- DL manuals

- Bard

- Air Conditioner

- D25A2PA

- Installation And Service Instructions Manual

Bard D25A2PA Installation And Service Instructions Manual

Page

1 of 59

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-643C

Supersedes: 2100-643B

Date: 7-28-16

INSTALLATION AND

SERVICE INSTRUCTIONS

DUAL-TEC™

WALL-MOUNT PACKAGE

AIR CONDITIONER

Models:

NOTE: LC Series Controllers must be used with

D-Series Wall-Mount Units

Part of the Bard DC Free Cooling Unit System

D25A2PA

D28A2PA

D28A2PB

D35A2PA

D35A2PB

D36A2PA

D36A2PB

D42A2PA

D42A2PB

D48A2PA

D48A2PB

D60A2PA

D60A2PB

D25L2PA

D25L2PB

D28L2PA

D28L2PB

D35L2PA

D35L2PB

D36L2PA

D36L2PB

D42L2PA

D42L2PB

D48L2PA

D48L2PB

D60L2PA

D60L2PB

Summary of D25A2PA

Page 1

Page 1 of 59 bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual: 2100-643c supersedes: 2100-643b date: 7-28-16 installation and service instructions dual-tec™ wall-mount package air conditioner models: note: lc series controllers must be used with d-series wall-mount units pa...

Page 2: Contents

Manual 2100-643c page 2 of 59 figures and tables figure 1.1 wall-mount unit model nomenclature ......6 figure 1.2 dimensions ............................................8 figure 1.3a d25a, d25l, d35a, d35l mounting instructions ...........................10 figure 1.3b d28a, d28l, d36a, d36l, d42a, ...

Page 3: General Information

Manual 2100-643c page 3 of 59 general information dc free cooling unit system the bard dc free cooling unit system is composed of two (2) d-series dual-tec™ wall-mount air conditioners matched with one (1) lc series lead/lag controller. The d-series, specifically engineered for the telecom market, c...

Page 4: Warning

Manual 2100-643c page 4 of 59 electrical shock hazard. Have a properly trained individual perform these tasks. Failure to do so could result in electric shock or death. ! Warning fire hazard. Maintain minimum 1/4” clearance between the supply air duct and combustible materials in the first 3’ feet o...

Page 5: Section 1:

Manual 2100-643c page 5 of 59 section 1: installation instructions.

Page 6

Manual 2100-643c page 6 of 59 list of necessary materials/tools d 25 a 2 p a 05 4 p x x x j model series control modules j –high pressure switch, low pressure switch, compressor control module, low ambient control, alarm contacts, start assist c –j module + compressor crankcase heater -48vdc free co...

Page 7: Site Preparation

Manual 2100-643c page 7 of 59 site preparation new shelter installation vs. Retrofit installation these installation instructions cover both new shelter installations and retrofit installations. Each installation is unique and may require special accomodations and modifications. Although bard manufa...

Page 8

Manual 2100-643c page 8 of 59 figure 1.2 dimensions of basic unit for architectural and installation requirements (nominal) all dimensions are in inches. Dimensional drawings are not to scale. Model width (w) depth (d) height (h) supply return a b c b e f g i j k l m n o p q r s t d25a/l d35a/l 38.2...

Page 9: Wall-Mount Unit Installation

Manual 2100-643c page 9 of 59 5. If desired, hook top rain flashing (attached to front- right of supply flange for shipping) under back bend of top. 6. Position unit in opening and secure with fasteners sufficient for the application such as 5/16" lag/ anchor/carriage bolts; use 7/8" diameter flat w...

Page 10

Manual 2100-643c page 10 of 59 figure 1.3a d25a, d25l, d35a, d35l mounting instructions 2 c d c 1 2" 1 2" 1 2" 1 2" 1 2" b 2 8" 1 4" 4 11 16 " 4 11 16 " 4" typ. " 1 8 a 7 8 " 7 8 " 4" typ. 3 7 8 " e 9 1 16 " 4 7 8 " ret ur n air silic one cau lking be placed behin d suppli ed no tes: ent ir e len gt...

