- DL manuals

- Bard

- Air Conditioner

- LC5000

- Installation And Service Instructions Manual

Bard LC5000 Installation And Service Instructions Manual

Page

1 of 82

AIR CONDITIONER MODELS

W48A2PQ W48L2PQ

W60A2PQ W60L2PQ

W72A2PQ W72L2PQ

CONTROLLER MODEL

LC5000-100

NOTE: BARD-LINK

™

LC5000-100 Controller is required for operation when

multiple W***2PQ units are used.

INSTALLATION AND

SERVICE INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual :

2100-642

Supersedes:

NEW

Date: 9-15-15

FREE COOLING UNIT SYSTEM

WALL-MOUNTED PACKAGE

AIR CONDITIONER(S)

&

BARD-LINK™ PLC

LEAD/LAG CONTROLLER

Summary of LC5000

Page 1

Page 1 of 82 air conditioner models w48a2pq w48l2pq w60a2pq w60l2pq w72a2pq w72l2pq controller model lc5000-100 note: bard-link ™ lc5000-100 controller is required for operation when multiple w***2pq units are used. Installation and service instructions bard manufacturing company, inc. Bryan, ohio 4...

Page 2: Contents

Manual 2100-642 page 2 of 82 figures and tables figure 1.1 w-series model nomenclature .................8 figure 1.2 dimensions ..........................................10 figure 1.3 mounting instructions ...........................12 figure 1.4 electric heat clearance .........................13 f...

Page 3: General Information

Manual 2100-642 page 3 of 82 general information free cooling unit system the bard free cooling unit system is composed of wall-mounted air conditioners matched with a bard-link tm plc lead/lag controller or thermostat. The wall mounts are specifically engineered for telecom motor control center roo...

Page 4

Manual 2100-642 page 4 of 82 additional publications these publications can help when installing the furnace. They can usually be found at the local library or purchased directly from the publisher. Be sure to consult the current edition of each standard. National electrical code ......................

Page 5: Warning

Manual 2100-642 page 5 of 82 ansi z535.5 definitions: danger: indicate[s] a hazardous situation which, if not avoided, will result in death or serious injury. The signal word “danger” is to be limited to the most extreme situations. Danger [signs] should not be used for property damage hazards unles...

Page 6

Manual 2100-642 page 6 of 82.

Page 7: Section 1:

Manual 2100-642 page 7 of 82 section 1: installation instructions.

Page 8

Manual 2100-642 page 8 of 82 list of necessary materials/tools additional hardware and miscellaneous supplies are needed for installation. These items are field supplied and must be sourced before installation. This list also includes tools needed for installation. List of materials/tools • personal...

Page 9: Site Preparation

Manual 2100-642 page 9 of 82 site preparation new shelter installation vs. Retrofit installation these installation instructions cover both new shelter installations and retrofit installations. Each installation is unique and may require special accomodations and modifications. Although bard manufac...

Page 10

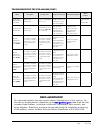

Manual 2100-642 page 10 of 82 figure 1.2 dimensions of basic unit for architectural and installation requirements (nominal) all dimensions are in inches. Dimensional drawings are not to scale. Model width (w) depth (d) depth total (dt) height (h) supply return a b c b e f g i j k l m n o p q r s t w...

Page 11: Wall-Mount Unit Installation

Manual 2100-642 page 11 of 82 5. If desired, hook top rain flashing (attached to front- right of supply flange for shipping) under back bend of top. 6. Position unit in opening and secure with 5/16" lag/ anchor/carriage bolts; use 7/8" diameter flat washers on the lag bolts. It is recommended that a...

Page 12

Manual 2100-642 page 12 of 82 figure 1.3 mounting instructions d 16" 16" 16" 16" 16" 1 7 8 " 6 1 2 " 6 1 2 " 2 1 8 " 7 8 " 1" 3" 4" ty p. 4" ty p. 6 1 2 " 30" e 16" a c c 3 1 8 " b foa m ai r seal w all opening and hole loc ation view 2 duct supp ly o pen ing 1/ 4" m in .C lea ra nc e fr om co m bu ...

Page 13

Manual 2100-642 page 13 of 82 figure 1.4 electric heat clearance figure 1.5 wall mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on open...

