- DL manuals

- Bard

- Air Conditioner

- HA4S3

- Installation Instructions Manual

Bard HA4S3 Installation Instructions Manual

Manual

2100-573A

Page

1 of 21

Manual :

2100-573A

Supersedes:

2100-573

File:

Volume III Tab 16

Date:

07-09-12

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

0,6

WALL MOUNTED

PACKAGED

AIR CONDITIONER

INSTALLATION

INSTRUCTIONS

Models:

HA4S3

HL4S2

HA5S3

HL5S2

Summary of HA4S3

Page 1

Manual 2100-573a page 1 of 21 manual : 2100-573a supersedes: 2100-573 file: volume iii tab 16 date: 07-09-12 bard manufacturing company, inc. Bryan, ohio 43506 since 1914...Moving ahead just as planned. 0,6 wall mounted packaged air conditioner installation instructions models: ha4s3 hl4s2 ha5s3 hl5...

Page 2: Contents

Manual 2100-573a page 2 of 21 contents figures figure 1 unit dimensions ..................................... 5 figure 2 mounting instructions ............................. 9 figure 3 wall-mounting instructions .................. 10 figure 4 wall-mounting instructions .................. 10 figure 5 ...

Page 3

Manual 2100-573a page 3 of 21 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

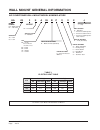

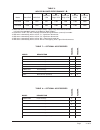

Manual 2100-573a page 4 of 21 wall mount general information air conditioner wall mount model nomenclature ha 4s 3 k a 05 b p x x x j table 1 electric heat table l a n i m o n w k ) 1 ( v 0 4 2 t a ) 1 ( v 8 0 2 t a w k s p m a h p - 1 h u t b w k s p m a h p - 1 h u t b 0 . 5 0 . 5 8 . 0 2 5 6 0 , ...

Page 5

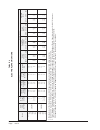

Manual 2100-573a page 5 of 21 table 2 dimensions of basic unit for architectural & installation requirements (nominal) t i n u h t d i w w h t p e d d t h g i e h h y l p p u s n r u t e r e f g i j k l m n o p q r s1 2 s t a b c b 3 s 4 a h 2 s 4 l h 5 7 0 . 2 4 2 3 4 . 2 2 5 7 8 . 4 9 8 8 . 9 8 8 ...

Page 6

Manual 2100-573a page 6 of 21 l e d o m d et a r stl o v es ah p dn a dl ei f . O n r e w o p sti uc ri c ti u cri c el g ni s ti u cri c el pit l u m 3 mu mi ni m ti uc ri c yti c a p m a 1 mu mi x a m es u fl an r et x e .R kr b .T k c r o 2 dl ei f r e w o p ezi s eri w 2 dn u or g eri w 3 mu mi ...

Page 7: Caution

Manual 2100-573a page 7 of 21 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. General...

Page 8: Installation Instructions

Manual 2100-573a page 8 of 21 wall mounting information 1. Two holes, for the supply and return air openings, must be cut through the wall as shown in figure 3. 2. On wood-frame walls, the wall construction must be strong and rigid enough to carry the weight of the unit without transmitting any unit...

Page 9

Manual 2100-573a page 9 of 21 figure 2 mounting instructions the unit rating plate lists a “maximum time delay relay fuse” or “hacr” type circuit breaker that is to be used with the equipment. The correct size must be used for proper circuit protection and also to assure that there will be no nuisan...

Page 10

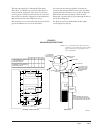

Manual 2100-573a page 10 of 21 figure 4 wall-mounting instructions figure 3 wall-mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on open...

Page 11

Manual 2100-573a page 11 of 21 figure 5 common wall-mounting installations lowered raised floor rafters supply air ceiling surface wall sleeve return air closet wall grille flashing return air flashing supply duct maybe located in an attic or below ceiling rafters as shown supply duct may be located...

Page 12: Warning

Manual 2100-573a page 12 of 21 figure 6 electric heat clearance wiring – main power low voltage connection these units use a 24-volt ac low voltage circuit. The “r” terminal is the hot terminal and the “c” terminal is grounded. “g” terminal is the fan input. “y1” terminal is the compressor input for...

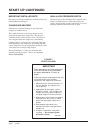

Page 13: Start Up

Manual 2100-573a page 13 of 21 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 p...

Page 14: Start Up Continued

Manual 2100-573a page 14 of 21 start up continued important installer note for improved start-up performance, wash the indoor coil with a dishwasher detergent. Crankcase heaters all units covered in this manual are provided with compressor crankcase heat. This crankcase heater is a band type heater ...

Page 15

Manual 2100-573a page 15 of 21 service hints 1. Maintain clean air filters at all times. Also, do not close off or block supply and return air registers. This reduces air flow through the system, which shortens equipment service life as well as increasing operating costs. 2. Check all power fuses or...

Page 16

Manual 2100-573a page 16 of 21 motor start device single phase (-a) model compressor circuits are equipped with a 25 ohm ptcr (positive temperature coefficient resistor) motor starting device as standard equipment. The ptcr is wired in parallel with the run capacitor. When voltage is applied, and de...

Page 17: Troubleshooting

Manual 2100-573a page 17 of 21 fan blade setting dimensions shown in the drawing below are the correct fan blade setting dimensions for proper air delivery across the outdoor coil. See figure 8. Any service work requiring removal or adjustment in the fan and/or motor area will require that the dimen...

Page 18: Troubleshooting Cont’D.

Manual 2100-573a page 18 of 21 table 5 cooling pressure – (all temperatures °f) low side pressure ± 4 psig high side pressure ± 10 psig g n i l o o c y t i c a p a c h g i h f e e r g e d l i o c r o o d t u o g n i r e t n e e r u t a r e p m e t r i a l e d o m r i a n r u t e r e r u t a r e p m ...

Page 19: Troubleshooting Ge Ecm

Manual 2100-573a page 19 of 21 troubleshooting ge ecm ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/proced...

Page 20: Troubleshooting Ge Ecm

Manual 2100-573a page 20 of 21 troubleshooting ge ecm ™ motors cont’d. Motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts and alignment pin supplied whe...

Page 21

Manual 2100-573a page 21 of 21 1 motor will deliver consistent cfm through voltage supply range with no deterioration. (197-253v for 230/208v models, 414-506v for 460v models) 2 continuous cfm is the total air being circulated during continuous (manual) fan mode. 3 will occur automatically with a ca...