- DL manuals

- Bard

- Heat Pump

- I30H1

- Installation Instructions Manual

Bard I30H1 Installation Instructions Manual

Manual 2100-549G

Page

1 of 59

Models:

I30H1

I36H1

I42H1

I48H1

I60H1

I30H1D

I36H1D

I42H1D

I48H1D

I60H1D

I-TEC SERIES

PACKAGED HEAT PUMP

INSTALLATION

INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914 . . . Moving ahead, just as planned.

Manual:

2100-549G

Supersedes:

2100-549F

File:

Vol. II Tab 14

Date:

11-05-13

MIS-2957 A

Summary of I30H1

Page 1

Manual 2100-549g page 1 of 59 models: i30h1 i36h1 i42h1 i48h1 i60h1 i30h1d i36h1d i42h1d i48h1d i60h1d i-tec series packaged heat pump installation instructions bard manufacturing company, inc. Bryan, ohio 43506 since 1914 . . . Moving ahead, just as planned. Manual: 2100-549g supersedes: 2100-549f ...

Page 2: Contents

Manual 2100-549g page 2 of 59 contents getting other information and publications for more information, contact these publishers: .......... 3 general & ansi z535.5 definitions ............................. 4 i-tec general information i-tec model nomenclature ...........................................

Page 3

Manual 2100-549g page 3 of 59 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-549g page 4 of 59 general the equipment covered in this manual is to be installed by trained, experienced service and installation technicians. The i-tec must be installed with the bard manufactured iws wall sleeve and ilg louver grille accessories. These are sold as separate accessories...

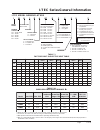

Page 5

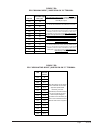

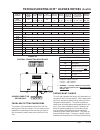

Manual 2100-549g page 5 of 59 table 1 factory built-in electric heat table s l e d o m a - 1 h 0 3 i b - 1 h 0 3 i c - 1 h 0 3 i a - 1 h 6 3 i a - 1 h 2 4 i b - 1 h 6 3 i b - 1 h 2 4 i c - 1 h 6 3 i c - 1 h 2 4 i a - 1 h 8 4 i b - 1 h 8 4 i b - 1 h 0 6 i c - 1 h 8 4 i c - 1 h 0 6 i a - 1 h 0 6 i w k...

Page 6

Manual 2100-549g page 6 of 59 table 2 electrical specifications d e t a r z t r e h , s tl o v e s a h p d n a d l e i f . O n r e w o p s t i u c r i c t i u c r i c e l g n i s t i u c r i c l a u d l e d o m m u m i n i m t i u c r i c y t i c a p m a m u m i x a m e s u f l a n r e t x e . R k r...

Page 7

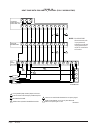

Manual 2100-549g page 7 of 59 3 3 4 " 24 1 2 " 22 1 4 " low er sec tion 71 3 4 " u pper sec tion sl eev e inner re tu rn sl eev e outer sl eev e inner ai r re tu rn sl eev e outer ai r suppl y ai r (2 ) opt. Un it dra in entr ances " 8 3 1 8" 3 1 8 " h igh vol tage entr anc e entr ance low vol tage ...

Page 8: Warning

Manual 2100-549g page 8 of 59 shipping damage upon receipt of equipment, the unit should be checked for external signs of shipping damage. The skid must remain attached until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immediately, prefer...

Page 9

Manual 2100-549g page 9 of 59 required steps after final placement the compressor is secured to the base with two (2) bolts for shipping. Although the unit will perform as designed with the shipping bolts in place, there may be a noticeable additional noise and vibration noted. To obtain the lowest ...

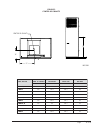

Page 10

Manual 2100-549g page 10 of 59 7 3/8 18 3/4 17.5" 35" front (wall only) view right side view cl cl mis-2918 c wall unit outside grille telescoping duct wall sleeve** floor ceiling optional optional trim or supply duct box 31" min. 34" max. Room floor level outside (4) optional unit mounting holes (4...

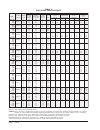

Page 11

Manual 2100-549g page 11 of 59 "y" "x" "z" mis-3269 center of gravity d e t s e t t i n u t i n u f o t n o r f r e t n e c o t r o o d e d i s t f e l r e t n e c o t r e t n e c o t r o o l f v r e & v r c r e t n e c o t r o o l f t n e v o n n o i s n e m i d " x " n o i s n e m i d " y " n o i ...

Page 12

Manual 2100-549g page 12 of 59 48" min. 31 3/8" 12" min. 12" min. 48" min. For filter access 24" min. 24" min. 12" min. For right side access 12" min. For left side access 12" min. 12" min. 12" min. 12" min. 0" required 12" recomended 0" required 12" recomended closet construction top view left corn...

