter interface board 210 r59770072 flm series 19/03/2007.

Page 213

21. Pixel map processor board 21. Pixel map processor board about this chapter this chapter gives an overview of the procedure to replace the pixel map processor (pmp) board. C420 c411 c 129 61 1 120 60 j103 c 100 i811 r 338 r553 r 334 r 355 j108 r555 l502 x800 c171 r836 ptc1 c267 r 948 l903 c 566 c...

Page 214

21. Pixel map processor board 21.1 diagnostics overview when removing input slot 4, 4 leds become visible for diagnostic purposes. Start with the power check leds and continue with the fpga configuration check leds. Led 0 led 1 power ok power in ok image 21-2 led name status description red power su...

Page 215

21. Pixel map processor board 21.2 building out the pmp first remove the input & communication cover and take out the input & communication unit. Necessary tools • allen key 2.5 mm • wrench 6 mm • torx screwdriver tx10 • philips screwdriver how to build out 1. Remove all input units (a) and the comm...

Page 216

21. Pixel map processor board image 21-5 fixation pin removal 4. Pull out the pmp assembly. Image 21-6 assembly removal 5. Disconnect the plug and turn out the 13 indicated screws. Take off the board. 214 r59770072 flm series 19/03/2007.

Page 217

21. Pixel map processor board image 21-7 pmp removal r59770072 flm series 19/03/2007 215.

Page 218

21. Pixel map processor board 21.3 mounting a new pmp board necessary tools • allen key 2.5 mm • wrench 6 mm • torx screwdriver tx10 • philips screwdriver how to mount 1. Place the new pmp board on the support plate and turn in the 13 screws. Image 21-8 mount pmp 2. Plug in the connector. 3. Turn th...

Page 219

21. Pixel map processor board image 21-10 secure pmp 5. Secure the assembly in the cabinet by turning in the indicated screws. 6. Reinsert the communication unit and all inputs and secure with the fixation screws. Reinstall the communication & input unit and close the communication & input cover. R5...

Page 220

21. Pixel map processor board 218 r59770072 flm series 19/03/2007.

Page 221: 22. Lcd Panel Replacement

22. Lcd panel replacement 22. Lcd panel replacement about this chapter this chapter gives an overview of the procedure to replace the lcd panel in the input & communication unit. Functionality when entering the menu, this lcd panel displays the same menus as the on screen menus even when the lamp is...

Page 222

22. Lcd panel replacement 22.1 removing the lcd panel first remove the input cover and take out the input & communication unit. Necessary tools • nut driver 5.5 mm • allen key 3 mm • allen key 2 mm how to remove the panel 1. Remove all input modules (a) and the communication module (b). A b image 22...

Page 223

22. Lcd panel replacement image 22-4 disconnect pmp 4. Remove the 4 screws of the lcd cover plate and take off this plate. Image 22-5 remove lcd cover 5. Disconnect the flat cable between the lcd panel and the keypad unit r59770072 flm series 19/03/2007 221.

Page 224

22. Lcd panel replacement image 22-6 connection lcd - keypad 6. Remove the 4 fixation screws of the lcd panel. Image 22-7 remove lcd panel 7. Remove the defective lcd panel. 222 r59770072 flm series 19/03/2007.

Page 225

22. Lcd panel replacement 22.2 mounting a new lcd panel necessary tools • nut driver 5.5 mm • allen key 3 mm • allen key 2 mm how to mount 1. Place an new lcd assembly with the flat cable connector facing the keypad unit on its place and turn in the 4 screws. Image 22-8 lcd panel 2. Reestablish the ...

Page 226

22. Lcd panel replacement image 22-10 lcd panel cover 4. Reestablish the connection between the pmp and the keypad unit (if it was removed) image 22-11 connection pmp - keypad unit 5. Place the housing back and secure with the 8 nuts. A a a a image 22-12 close housing 6. Mount the handles by turning...

Page 227

22. Lcd panel replacement reinsert the input & communication unit and close the input cover. R59770072 flm series 19/03/2007 225.