Page 14

Manual 2100-642 page 14 of 82 figure 1.6 wall mounting instructions i a c k e + 1.000 b 1.000 supply duct over frame interior finished wall all around duct framing material exterior finish wall opening for actual dimensions. 2 x 4's, 2 x 6's &/or structural steel attach to top 1.000" clearance 1.000...

Page 15: Warning

Manual 2100-642 page 15 of 82 wall-mount unit supply wiring refer to the unit rating plate or table 1.1 for wire sizing information and maximum fuse or circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. The field wiring used must be sized to carry that amount of cur...

Page 16

Manual 2100-642 page 16 of 82 figure 1.9 vac supply wiring landing points note: right-hand access model wiring landing points are shown here; left-hand access models will mirror this image. The electrical data lists fuse and wire sizes (75°c copper) for all models including the most commonly used he...

Page 17

Manual 2100-642 page 17 of 82 figure 1.10 adjusting the vac transformer it is very important that the transformer is wired for the correct 575v voltage 2. Confirm correct wires are connected: for 575v, the gray (575) and black (common) transformer wires must be used. Shelter supply breaker in on pos...

Page 18: Preliminary Start-Up

Manual 2100-642 page 18 of 82 preliminary start-up running in stand alone (orphan) mode with the ac breakers turned on, each w-series wall-mount system has the capability to run without the plc controller attached—this feature is called stand alone or orphan mode, and it basically keeps the shelter ...

Page 19: Bard-Link

Manual 2100-642 page 19 of 82 bard-link tm controller installation figure 1.11 typical lc5000 wiring plc board smoke alarm jumper rj11 cable to display power input 120v, 230v & 240v transformer ethernet cable connection zone 1, 2 & 3 sensor shielded wires web card rs485 communication cable.

Page 20: Warning

Manual 2100-642 page 20 of 82 lc5000-100 controller the bard-link tm lc5000-100 controller is part of the wall mount free cooling unit system. It is used to control up to 12 wall-mount air conditioners from one controller. The microprocessor control provides an easy-to-read interface with large lcd ...

Page 21

Manual 2100-642 page 21 of 82 figure 1.12 remote indoor temperature/humidity sensor installation 1. Connect wires from the 18 gauge shielded cable to terminals #6, #7, #17, #18 and #19. 2. Connect the other end of the shielded cable to the sensor terminals. Be sure wires are connected to proper term...

Page 22

Manual 2100-642 page 22 of 82 one additional temperature sensor can be added to zone 1 and additional temperature/humidity sensors may be added to zones 2 and 3 (one per zone). Be sure the sensors are connected to the proper terminals as listed below. Figure 1.13 additional remote temperature and te...

Page 23

Manual 2100-642 page 23 of 82 figure 1.14 power and signal connections for smoke detector 3. Smoke alarm the lc5000 plc controller is shipped with smoke detector contacts. There is a factory-installed jumper across terminals #23 and #24. If there is no smoke detector, no action is necessary. If smok...

Page 24

Manual 2100-642 page 24 of 82 bard-link tm controller wall-mount unit wall-mount unit figure 1.15 communication wiring 4. Communication wiring connect the communication wiring from the wall-mount units to the controller in the manner shown in figure 1.15. The communication wire should be 2-wire, 18 ...

Page 25

Manual 2100-642 page 25 of 82 1. Using the field-provided shielded cable, make a small service loop after entering the controller and attach the provided emi filter at the intersection of the loop. Figure 1.16 communication wiring: termination at the controller 2. Connect one wire to terminal #27 (n...

Page 26

Manual 2100-642 page 26 of 82 figure 1.17 communication wiring: termination at the first wall-mount unit 1. From the controller, extend the shielded cable through a separate conduit and route to the provided terminal block next to the wall-mount control board. Note that the terminal block label is c...

Page 27

Manual 2100-642 page 27 of 82 rs485 r+t+ / r-t- rs485 r+t+ / r-t- 1. Route the cable from the first wall-mount unit to the terminal block of the second wall-mount unit. Make a small service loop and attach emi filter as shown. Figure 1.18 communication wiring: termination at additional wall-mount un...