Page 13

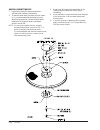

Manual 2100-549g page 13 of 59 figure 5 compressor shipping bolts figure 6 removal of air duct É É compressor shipping bolt compressor shipping bolt crv / erv air duct.

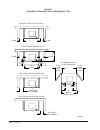

Page 14

Manual 2100-549g page 14 of 59 9'-2" minimum re quire d ins ta lla tion he ight cle a ra nce re comme nde d to b ottom of roof 9'-7" minimum or fix e d ce iling floor or fix e d ce iling b ottom of roof su spen d ed ce iling 20" minimum 7'-9 3/4" unit he ight fie ld s up p lie d duct turning v a ne ...

Page 15

Manual 2100-549g page 15 of 59 9'-5" min imu m requi r ed ins t a lla tion hei g ht clearance recom m e nded to b ottom of roof 9'-10" minimum or fix e d c e ilin g 3 " ri ser fi eld suppli e d duct turni ng vanes recom m e nded 12" min imu m 4" minimum from top of unit to duct bottom mis -2989 b fl...

Page 16

Manual 2100-549g page 16 of 59 10'-1" minimum cle a ra nce re comme nde d to b ottom of roof or fix e d ce iling 6" ris e r 9'-8" minimum re quire d ins ta lla tion he ight b ottom of roof floor or fix e d ce iling su spen d ed ce iling minimum 20" 7'-9 3/4" unit he ight fie ld s up p lie d duct mis...

Page 17

Manual 2100-549g page 17 of 59 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acc...

Page 18

Manual 2100-549g page 18 of 59 (2)optional drain holes optional floor mounting holes 18 3/4" wall 35" " 4 3 40 7 3/16" 16 1/2" entrances unit drain (2) unit drains (2) optional drain access locations 3 " 8 3 8" 3 3 8 " mis-2960 b condensate drain there are two condensate drain connections from the c...

Page 19

Manual 2100-549g page 19 of 59 (6) 5/16" - 3/4" non-tapping (4) 5/16" - 1/2" non-tapping (16) 5/16" - 3/4" self tapping ref. D ref. A and b ref. C b c ref. Ref. A ref. Ref. D mis-3014 outer sleeve. Important! To not damage gasketing material. Important! Entire perimeter seam important! Seal between ...

Page 20

Manual 2100-549g page 20 of 59 interior floor inside wall sleeve area between (insulated) wall and sleeve outside wall (size varies) outdoor grille fill insulation i-tec unit (insulated) drain area insulated with 6" batt material mis-2928 b figure 11b unit mounting.

Page 21: Installation Instructions

Manual 2100-549g page 21 of 59 installation instructions mounting the unit the wall sleeve is attached to the i-tec unit from the outside of the building. See figures 11a & 11b. Refer to wall sleeve manual 2100-562 supplied with sleeve. Following are the steps for attaching the i-tec to the wall sle...

Page 22: Caution

Manual 2100-549g page 22 of 59 the standard unit includes a remote thermostat connection terminal strip. See figures 13 through 19 for connection diagrams. Compatible thermostats are listed in table 4. Table 3 — operating voltage range note: the voltage should be measured at the field power connecti...

Page 23

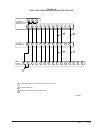

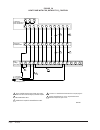

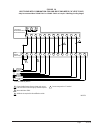

Manual 2100-549g page 23 of 59 figure 13 basic heat pump with no ventilation package 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 mi...

Page 24

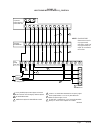

Manual 2100-549g page 24 of 59 figure 14 heat pump with crv, without co 2 control 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 5 mis...

Page 25

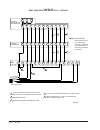

Manual 2100-549g page 25 of 59 figure 15 heat pump with crv and co 2 control sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc 5 2 1 6 thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 3 low mis-3018 3 1 additional wire required for dehumidification...

Page 26

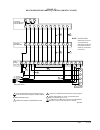

Manual 2100-549g page 26 of 59 figure 16 heat pump with erv, without co 2 control 6 4 w3 a d l b/w1 y2 y1 rt g c w2 low voltage term. Strip r 3 sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 orang...

Page 27

Manual 2100-549g page 27 of 59 figure 17 heat pump with erv and co 2 control (on/off cycling) sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 pink 6 1 additional wire required for dehumidification ...

Page 28

Manual 2100-549g page 28 of 59 figure 18 heat pump with erv and co 2 control (fully modulating) sc w1/e a d l o/b y2 y1 24v g com w2 completestat model #cs9b-tho or model #cs9be-tho sc sc thermostat w1/e a yo/d l o/b y2 y1 r g c w2 bard #8403-060 pink d l without "occupance signal" is used. Term. St...