Page 228

22. Lcd panel replacement 226 r59770072 flm series 19/03/2007.

Page 229

23. Keypad board replacement 23. Keypad board replacement about this chapter this chapter gives the procedures how to replace the keypad board. Order information order number description r764869k keypad unit overview • removing the keypad unit • mounting the new keypad unit r59770072 flm series 19/0...

Page 230

23. Keypad board replacement 23.1 removing the keypad unit first remove the input cover and take out the input & communication unit. Necessary tools • nut driver 5.5 mm • allen key 3 mm • torx screwdriver tx10 how to remove 1. Remove all input modules (a) and the communication module (b). A b image ...

Page 231

23. Keypad board replacement image 23-3 5. Turn out the 4 fixation screws and take off the module. Image 23-4 remove keypad unit r59770072 flm series 19/03/2007 229.

Page 232

23. Keypad board replacement 23.2 mounting the new keypad unit necessary tools • nut driver 5.5 mm • allen key 3 mm • torx screwdriver tx10 how to mount 1. Place the new unit on the fixation studs and turn in the 4 screws. Image 23-5 mount keypad board 2. Reestablish the connections coming from the ...

Page 233

23. Keypad board replacement a a a a image 23-7 close housing 4. Mount the handles by turning in screws a. 5. Reinstall the communication unit and all inputs. Reinsert the input & communication unit and close the input cover. R59770072 flm series 19/03/2007 231.

Page 234

23. Keypad board replacement 232 r59770072 flm series 19/03/2007.

Page 235: 24. Fan Replacements

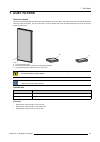

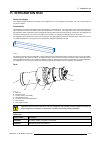

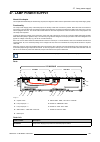

24. Fan replacements 24. Fan replacements about this chapter this chapter gives an overview of all procedure to replace a fan somewhere inside the projector. Image 24-1 b3245964d image 24-2 b3245651dk image 24-3 b32466391d order info heat exchanger fan, cold mirror fan, light processor compartment f...

Page 236

24. Fan replacements 24.1 heat exchanger fan about this chapter this chapter describes how to replace the heat exchanger fan. Image 24-4 order info fan order number description b3245964dk axial fan 59ls 50$mdl overview • building out the heat exchanger assembly • replacing the old fan with a new fan...

Page 237

24. Fan replacements 24.1.1 building out the heat exchanger assembly necessary tools screwdriver 7 mm how to build out 1. Remove the side cover, see "removal of the side cover", page 73. 2. Uncouple the cooling circuit from the heat exchanger. Press on the connector tab (1) and pull out the male val...

Page 238

24. Fan replacements 5. Disconnect the heat exchanger fan, connector in the near of the flow switch. 6. Pull out the complete assembly. Image 24-8 removing heat exchanger assembly 236 r59770072 flm series 19/03/2007.

Page 239

24. Fan replacements 24.1.2 replacing the old fan with a new fan necessary tools allen key 3 mm how to replace 1. Turn out the 4 socket head cap screws (a) on top of the fan. A b c d image 24-9 fan replacement 2. Take off the fan cover plate (b). 3. Remove the fan (c). 4. Place a new fan (c) on the ...

Page 240

24. Fan replacements 24.1.3 mounting the heat exchange assembly into the projector how to mount 1. Slide the heat exchanger assembly into the projector. Make sure the guides match the grooves of the assembly. Image 24-10 mounting assembly 2. Fasten both screws. 3. Reinstall both electrical connectio...

Page 241

24. Fan replacements 24.2 cold mirror fan about this chapter this chapter describes how to replace the cold mirror fan without removing the cold mirror itself. Readjustment of the cold mirror is in that case not necessary. Image 24-12 order info fan order number description b3245964dk axial fan 59ls...

Page 242

24. Fan replacements 24.2.1 removal of the cold mirror fan remove all covers of the projector before starting the procedure. Necessary tools • allen key 3 mm • allen key 2.5 mm • allen key with ball head 2.5 mm how to remove the fan 1. Slide out the dust filter. Image 24-13 remove dust filter 2. Dis...