Page 11

Manual 2100-643c page 11 of 59 figure 1.3b d28a, d28l, d36a, d36l, d42a, d42l mounting instructions d 16" 16" 16" 16" 16" 1 7 8 " 6 1 2 " 6 1 2 " 2 1 8 " 7 8 " 1" 3" 4" ty p. 4" ty p. 6 1 2 " 30" e 16" a c c 3 1 8 " b w all opening and hole lo ca tion view re turn air 1 req ui re d di m en sio ns to...

Page 12

Manual 2100-643c page 12 of 59 figure 1.3c d48a, d48l, d60a, d60l mounting instructions d 16" 16" 16" 16" 16" 2 " 6 8 " 5 8 9 7 " 1" 3" ty p. 1 4" 4" ty p. 6 1 2 " 30" e 16" a c c " 7 8 3 b " 8 7 1 1 2 " 6 1 1/4 30 1/2 1/ 4" cl ea ra nc e o n a ll su pplied foa m ai r seal a su pp ly o pen ing si li...

Page 13

Manual 2100-643c page 13 of 59 figure 1.4 electric heat clearance figure 1.5 wall mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on ope...

Page 14

Manual 2100-643c page 14 of 59 figure 1.6 wall mounting instructions i a c k e + 1.000 b 1.000 supply duct over frame interior finished wall all around duct framing material exterior finish wall opening for actual dimensions. 2 x 4's, 2 x 6's &/or structural steel attach to top 1.000" clearance 1.00...

Page 15: Warning

Manual 2100-643c page 15 of 59 wall-mount unit supply wiring refer to the unit rating plate or table 1.1 on page 16 for wire sizing information and maximum fuse or circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. The field wiring used must be sized to carry that a...

Page 16

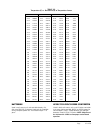

Manual 2100-643c page 16 of 59 these “minimum circuit ampacity” values are to be used for sizing the field power conductors. Refer to the national electric code (latest version), article 310 for power conductor sizing. Caution: when more than one field power circuit is run through one conduit, the c...

Page 17

Manual 2100-643c page 17 of 59 figure 1.9 vac and vdc supply wiring landing points figure 1.10 adjusting the 230/208 vac transformer 230/208v 1 phase and 3 phase equipment use dual primary voltage transformers. All equipment leaves the factory wired on 240v tap. It is very important that the correct...

Page 18

Manual 2100-643c page 18 of 59 figure 1.11 bard polarity-voltage monitor if the vdc wiring is not terminated correctly on the specific polarity-indicated terminals of the vdc terminal block, the vdc controls and motors will not activate and the wall-mounted unit will not function. If field wiring is...

Page 19: Preliminary Start-Up

Manual 2100-643c page 19 of 59 preliminary start-up running in stand alone (orphan) mode with both ac and dc breakers turned on, each d-series wall-mount system has the capability to run without the controller attached—this feature is called stand alone or orphan mode, and it basically keeps the she...

Page 20

Manual 2100-643c page 20 of 59.

Page 21: Section 2:

Manual 2100-643c page 21 of 59 section 2: service instructions.

Page 22

Manual 2100-643c page 22 of 59 general refrigerant information general 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi/250 psi low). 4. R-410a is a binary ...

Page 23

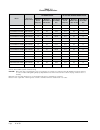

Manual 2100-643c page 23 of 59 model return air temperature pressure air temperature entering outdoor coil, degree °f capacitors 75 80 85 90 95 100 105 110 115 120 part no. Ratings d25a/l 75° db 62° wb low side high side 132 292 133 308 134 327 136 347 137 369 138 392 140 417 142 445 144 474 147 505...