Page 29

Manual 2100-549g page 29 of 59 y1 r crv/econ wiring harness brown/white 8 w3 1 rt 24v a 1 b/w1 gray d to n.C fire alarm circuit if emergency shutdown required. Com factory installed jumper. Remove jumper and connect 3 additional wire required for dehumidification models. 4 purple/white c g model #cs...

Page 30: Start Up

Manual 2100-549g page 30 of 59 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 p...

Page 31: Start Up

Manual 2100-549g page 31 of 59 start up description of standard equipment solid state electronic heat pump control provides efficient 30, 60 or 90-minute defrost cycle. A thermistor sensor and speed up terminal for service along with a 8-minute defrost override a re standard on the electronic heat p...

Page 32

Manual 2100-549g page 32 of 59 sequence of operation cooling part load – circuit r-y1 makes at thermostat pulling in compressor contactor, starting the compressor and outdoor motor. The g (indoor motor) circuit is automatically completed on any call for cooling operation or can be energized by manua...

Page 33

Manual 2100-549g page 33 of 59 defrost cycle the defrost cycle is controlled by temperature and time on the solid state heat pump contr ol. See figure 20. When the outdoor temperature is in the lower 40°f temperature range or colder, the outdoor coil temperature is 32°f or below. This coil temperatu...

Page 34

Manual 2100-549g page 34 of 59 i-tec commercial room ventilator system general description the i-tec commercial room ventilator (crv) is designed to be used with all bard i-tec models. The only intent of this device is to provide the required ventilation by delivering fresh air to meet i.A.Q. (indoo...

Page 35

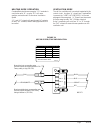

Manual 2100-549g page 35 of 59 figure 21 crv motor speed/cfm configuration med. Hi 7961-7554 m otor speeds lo med. Lo hi orange vent option intake/exhaust speeds brown/white black blue orange nom. Cfm black blue wire color speed red wire with white trace. 300 375 450 525 lo med-lo med-hi hi red move...

Page 36

Manual 2100-549g page 36 of 59 figure 22 crv speed change terminal access remove (5) screws from crv door to access crv components mis-3023 crv intake blower note: crv exhaust blower is behind intake blower blower speed control location blower speed control blower removed for clarity.

Page 37

Manual 2100-549g page 37 of 59 i-tec combination crv & economizer ventilation system description the i-tec combination commercial room ventilator (crv) and dry bulb economizer is designed to be used with all bard i-tec models. This ventilation package and its control provides two (2) roles: • it wil...

Page 38

Manual 2100-549g page 38 of 59 7 nc 7 d r2 6 y2 no r3 com no 3 r4 econ vent speed yo a factory wire a r1 d 6 g r y2 8 y1 c y1 r4 r2 r1 r3 4 com r2 7 1 r2 5 8 com r2 r1 = dehum relay r2 = high ambient relay r3 = full load relay r4 = blower interlock relay field wire crv vent speed mis-3272 unit low v...

Page 39

Manual 2100-549g page 39 of 59 med. Hi 7961-7554 m otor speeds lo med. Lo hi 375 vent option intake/exhaust speeds brown/white black blue orange red hi black blue speed nom. Cfm red wire with white trace. 300 wire color 450 525 lo med-lo med-hi orange move brown/white wire to corresponding motor spe...

Page 40

Manual 2100-549g page 40 of 59 i-tec energy recovery ventilator system general description the i-tec energy recovery ventilator (erv) was designed to provide energy efficient, cost effective ventilation to meet i.A.Q (indoor air quality) requirements while still maintaining good indoor comfort and h...

Page 41

Manual 2100-549g page 41 of 59 recommended control sequences several possible scenarios are listed below: 1. Use a programmable electronic thermostat with auxiliary terminal to control the erv based on daily programmed occupance periods. Bard markets and recommends bard part #8403-060 programmable e...

Page 42

Manual 2100-549g page 42 of 59 legend: vlt = ventilation load – total vls = ventilation load – sensible vll = ventilation load – latent hrt = heat recovery – total hrs = heat recovery – sensible hrl = heat recovery – latent wvl = winter ventilation load whr = winter heat recovery note: all performan...

Page 43

Manual 2100-549g page 43 of 59 figure 25a erv “manual mode” jumper pin on “m” terminal figure 25b erv “modulating mode” jumper pin on “p” terminal erv cfm flow index (light blink code) 450 100 425 89 400 83 375 76 350 59 325 50 300 40 275 32 250 25 225 12 200 9 175 4 150 1 to adjust the airflow vent...

