- DL manuals

- Bard

- Cooling boxes

- Fusion-Tec

- Installation Instructions Manual

Bard Fusion-Tec Installation Instructions Manual

Page

1 of 41

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-674A

Supersedes: 2100-674

Date: 7-13-17

NOTE: LV1000 Controller is required for operation when

multiple HR**AP* units are used.

INSTALLATION INSTRUCTIONS

FUSION-TEC™

Wall-Mount Air Conditioner

Models:

HR36APA HR36APB

HR58APA HR58APB

FUSION-TEC™/LV1000

Free Cooling Unit System

LV1000-100 Lead/Lag Controller

Summary of Fusion-Tec

Page 1

Page 1 of 41 bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual: 2100-674a supersedes: 2100-674 date: 7-13-17 note: lv1000 controller is required for operation when multiple hr**ap* units are used. Installation instructions fusion-tec™ wall-mount air conditioner models: hr36a...

Page 2: Contents

Manual 2100-674a page 2 of 41 contents list of necessary materials/tools ....................6 site preparation ...................................................7 model identification .......................................... 7 new shelter installation vs. Retrofit installation .. 7 minimum clear...

Page 3: General Information

Manual 2100-674a page 3 of 41 general information free cooling unit system this bard free cooling unit system is composed of fusion-tec wall-mounted air conditioners matched with an lv1000 lead/lag controller. The wall mounts are specifically engineered for telecom/motor control center rooms. Note: ...

Page 4

Manual 2100-674a page 4 of 41 sizing of systems for proposed installation should be based on heat loss and heat gain calculations made according to methods of air conditioning contractors of america (acca). The supply flange should be installed in accordance with the standards of the national fire p...

Page 5: Warning

Manual 2100-674a page 5 of 41 electrical shock hazard. Have a properly trained individual perform these tasks. Failure to do so could result in electric shock or death. ! Warning fire hazard. Maintain minimum 1/4" clearance between the supply flange and combustible materials. Failure to do so could ...

Page 6

Manual 2100-674a page 6 of 41 list of necessary materials/tools additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must be sourced before installation. This list also includes tools needed for installation. List of materials/tools • persona...

Page 7: Site Preparation

Manual 2100-674a page 7 of 41 figure 1 fusion-tec wall-mount unit model nomenclature control logic and climate options p – programmable logic board hr 58 a p a 0z e p x x x x unit series revision a – revision level maximum sensible capacity 36 –3 ton 2 stage step capacity 58 –5 ton 2 stage step capa...

Page 8: Warning

Manual 2100-674a page 8 of 41 fire hazard. Maintain minimum 1/4" clearance between the supply flange and combustible materials. Failure to do so could result in fire causing damage, injury or death. ! Warning table 1 clearance required for service access and adequate condenser airflow model side(s) ...

Page 9

Manual 2100-674a page 9 of 41 figure 2 dimensions of basic unit for architectural and installation requirements (nominal) model w idth (w) depth (d) height (h) return s upply a b c b e f g i j k l m n o p q r hr36 hr58 42.00 30.00 76.00 9.88 29.88 14.25 29.88 44.00 40.00 34.13 30.00 29.13 13.00 31.1...

Page 10: Wall-Mount Unit Mounting

Manual 2100-674a page 10 of 41 2. If desired, hook top rain flashing under back bend of top. 3. Position unit in opening and secure with fasteners sufficient for the application such as 5/16" lag/ anchor bolts; use 7/8" diameter flat washers on the lag bolts. It is recommended that a bead of commerc...

Page 11

Manual 2100-674a page 11 of 41 figure 3 prefilling traps on indoor drain pan hoses pour water into evaporator drain pan directly above left and right drain fittings until coiled drain tubes in blower section are visibly full. Evaporator drain pan left side drain hose evaporator drain pan right right...

Page 12

Manual 2100-674a page 12 of 41 rear deflectors as shipped rear deflectors raised and secured together figure 5 fold-out diverter figure 6 downward curved diverter blades diverter blades as shipped (left), and after raising (right) figure 7 view of installed grille (as seen from above) supply air gri...