Page 28

Manual 2100-642 page 28 of 82 figure 1.19 bard-link tm lc5000-100 controller circuit install 6. Supply wiring the lc5000-100 controller is powered by 120/208/230 from the shelter. Field-supplied supply wiring should be minimum 16 guage, maximum 14 guage (see figure 1.19). A reliable earth ground mus...

Page 29

Manual 2100-642 page 29 of 82 table 1.2 terminal block index tb# wire mark description 1 115 vac input 2 208 vac input 3 240 vac input 4 power input common 5 power input ground 6 b1 indoor remote sensor (zone 1) 7 gnd ground 8 b2 indoor remote sensor (zone 1 – optional) 9 gnd ground 10 b3 indoor rem...

Page 30

Manual 2100-642 page 30 of 82 figure 1.21 lc5000 wiring diagram 4206-111 mat' l bard mfg. Co. Bry an, o hio rev da te rev isi on s appr ch k dr n ecn no . Dis tr ibu tio n 1 2 3 4 5 ch ecked na me dw g. No . Dr aw nby sca le no . Da te par t par t appr ov ed wir ed iag ra m ca l sd 6/5 /20 15 420 6-...

Page 31: System Start-Up

Manual 2100-642 page 31 of 82 system start-up the bard-link tm controller and tec-eye hand- held diagnostic tool will both be used to set up the controller and wall-mount units (see figure 1.24 on page 32). The tec-eye diagnostic tool is shipped inside the controller. 1. Set controller date and time...

Page 32

Manual 2100-642 page 32 of 82 figure 1.24 bard-link tm controller and tec-eye down key alarm key menu key up key enter key escape key alarm key allows viewing of active alarms silences audible alarms resets active alarms menu key allows entry to main menu escape key returns to previous menu level ca...

Page 33

Manual 2100-642 page 33 of 82 figure 1.25 status display showing units "online" 4. Verify communication to units check controller display to see that all units are "online". This typically takes 3-4 minutes after controller is powered. If all units are online, the display will appear as shown in fig...

Page 34

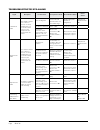

Manual 2100-642 page 34 of 82 figure 1.28 executing run test description default setpoint temperature at local remote (main) sensor -- temperature setpoint 77°f heating setpoint 60°f temperature high limit – level 1 85°f temperature high limit – level 2 (high temp alarm) 90°f temperature low limit 4...

Page 35: Section 2:

Manual 2100-642 page 35 of 82 section 2: service instructions.

Page 36

Manual 2100-642 page 36 of 82 general refrigerant information general 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi/250 psi low). 4. R-410a is a binary b...

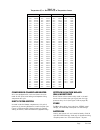

Page 37

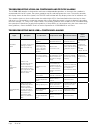

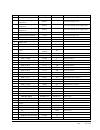

Manual 2100-642 page 37 of 82 model return air temperature pressure air temperature entering outdoor coil, degree °f 75 80 85 90 95 100 105 110 115 120 w48 75° db 62° wb low side high side 129 289 130 309 132 331 133 353 135 376 136 401 137 426 138 452 139 481 141 509 80° db 67° wb low side high sid...

Page 38: Sequence of Operation

Manual 2100-642 page 38 of 82 sequence of operation wall-mount unit sequence of operation overview this product is designed to function like a typical telecom air conditioning system with an outdoor air-cooling damper. However, the fcu system does have some special features, like a plc control which...

Page 39

Manual 2100-642 page 39 of 82 3. If after 2 minutes, the low pressure switch is still open, or opens again immediately aftward, the board will delay for 2 minutes again (soft lockout). 4. On the 3rd attempt, the board will lock out the compressor and outdoor fan until manually reset. • high temperat...

Page 40

Manual 2100-642 page 40 of 82 lc series plc controller sequence of operation overview the lc series plc controller is designed to operate up to 12 bard wall-mount units in a lead/lag fashion, while offering extensive alarming capabilities as well as remote communication. The duty of the plc controll...

Page 41

Manual 2100-642 page 41 of 82 figure 2.3 lc-5000 controller control board and terminal block lc-5000 control board 10 4 3 2 29 1 6 7 8 9 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 5 26 27 28 mis-3730 terminal block figure 2.4 lc-5000 controller control board –24vdc from transformer common for smok...

