- DL manuals

- Bard

- Air Conditioner

- HA4S4KA

- Installation Instructions Manual

Bard HA4S4KA Installation Instructions Manual

Summary of HA4S4KA

Page 1

Page 1 of 26 mis-2498 installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual: 2100-646 supersedes: new date: 9-3-15 wall-mounted packaged air conditioner models: ha4s4ka ha5s4ka hl4s4ka hl5s4ka mis-2498.

Page 2: Contents

Manual 2100-646 page 2 of 26 contents figures figure 1 unit dimensions .................................. 5 figure 2 mounting instructions .......................... 9 figure 3 wall mounting instructions ................. 10 figure 4 wall mounting instructions ................. 10 figure 5 common wa...

Page 3

Manual 2100-646 page 3 of 26 getting other information and publications for more information, contact these publishers: acca air conditioning contractors of america 1712 new hampshire ave. N.W. Washington, dc 20009 telephone: (202) 483-9370 fax: (202) 234-4721 ansi american national standards instit...

Page 4

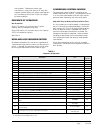

Manual 2100-646 page 4 of 26 wall mount general information air conditioner wall mount model nomenclature ha 4s 4 k a 05 b p x x x j table 1 electric heat table see table 3 for heater availability by model nominal kw at 240v at 208v kw 1-ph amps btuh kw 1-ph amps btuh 5.0 5.0 20.8 17,065 3.75 18...

Page 5

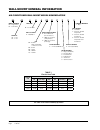

Manual 2100-646 page 5 of 26 table 2 dimensions of basic unit for architectural and installation requirements (nominal) all dimensions in inches. Dimensional drawings are not to scale. Unit width w depth d height h supply return e f g i j k l m n o p q r s1 s2 t a b c b ha4s4 hl4s4 ha5s4 hl5s4 42.07...

Page 6

Manual 2100-646 page 6 of 26 these “minimum circuit ampacity” values are to be used for sizing the field power conductors. Refer to the national electric co de (latest version), article 310 for power conductor sizing. Caution: when more than one filed power conductor circuit is run through one condu...

Page 7: Caution

Manual 2100-646 page 7 of 26 some installations may not require any return air duct. A return air grille is required with installations not requiring a return air duct. The spacing between louvers on the grille shall not be larger than 5/8". ! Caution shipping damage upon receipt of equipment, the c...

Page 8: Warning

Manual 2100-646 page 8 of 26 clearances required for service access and adequate condenser airflow models left side right side discharge side ha4s4, hl4s4 ha5s4, hl5s4 20" 20" 10” note: for side-by-side installation of two h**s4 models, there must be 20" between units. This can be reduced to 15" by ...

Page 9

Manual 2100-646 page 9 of 26 figure 2 mounting instructions the unit rating plate lists a “maximum time delay relay fuse” or circuit breaker that is to be used with the equipment. The correct size must be used for proper circuit protection and also to assure that there will be no nuisance tripping d...

Page 10

Manual 2100-646 page 10 of 26 figure 4 wall mounting instructions figure 3 wall mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on openi...

Page 11

Manual 2100-646 page 11 of 26 figure 5 common wall mounting installations lowered raised floor rafters supply air ceiling surface wall sleeve return air closet wall grille flashing return air flashing supply duct maybe located in an attic or below ceiling rafters as shown supply duct may be located ...

Page 12: Warning

Manual 2100-646 page 12 of 26 ! Warning a minimum of 1/4" clearance must be maintained between the supply air duct and combustible materials. This is required for the first 3' of ducting. It is important to insure that the 1/4" minimum spacing is maintained at all points. Failure to do this could re...

Page 13

Manual 2100-646 page 13 of 26 mis-3054 timer to be set here (500 seconds) mis-3054 dirty filter switch and relay these units include an adjustable dirty filter indicator switch. This switch if connected to normally closed contacts on the filter relay wired to terminals 10 and 11 on the low voltage t...

Page 14: Start Up

Manual 2100-646 page 14 of 26 start up these units require r-410a refrigerant and polyol ester oil. General 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi...

Page 15

Manual 2100-646 page 15 of 26 site variables. Telecommunication type installations in high traffic areas or in areas with frequent airborne debris will require more frequent coil maintenance than those in areas not subject to those conditions. Sequence of operation non-economizer stage 1 (7) cooling...

Page 16

Manual 2100-646 page 16 of 26 high pressure switch and lockout sequence if the high pressure switch opens, the compressor contactor will de-energize immediately. The lockout timer will go into a soft lockout and stay in soft lockout until the high pressure switch closes and the delay- on-break time ...

Page 17

Manual 2100-646 page 17 of 26 the decal in figure 7 is affixed to all model units detailing start up procedure. This is very important. Please read carefully. Important these procedures must be followed at initial start up and at any time power has been removed for 12 hours or longer. To prevent com...

Page 18: Service

Manual 2100-646 page 18 of 26 fan blade setting dimensions the correct fan blade setting dimensions for proper air delivery across the outdoor coil are shown in figure 8. Any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions below be checked a...

Page 19

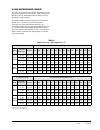

Manual 2100-646 page 19 of 26 table 6 cooling pressure – (all temperatures °f) low side pressure ±4 psig high side pressure ±10 psig r-410a refrigerant charge this unit was charged at the factory with the quantity of refrigerant listed on the serial plate. Ahri capacity and efficiency ratings were d...

Page 20

Manual 2100-646 page 20 of 26 caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/procedure motor rocks slightly • this i...

Page 21

Manual 2100-646 page 21 of 26 replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor, take the following steps: 1. It is essential to have the correct replacement module. The controls are factory programmed for specific operating modes. Even though t...

Page 22

Manual 2100-646 page 22 of 26 motor will deliver consistent cfm through voltage supply range with no deterioration. (197-253v for 230/208v models, 414-506v for 460v models) continuous cfm is the total air being circulated during continuous (manual) fan mode. Will occur automatically with a call for ...

Page 23

Manual 2100-646 page 23 of 26 this page intentionally left blank.

Page 24: Eld Conn

Manual 2100-646 page 24 of 26 figure 12a h**s4 wiring diagram – top ifo pt ion not a w ires connect used fie ld lo w vo ltage hi gh vo ltage op tional fa ctory us e c opp er c on du ct ors on ly s ui ta bl e fo r a t le ast 75 ° c. War ni ng ! W ire iden tifi ca tion nu m be rs fo rb ar d use on ly....

Page 25: Eld Conn

Manual 2100-646 page 25 of 26 figure 12b h**s4 wiring diagram – bottom ifo pt ion not a w ires connect used fie ld lo w vo ltage hi gh vo ltage op tional fa ctory us e c opp er c on du ct ors on ly s ui ta bl e fo r a t le ast 75 ° c. War ni ng ! W ire iden tifi ca tion nu m be rs fo rb ar d use on ...

Page 26

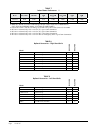

Manual 2100-646 page 26 of 26 figure 13 h**s4 low voltage ladder diagram for unit and mv connections low voltage terminal strip 3 2 10 11 6 20 9 16 17 18 12 13 21 4 19 1 5 7 hot common 8 14 15 filter light filter switch filter reset button r on compressor control module filter relay pin 6 on heater ...