Page 243

24. Fan replacements a a a a image 24-15 cold mirror fan removal 4. Slide out the fan and the protection grid. Be careful not to drop the rubber cushioning rings (a) inside the projector. R59770072 flm series 19/03/2007 241.

Page 244

24. Fan replacements 24.2.2 mounting a new cold mirror fan necessary tools • allen key 3 mm • allen key 2.5 mm • allen key with ball head 2.5 mm how to mount 1. Slide in the fan with the arrow indication downside. Insert the 4 rubber cushioning rings (a) between the fan and the fan plate. A a a a im...

Page 245

24. Fan replacements image 24-17 mount top dust filter reinstall all covers, start with the top cover. R59770072 flm series 19/03/2007 243.

Page 246

24. Fan replacements 24.3 light processor compartment fan about this chapter this chapter describes how to replace the light processor compartment fan. Image 24-18 order info fan order number description b3245964dk axial fan 59ls 50$mdl overview • remove of the top plate • removal of the axial fan •...

Page 247

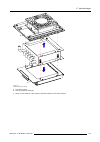

24. Fan replacements 24.3.1 remove of the top plate remove first all cover of the projector, take out the light processor assembly and remove the input and com- munication unit. Necessary tools allen key 3 mm how to remove the top plate 1. Remove both interlocking adapters in the same way as the fro...

Page 248

24. Fan replacements 24.3.2 removal of the axial fan necessary tools allen key 3 mm how to remove the fan 1. Disconnect the fan. Connector is situated in compartment below the cooling channel. 2. Cut the cable tie (a) and pull the cable out of the cable guide. Image 24-21 fan connector 3. Turn out t...

Page 249

24. Fan replacements 24.3.3 mounting a new axial fan how to install the new fan 1. Insert the fan with the arrow indication on the fan pointing to the mounting plate. Image 24-23 mounting axial fan 2. Secure the fan with the 4 hexagon socket head cap screws. 3. Guide the cable through the cable guid...

Page 250

24. Fan replacements 24.3.4 mounting the top plate necessary tools • allen key 3 mm • flat screwdriver 7 mm how to mount 1. Place first the big plate on the projector frame. A image 24-24 mounting top plate 2. Turn in the screws which will be covered by the small plate. 3. Push the joggle of the sma...

Page 251

24. Fan replacements 24.4 cathode fan replacement about this chapter this chapter describes how to replace the cathode fan. Image 24-25 order info fan order number description b3245651dk radial fan 24v 143d175cp overview • removal of the fan assembly • fan replacement • mounting the fan assembly r59...

Page 252

24. Fan replacements 24.4.1 removal of the fan assembly remove the lamp cover and take out the lamp house. Necessary tools • allen key 3 mm • flat screws driver 7 mm • nut driver 7 mm how to remove the fan 1. Turn out the 5 indicated screws with an allen key 3 mm. Image 24-26 partial lamp house remo...

Page 253

24. Fan replacements image 24-28 image 24-29 4. Turn out the 3 screws of the side plate of the air channel and take the plate away. Cut the foam rubber as it is stuck on the different plates. Image 24-30 side plate air channel 5. Turn out the 4 screws holding the fan assembly to the frame and cut th...

Page 254

24. Fan replacements image 24-31 removing fan assembly 6. Slide the assembly upwards and take out the fan assembly. 252 r59770072 flm series 19/03/2007.

Page 255

24. Fan replacements 24.4.2 fan replacement necessary tools allen key 3 mm how to replace 1. Turn out the 4 screws a and away the lock washers. Remove also screw b. D c b a image 24-32 removing fan 2. Take off the fan fixation plate c. 3. Lift up plate d and pull the cable through the hole. The defe...

Page 256

24. Fan replacements 24.4.3 mounting the fan assembly necessary tools • allen key 3 mm • flat screwdriver 7 mm • nut driver 7 mm how to mount the fan assembly 1. Insert the fan assembly in the projector with the fixation plate towards the lamp cabinet and the cable to the inside of the projector. Im...