Page 42

Manual 2100-642 page 42 of 82 figure 2.5 free cooling damper operation free cooling can take place providing the outside air meets three (3) separate criteria: 1. The dewpoint must be below 60°f 2. The relative humidity must be below 80% 3. The outside air must be cooler than the current setpoint. W...

Page 43: Advanced Programming

Manual 2100-642 page 43 of 82 advanced programming figure 2.6 bard-link tm controller display alarm key allows viewing of active alarms silences audible alarms resets active alarms menu key allows entry to main menu escape key returns to previous menu level cancels a changed entry up key steps to ne...

Page 44

Manual 2100-642 page 44 of 82 controller interface menu structure on/off unit setpoints clock/scheduler input/output analog inputs digital inputs relay outputs analog outputs alarm history board switch technician information bms configuration service settings i/o configuration probe adjustment contr...

Page 45

Manual 2100-642 page 45 of 82 1. Press menu button to go to main menu. 2. Go to board switch menu, press enter. Display will show which unit or units are offline (see figure 2.11). Units offline will show up as "no device connected". In the example below, unit 3 is not showing up as online. 3. Check...

Page 46

Manual 2100-642 page 46 of 82 adjusting date and time 1. Go to clock/scheduler menu, press enter key. 2. Move the cursor to the selected choice by pressing the enter key. 3. Press up or down arrow keys to change the date and/or time. The day will automatically change when the date has been altered. ...

Page 47

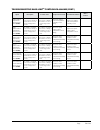

Manual 2100-642 page 47 of 82 description range default setpoint units temperature at local remote (main) sensor -- -- -- temperature setpoint 65 - 90 77 °f heating setpoint 52 -75 60 °f temperature high limit - level 1 70 - 120 85 °f temperature high limit - level 2 70 - 120 90 °f temperature low l...

Page 48: Using The Tec-Eye

Manual 2100-642 page 48 of 82 figure 2.14 tec-eye connection to unit control modular phone connector for tec-eye hand-held diagnostic tool using the tec-eye tec-eye hand-held diagnostic tool the microprocessor control used in this wall mount air conditioning system allows for complete control and mo...

Page 49

Manual 2100-642 page 49 of 82 tec-eye menu structure on/off unit setpoints clock/scheduler input/output analog inputs digital inputs relay outputs analog outputs alarm history board switch technician information working hours service settings i/o configuration probe adjustment control setting histor...

Page 50

Manual 2100-642 page 50 of 82 executing a run test execute a run test on each unit to verify the equipment is functioning correctly. 1. Go to technician menu, press enter key. 2. Press up or down arrow keys to get to service settings menu, press enter key. 3. Press up or down arrow keys to get to co...

Page 51

Manual 2100-642 page 51 of 82 compressor 1. Go to technician menu, press enter key. 2. Go to manual management, press enter key. 3. Go to relay output, press enter key. 4. Go to relay output cooling stage. Press up or down arrow keys to change manual relay to “on”; press enter key. Press up or down ...

Page 52: Componentry Specifications

Manual 2100-642 page 52 of 82 componentry specifications low pressure switch cut-out pressure: 40psi (+/- 4 psi) cut-in pressure: 55psi (+/- 4psi) high pressure switch cut-out pressure: 650psi (+/- 10 psi) cut-in pressure: 520psi (+/- 15psi) low ambient control modulating head-pressure control that ...

Page 53

Manual 2100-642 page 53 of 82 compressor crankcase heater units are equipped with crankcase heaters that are rated for the connnected voltage and operate during compressor off cycle. Dirty filter switch located inside the blower compartment, this switch measures air pressure differential across the ...

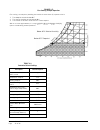

Page 54

Manual 2100-642 page 54 of 82 model dimension a all covered by this manual 1.75" figure 2.18 fan blade setting "a" airflow mis-1724 figure 2.19 dirty filter switch and airflow switch (two switches) table 2.5 indoor blower performance free cooling logic control derives at this decision point and swit...

Page 55

Manual 2100-642 page 55 of 82 figure 2.21 unit control panel mis-3732 contactor block disconect terminal terminal block filter switch toggle bracket ground plc controller block toggle sensor terminal "l1" 25 amp cable wire sheild terminal evap. Temp. Cable duct transformer block base monitior phase ...

