- DL manuals

- Bard

- Heat Pump

- I30H1-A

- Installation Instructions Manual

Bard I30H1-A Installation Instructions Manual

Page

1 of 61

MIS-2957 A

I-TEC

®

SERIES

PACKAGED HEAT PUMP

Models:

INSTALLATION INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-549Q

Supersedes: 2100-549P

Date:

6-14-17

I30H1-A

I30H1-B

I30H1-C

I36H1-A

I36H1-B

I36H1-C

I42H1-A

I42H1-B

I42H1-C

I48H1-A

I48H1-B

I48H1-C

I60H1-A

I60H1-B

I60H1-C

I30H1DA

I30H1DB

I30H1DC

I36H1DA

I36H1DB

I36H1DC

I42H1DA

I42H1DB

I42H1DC

I48H1DA

I48H1DB

I48H1DC

I60H1DA

I60H1DB

I60H1DC

Summary of I30H1-A

Page 1

Page 1 of 61 mis-2957 a i-tec ® series packaged heat pump models: installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual: 2100-549q supersedes: 2100-549p date: 6-14-17 i30h1-a i30h1-b i30h1-c i36h1-a i36h1-b i36h1-c i42h1-a i42h1-b i42h1-c i48h1-a i48h1-...

Page 2: Contents

Manual 2100-549q page 2 of 69 contents getting other information and publications .........4 general ...................................................................5 ansi z535.5 definitions ...........................................5 i-tec series general information ...............................

Page 3

Manual 2100-549q page 3 of 69 figures figure 1 unit dimensions .................................... 8 figure 2a unit on lift ........................................... 9 figure 2b unit side .............................................. 9 wall mounting bracket location ............ 10 bracket wall ...

Page 4

Manual 2100-549q page 4 of 69 getting other information and publications these publications can help when installing the air conditioner or heat pump. They can usually be found at the local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Nat...

Page 5

Manual 2100-549q page 5 of 69 general the equipment covered in this manual is to be installed by trained, experienced service and installation technicians. The i-tec must be installed with the bard manufactured iws wall sleeve and ilg louver grille accessories. These are sold as separate accessories...

Page 6: I-Tec

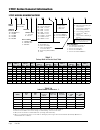

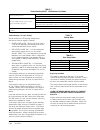

Manual 2100-549q page 6 of 69 table 1 factory built-in electric heat table models i30h1-a i30h1-b i30h1-c i36h1-a i42h1-a i36h1-b i42h1-b i36h1-c i42h1-c i48h1-a i48h1-b i60h1-b i48h1-c i60h1-c i60h1-a kw 240v-1 208v-1 240v-3 208v-3 460v-3 240v-1 208v-1 240v-3 208v-3 460v-3 240v-1 208v-1 240v-3 208v...

Page 7

Manual 2100-549q page 7 of 69 table 2 electrical specifications model rated volts, hertz & phase single circuit dual circuit no. Field power circuits minimum circuit ampacity maximum external fuse or ckt. Brkr. Field power wire size ground wire minimum circuit ampacity maximum external fuse or ckt. ...

Page 8

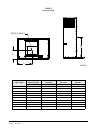

Manual 2100-549q page 8 of 69 3 3 4 " 24 1 2 " 22 1 4 " lo we r se cti on 71 3 4 " up pe r se cti on supply air re tu rn air re tu rn air inner slee ve ou ter slee ve ou ter slee ve inner slee ve un itd rain (2 )o pt. En tran ces u ni t s pe ci fic at ion s heet top v iew fron tv iew ri gh ts ide v ...

Page 9: Warning

Manual 2100-549q page 9 of 69 shipping damage upon receipt of equipment, the unit should be checked for external signs of shipping damage. The skid must remain attached until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immediately, prefer...

Page 10

Manual 2100-549q page 10 of 69 required steps after final placement the compressor is secured to the base with two (2) bolts for shipping. Although the unit will perform as designed with the shipping bolts in place, there may be a noticeable additional noise and vibration noted. To obtain the lowest...