Page 13

Manual 2100-674a page 13 of 41 figure 8 mounting instructions a 17 " 17 " 17 " 17 " b 16.25 " e d suppl ya ir opening re tu rn ai ropening w all w all opening and hole lo ca tion view a b c d e re qu ir ed di m en si on s t o m ai ntai n 1/ 4" m in . Cl ea ra nc e f ro m co m bu stib le m ate ria ls...

Page 14

Manual 2100-674a page 14 of 41 figure 9 electric heat clearance figure 10 wall mounting instructions see figure 2 – mounting instructions 1/4" min. 1/4" min. Supply air duct flange of wall wall frame inside sheeting typical building outside sheeting mis-3897 supply grille mount on unit return air op...

Page 15

Manual 2100-674a page 15 of 41 figure 11 wall mounting instructions figure 12 common wall mounting installation 9.88 14.25 13.00 29.88 1.000 45.00 framing material 2 x 4's, 2 x 6's &/or structural steel l 2 x 6 c supply duct if required all around duct 1.000" clearance opening return duct interior f...

Page 16: Wall-Mount Unit Wiring

Manual 2100-674a page 16 of 41 wall-mount unit wiring main power wiring refer to the unit rating plate or table 3 for wire sizing information and maximum fuse or circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. The field wiring used must be sized to carry that amo...

Page 17

Manual 2100-674a page 17 of 41 figure 13 wire routing figure 14 vac supply wiring landing points unit control voltage wiring 230/208v 1 phase and 3 phase equipment use dual primary voltage transformers. All equipment leaves the factory wired on 240v tap. It is very important that the correct voltage...

Page 18

Manual 2100-674a page 18 of 41 figure 15 adjusting the 230/208 vac transformer 230/208v 1 phase and 3 phase equipment use dual primary voltage transformers. All equipment leaves the factory wired on 240v tap. It is very important that the correct voltage tap is used. For 208v operation, reconnect fr...

Page 19: Preliminary Start Up

Manual 2100-674a page 19 of 41 preliminary start up running in stand alone (orphan) mode with the ac breakers turned on, each fusion-tec wall-mount unit has the capability to run without the lv1000 controller attached—this feature is called stand alone or orphan mode. This keeps the shelter between ...

Page 20

Manual 2100-674a page 20 of 41 lv1000 controller installation figure 17 typical lv1000 component location control board rj11 cable to display -48vdc to 24v power supply usb connection terminal block power supply connections power loss relay.

Page 21: Warning

Manual 2100-674a page 21 of 41 mounting the lv1000 controller the dimensions of the lv controller are 16" by 12" by 6". Because the lv1000 controller utilizes a remote temperature sensor as opposed to one located in the controller box, the controller itself can be installed in any indoor location th...

Page 22

Manual 2100-674a page 22 of 41 1 2 3 4 5 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 6 dp1 dp2 installing remote indoor temperature/humidity sensor(s) one remote indoor temperature/humidity sensor and 35' of 18 gauge 5-conducto...

Page 23

Manual 2100-674a page 23 of 41 up to two additional temperature/humidity sensors may be added. Be sure the sensors are connected to the proper terminals on the terminal block and sensor as listed below. See page 22 for information on correct sensor jumper position. Figure 20 additional remote temper...

Page 24

Manual 2100-674a page 24 of 41 additional lv1000 connections there are factory-installed jumpers across terminals #8 and #9 (smoke detector), #10 and #11 (hydrogen detector) and #12 and #13 (generator run). Remove the factory-installed jumpers before connecting to the detectors and/or generator (if ...

Page 25

Manual 2100-674a page 25 of 41 communication wiring connect the communication wiring from the wall-mount units to the controller in the manner shown in figures 21, 22 or 23 (page 26). The daisy chain does not need to follow the addressing order. The communication wire should be 2-wire, 18 gauge shie...

Page 26

Manual 2100-674a page 26 of 41 figure 23 placement of communication wire filters (daisy chain and alternate methods) lv1000 place filter here daisy chain wiring (up to four units) alternate wiring (up to four units) unit 1 unit 2 unit 3 unit 4 place filter here unit 1 unit 2 unit 3 unit 4 lv1000* pl...

