- DL manuals

- Bard

- Furnace

- FC085D36D

- Installation Instructions Manual

Bard FC085D36D Installation Instructions Manual

FH085D36D

FH110D48D

FH110D60D

FLF085D36D

FLR085D36D

FLF110D48D

FLR110D48D

FLR140D60D

FC085D36D

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE

INSTALLATION.

THIS INSTALLATION MUST COMPLY WITH THESE INSTRUCTIONS AND

THE REQUIREMENTS OF ALL GOVERNING CODES AND ORDINANCES FOR

THE INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW AND UNDERSTAND

ALL OF THESE REQUIREMENTS.

FAILURE TO DO SO COULD CREATE A HAZARD RESULTING IN PROPERTY

DAMAGE, BODILY INJURY OR DEATH.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

IMPORTANT NOTICE

THIS FURNACE IS NOT INTENDED FOR USE AS A CONSTRUCTION

HEATER. USE OF THIS FURNACE DURING CONSTRUCTION AND FINISHING

PHASES OF A STRUCTURE IS CONSIDERED AS "OPERATION IN A

CORROSIVE ATMOSPHERE" AND "UNUSUAL, NEGLIGENT OR IMPROPER

USE" AND AS SUCH ARE CONSIDERED EXCLUSIONS BY THE BARD

MANUFACTURING COMPANY LIMITED WARRANTY.

OIL FURNACE

INSTALLATION INSTRUCTIONS

MODELS

Manual:

2100-392A

Supersedes:

File:

VOL. I, TAB 3

Date:

12-17-01

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Copyright 2001

Summary of FC085D36D

Page 1

Fh085d36d fh110d48d fh110d60d flf085d36d flr085d36d flf110d48d flr110d48d flr140d60d fc085d36d warning read all instructions carefully before beginning the installation. This installation must comply with these instructions and the requirements of all governing codes and ordinances for the installat...

Page 2: Contents

Contents getting other information and publications installation and operating instructions equpment selection ............................................... 2 locating the furnace .............................................. 2 duct work ..............................................................

Page 3

Manual 2100-392 page 1 getting other information and publications these publications can help you install the furnace. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. National fuel gas code .............

Page 4

Manual 2100-392 page 2 installation and operating instructions equipment selection an accurate heating load calculation must be conducted using american society of heating, refrigeration and air conditioning engineers (ashrae) or air conditioning contractors of america (acca) manuals. Do not add a l...

Page 5

Manual 2100-392 page 3 mis-1345 j washable type filter 1” nom. Thickness table 2 lo-boy models dimensions (inches) l e d o m r e b m u n t e n i b a c m u n e l p s g n i n e p o n o i t c e n n o c e u l f s r e t l i f r i a 1 a h t d i w b h t p e d c t h g i e h e x d y l p p u s f x d n r u t e...

Page 6

Manual 2100-392 page 4 table 3 hi-boy models dimension (inches) j washable type filter k left or right side return air option. Must be cut in by installer. L e d o m r e b m u n t e n i b a c s g n i n e p o m u n e l p g . A i d e u l f a h t d i w b h t p e d c t h g i e h e x d y l p p u s h x f ...

Page 7

Manual 2100-392 page 5 table 4 counterflow models dimension (inches) l e d o m r e b m u n t e n i b a c s g n i n e p o m u n e l p g . A i d e u l f a h t d i w b h t p e d c t h g i e h e x d 2 n r u t e r h x f y l p p u s 1 e z i s r e t l i f d 6 3 d 5 8 0 c f 3 2 2 / 1 - 9 2 6 5 0 2 x 2 2 9 1...

Page 8: Important

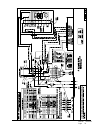

Manual 2100-392 page 6 duct work the air distribution system should be designed and installed in conformance with manuals published by air conditioning contractors of america (acca) as set forth in manual d, or ashrae publications. Installing a cooling unit when the furnace is used in connection wit...

Page 9

Manual 2100-392 page 7 table 5 electrical data l e d o m h p - z h - s t l o v l a t o t s p m a r o t o m r e w o l b r o t o m r e n r u b m u m i n i m t i u c r i c y t i c a p m a e m i t . X a m e s u f y a l e d r c a h r o r e k a e r b t i u c r i c p h a l f p h a l f d 6 3 d 5 8 0 h f 1 -...

Page 10: Warning

Manual 2100-392 page 8 oil line piping first determine whether the pipe system is to be a single line system or a two line system. All connections must be absolutely air tight or you will have a malfunction of the burner. When installing the piping, a good oil filter should be installed close to the...

Page 11

Manual 2100-392 page 9 the following is a detailed explanation of each control included in the becket afg oil burner, how each operates, how to set up the burner, and how to troubleshoot problems should they occur. Beckett “cleancut” oil pump this oil pump is equipped with an oil solenoid valve inst...

Page 12

Manual 2100-392 page 10 beckett r7184b primary operational guide pre-purge delay – 15 seconds on delay led codes – flashing 1/2 second on / 1/2 second off – system is locked out or in restricted mode (hard lockout). – flashing 2 seconds on / 2 seconds off – control is in recycle mode (soft lockout)....

Page 13: Important

Manual 2100-392 page 11 burner setup and adjustments all oil burner installations should be performed by a qualified installer in accordance with regulations of the national fire protection standard for oil-burning equipment, nfpa31 -- latest edition, and in complete compliance with all local codes ...

Page 14

Manual 2100-392 page 12 8. Measure the co 2 (or o 2 ) in the flue gas at the trace of smoke level. Open the air control and add reserve air until the co 2 is lowered by 1.5%. Example: original co 2 at trace of smoke level was 13.0% (3.30% o 2 ) . Lower to 11.5% co 2 (5.3% 0 2 ). See table 7. 9. Perf...