Page 11

Manual 2100-549q page 11 of 69 7 3/8 18 3/4 35" 17.5" cl right side view front (wall only) view wall section view mis-2918 d cl riser kit dim a dim b dim c none 31"-34" max 29 17/32" 94 1/8" irp-3 (3") 34"-37" max 32 17/32" 97 1/8" irp-6 (6") 37"-40" max 35 17/32" 100 1/8" outside grille telescoping...

Page 12

Manual 2100-549q page 12 of 69 figure 3 center of gravity "y" "x" "z" mis-3269 center of gravity unit tested front of unit door to center left side to center floor to center crv & erv floor to center no vent "x" dimension "y" dimension "z" dimension "z" dimension i30h1-a, -b 14" 24" 43½" 47" i30h1-c...

Page 13

Manual 2100-549q page 13 of 69 figure 4 required clearances and recommended access 12" min. For right side access 12" min. For left side access 12" min. 12" min. 12" min. 12" min. 0" required 12" recomended 0" required 12" recomended 48" min. 31 3/8" 12" min. 12" min. 48" min. For filter access 24" ...

Page 14

Manual 2100-549q page 14 of 69 compressor shipping bolt compressor shipping bolt crv/erv air duct figure 5 compressor shipping bolts figure 6 removal of air duct.

Page 15

Manual 2100-549q page 15 of 69 9'-2" minimum re quir ed in st all ation he ight cl ea ra nce re comm end ed to bottom of roof 9'-7" minimum or fi xe d c eiling floor or fi xe d c eiling bottom of roof su spe nd ed ce iling 20" minimum 7'-9 3/4" unit h eight fi eld su pp li ed duct turning va nes re ...

Page 16

Manual 2100-549q page 16 of 69 9'- 5" m in im um re qu ir ed in st all at ion he ig ht cl ea ra nce re co mm end ed to botto m of roof 9'- 10 " mi ni m um or fi xe d ce il ing 3" ri se r fi el d su pp li ed duct turn in g va nes re co mm end ed 12" m in im um 4" mi ni m um fr om to p of un it to duc...

Page 17

Manual 2100-549q page 17 of 69 10'-1" minimum cl ea ra nce re comm end ed to bottom of roof or fi xe d c eiling 6" ri se r 9'-8" minimum re quir ed in st all ation he ight bottom of roof floor or fi xe d c eiling su spe nd ed ce iling minimum 20" 7'-9 3/4" unit h eight fi eld su pp li ed duct mi s-2...

Page 18

Manual 2100-549q page 18 of 69 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acc...

Page 19

Manual 2100-549q page 19 of 69 condensate drain there are four condensate drain connections from the condenser drain pan (compressor area). These are visible from the rear of the unit. The drain header assembly is field installed and can be found attached to the back of the vent section (see figure ...

Page 20

Manual 2100-549q page 20 of 69 d ref. A and b ref. (4) 5/16" - 1/2" non-tapping ref. E ref. (6) 5/16" - 3/4" non-tapping c (4) 1-1/2" long screws ref. E (18) 5/16" - 3/4" self tapping b c ref. Ref. Ref. A ref. D mis-3014 a use (4) 1-1/2" long louver grille to outer sleeve. Screws to attach to outer ...

Page 21

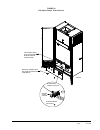

Manual 2100-549q page 21 of 69 outdoor louver sleeve area between wall and sleeve (insulated) outside wall (size varies) i-tec unit interior floor inside wall fill insulation mis-2928 c (insulated) drain area insulated with 6" batt material figure 11b unit mounting.

Page 22: Installation

Manual 2100-549q page 22 of 69 installation mounting the unit the wall sleeve is attached to the i-tec unit from the outside of the building. See figures 11a & 11b. Refer to wall sleeve manual 2100-562 supplied with sleeve. Following are the steps for attaching the i-tec to the wall sleeve. 1. Lift ...

