Manual 2100-457d page 1 of 16 commercial room ventilators with exhaust model crvmp-5 for use with bard 3 through 5 ton wa*s series wall mount air conditioners installation instructions manual : 2100-457d supersedes: 2100-457c file: volume iii tab 19 date: 01-24-14 bard manufacturing company, inc. Br...

Manual 2100-457d page 2 of 16 contents general general information .................................................. 3 unpacking ................................................................. 3 description ................................................................ 3 models ...................

Manual 2100-457d page 3 of 16 general general information the ventilator should only be installed by a trained heating and air conditioning technician. These instructions serve as a guide to the technician installing the ventilator package. They are not intended as a step by step procedure with whic...

Manual 2100-457d page 4 of 16 2. Remove and save the existing exterior blower access and service access panels on the bard wall mount unit. (see figure 1.) installation basic installation 1. Unpack the ventilator assembly which includes the integral ventilator with attached electrical harness, step ...

Manual 2100-457d page 5 of 16 figure 2 remove air filter and exhaust cover plate 3. Remove and save existing unit air filter and screws from front center grille. (see figure 2.) 4. Remove and discard the exhaust cover plate..

Manual 2100-457d page 6 of 16 6. Open control panel to gain access to unit low voltage terminal block. 7. Route electrical harness leads through the 7/8" bushing in control panel (figure 3) into low voltage box. 5. Install ventilator sheet metal assembly by inserting the ventilator into the unit to ...

Manual 2100-457d page 7 of 16 8. Connect “orange lead” with the fork terminal to either the “g” terminal of the low voltage strip (will ventilate anytime there is a call for the blower), or the “f” terminal (can be used as a junction point for on-demand ventilation with a capable thermostat or occup...

Manual 2100-457d page 8 of 16 f. Now energize the stage #2 cooling/heating by increasing the thermostat setting to a greater offset than the actual room temperature. (jumper “r” to “g”, “y1” and “y2”) g. Ventilator should now open to the position set by “r3” potentiometer on step control board. (see...

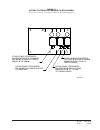

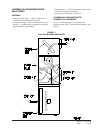

Manual 2100-457d page 9 of 16 figure 5 setting 3-position crv damper control board (utilize the charts for your specific model on the following pages) mis-2117 a "r2" adjustment potentiometer for "stage #1" heating or cooling damper position. ("g" and "y1" control signals) for "stage #2" heating or ...

Manual 2100-457d page 10 of 16 blade adjustment for desired ventilator air the amount of ventilation air supplied by the commercial room ventilator is dependent on five (5) factors. 1. Return air duct static pressure drop. 2. Supply air duct static pressure drop. 3. Indoor blower motor speed. 4. Dam...

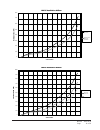

Manual 2100-457d page 11 of 16 0 100 200 300 400 500 600 700 800 0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30 ve nt ila tion air flow (c fm ) vent position wa3s ventilation airflow stage #2 operation blower only & stage #1 operation 0 100 200 300 400 500 600 700 800 900 1000 0 2.5 5 7.5 10 12.5 15...

Manual 2100-457d page 12 of 16 0 100 200 300 400 500 600 700 800 900 1000 0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30 ve nt ila tio n air flo w (c fm ) vent position wa5s ventilation airflow stage #2 operation stage #1 operation blower only.

Manual 2100-457d page 13 of 16 adding optional co 2 control sensor adding an optional bard part #8403-067 to this control will maximize the capabilities of this vent by only supplying fresh air intake to maintain co 2 levels. This has multiple benefits. • minimizes ventilation load on structure as i...

Manual 2100-457d page 14 of 16 figure 6 8403-067 co 2 sensor set up 17 12 fully open 1500 20 16 1450 19 15 1400 18 14 1350 17 12 1300 16 11 1250 15 10 1200 14 9 1150 13 8 1100 mis-3009 a 4-20ma an (ppm) damper (1) approc. Blade position (2) 4 700 fully closed 0 5 750 1 6 800 2 7 850 3 8 900 4 9 950 ...

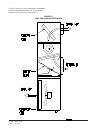

Manual 2100-457d page 15 of 16 figure 7 call for blower operation commercial room ventilator – wa*s series features • one piece construction – easy to install with no mechanical linkage adjustment required. • exhaust air damper – built in with positive closed position. Provides exhaust air capabilit...

Manual 2100-457d page 16 of 16 a call for cooling cycles the compressor, and dampers remain in the ventilation mode. On loss of blower operation, crv closes fully. See figure 8. Figure 8 call for cooling operation.