Page 44

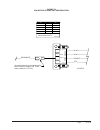

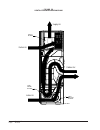

Manual 2100-549g page 44 of 59 figure 26 ventilation airflow diagram exhaust return air indoor air vent outdoor air blower blower intake supply air vent supply blower mis-3024.

Page 45

Manual 2100-549g page 45 of 59 figure 27 erv access erv door to access erv components assemblies remove (5) screws from panel location mis-3025 erv control erv cassette note: erv exhaust blower is behind intake blower erv intake blower.

Page 46

Manual 2100-549g page 46 of 59 figure 28 control board configuration/setting configuring bard part #8403-067 co 2 control for erv modulating control bard part #8403-067 carbon dioxide and temperature transmitters accurately monitorthe co2concentration and temperature in schools, office buildings, an...

Page 47

Manual 2100-549g page 47 of 59 configuring bard part #8403-067 co 2 control for erv modulating control (continued) mounting 1. Push tab on bottom of cover and lift cover from back plate. 2. Select the mounting location, away from diffusers, lights or any external influences. 3. Mount transmitter on ...

Page 48

Manual 2100-549g page 48 of 59 menu descriptions ron relay on set point sets the co 2 concentration which the optional relay is energized. Low limit: 0 ppm factory setting: 1000 ppm high limit: 2000/5000 ppm (depending on model) rof relay off set point sets the co 2 concentration which the optional ...

Page 49

Manual 2100-549g page 49 of 59 energy recovery ventilator maintenance general information the ability to clean exposed surfaces within air moving systems is an important design consideration for the maintenance of system performance and air quality. The need for periodic cleaning will be a function ...

Page 50

Manual 2100-549g page 50 of 59 figure 29 annual maintenance 1. Inspect and conduct the same procedures as outlined under quarterly maintenance. 2. To maintain peak latent (moisture) removal capac- ity, it is recommended that the energy recovery wheels be sprayed with a diluted nonacid based evaporat...

Page 51: Troubleshooting

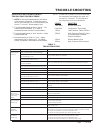

Manual 2100-549g page 51 of 59 troubleshooting solid state heat pump control troubleshooting procedure 1. Note: a thorough understanding of the defrost cycle sequence is essential. Review that section earlier in this manual prior to troubleshooting the control. Turn on ac power supply to unit. 2. Tu...

Page 52

Manual 2100-549g page 52 of 59 checking temperature sensor 1. Disconnect temperature sensor from board and from right-hand outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance use s...

Page 53

Manual 2100-549g page 53 of 59 troubleshooting ecm™ 142r outdoor fan motor you must obtain the correct replacement motor from the manufacturer that is a direct replacement for the failed motor. Using the wrong motor voids all warranties and may produce unexpected results. Do not operate motor withou...

Page 54

Manual 2100-549g page 54 of 59 troubleshooting ecm™ 142r outdoor fan motor • line power is connected as follows: “red wire” connects to “l1” “black wire” connects to “l2” “green/yellow wire” connects to “ground” • control power is connected as follows: “blue wire” connects to fan relay of the defros...

Page 55

Manual 2100-549g page 55 of 59 troubleshooting indoor ecm™ blower motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom ca...

Page 56

Manual 2100-549g page 56 of 59 troubleshooting indoor ecm™ blower motors (cont’d.) replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory ...

Page 57

Manual 2100-549g page 57 of 59 fan blade setting dimensions the position of the fan blade should be flush with the leaving face of the orifice plate. Check to make sure the blades do not extend beyond the rear casing of the unit. Spin the blade by hand to make sure it does not hit the ring. Refriger...

Page 58

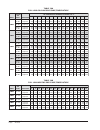

Manual 2100-549g page 58 of 59 table 10a full load cooling pressure/temperature l e d o m n r u t e r r i a . P m e t e r u s s e r p f ° l i o c r o o d t u o g n i r e t n e e r u t a r e p m e t r i a 5 5 0 6 5 6 0 7 5 7 0 8 5 8 0 9 5 9 0 0 1 5 0 1 0 1 1 5 1 1 0 2 1 5 2 1 1 h 0 3 i b d 5 7 b w 2 ...

Page 59

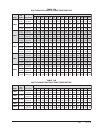

Manual 2100-549g page 59 of 59 table 11a part load cooling pressure/temperature l e d o m n r u t e r r i a . P m e t e r u s s e r p f ° l i o c r o o d t u o g n i r e t n e e r u t a r e p m e t r i a 5 5 0 6 5 6 0 7 5 7 0 8 5 8 0 9 5 9 0 0 1 5 0 1 0 1 1 5 1 1 0 2 1 5 2 1 1 h 0 3 i b d 5 7 b w 2 ...