Page 24: Sequence of Operation

Manual 2100-643c page 24 of 59 sequence of operation d-series wall-mount unit sequence of operation overview this product is designed to function like a typical telecom air conditioning system with an outdoor air- cooling damper. However, the dc free cooling unit system does have some special featur...

Page 25

Manual 2100-643c page 25 of 59 • if conditions outside are not conducive to free cooling, the control board will send: 1. 24vac signal from n02 to ccm (compressor) 2. 24vdc from terminal n07 (blower motor start relay) 3. 0-10vdc signal from y1 (speed voltage) heating call when a call for heating gen...

Page 26

Manual 2100-643c page 26 of 59 special considerations • compressor run time – once activated, the compressor will run for a minimum of 5 minutes, regardless of setpoint (control board programming) • compressor off time – once deactivated, the compressor will not start again for a minimum of 2 minute...

Page 27: Using The Tec-Eye

Manual 2100-643c page 27 of 59 figure 2.4 tec-eye tm connection to unit control modular phone connector for tec-eye tm hand-held diagnostic tool using the tec-eye tm tec-eye tm hand-held diagnostic tool the microprocessor control used in this wall mount air conditioning system allows for complete co...

Page 28

Manual 2100-643c page 28 of 59 status screen the status screen is the default start-up screen and also the return screen after 5 minutes of no activity. The screen can be accessed any time by pressing the escape button repeatedly. The status screen displays the current date, time, return air tempera...

Page 29

Manual 2100-643c page 29 of 59 identifying a unit address 1. Go to setpoints menu, press enter key. 2. Press up or down arrow keys to get to fieldbus address, press enter key. The wall-mount unit's current address value will display. Note: this value can be changed if there was an error with the aut...

Page 30: Componentry Specifications

Manual 2100-643c page 30 of 59 componentry specifications low pressure switch cut-out pressure: 40psi (+/- 4 psi) cut-in pressure: 55psi (+/- 4psi) high pressure switch cut-out pressure: 650psi (+/- 10 psi) cut-in pressure: 520psi (+/- 15psi) low ambient control modulating head-pressure control that...

Page 31

Manual 2100-643c page 31 of 59 batteries used in wall-mount unit and controller boards, flat- disk style br2330 3v battery. Used only for time/date during complete power loss. Estimated lifespan 7-8 years. Table 2.3 temperature (f) vs. Resistance (r) of temperature sensor 48vdc to 24vdc power conver...

Page 32

Manual 2100-643c page 32 of 59 outdoor fan motor due to design considerations of the condenser section of the wall-mount unit, placement/clearance of the motor/fan blade is critical to heat dispersal. Should a change of motor or fan blade be necessary, please view figure 2.6 for proper clearance adj...

Page 33

Manual 2100-643c page 33 of 59 figure 2.8 power loss relay circuit figure 2.9 high pressure relay circuit figure 2.10 blower motor start relay circuit blower motor start relay.

Page 34

Manual 2100-643c page 34 of 59 figure 2.11 d25a/l, d35a/l unit control panel software control module rs485 label control panel 20 amp 2 pole contactor circuit breaker base labels dc circuit breaker circuit breaker dc polarity voltage monitor transformer circuit breaker din rail end clamp terminal bl...

Page 35

Manual 2100-643c page 35 of 59 figure 2.12 d28a/l, d36a/l, d42a/l, d48a/l, d60a/l unit control panel breaker circuit duct transformer cable 20 amp contactor 2 pole monitor voltage breaker base circuit evap. Temp. Sensor terminal ground breaker switch terminal block dc circuit dc polarity cable duct ...

Page 36

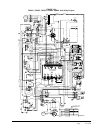

Manual 2100-643c page 36 of 59 figure 2.13 d25a/l, d35a/l unit wiring diagram start kit c ye llo w ye llo w he rm fan fan motor outdoor (see chart) r compressor s c + 2....10 vdc 2....10 vdc 24 vac/vdc 1 com 2 + 3 y 5 u + damper actuator motor 48 vdc to 24 vdc - + - + output input x x x x x + adj. C...

