- DL manuals

- Bard

- Heat Pump

- CH3S1

- Installation Instructions Manual

Bard CH3S1 Installation Instructions Manual

Manual 2100-455M

Page

1 of 27

INSTALLATION INSTRUCTIONS

WALL MOUNTED

PACKAGE HEAT PUMPS

Models:

CH3S1

CH4S1

CH5S1

Manual :

2100-455M

Supersedes: 2100-455L

File:

Volume III Tab 17

Date: 02-06-12

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Note

T

his

is

an

R-410a

h

igh

P

RessuRe

R

efRigeRanT

s

ysTem

Summary of CH3S1

Page 1

Manual 2100-455m page 1 of 27 installation instructions wall mounted package heat pumps models: ch3s1 ch4s1 ch5s1 manual : 2100-455m supersedes: 2100-455l file: volume iii tab 17 date: 02-06-12 bard manufacturing company, inc. Bryan, ohio 43506 since 1914...Moving ahead just as planned. Note t his i...

Page 2: Contents

Manual 2100-455m page 2 of 27 contents figures figure 1 unit dimensions ch3s1 ........................5 figure 2 unit dimensions ch4s1 & ch5s1 ........6 figure 3 optional top outlet flange ....................9 figure 4 mounting instructions ch3s1 ..............10 figure 5 mounting instructions ch4s...

Page 3

Manual 2100-455m page 3 of 28 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-455m page 4 of 28 wall mount general information heat pump wall mount model nomenclature ch 4s 1 – a 05 b p x x x x table 1 electric heat table models kw ch3s1-a ch3s1-b ch3s1-c ch4s1-a ch5s1-a ch4s1-a ch5s1-a ch4s1-a ch5s1-a 240-1 208-1 240-3 208-3 460-3 240-1 208-1 240-3 208-3 460-3 a ...

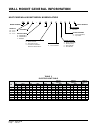

Page 5: "ch3S1" Unit Dimensions

Manual 2100-455m page 5 of 28 fig ure 1 un it di mens io ns 16" 16" 16" 16" 16" 31 5/8" 32 3/4" 84 11/16" 43 7/8" 42 3/16" 13 3/8" 48 1/16" 5 13/16" " 31" 6 7/8" 39 7/8" 9 13/16" 15 7/8" 29 7/8" 6 1/8" 1 3/8" 43" 6 9/16" 7/8" 2 1/4" 8 9/16" left side view (1 2) w all rig ht s ide vi ew back view ent...

Page 6

Manual 2100-455m page 6 of 28 fig ure 2 un it di mens io ns 42 3/4" 39 7/8" 1 3/8" 6 7/8" right side view front view mis-2020 a lef t s ide v iew "ch4s1 and ch5s1" unit dimensions back view door filter access supply opening mounting (1 2) w all return opening to p r ain flashing evap. Drain hose hol...

Page 7

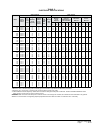

Manual 2100-455m page 7 of 28 table 2 electrical specifications maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. Based on 75°c copper wire. All wiring must conform to nec and all local codes. These “minimum circuit ampacity” values are to be...

Page 8

Manual 2100-455m page 8 of 28 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. General...

Page 9: Installation Instructions

Manual 2100-455m page 9 of 28 insulation mis-2306 top insert top outlet flange from inside unit and compress insulation insert top outlet flange from inside unit and compress insulation fasten flanges to top using (8) screws installation instructions optional top outlet flange top outlet flange is s...

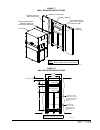

Page 10

Manual 2100-455m page 10 of 28 7 0" min. 0" min. " 6 8 1 3 8 " top rain flashing (supplied) flanges apply a bead of caulk along entire length of top and behind side mounting foam "ch3s1" wall mounting instructions a b c d e required dim. To maintain 0" min. Clearance from co mb us ti bl e m at er ia...

Page 11

Manual 2100-455m page 11 of 28 fig ure 5 m o unt in g i nstruct io ns 1 3/8" 0" min. 0" min. 6 7/8" return opening ho les, 12 pl ac es unit mounting wall * n ot u se d on to p outlet units c 16" d b 16" 16" 16" e 16" 30" c 16" 16" 16" a 16" 16" 43" d 16" supply opening * "ch4s1 and ch5s1" wall mount...

