- DL manuals

- Bard

- Heat Pump

- GSVS242-A

- Installation instructions manual

Bard GSVS242-A Installation instructions manual

Manual

2100-317J

Page

1 of 39

Earth Loop Fluid

Temperatures 25° - 110°

Ground Water Temperatures 45° - 75°

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

Manual:

2100-317J

Supersedes:

2100-317

I

File:

Volume I, Tab 8

Date:

05-16-08

INSTALLATION

INSTRUCTIONS

WATER SOURCE

HEAT PUMPS

Models:

GSVS242-A, GSVS302-A

GSVS361-A, GSVS421-A

GSVS481-A, GSVS601-A

Summary of GSVS242-A

Page 1

Manual 2100-317j page 1 of 39 earth loop fluid temperatures 25° - 110° ground water temperatures 45° - 75° bard manufacturing company, inc. Bryan, ohio 43506 since 1914...Moving ahead, just as planned. Manual: 2100-317j supersedes: 2100-317 i file: volume i, tab 8 date: 05-16-08 installation instruc...

Page 2

Manual 2100-317j page 2 of 39 contents getting other informations and publications ........ 3 general information water source nomenclature ................................... 4 heater package nomenclature ............................... 8 application and location general ..............................

Page 3

Manual 2100-317j page 3 of 39 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-317j page 4 of 39 water source product line nomenclature table 1 1 indoor blower performance (rated cfm) l e d o m d e t a r p s e x a m p s e 2 s u o u n i t n o c w o l f r i a 3 d e t a r g n i l o o c m f c 4 d e t a r g n i t a e h m f c c i r t c e l e t a e h m f c 2 4 2 s v s g 0...

Page 5

Manual 2100-317j page 5 of 39 + 75°c copper wire ++ hacr type circuit breaker table 2 flow rates for various fluids s di u l f s u oi r a v s l e d o m a- 2 4 2 s v s ga - 2 0 3 s v s ga - 1 6 3 s v s ga - 1 2 4 s v s ga - 1 8 4 s v s ga - 1 0 6 s v s g r et a w h s erf m p g d eri u q er et ar w ol...

Page 6

Manual 2100-317j page 6 of 39 table 4 water coil pressure drop l e d o m 2 4 2 s v s g 2 0 3 s v s g , 1 6 3 s v s g 1 2 4 s v s g 1 8 4 s v s g 1 0 6 s v s g m p g g i s p . D h . T f g i s p . D h . T f g i s p . D h . T f g i s p . D h . T f g i s p . D h . T f 3 0 0 . 1 1 3 . 2 - - - - - - - - -...

Page 7

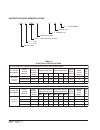

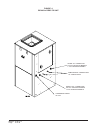

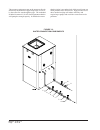

Manual 2100-317j page 7 of 39 m a h d k l n o p optional heater package electrical opening low voltage inlet unit electrical opening j e b g c i return air filter rack supply air q v u r s w t u drain 3/4" fpt water piping connections 3/4" or 1" fpt domestic hot water heat exchanger water connection...

Page 8

Manual 2100-317j page 8 of 39 heater package nomenclature table 5 electrical specifications + based on 75f copper wire. All wiring must conform to national electrical code (latest edition) and all local codes. ) y l n o 2 4 - 6 3 - 0 3 - 4 2 s v s g ( s e g a k c a p r e t a e h d e l l a t s n i - ...

Page 9

Manual 2100-317j page 9 of 39 application and location general units are shipped completely assembled and internally wired, requiring only duct connections, thermostat wiring, 230/208 volt ac power wiring, and water piping. The equipment covered in this manual is to be installed by trained, experien...

Page 10

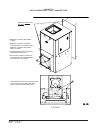

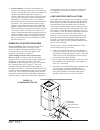

Manual 2100-317j page 10 of 39 figure 2 field-conversion to left hand return remove single and double doors reposition doors so double doors are on control panel side, and single door on opposite side 1 remove 4 screws securing cover 2 remove 2 screws holding control box to corner panel remove 2 scr...

Page 11

Manual 2100-317j page 11 of 39 figure 3a gsvs24 - 42 models filter this unit must not be operated without a filter. It comes equipped with disposable filters, which should be checked often and replaced if dirty. Insufficient airflow due to undersized duct systems or dirty filters can result in nuisa...

Page 12

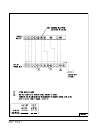

Manual 2100-317j page 12 of 39 figure 4 piping access to unit water “in” connection 3/4" fpt gsvs24-42 models 1" fpt gsvs48-60 models pump module connections 1/2" copper stub water “out” connection 3/4" fpt gsvs24-42 models 1" fpt gsvs48-60 models condensate drain 3/4" fpt.

Page 13

Manual 2100-317j page 13 of 39 wiring instructions general all wiring must be installed in accordance with the national electrical code and local codes. In canada, all wiring must be installed in accordance with the canadian electrical code and in accordance with the regulations of the authorities h...

Page 14

Manual 2100-317j page 14 of 39 thermostat indicators 8403-058 (th5220d1151) thermostat: thermostat will display on the screen “em heat” when the thermostat is set on emergency heat. 8403-060 (1120-445) temperature/humidity control: in heating or cooling, the display may be black and light gray, or b...

Page 15

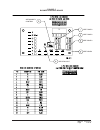

Manual 2100-317j page 15 of 39 figure 5 blower control board see humidity control see table 8 see table 8 see table 8 see table 8 see cfm light.

Page 16

Manual 2100-317j page 16 of 39.

Page 17

Manual 2100-317j page 17 of 39.