Page 15

Manual 2100-392 page 13 table 7 correlation of percent of co 2 , o 2 and reserve air n o b r a c e d i x o i d n e g y x o r i a e v r e s e r ) . X o r p p a ( 4 . 5 1 0 . 5 1 5 . 4 1 0 . 0 6 . 0 2 . 1 0 . 0 0 . 3 0 . 6 0 . 4 1 5 . 3 1 0 . 3 1 0 . 2 6 . 2 3 . 3 0 . 0 1 0 . 5 1 0 . 0 2 5 . 2 1 0 . 2...

Page 16

Manual 2100-392 page 14 ventilation and combustion air appliances shall be installed in a location where the facilities for ventilation permit satisfactory combustion of oil, proper venting and the maintenance of ambient temperature at safe limits under normal conditions of use. Applications shall b...

Page 17

Manual 2100-392 page 15 appliances located in confined spaces in unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, ventilation, and dilution of flue gasses. However, in buildings of unusually tight construction, additional air shall be provided using the met...

Page 18

Manual 2100-392 page 16 all air from outdoors a. The confined space shall be provided with two permanent openings, one in or near the top of the enclosure and one in or near the bottom. The openings shall communicate directly, or by means of ducts with outdoors or to such spaces (crawl or attic) tha...

Page 19

Manual 2100-392 page 17 figure 10 appliances located in confined spaces all air from outdoors through ventilated attic mis-1338 note: the inlet and outlet air openings shall each have a free area of not less than one square inch per 4,000 btu per hour (35 square inches per gallon per hour) of the to...

Page 20: Important

Manual 2100-392 page 18 important do not set the blower “on” set point lever of the combination fan/limit control above 150. Louvers and grilles in calculating free area for above ventilation and combustion air requirements, consideration shall be given to the blocking effect of louvers, grilles, or...

Page 21

Manual 2100-392 page 19 table 13 temperature rise ranges, limit control settings, and heating blower speeds j 70 degree hollow cone spray pattern, 100 psig pump pressure l e d o m 1 e l z z o n s e g n a r e s i r m u m i x a m r i a t e l t u o . P m e t g n i t a e h r e w o l b d e e p s g n i t ...

Page 22

Manual 2100-392 page 20 hi-boy models – filter locations, & removal and replacement procedures 16 x 25 x 1 external filter racks are supplied as standard equipment for all fh models (20 x 25 x 1 is standard for fh110d60d model). A 14 x 23 opening is to be cut into either the left or right side of th...

Page 23

Manual 2100-392 page 21 counterflow models – filter locations counterflow models normally have filters installed in the return air plenum above the furnace unless a common return air/filter grille is used. The electrical switch should be turned “off” before the front door to furnace is removed. Afte...

Page 24

Manual 2100-392 page 22 lo-boy models – filter locations lo-boy models have the filter installed in the return air cabinet section of the furnace. It is accessible from the rear of the furnace by removing the blower/filter access door. The electrical switch should be turned “off” prior to removing t...

Page 25: Caution

Manual 2100-392 page 23 maintenance lubrication no lubrication is required for either the burner or the blower motor. Both are permanently lubricated. Inspect air filter washable air filters are supplied with each furnace. Washable filters should not be replaced with disposable type. Clean filters b...

Page 26: Warning

Manual 2100-392 page 24 combination combustion chamber/burner mounting system the furnace has been designed with a combustion chamber mounting system that enables service personnel to remove the combustion chamber, its mounting system, and burner assembly as one unit for inspection and/or service on...

Page 27

Manual 2100-392 page 25 to remove burner only disconnect fuel line, power cord and wires from t, t on primary control. Loosen (3) 1/4 inch nuts securing burner mounting flange. Twist burner counterclockwise and pull straight back away from the furnace. (see figure 16a.) to remove the entire combusti...

Page 28: Warning

Manual 2100-392 page 26 pump squeals or chatters this may be caused by air in pipes. Check all joints in the oil supply pipe for leaks. Check strainer in pump; if dirty, clean. Insufficient heat check limit control setting. It may be that flame is not allowed to stay on long enough to generate suffi...

Page 29

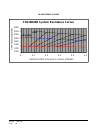

Manual 2100-392 page 27 fh resistance curves fh085d36d system resistance curves 700 800 900 1000 1100 1200 1300 1400 0 0.1 0.2 0.3 0.4 0.5 external static pressure in inches of water cfm standard airflow high med. Low fh110d48d system resistance curves 800 1000 1200 1400 1600 1800 2000 0 0.1 0.2 0.3...

Page 30

Manual 2100-392 page 28 fh resistance curves fh110d60d system resistance curves 1000 1200 1400 1600 1800 2000 2200 2400 0 0.1 0.2 0.3 0.4 0.5 external stactic pressure in inches of water cfm standard airflow high med. High external static pressure in inches of water.

Page 31

Manual 2100-392 page 29 flf / flr resistance curves flf/r085d36d system resistance curves 700 800 900 1000 1100 1200 1300 1400 1500 0 0.1 0.2 0.3 0.4 0.5 external static pressure in inches of water cfm standard airflow high med. Low flf/r110d48d system resistance curves 800 1000 1200 1400 1600 1800 ...

Page 32

Manual 2100-392 page 30 resistance curves fc085d36d system resistance curves 600 800 1000 1200 1400 1600 0 0.1 0.2 0.3 0.4 0.5 external static pressure in inches of water cfm standard airflow high med. Low flr140d60d system resistance curves 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 0 0.05 0...

Page 33

Manual 2100-392 page 31.

Page 34

Manual 2100-392 page 32.

Page 35

Manual 2100-392 page 33.