Page 37

Manual 2100-643c page 37 of 59 figure 2.14 d28a/l, d36a/l, d42a/l, d48a/l, d60a/l unit wiring diagram co m nc no start kit c ye llo w ye llo w he rm fan fan motor outdoor (see chart) r compressor s c + 2....10 vdc 2....10 vdc 24 vac/vdc 1 com 2 + 3 y 5 u + damper actuator motor 48 vdc to 24 vdc - + ...

Page 38: Caution

Manual 2100-643c page 38 of 59 maintenance and troubleshooting standard maintenance procedures 4. Manually spin fan and blower motors to ensure they turn freely. All motors are permanently lubricated, so no oil is necessary. 5. Inspect free cooling damper actuator and linkage. 6. Install new air fil...

Page 39

Manual 2100-643c page 39 of 59 table 2.5 troubleshooting the 48vdc indoor blower motor motor controller molex plug color function description of application 1 red speed input 0-10 vdc input, varying voltage input between 0-10 vdc dictates the motor speed/ cfm delivery 2 3 4 orange run start command ...

Page 40

Manual 2100-643c page 40 of 59 figure 2.16 troubleshooting motor start command figure 2.17 troubleshooting speed voltage female plug motor start command: with the meter set to continuity beeper, place the black (–) lead on pin 5 and the red (+) lead on pin 4 of the female portion of the molex-style ...

Page 41

Manual 2100-643c page 41 of 59 figure 2.18 vdc polarity check bard system supply breakers shelter vdc power supply -48vdc, positive ground + if the vdc wiring is not terminated correctly on the specific polarity-indicated terminals of the vdc terminal block, the vdc controls and motors will not acti...

Page 42

Manual 2100-643c page 42 of 59 figure 2.19 verifying incoming voltage: vdc 48vdc shelter system voltage range: 40vdc – 56vdc typical running range: 48vdc – 53vdc multimeter set to vdc shelter supply breaker in on position bard system breaker in off position 52vdc displayed voltage must be within thi...

Page 43

Manual 2100-643c page 43 of 59 signal description possible cause component to check recommended action device actions low pressure alarm alarm is activated when a low pressure event is present in the refrigeration system and the compressor is running. Lack of refrigerant run the unit and check if th...

Page 44

Manual 2100-643c page 44 of 59 signal description possible cause component to check recommended action device actions dc free cooling damper fails to close alarm alarm is reset automatically. Dc free cooling damper fails to close. Check the damper linkage. Check to see if anything is in the way of t...

Page 45: Section 3:

Manual 2100-643c page 45 of 59 section 3: appendix.

Page 46

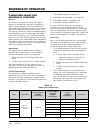

Manual 2100-643c page 46 of 59 wall-mount unit architecture caution: the bard dc free cooling unit system has been pre-programmed with what is widely considered to be the best settings for efficiency and operation. Any changes to internal programming through the lc series controller or the tec-eye t...

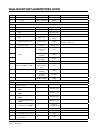

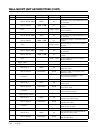

Page 47

Manual 2100-643c page 47 of 59 screen menu item range default value description reset temperature 0°f – 99.9°f 55°f temperature sensed by freezestat which cancels compressor shutdown reset time 0-999 300 seconds time alloted which will also cancel compressor shutdown blower settings continuous none/...

Page 48

Manual 2100-643c page 48 of 59 wall-mount unit architecture (cont.) screen menu item range default value description maximum -1000 – 1000 1000 period 500 – 9999ms 500ms end of setpoints clock/scheduler clock time date (current date) hour 1:00 – 24:00 (current time) day mon. – fri. (current day of we...