Page 56

Manual 2100-642 page 56 of 82 figure 2.22 unit wiring diagram + 2....10 vdc 2....10 vdc 24 vac/vdc 1 com 2 + 3 y 5 u + damper actuator motor mixed air sensor no com nc hpc r y cc alr c m inu tes 1 2 3 4 5 lpc no nc 2 1 3 4 5 6 return air sensor 1 1 4 3 2 0 i toggle disconnect 11 20 8v c r co m 24 0v...

Page 57: Caution

Manual 2100-642 page 57 of 82 maintenance and troubleshooting standard maintenance procedures 4. Manually spin fan and blower motors to ensure they turn freely. All motors are permanently lubricated, so no oil is necessary. 5. Inspect free cooling damper actuator and linkage. 6. Install new air filt...

Page 58

Manual 2100-642 page 58 of 82 troubleshooting lc5000-100 controller and tec-eye alarms the lc5000-100 controller is designed for continuous and dependable operation. In the event that a problem is encountered with the a/c system, the system controller may be used to diagnose the cause. The system co...

Page 59

Manual 2100-642 page 59 of 82 signal description possible cause component to check recommended action device actions remote indoor temperature sensor failed alarm (b001) the alarm is activated if the sensor is faulty, a sensor wire is loose or an out-of-range value is read. The alarm is activated if...

Page 60

Manual 2100-642 page 60 of 82 signal description possible cause component to check recommended action device actions low pressure alarm if the alarm activates once or twice in an hour, it is reset automatically. If it occurs three times in an hour, the compressor and condenser fan are locked. Lack o...

Page 61

Manual 2100-642 page 61 of 82 signal description possible cause component to check recommended action device actions free cooling damper fails to close alarm alarm is reset automatically. Dc free cooling damper fails to close. Check the damper linkage. Check to see if anything is in the way of the d...

Page 62

Manual 2100-642 page 62 of 82.

Page 63: Section 3:

Manual 2100-642 page 63 of 82 section 3: appendix.

Page 64: Tec-Eye Architecture

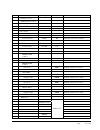

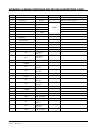

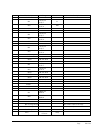

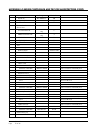

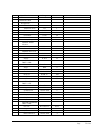

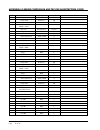

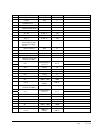

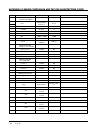

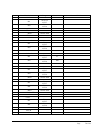

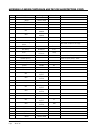

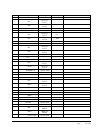

Manual 2100-642 page 64 of 82 screen menu item range default value description 1 main status screen date and time displays current date and time zone 1 temp degrees disaplays zone temp zone 2 temp degrees display zone temp if enabled zone 3 temp degrees display zone temp if enabled zone 1 humidity %...

Page 65

Manual 2100-642 page 65 of 82 screen menu item range default value description 29 last hour averages averages for the last hour zone 1 indoor average temperature degrees last hour average value zone 2 indoor average temperature degrees last hour average value if applicable zone 3 indoor average temp...

Page 66

Manual 2100-642 page 66 of 82 appendix: lc-series controller and tec-eye architecture (cont.) screen menu item range default value description rotate days 0-30 1 by alarm yes/no yes by demand yes/no yes mode rotation manual switch mode yes/no no by time yes/no no rotate days 0-99 days clock (cont.) ...

Page 67

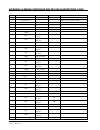

Manual 2100-642 page 67 of 82 screen menu item range default value description information (cont.) power cycle status last off time time/date last time controller powered off last on time time/date last time controller powered on length of last off time hours/minutes length of last off time unit set...

Page 68

Manual 2100-642 page 68 of 82 screen menu item range default value description bms port 1 (cont.) address 0-999 11 communications address baud rate 19200 19200 communications baud rate 9600 4800 2400 1200 service settings i/o config. Analog inputs zone 1 enable on/off on type normal/hi res normal, o...

