- DL manuals

- Bard

- Furnace

- FC085V42A FH085V42A FH110V48AFH110V60A

- Installation Instructions Manual

Bard FC085V42A FH085V42A FH110V48AFH110V60A Installation Instructions Manual

Manual

2100-540D

Page

1 of 45

FC085V42A

FH085V42A

FH110V48A

FH110V60A

FLF085V42A

FLF110V48A

FLF110V60A

FLR085V42A

FLR110V48A

FLR110V60A

FLR140V60A

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

IMPORTANT NOTICE

THIS FURNACE IS NOT INTENDED FOR USE AS A CONSTRUCTION HEATER. USE OF THIS

FURNACE DURING CONSTRUCTION AND FINISHING PHASES OF A STRUCTURE IS

CONSIDERED AS "OPERATION IN A CORROSIVE ATMOSPHERE" AND "UNUSUAL,

NEGLIGENT OR IMPROPER USE" AND AS SUCH ARE CONSIDERED EXCLUSIONS BY THE

BARD MANUFACTURING COMPANY LIMITED WARRANTY.

WARNING

CARBON MONOXIDE POISONING HAZARD

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN PERSONAL INJURY OR DEATH.

Carbon Monoxide is invisible, orderless and toxic! Bard Manufacturing recommends a carbon

monoxide alarm in your home, even if you do not own a gas appliance. Locate the carbon

monoxide alarm in the living area of your home and away from doorways to attached garages.

Follow the alarm manufacturer’s instructions included with the alarm.

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION.

THIS INSTALLATION MUST COMPLY WITH THESE INSTRUCTIONS AND THE REQUIREMENTS

OF ALL GOVERNING CODES AND ORDINANCES FOR THE INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW AND UNDERSTAND ALL OF THESE

REQUIREMENTS.

FAILURE TO DO SO COULD CREATE A HAZARD RESULTING IN PROPERTY DAMAGE, BODILY

INJURY OR DEATH.

OIL FURNACE

INSTALLATION INSTRUCTIONS

Manual:

2100-540D

Supersedes:

2100-540C

File:

VOL. I, TAB 3

Date:

04-24-13

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

MODELS

Summary of FC085V42A FH085V42A FH110V48AFH110V60A

Page 1

Manual 2100-540d page 1 of 45 fc085v42a fh085v42a fh110v48a fh110v60a flf085v42a flf110v48a flf110v60a flr085v42a flr110v48a flr110v60a flr140v60a for your safety do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. Important notice this f...

Page 2: Contents

Manual 2100-540d page 2 of 45 contents getting other information and publications ........ 3 installation and operating instructions equipment selection ............................................. 4 locating the furnace ............................................ 4 installing the furnace ...........

Page 3

Manual 2100-540d page 3 of 45 getting other information and publications these publications can help you install the furnace. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. National fuel gas code ......

Page 4

Manual 2100-540d page 4 of 45 installation and operating instructions equipment selection an accurate heating load calculation must be conducted using american society of heating, refrigeration and air conditioning engineers (ashrae) or air conditioning contractors of america (acca) manuals. Do not ...

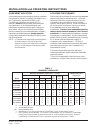

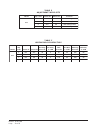

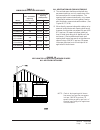

Page 5

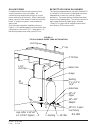

Manual 2100-540d page 5 of 45 figure 1 flf/r models dimensions 1 w ashable type filter 1” nom. Thickness table 2 flf/r models dimensions (inches) l e d o m r e b m u n t e ni b a c m u n el p s g ni n e p on oit c e n n o c e ul fs r etl i f ri a 1 a ht di w b ht p e d c t h gi e h e x d yl p p u s ...

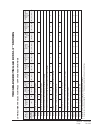

Page 6

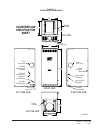

Manual 2100-540d page 6 of 45 figure 2 fh models dimensions 53" (fh085) 59" (fh110) 23" vestibule door front view 30 1/2" 21 7/8" 19 7/8" flue knockout supply opening f h 0 8 5 a n d f h 1 1 0 s p e c if ic a t io n s h e e t 19 1/4" 16" return opening (cut out) optional oil entrance oil entrance fr...