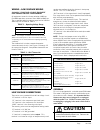

Page 23: Caution

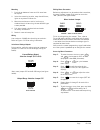

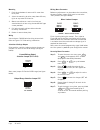

Manual 2100-549q page 23 of 69 tap range 240v 253 – 216 208v 220 – 187 low voltage connections for ddc control fan only energize g cooling part load energize g, y1 cooling full load energize g, y1, y2 hp heating part load energize g, y1, b/w1 hp heating full load energize g, y1, y2, b/w1 hp heating ...

Page 24

Manual 2100-549q page 24 of 69 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc sc gnd w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc sc gnd g com w2 comple...

Page 25

Manual 2100-549q page 25 of 69 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd w2 completestat...

Page 26

Manual 2100-549q page 26 of 69 5 2 1 6 thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 blue yellow orange w3 mis-3018 a sc model #cs9be-tho 1 dehumidification models. Additional wire required for 2 3 emergency shutdown required. And connect to n.C fire alarm circuit if factory installed j...

Page 27

Manual 2100-549q page 27 of 69 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc w1/e a d l o/b y2 y1 sc gnd sc w1/e a d l o...

Page 28

Manual 2100-549q page 28 of 69 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc sc ...

Page 29

Manual 2100-549q page 29 of 69 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc gnd w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc sc gnd w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9b...

Page 30

Manual 2100-549q page 30 of 69 blue yellow orange voltage blue model #cs9b-thoc or b/w1 red gnd low additional wire required for dehumidification models. 1 not needed below 15kw. 2 2 3 to n.C fire alarm circuit if emergency shutdown required. Factory installed jumper. Remove jumper and connect 3 con...

Page 31: Start Up

Manual 2100-549q page 31 of 69 start up these units require r-410a refrigerant and polyol ester oil. General 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 ps...

Page 32

Manual 2100-549q page 32 of 69 description of standard equipment solid state electronic heat pump control provides efficient 30-, 60- or 90-minute defrost cycle. A thermistor sensor and speed up terminal for service along with a 8-minute defrost override are standard on the electronic heat pump cont...

Page 33

Manual 2100-549q page 33 of 69 sequence of operation cooling part load – circuit r-y1 makes at thermostat pulling in compressor contactor, starting the compressor and outdoor motor. The g (indoor motor) circuit is automatically completed on any call for cooling operation or can be energized by manua...

Page 34

Manual 2100-549q page 34 of 69 if some abnormal or temporary condition such as a high wind causes the heat pump to have a prolonged defrost cycle, the heat pump control will restore the system to heating operation automatically after 8 minutes. The heat pump defrost control board has an option of 30...

Page 35: (Vent Code "m")

Manual 2100-549q page 35 of 69 general description the i-tec commercial room ventilator (crv) is designed to be used with all bard i-tec models. The only intent of this device is to provide the required ventilation by delivering fresh air to meet iaq (indoor air quality) requirements. In the install...

Page 36: Suction

Manual 2100-549q page 36 of 69 1. Open front swinging doors of main unit (by popping front door latches). 2. Throw main power disconnect to the “off” position to eliminate risk of injury or death due to electrical shock. 3. Remove six (6) screws holding front crv door in place (see figure 22). 4. Lo...

Page 37

Manual 2100-549q page 37 of 69 remove (5) screws from crv door to access crv components mis-3023 crv intake blower note: crv exhaust blower is behind intake blower blower speed control location blower speed control blower removed for clarity figure 22 crv speed change terminal access.

Page 38: I-Tec Combination Crv And

Manual 2100-549q page 38 of 69 general description the i-tec combination commercial room ventilator (crv) and dry bulb economizer is designed to be used with all bard i-tec models. This ventilation package and its control provides two roles: • it will provide the required ventilation by delivering f...

Page 39

Manual 2100-549q page 39 of 69 setting the ventilation cfm levels the i-tec crv has four pre-set levels of ventilation cfm available. These are 300, 375, 450 and 525 cfm of ventilation air. This ventilation package is shipped from the factory set on the 375 cfm ventilation level while the economizer...

Page 40

Manual 2100-549q page 40 of 69 i-tec economizer sequence of operation if outdoor temperature is below outdoor thermostat setpoint on call from completestat tm for first stage cooling: • “yo” thermostat signal powers vent blower motors at economizer speed/airflow (black – 525 cfm) through nc contacts...

