- DL manuals

- Bard

- Air Conditioner

- K36A2-A

- Installation Instructions Manual

Bard K36A2-A Installation Instructions Manual

Page

1 of 24

WALL-MOUNTED PACKAGED

AIR CONDITIONER

Models:

K36A2-A

K36A2-N

K42A2-A

K42A2-N

K48A2-A

K48A2-N

INSTALLATION INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual: 2100-628

Supersedes:

NEW

Date: 12-1-14

K60A2-A

K60A2-N

K36L2-A

K36L2-N

K42L2-A

K42L2-N

K48L2-A

K48L2-N

K60L2-A

K60L2-N

Summary of K36A2-A

Page 1

Page 1 of 24 wall-mounted packaged air conditioner models: k36a2-a k36a2-n k42a2-a k42a2-n k48a2-a k48a2-n installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual: 2100-628 supersedes: new date: 12-1-14 k60a2-a k60a2-n k36l2-a k36l2-n k42l2-a k42l2-n k48l...

Page 2: Contents

Manual 2100-628 page 2 of 24 contents figures figure 1 unit dimensions ................................... 7 figure 2 mounting instructions – k36, 42, 48, 60 ...... 8 figure 3 electric heat clearance ......................... 9 figure 4 wall mounting instructions .................. 10 figure 5 wall ...

Page 3

Manual 2100628 page 3 of 24 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Nationa...

Page 4

Manual 2100-628 page 4 of 24 wall-mount general information air conditioner wall-mount model nomenclature k 42 a 2 – a 05 n p x x x j shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact th...

Page 5

Manual 2100628 page 5 of 24 duct work all duct work, supply and return, must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acca) is an excellent guide to proper sizing. All duct work or portions thereof not in the conditioned space sh...

Page 6: Installation

Manual 2100-628 page 6 of 24 clearances required for service access and adequate condenser airflow models left side right side discharge side k36a, k42a, k48a, k60a 20" 20" 10' k36l, k42l, k48l, k60l 20" 20" 10' minimum clearances required to combustible materials models supply air duct first three ...

Page 7

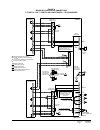

Manual 2100628 page 7 of 24 figure 1 all dimensions are in inches. Dimensional drawings are not to scale. Dimensions of basic unit for architectural and installation requirements (nominal) model width (w) depth (d) height (h) supply return a b c b e f g i j k l m n o p q r s t k36a/l k42a/l 42.075 2...

Page 8

Manual 2100-628 page 8 of 24 figure 2 k36a2, k36l2, k42a2, k42l2, k48a2, k48l2, k60a2, k60l2 mounting instructions d 16" 16" 16" 16" 16" 1 7 8 " 6 1 2 " 6 1 2 " 2 1 8 " 7 8 " 1" 3" 4" ty p. 4" ty p. 6 1 2 " 30" e 16" a c c 3 1 8 " b w all opening and hole lo ca tion view re turn air 1 req ui re d di...

Page 9: Warning

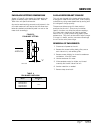

Manual 2100628 page 9 of 24 figure 3 electric heat clearance k36a2, k36l2, k42a2, k42l2, k48a2, k48l2, k60a2, k60l2 warning a minimum of 1/4 inch clearance must be maintained between the supply air duct and combustible materials. This is required for the first 3 feet of ducting. It is important to i...

Page 10

Manual 2100-628 page 10 of 24 figure 4 wall mounting instructions figure 5 wall mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on openi...

Page 11

Manual 2100628 page 11 of 24 figure 6 common wall mounting installations lowered raised floor rafters supply air ceiling surface wall sleeve return air closet wall grille flashing return air flashing supply duct maybe located in an attic or below ceiling rafters as shown supply duct may be located i...

Page 12

Manual 2100-628 page 12 of 24 wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse or circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount of current. D...

Page 13

Manual 2100628 page 13 of 24 humidity control option when two units are controlled and connected with the mv4001k-b, they can be adapted to perform dehumidification with the addition of a simple humidity controller that closes-on-rise, and is connected to terminals "h1" and "h2" on the main controll...

Page 14

Manual 2100-628 page 14 of 24 figure 7 thermostat connections.

Page 15

Manual 2100628 page 15 of 24 figure 8 mv4001k-b controller connections 1-stage (k**a/k**l series) air conditioners – no economizer cu, and silver must note: all sensors are polarity sensitive. Copper lead must connect to lead to ag 48 vdc - + circuit breaker 2 e f 2 3 e f 3 41 44 42 mv4001 controlle...

Page 16: Start Up

Manual 2100-628 page 16 of 24 start up these units require r-410a refrigerant and polyol ester oil. General 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi...

Page 17

Manual 2100628 page 17 of 24 important installer note for improved start up performance wash the indoor coil with a dish washing detergent. High pressure switch all k**a/k**l wall mounted air conditioner series models are supplied with a remote reset for the high and low pressure switch. If tripped,...

Page 18

Manual 2100-628 page 18 of 24 sequence of operation cooling – circuit r-y makes at thermostat pulling in compressor contactor, starting the compressor and outdoor motor. (see note on previous page under condenser fan operation if equipped with low ambient control.) the g (indoor motor) circuit is au...

Page 19: Service

Manual 2100628 page 19 of 24 service figure 9 fan blade setting table 4 fan blade dimension r-410a refrigerant charge this unit was charged at the factory with the quantity of refrigerant listed on the serial plate. Ahri capacity and efficiency ratings were determined by testing with this refrigeran...

Page 20

Manual 2100-628 page 20 of 24 troubleshooting constant torque ecm motors if the motor is running 1. It is normal for the motor to rock back and forth on start up. Do not replace the motor if this is the only problem identified. 2. If the system is excessively noisy, does not appear to change speeds ...

Page 21

Manual 2100628 page 21 of 24 communication diagnostics the motor is communicated through 24 vac low voltage (thermostat control circuit wiring). 1. Start with unit wiring diagram to confirm proper connections and voltage (see figure 11). 2. Initiate a demand from the thermostat and check the voltage...

Page 22

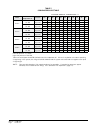

Manual 2100-628 page 22 of 24 table 5 cooling pressure table outdoor ambient temperature °c low side pressure ± 4 psig high side pressure ± 10 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the char...

Page 23

Manual 2100628 page 23 of 24 table 6 electrical specifications model rated volts, hertz & phase no. Field power circuits single circuit minimum circuit ampacity maximum external fuse or ckt. Brkr. Field power wire size ground wire k36a2-a0z 208/230-60-1 1 -a05 1 k36a2-n0z 400-60-3 1 8.2 10 14 14 -n0...

Page 24

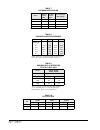

Manual 2100-628 page 24 of 24 table 9 maximum esp of operation electric heat only values shown are for units equipped with standard 1-inch throwaway filter or 1-inch washable filter. Derate esp by .15 for 2-inch pleated filters. Model k36a/l, k42a/l, k48a/l, k60a/l outlet front speed high low -a0z -...