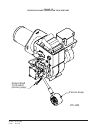

Page 7: Counterflow

Manual 2100-540d page 7 of 45 figure 3 fc085 model dimensions 54 1/4" 23" door cleanout optional oil entrance high voltage entrance low voltage entrance rear flue knockout optional high voltage entrance entrance fresh air low voltage knockout oil entrance flue knockout optional optional oil entrance...

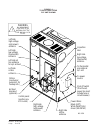

Page 8: Important

Manual 2100-540d page 8 of 45 important when a furnace is installed so that supply ducts carry air circulated by the furnace to areas outside the space containing the furnace, the return air must also be handled by a duct(s) sealed to the furnace casing and terminating outside the space containing t...

Page 9

Manual 2100-540d page 9 of 45 wiring factory wiring all units are fully factory wired. Multispeed blowers are factory wired on high speed for cooling/manual fan operation. Heating speeds are wired for the largest input and may need lower speed for field installed low input nozzle. If replacement wir...

Page 10

Manual 2100-540d page 10 of 45 power wires: black (hot) white (neutral) green (ground) control panel (junction box in fh units) left side oil line entrance left side oil line entrance for opt. Air boot left side low voltage (thermostat) entrance left side high voltage (unit power) entrance right sid...

Page 11

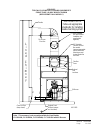

Manual 2100-540d page 11 of 45 figure 5 typical flue installation requirements front flue lo-boy model shown (represents all models) 1/4 inch per 1 foot rise draft regulator (be sure to follow installation inst. Supplied with regulator). 90° rotatable flue box on front flue models (remove appropriat...

Page 12

Manual 2100-540d page 12 of 45 oil line piping first determine whether the pipe system is to be a single line system or a two line system. All connections must be absolutely air tight or you will have a malfunction of the burner. When installing the piping, a good oil filter should be installed clos...

Page 13: Warning

Manual 2100-540d page 13 of 45 the following is a detailed explanation of each control included in the beckett afg oil burner, how each operates, how to set up the burner, and how to troubleshoot problems should they occur. Beckett “cleancut” oil pump this oil pump is equipped with an oil solenoid v...

Page 14

Manual 2100-540d page 14 of 45 primary operational guide beckett genisys 7505 sequence of operation mis-2491 beckett genisys model 7505 burner states 1. Standby: the burner is idle, waiting for a call for heat. 2. Valve-on delay (prepurge): the igniter and motor are on while the control delays turni...

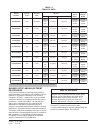

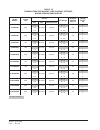

Page 15

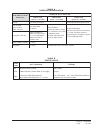

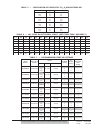

Manual 2100-540d page 15 of 45 table a reset button operation table b status lights e h t n i s i r e n r u b e h t f i : e t a t s w o l e b : l l i w n o t t u b t e s e r e h t g n i h s u p k c i l c n o t t u b ) d n o c e s 1 s s e r p ( d l o h n o t t u b ) d n o c e s 1 > s s e r p ( d l o ...

Page 16: Warning

Manual 2100-540d page 16 of 45 priming the pump 1. Prepare the burner for priming by fully opening the pump bleed port and attaching a clear plastic hose over the bleed port fitting. Use a suitable container to collect purged oil. 2. Initiate a call for heat. 3. After the burner starts, press and ho...

Page 17: Caution

Manual 2100-540d page 17 of 45 • then, to reset, hold the button down for 15 seconds until the red light turns off and the yellow led turns on. Observe at least one full control sequence of operation from startup to shutdown. Simulate a flame failure lockout by following the procedure (within this m...

Page 18

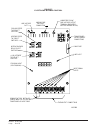

Manual 2100-540d page 18 of 45 figure 7 electronic blower control mis-2869 cfm blink light (100 cfm/blink) limit light input signal lights switches 3 amp fuse 24v secondary connections switches delay select transformer line voltage switches line voltage tap select tap select cooling speed switches h...

Page 19

Manual 2100-540d page 19 of 45 table c heating tap select settings by model table d cooling tap select settings by model note: part load airflow for 2-stage a/c or hp systems is achieved when removing the factory installed jumper wire on the electronic blower control interface board that is (install...