Page 41

Manual 2100-549q page 41 of 69 i-tec modulating commercial room ventilator system (vent code "q") general description the i-tec commercial room ventilator (crv) is designed to be used with all bard i-tec models. The only intent of this device is to provide the required ventilation by delivering fres...

Page 42: Suction

Manual 2100-549q page 42 of 69 changing ventilation cfm rates in manual mode to adjust the airflow ventilation rate, first refer to figure 25a to look up the “flow index” needed for the intake and exhaust blowers for the cfm required. Then, perform the following steps: 1. Open front swinging doors o...

Page 43

Manual 2100-549q page 43 of 69 figure 25a crv “manual mode” jumper pin on “m” terminal figure 25b crv “modulating mode” jumper pin on “p” terminal cfm flow index (light blink code) 525 100 500 92 475 85 450 79 425 72 400 66 375 59 350 53 325 46 300 40 275 33 250 27 225 20 200 14 175 7 150 1 to adjus...

Page 44

Manual 2100-549q page 44 of 69 exhaust return air indoor air vent outdoor air blower blower intake supply air vent supply blower mis-3024 figure 26 ventilation airflow diagram.

Page 45

Manual 2100-549q page 45 of 69 plates mis-3846 crv control panel location crv diffuser note: crv exhaust blower is behind intake blower remove (5) screws from crv door to access crv components crv intake blower figure 27 crv control access.

Page 46

Manual 2100-549q page 46 of 69 figure 28 control board configuration/setting configuring bard part #8403-067 co 2 control for crv modulating control bard part #8403-067 c arbon dioxide and temperature transmitters accurately monitor the co 2 concentration and temperature in schools, office buildings...

Page 47

Manual 2100-549q page 47 of 69 mounting 1. Push tab on bottom of cover and lift cover from back plate. 2. Select the mounting location, away from diffusers, lights or any external influences. 3. Mount transmitter on a vertical surface to a standard electrical box using the two #6 m2c type screws pro...

Page 48

Manual 2100-549q page 48 of 69 menu descriptions ron relay on setpoint sets the co 2 concentration which the optional relay is energized. Low limit: 0 ppm factory setting: 1000 ppm high limit: 2000/5000 ppm (depending on model) rof relay off setpoint sets the co 2 concentration which the optional re...

Page 49: (Vent Code "r")

Manual 2100-549q page 49 of 69 general description the i-tec energy recovery ventilator (erv) was designed to provide energy efficient, cost effective ventilation to meet iaq (indoor air quality) requirements while still maintaining good indoor comfort and humidity control for a variety of applicati...

Page 50: Suction

Manual 2100-549q page 50 of 69 recommended control sequences several possible scenarios are listed below: 1. Use a programmable electronic thermostat with auxiliary terminal to control the erv based on daily programmed occupance periods. Bard markets and recommends bard part #8403-060 programmable e...

Page 51

Manual 2100-549q page 51 of 69 legend: vlt = ventilation load – total vls = ventilation load – sensible vll = ventilation load – latent hrt = heat recovery – total hrs = heat recovery – sensible hrl = heat recovery – latent wvl = winter ventilation load whr = winter heat recovery note: all performan...

Page 52

Manual 2100-549q page 52 of 69 cfm flow index (light blink code) 450 100 425 89 400 83 375 76 350 59 325 50 300 40 275 32 250 25 225 12 200 9 175 4 150 1 to adjust the airflow ventilation rate (no co 2 control/non- modulating), determine the "flow index" needed for the intake and exhaust blowers for...

Page 53

Manual 2100-549q page 53 of 69 exhaust return air indoor air vent outdoor air blower blower intake supply air vent supply blower mis-3024 figure 30 ventilation airflow diagram.

Page 54

Manual 2100-549q page 54 of 69 erv door to access erv components assemblies remove (5) screws from panel location mis-3025 erv control erv cassette note: erv exhaust blower is behind intake blower erv intake blower figure 31 erv control access.