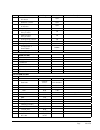

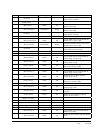

Page 49

Manual 2100-643c page 49 of 59 screen menu item range default value description low pressure switch di4 status open blower di 5 status open damper switch di 6 status open relay outputs cooling stage 1 relay 2 status off cooling stage 2 relay 3 status off heating relay 4 status off blower relay 7 sta...

Page 50

Manual 2100-643c page 50 of 59 wall-mount unit architecture (cont.) screen menu item range default value description working hours run hours -3276.8 – 3276.7 compressor run hours -3276.8 – 3276.7 hours of operation num starts -3276.8 – 3276.7 number of starts compressor full load run hours -3276.8 –...

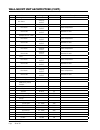

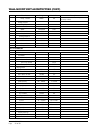

Page 51

Manual 2100-643c page 51 of 59 screen menu item range default value description language language 0-1 english probe adjustment analog inputs sat input b001 offset -9.9 – 9.9 0 value -3276.8 – 3276.7 oat input b002 offset -9.9 – 9.9 0 value -3276.8 – 3276.7 rat input b003 offset -9.9 – 9.9 0 value -3...

Page 52

Manual 2100-643c page 52 of 59 wall-mount unit architecture (cont.) screen menu item range default value description return air temp manual control b003 off/on off on to manually change temperature seen by controller manual position -1000 – 1000 0 degrees of change in sensor for manual control value...

Page 53

Manual 2100-643c page 53 of 59 screen menu item range default value description d4 status current status of low pressure input (open means no input) blower status manual di 5 off/on off "on" to allow artificial manipulation of blower status input manual position closed/open closed change to "closed"...

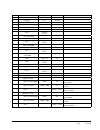

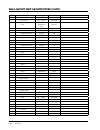

Page 54

Manual 2100-643c page 54 of 59 wall-mount unit architecture (cont.) screen menu item range default value description relay 7 status off/on off current status of blower relay (off means no relay action) analog outputs analog output 1 blower motor mode hand/auto auto manual value 0.0 – 10.0vdc 0vdc ou...

Page 55

Manual 2100-643c page 55 of 59 screen menu item range default value description time 0m – 500m 60m local setpoint reset 0m – 180m 60m pw/return delay 0s – 9999s 300s i/o configuration analog inputs supply air temp enable b001 on/off on resolution normal/high res. Type ohm x5, ohm x1, ntc, pt1000, 0-...

Page 56

Manual 2100-643c page 56 of 59 screen menu item range default value description maximum -3276.8 – 3276.7 100.0 offset -3276.8 – 3276.7 0.0 value -3276.8 – 3276.7 outdoor air temp input b002 out of range alarm power delay 0s – 999s 5 seconds run delay 0s – 999s 5 seconds units pressure/ temperature/ ...

Page 57

Manual 2100-643c page 57 of 59 screen menu item range default value description type ohm x5, ohm x1, ntc, pt1000, 0-1vdc, 0-10vdc, 4-20ma, on/off, 0-4vdc, ntc ht, 50t90, 10t170, nu10, spkp00b7t0, nu12, nu13 normal 4-20ma minimum -3276.8 – 3276.7 0.0 maximum -3276.8 – 3276.7 100.0 offset -3276.8 – 32...

Page 58

Manual 2100-643c page 58 of 59 screen menu item range default value description power delay 0s – 999s 5 seconds run delay 0s – 535s 5 seconds units pressure/ temperature/ other pressure digital inputs power loss switch enable channel 1 on/off on action closed/open closed delay 0s – 999s 0 seconds st...

Page 59

Manual 2100-643c page 59 of 59 screen menu item range default value description cooling stage 2 enable no/yes yes channel 3 direction n.O./n.C. N.O. Status off heating enable no/yes yes channel 4 direction n.O./n.C. N.O. Status off blower enable no/yes yes channel 7 direction n.O./n.C. N.O. Status o...