Page 20

Manual 2100-540d page 20 of 45 table e adjustment tap selects table f heating delay profile taps l e d o m r e t t e l p a t 1 # h c t i w s 2 # h c t i w s n o i t c n u f l l a a f f o f f o e g n a h c o n b n o f f o w o l f r i a g n i t a e h % 0 1 + c f f o n o w o l f r i a g n i t a e h % 0...

Page 21: Ors

Manual 2100-540d page 21 of 45 troubleshooting ge ecm 2.3™ mot ors 16-pin blower tap select controls - outputs based upon mode f o e d o m n oi t ar e p o f f o s u o u ni t n o c r e w ol b li o e c a nr u f el g ni s e g at s g nil o o c 1 e g at s- 2 , g nil o o c d a o l tr a p 2 e g at s- 2 , g...

Page 22: Motors

Manual 2100-540d page 22 of 45 troubleshooting ge ecm 2.3 ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/pr...

Page 23: Troubleshooting Ge Ecm

Manual 2100-540d page 23 of 45 troubleshooting ge ecm ™ motors cont’d. Replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programmed f...

Page 24: Important

Manual 2100-540d page 24 of 45 burner setup and adjustment procedures all oil burner installations should be performed by a qualified installer in accordance with regulations of the national fire protection standard for oil-burning equipment, nfpa31 -- latest edition, and in complete compliance with...

Page 25

Manual 2100-540d page 25 of 45 1. Preparation steps a. Calibrate and check operation of measuring equipment follow manufacturer’s recommended procedures for calibration and equipment check out. B. Prepare heating unit for testing drill two 1/4 inch holes in the flue between the heating plant and the...

Page 26

Manual 2100-540d page 26 of 45 1. Air leaks into the combustion chamber or heat exchanger can dilute the combustion gases and prevent normal co 2 readings. Such leaks should be sealed with furnace cement or other high-temperature sealant. To check for dilution by leakage, measure the co 2 at as high...

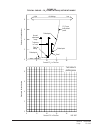

Page 27

Manual 2100-540d page 27 of 45 figure 11 typical smoke – co 2 chart with adjustment range tolerance to "knee" normal adjustment range 0 2 4 6 8 8 10 12 14 6 "knee" "best" air setting plotted point plotted point plotted point co curve from plotted points 2 air settings low high bacharach smoke number...

Page 28

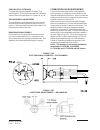

Manual 2100-540d page 28 of 45 figure 12 pressure gauge connection to bleed port mis-1660 pressure gauge remove bleed port to attach pressure guage..

Page 29

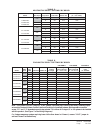

Manual 2100-540d page 29 of 45 table 5 — correlation of percent of co 2 , o 2 and reserve air e d i x o i d n o b r a c n e g y x o ) . X o r p p a ( r i a e v r e s e r 4 . 5 1 0 . 5 1 5 . 4 1 0 . 0 6 . 0 2 . 1 0 . 0 0 . 3 0 . 6 0 . 4 1 5 . 3 1 0 . 3 1 0 . 2 6 . 2 3 . 3 0 . 0 1 0 . 5 1 0 . 0 2 5 . ...

Page 30

Manual 2100-540d page 30 of 45 spacing of electrodes the electrodes should be spaced 5/32" apart. They should extend 1/16" beyond the end and 5/16" above the center of the nozzle tip as shown in figures 13a & 13b. Gun assembly adjustment the gun assembly can be adjusted in the slot inside of fan hou...

Page 31

Manual 2100-540d page 31 of 45 figure 14 combustion air boot assembly knockout air boot for oil line boot and secure insert outer air use this assemble inner flange to unit for air boot. According to manual in left side remove knockout make all settings remove pump to intake air tube mis-1833 afg bu...

Page 32

Manual 2100-540d page 32 of 45 appliances located in confined spaces in unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, ventilation, and dilution of flue gases. However, in buildings of unusually tight construction, additional air shall be provided using t...