Page 55

Manual 2100-549q page 55 of 69 figure 32 control board configuration/setting configuring bard part #8403-067 co 2 control for erv modulating control bard part #8403-067 c arbon dioxide and temperature transmitters accurately monitor the co 2 concentration and temperature in schools, office buildings...

Page 56

Manual 2100-549q page 56 of 69 mounting 1. Push tab on bottom of cover and lift cover from back plate. 2. Select the mounting location, away from diffusers, lights or any external influences. 3. Mount transmitter on a vertical surface to a standard electrical box using the two #6 m2c type screws pro...

Page 57

Manual 2100-549q page 57 of 69 menu descriptions ron relay on setpoint sets the co 2 concentration which the optional relay is energized. Low limit: 0 ppm factory setting: 1000 ppm high limit: 2000/5000 ppm (depending on model) rof relay off setpoint sets the co 2 concentration which the optional re...

Page 58

Manual 2100-549q page 58 of 69 energy recovery ventilator maintenance general information the ability to clean exposed surfaces within air moving systems is an important design consideration for the maintenance of system performance and air quality. The need for periodic cleaning will be a function ...

Page 59

Manual 2100-549q page 59 of 69 figure 33 hub assembly with ball bearings buildup of foreign material needs to be removed. 9. If any belt chirping or squealing noise is present, apply a small amount of lps-1 or equivalent dry film lubricant to the belt. Annual maintenance 1. Inspect and conduct the s...

Page 60: Troubleshooting

Manual 2100-549q page 60 of 69 troubleshooting solid state heat pump control 1. Note: a thorough understanding of the defrost cycle sequence is essential. Review that section beginning on page 33 prior to troubleshooting the control. Turn on ac power supply to unit. 2. Turn thermostat blower switch ...

Page 61

Manual 2100-549q page 61 of 69 checking temperature sensor 1. Disconnect temperature sensor from board and from right-hand outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance use s...

Page 62

Manual 2100-549q page 62 of 69 troubleshooting condensate overflow systems the bard i-tec series is equipped with dual condensate overflow switches. One switch (float type) is located in the indoor drain pan. It is secured to the drain pan with a screw-down clamp (see figure 34). The second switch (...

Page 63: Warning

Manual 2100-549q page 63 of 69 troubleshooting ecm tm 142r outdoor fan motors 1. In normal operation, this motor may rock back and forth on start up. Do not replace if this is the only symptom identified. 2. If the system is operating properly, but the motor appears to run slower than it should, the...

Page 64

Manual 2100-549q page 64 of 69 check line power to motor check between red and black wires for line power verify ground by checking green wire to l1 and l2 line power check for 24vac common signal to motor (against transformer "r" signal) check "br" terminal of fan logic control board check blue fan...

Page 65

Manual 2100-549q page 65 of 69 troubleshooting ecm tm indoor blower motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom ...

Page 66

Manual 2100-549q page 66 of 69 motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts and alignment pin supplied when replacing an ecm 2.0 control. Figure 3...

Page 67

Manual 2100-549q page 67 of 69 fan blade setting dimensions the position of the fan blade should be flush with the leaving face of the orifice plate. Check to make sure the blades do not extend beyond the rear casing of the unit. Spin the blade by hand to make sure it does not hit the ring. Refriger...

Page 68

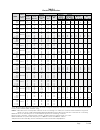

Manual 2100-549q page 68 of 69 table 10a full load cooling pressure/temperature table 10b full load heating pressure/temperature model return air temp. Pressure air temperature entering outdoor coil °f 55° 60° 65° 70° 75° 80° 85° 90° 95° 100° 105° 110° 115° 120° 125° i30h1 75° db 62° wb low side hig...

Page 69

Manual 2100-549q page 69 of 69 table 11a part load cooling pressure/temperature table 11b part load heating pressure/temperature model return air temp. Pressure air temperature entering outdoor coil °f 55° 60° 65° 70° 75° 80° 85° 90° 95° 100° 105° 110° 115° 120° 125° i30h1 75° db 62° wb low side hig...