Page 18

Manual 2100-317j page 18 of 39 closed loop (earth coupled ground loop applications) note: unit shipped from factory with 27 psig low pressure switch wired into control circuit and must be rewired to 15 psig low pressure switch for closed loop applications. This unit is designed to work on earth coup...

Page 19

Manual 2100-317j page 19 of 39 start up procedure for closed loop system 1. Be sure main power to the unit is off at disconnect. 2. Set thermostat system switch to off, fan switch to auto. 3. Move main power disconnect to on. Except as required for safety while servicing, do not open the unit discon...

Page 20

Manual 2100-317j page 20 of 39 0 10 20 30 40 50 60 70 0 5 10 15 20 25 30 35 flow (gpm) head (feet) figure 9 performance model gpm-2 loop pump module 0 5 10 15 20 25 30 35 0 5 10 15 20 25 30 35 flow (gpm) head (feet) figure 8 performance model gpm-1 loop pump module figure 7 test plug cap pete’s test...

Page 21

Manual 2100-317j page 21 of 39 open loop (well system applications) note: unit shipped from factory with 27 psig low pressure switch wired into control circuit for open loop applications. Water connections it is very important that an adequate supply of clean, noncorrosive water at the proper pressu...

Page 22

Manual 2100-317j page 22 of 39 figure 10 water connection components the pressure requirements put on the pump are directly affected by the diameter of pipe being used, as well as, by the water flow rate through the pipe. The worksheet included in manual 2110-078 should guarantee that the well pump ...

Page 23

Manual 2100-317j page 23 of 39 system start up procedure for open loop applications 1. Be sure main power to the unit is off at disconnect. 2. Set thermostat system switch to off, fan switch to auto. 3. Move main power disconnect to on. Except as required for safety while servicing – do not open the...

Page 24

Manual 2100-317j page 24 of 39 figure 11 cleaning water coil 4. Scale formation. Of all the water problems, the formation of scale by ground water is by far the most common. Usually this scale is due to the formation of calcium carbonate by magnesium carbonate or calcium sulfate may also be present....

Page 25

Manual 2100-317j page 25 of 39 figure 12 lake or pond installation d. Size the pump to provide necessary gpm for the ground water heat pump. A 12 gpm or greater water flow rate is required on all modes when used on this type system. E. A pressure tank should be installed in dwelling to be heated adj...

Page 26

Manual 2100-317j page 26 of 39 sequence of operation blower the blower on/off actuation will depend upon “delay” selection settings on blower control board, see blower control setup section. If thermostat is set to “manual” or “on” for continuous operation the cfm will drop to 400 anytime the system...

Page 27

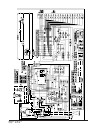

Manual 2100-317j page 27 of 39 figure 13 desuperheat coil low pressure switches reversing valve expansion valve high voltage in low voltage in water coil discharge service port high pressure switch compressor suction service port figure 14 control panel.

Page 28

Manual 2100-317j page 28 of 39 figure 15.

Page 29

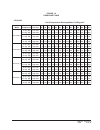

Manual 2100-317j page 29 of 39 figure 16 pressure table cooling fluid temperature entering water coil degree f l e d o m r i a n r u t e r e r u t a r e p m e t e r u s s e r p 5 4 0 5 5 5 0 6 5 6 0 7 5 7 0 8 5 8 0 9 5 9 0 0 1 5 0 1 0 1 1 a - 2 4 2 s v s g b d . G e d 5 7 b w . G e d 2 6 e d i s w o...

Page 30

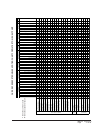

Manual 2100-317j page 30 of 39 figure 16a pressure table heating fluid temperature entering water coil degree f l e d o m r i a n r u t e r e r u t a r e p m e t e r u s s e r p 5 4 0 5 5 5 0 6 5 6 0 7 5 7 0 8 5 8 0 9 5 9 0 0 1 a - 2 4 2 s v s g b d . G e d 0 7 e d i s w o l e d i s h g i h 8 3 9 6 ...

Page 31

Manual 2100-317j page 31 of 39 heat gen. Power failure blown fuse or tripped breaker faulty wiring loose terminals low voltage defective contacts in contactor compressor overload potential relay run capacitor start capacitor faulty wiring loose terminals control transformer low voltage thermostat co...

Page 32

Manual 2100-317j page 32 of 39 service service hints 1. Caution homeowner to maintain clean air filters at tall times. Also, not to needlessly close off supply and return air registers. This reduces airflow through the system, which shortens equipment service life as well as increasing operating cos...

Page 33

Manual 2100-317j page 33 of 39 caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/procedure motor rocks slightly • this ...

Page 34

Manual 2100-317j page 34 of 39 replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programmed for specific operating modes. Even though...

Page 35

Manual 2100-317j page 35 of 39 figure 20 typical pump kit connection to unit gsvs model accessories add-on dpm26a pump module kit note: this section applies only if a dpm26a pump module is added. Refer to dpm26a instructions for complete installation details. General this high efficiency water sourc...

Page 36

Manual 2100-317j page 36 of 39 ground source heat pump performance report this performance check report should be filled out by installer and retained with unit. Date taken by: 1. Unit: mfgr model no. S/n thermostat: mfgr model no. P/n 2. Person reporting 3. Company reporting 4. Installed by date in...

Page 37

Manual 2100-317j page 37 of 39 the following information is needed to check performance of unit. Fluid side data cooling ** heating 9. Entering fluid temperature f 10. Leaving fluid temperature f 11. Entering fluid pressure psig 12. Leaving fluid pressure psig 13. Pressure drop through coil psig 14....

Page 38

Manual 2100-317j page 38 of 39.

Page 39

Manual 2100-317j page 39 of 39.