Page 33

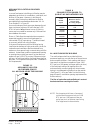

Manual 2100-540d page 33 of 45 all ventilation air from outdoors a. The confined space shall be provided with two permanent openings, one in or near the top of the enclosure and one in or near the bottom. The openings shall communicate directly, or by means of ducts with outdoors or to such spaces (...

Page 34

Manual 2100-540d page 34 of 45 figure 17 appliances located in confined spaces all air from outdoors through ventilated attic note: the inlet and outlet air openings shall each have a free area of not less than one square inch per 4,000 btu per hour (35 square inches per gallon per hour) of the tota...

Page 35

Manual 2100-540d page 35 of 45 louvers and grilles in calculating free area for ventilation and combustion air requirements, consideration shall be given to the blocking effect of louvers, grilles, or screens protecting openings. Screens used shall not be smaller than 1/4 inch (6.3 mm) mesh and shal...

Page 36

Manual 2100-540d page 36 of 45 table 10 temperature rise ranges, limit control settings, and heating blower speeds l e d o m r e b m u n r e n r u b e p y t e l z z o n s e g n a r e s i r m u m i x a m r i a t e l t u o ) f ° ( p m e t g n i t a e h r e w o l b p a t e z i s e p y t e r u s s e r p...

Page 37

Manual 2100-540d page 37 of 45 air filters only lo-boy models are shipped with air filters. Filter kits are available from your local distributor for upflow and counterflow models. Knockouts are provided in the sides of the fh series models to facilitate the cutting of the return openings. The upflo...

Page 38

Manual 2100-540d page 38 of 45 lo-boy models – filter locations lo-boy models have the filter installed in the return air cabinet section of the furnace. It is accessible from the rear of the furnace by removing the blower/filter access door. The electrical switch should be turned “off” prior to rem...

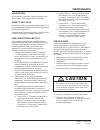

Page 39: Caution

Manual 2100-540d page 39 of 45 maintenance lubrication no lubrication is required for either the burner or the blower motor. Both are permanently lubricated. Inspect air filter replace filters before each heating season begins. It is recommended that filters also be replaced at least twice during th...

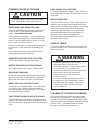

Page 40: Warning

Manual 2100-540d page 40 of 45 combination combustion chamber/burner mounting system the furnace has been designed with a combustion chamber mounting system that enables service personnel to remove the combustion chamber, its mounting system, and burner assembly as one unit for inspection and/or ser...

Page 41

Manual 2100-540d page 41 of 45 to remove burner only disconnect fuel line, power cord and wires from t, t on primary control. Loosen (3) 1/4 inch bolts securing burner mounting flange. Twist burner counterclockwise and pull straight back away from the furnace. (see figure 22.) to remove the entire c...

Page 42: Warning

Manual 2100-540d page 42 of 45 pump squeals or chatters this may be caused by air in pipes. Check all joints in the oil supply pipe for leaks. Check strainer in pump; if dirty, clean. Insufficient heat check limit control setting. It may be that flame is not allowed to stay on long enough to generat...

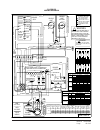

Page 43

Manual 2100-540d page 43 of 45 fh series wiring diagram *electrical shock hazard *disconnect power before servicing. Danger ! L2 (ign) tw tr igniter burner motor oil valve cad cell l1 - limit l2 (vlv) cad cell l2 valve l2 (mtr) motor igniter conditioner or heat 1 notes 2 if primary limit wires are t...

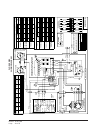

Page 44

Manual 2100-540d page 44 of 45 flf/r series wiring diagram *e l e ct ri ca l s ho ck ha z a rd *di s co nne ct p o w e r b e f o re ser vi c in g . Da n g e r ! Wh ite wh ite white white white pu rp le pu rp le orange orange green re d re d re d red/w hite tw tr ign it e r b urne r mo to r oil ce ll...

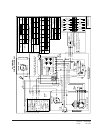

Page 45

Manual 2100-540d page 45 of 45 fc series wiring diagram *e l e ct ri ca l s ho ck ha z a rd *di s co nne ct p o w e r b e f o re ser vi c in g . Dan g e r ! Wh ite white white wh ite wh ite white pu rp le pu rp le orange orange green re d re d re d re d red/w hite tw tr l2 (v lv ) ca d ignit e r b u...