Page 12

Manual 2100-455m page 12 of 28 figure 6 electric heat clearance recommended 1" optional clearance duct outside sheeting unit inside sheeting wall frame supply air typical building supply air duct flange of wall mis-2210 side section view of supply air duct for wall mounted unit showing 0" clearance ...

Page 13

Manual 2100-455m page 13 of 28 figure 7 wall mounting instructions figure 8 wall mounting instructions flashing. Attach to "ch" unit structural steel steel siding wall exterior wood or when framing wall to support unit. Follow all local building codes opening interior finished wall supply opening re...

Page 14

Manual 2100-455m page 14 of 28 figure 9 common wall mounting installations isolation curb wm1cf5-x sup ply a ir return air silencer wapr11-x return air free blow supply plenum wafb51-x outside wall unit (outside) note: duct maybe in attic or below rafters as shown. Note: direction of return rafters ...

Page 15: Important

Manual 2100-455m page 15 of 28 eleven (11) wires should be run from thermostat subbase to the 24v terminal board in the unit. An eleven conductor, 18 gauge copper color-coded thermostat cable is recommended. The connection points are shown in figure 11. An additional wire is needed if dehumidificati...

Page 16: Start Up

Manual 2100-455m page 16 of 28 low voltage connections these units use a grounded 24 volt ac low voltage circuit and require at least a 2 stage heating and a 2 stage cooling thermostat. “g” terminal is the fan input. “y” terminal is the compressor stage 1 input. “y1” terminal is the compressor stage...

Page 17: Start Up Cont’D.

Manual 2100-455m page 17 of 28 start up cont’d. Safety practices: 1. Never mix r-410a with other refrigerants. 2. Use gloves and safety glasses, polyol ester oils can be irritating to the skin, and liquid refrigerant will freeze the skin. 3. Never use air and r-410a to leak check; the mixture may be...

Page 18

Manual 2100-455m page 18 of 28 phase monitor all units with three phase compressors are equipped with a 3 phase line monitor to prevent compressor damage due to phase reversal. The phase monitor in this unit is equipped with two leds. If the y signal is present at the phase monitor and phases are co...

Page 19

Manual 2100-455m page 19 of 28 defrost cycle the defrost cycle is controlled by temperature and time on the solid state heat pump control. When the outdoor temperature is in the lower 40°f temperature range or colder, the outdoor coil temperature is 32°f or below. This coil temperature is sensed by ...

Page 20

Manual 2100-455m page 20 of 28 there is an initiate defrost jumper (sen jump) on the control that can be used at any outdoor ambient during the heating cycle to simulate a 0° coil temperature. This can be used to check defrost operation of the unit without waiting for the outdoor ambient to fall int...

Page 21: Troubleshooting

Manual 2100-455m page 21 of 28 solid state heat pump control troubleshooting procedure 1. Note: a thorough understanding of the defrost cycle sequence is essential. Review that section earlier in this manual prior to troubleshooting the control. Turn on ac power supply to unit. 2. Turn thermostat bl...

Page 22

Manual 2100-455m page 22 of 28 checking temperature sensor outside unit circuit 1. Disconnect temperature sensor from board and from outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resist...

Page 23: R-410A

Manual 2100-455m page 23 of 28 removal of fan shroud 1. Disconnect all power to the unit. 2. Remove the screws holding both grilles, one on each side of unit, and remove grilles. 3. Remove screws holding fan shroud to condenser and bottom. Nine (9) screws. 4. Unwire condenser fan motor. 5. Slide com...

Page 24

Manual 2100-455m page 24 of 28 table 7 maximum esp of operation note: these units are equipped with a variable speed (ecm) indoor motor that automatically adjusts itself to maintain approximately the same rate of indoor airflow in both heating and cooling, dry and wet coil conditions and at both 230...

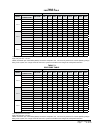

Page 25

Manual 2100-455m page 25 of 28 table 8 pressure table table 9 pressure table low side pressure ± 2 psig high side pressure ± 5 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the charge should be rem...

Page 26

Manual 2100-455m page 26 of 28 table 10 pressure t able table 1 1 pressure t able low side pressure ± 2 psig high side pressure ± 5 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the charge should b...

Page 27: Troubleshooting Ge Ecm

Manual 2100-455m page 27 of 28 caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/procedure motor rocks slightly • this ...

Page 28: Troubleshooting Ge Ecm

Manual 2100-455m page 28 of 28 troubleshooting ge ecm ™ motors (cont'd.) replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programmed...