Page 257

24. Fan replacements image 24-35 side plate air channel 4. Connect the fan and push the connector and cable behind the plate. Image 24-36 image 24-37 5. Insert the side panel of the lamp cabinet and secure with 5 screws. Image 24-38 insert side panel r59770072 flm series 19/03/2007 255.

Page 258

24. Fan replacements image 24-39 partial lamp house installation 6. Reinsert the lamp house, see "installation of the lamp house", page 91 and reinstall the lamp cover, see "installation of the lamp cover", page 82. 256 r59770072 flm series 19/03/2007.

Page 259

24. Fan replacements 24.5 anode fan replacement about this chapter this chapter describes how to replace the anode fan. Image 24-40 order info fan order number description b3245651dk radial fan 24v 143d175cp overview • access to the anode fan • removing the anode fan • fan replacement • mounting the...

Page 260

24. Fan replacements 24.5.1 access to the anode fan remove the side cover and take out the light processor assembly. What should be done the heat exchanger and flow switch must be taken out of the projector without disconnecting them from the cooling circuit. Once the heat exchanger is slide out, it...

Page 261

24. Fan replacements image 24-42 turning out the heat exchanger 4. Rotate this assembly, together with the connected hose and flow switch (not available in flm hd versions). If necessary, disconnect the cables. R59770072 flm series 19/03/2007 259.

Page 262

24. Fan replacements 24.5.2 removing the anode fan necessary tools • allen key 3 mm • allen key 5 mm how to remove the anode fan 1. Turn out the 4 screws of the fan security grid and take off that grid (a) . Take out also the air channel plate b. A b image 24-43 removing grid and channel plate 2. Pu...

Page 263

24. Fan replacements 3. Turn out the 3 indicated fixation bolts. Image 24-45 4. Slide out the fan assembly. R59770072 flm series 19/03/2007 261.

Page 264

24. Fan replacements 24.5.3 fan replacement necessary tools allen key 3 mm how to replace 1. Turn out the 11 screws and take out the fan assembly. Image 24-46 2. Turn out the 4 fixation screws and remove the lock washers.. A b image 24-47 fan removal 3. Take off plate b and then plate a. 4. Take the...

Page 265

24. Fan replacements a b image 24-48 fan assembly 5. Push the cable through the hole in plate b and place plate b on plate a so that the fixation holes match the holes in plate a. 6. Secure with 4 screws. Insert lock washer between each screw and the plate. 7. Insert the assembly in its cabinet and ...

Page 266

24. Fan replacements 24.5.4 mounting the fan assembly necessary tools • allen key 3 mm • allen key 5 mm how to mount 1. Slide in the assembly into the projector. Image 24-50 mounting anode fan assembly 2. Turn in the 3 indicated fixation screws. 3. Place the air channel plate b on the fixation holes...

Page 267

24. Fan replacements a b image 24-51 4. Turn in the 4 fixation screws. 5. Reconnect the fan. R59770072 flm series 19/03/2007 265.

Page 268

24. Fan replacements 24.5.5 finalizing the replacement necessary tools flat screwdriver 3 mm what to do 1. Rotate the heat exchanger assembly back and slide it into the projector. Image 24-52 2. Fasten both fixation screws. 3. Connect those cables which where disconnected and tie up the cables where...

Page 269

24. Fan replacements 24.6 mains input fan about this chapter this chapter describes how to replace the mains input fan. Image 24-53 order information order number description b32466391d axial fan 24v 37ls43 92l120 overview • replacing the mains input fan r59770072 flm series 19/03/2007 267.

Page 270

24. Fan replacements 24.6.1 replacing the mains input fan remove the back cover necessary tools allen key 3 mm how to replace the fan 1. Disconnect the fan. Image 24-54 fan connection 2. Turn out the 4 screws. 268 r59770072 flm series 19/03/2007.

Page 271