Page 27

Manual 2100-674a page 27 of 41 1. Using the field-provided shielded cable, make a small service loop after entering the controller and attach the provided emi filter at the intersection of the loop. Figure 24 communication wiring: termination at the controller 2. Connect one wire to terminal #42 (ne...

Page 28

Manual 2100-674a page 28 of 41 figure 25 communication wiring: termination at the first wall-mount unit 1. From the controller, extend the shielded cable through a separate conduit and route to the provided terminal block next to the wall-mount control board. These connections are polarity-sensitive...

Page 29

Manual 2100-674a page 29 of 41 1. Route the cable from the first wall-mount unit to the terminal block of the second wall-mount unit. If this is the last unit to be connected, make a small service loop and attach emi filter as shown. Figure 26 communication wiring: termination at additional wall-mou...

Page 30

Manual 2100-674a page 30 of 41 figure 28 controller grounding posts a reliable earth ground must be connected in addition to any grounding from conduit. Attach earth ground to dedicated lugs on side of controller box. Failing to ground the controller box properly could result in damage to the equipm...

Page 31

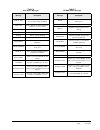

Manual 2100-674a page 31 of 41 table 4 lv1000 terminal block index tb# wire mark description 1 48+ 48vdc +input 2 48– 48vdc – input 3 - ground 4 - 24vdc + 5 - 24vdc – 6 24+ 24vdc + 7 24– 24vdc – 8 di1 smoke detector input 9 gnd smoke detector common 10 di2 hydrogen detector input 11 gnd hydrogen det...

Page 32

Manual 2100-674a page 32 of 41 figure 29 lv1000 wiring diagram.

Page 33: System Set Up

Manual 2100-674a page 33 of 41 the lv1000 controller and tec-eye hand-held diagnostic tool will both be used to set up the bard free cooling unit system. System set up figure 30 tec-eye connection to unit control modular phone connector for tec-eye hand-held diagnostic tool alarm key allows viewing ...

Page 34

Manual 2100-674a page 34 of 41 in addition to setting up the address, the user may also want to set the unit of measure (uom) and economizer control type. To change these settings: 1) press menu key to access the main menu screen. 2) press up or down keys and enter key to enter user password 2000. 3...

Page 35

Manual 2100-674a page 35 of 41 figure 34 executing run test parameter description damper test volts: this is the control voltage applied to the actuator during opening sequence for damper. Damper time: this is the time (in seconds) allowed for both the opening sequence and closing sequence. Heat/coo...

Page 36

Manual 2100-674a page 36 of 41 down key alarm key menu key up key enter key escape key figure 36 lv1000 controller display and interface (status screen shown) figure 37 changing timezone figure 38 setting controller date and time setting up lv1000 for operation the lv1000 controller will be used for...

Page 37

Manual 2100-674a page 37 of 41 to enable/disable indoor humidity 2: 1) press menu key to go to the main menu screen. 2) press up or down keys and enter key to enter technician password 1313. 3) press up or down keys to scroll to io config; press enter key. 4) press up or down keys to scroll to indoo...

Page 38

Manual 2100-674a page 38 of 41 figure 42 configuring indoor temperature 1 sensor figure 43 configuring indoor temperature 2 sensor figure 44 configuring indoor temperature 3 sensor 4) press up or down keys to scroll to indoor temperature 1 (c6). 5) press enter key to scroll to enable (see figure 42)...

Page 39

Manual 2100-674a page 39 of 41 figure 46 verifying units 8. Clear controller alarm logs to clear the lv controller alarm logs: 1) press menu key to go to the main menu screen. 2) use up or down keys and enter key to enter user password 2000. 3) press up or down keys to scroll to settings; press ente...

Page 40: Additional Information

Manual 2100-674a page 40 of 41 menu screens and password levels a system config: a1-a10 user b adv sys config: b1-b4 technician c i-o config: c1-c18 technician d on/off: user e alarm logs: user f settings: date/time: technician language: user network config: technician serial ports: technician initi...

Page 41

Manual 2100-674a page 41 of 41 message description orphan stby unit is on and in orphan mode with no calls for heating or cooling power loss unit is operating under power loss conditions (inverter model) freecooling unit is actively economizing cooling unit is actively mechanical cooling heating uni...