Page 69

Manual 2100-642 page 69 of 82 screen menu item range default value description ohm x 5 min -3276.8 to 3276.7 0 max -3276.8 to 3276.8 100 offset -99.9 to 99.9 nu13 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 nu12 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 sp...

Page 70

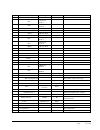

Manual 2100-642 page 70 of 82 screen menu item range default value description remote zone 1 same as zone temp 1 above remote zone 2 same as zone temp 1 above remote zone 3 same as zone temp 1 above humidity zone 1 same as zone temp 1 above enable on/off on type normal/hi res normal, 0-1vdc 4-20ma m...

Page 71

Manual 2100-642 page 71 of 82 screen menu item range default value description nu12 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 spkp0087to offset -99.9 to 99.9 nu10 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 10t170 offset -99.9 to 99.9 -50t90 offset -99.9 t...

Page 72

Manual 2100-642 page 72 of 82 screen menu item range default value description probe adjustment indoor temp indoor temp offset -9.9 to +9.9 control settings displays unit information service settings zone 1 average/highest average zone 2 average/highest average zone 3 average/highest average humidif...

Page 73

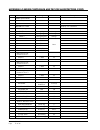

Manual 2100-642 page 73 of 82 screen menu item range default value description z2 high alarm 70-120 deg 85 z2 high alarm 2 70-120 deg 90 z3 high alarm 70-120 deg 85 z3 high alarm 2 70-120 deg 90 control dead band: zone 1 cool up differential -99.9 to 99.9 deg 2 down differential -99.9 to 99.9 deg -2...

Page 74

Manual 2100-642 page 74 of 82 screen menu item range default value current i/o value delay up 0 to 9999 sec 60 delay down 0 to 9999 sec 60 setpoint 77 control dead band: zone 3 heat up differential -99.9 to 99.9 deg 2 down differential -99.9 to 99.9 deg -2 delay up 0 to 9999 sec 60 delay down 0 to 9...

Page 75

Manual 2100-642 page 75 of 82 screen menu item range default value current i/o value 8 factory manufacturer configuration configuration temperature units f/c f pressure units psi/bar psi force clock enable yes/no yes clock mode 12/24 24 disable buzzer yes/no yes startup delay 0-9999 sec 30 sec dampe...

Page 76

Manual 2100-642 page 76 of 82 screen menu item range default value current i/o value delay up 0-999 sec 105 information only delay down 0-999 sec 60 setpoint 77 control deadband: zone 2 heat direction direct/reverse reverse stages 0-99 1 up differential -99.9 to 99.9 2 down differential -99.9 to 99....

Page 77

Manual 2100-642 page 77 of 82 screen menu item range default value current i/o value ht3/on 0-99 4 ht3/off 0-99 2 alarm delays airflow 0-99 sec 45 sec compressor delays min. On 0-999 sec 60 min. Off 0-999 sec 120 2 starts 0-999 sec 120 stage 2 0-999 sec 120 setpoint: refrigerant low pressure alarm s...

Page 78

Manual 2100-642 page 78 of 82 screen menu item range default value current i/o value modulating setup: humidifier zone 3 cntrl dir/rev/both p/pid/p+i/ rev, p band 0-999.9 20 deadbd 0-99.9 0 int 0-999 0 deriv 0-999 0 min -1000 to 1000 -1000 max -1000 to 1000 0 period 500ms to 9999ms 500 ms configurat...

Page 79

Manual 2100-642 page 79 of 82 screen menu item range default value current i/o value 0-1vdc min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 pt1000 offset -99.9 to 99.9 ntc offset -99.9 to 99.9 ohm x 1 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 ohm x 5 min -3276...

Page 80

Manual 2100-642 page 80 of 82 screen menu item range default value current i/o value -50t90 offset -99.9 to 99.9 ntcht offset -99.9 to 99.9 0-5vdc min -9999.9 to 9999.9 max -9999.9 to 9999.9 offset -99.9 to 99.9 current value out of range alarm will show if input out of range power delay 0-999 sec 5...

Page 81

Manual 2100-642 page 81 of 82 screen menu item range default value current i/o value ohm x 1 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9 to 99.9 ohm x 5 min -3276.8 to 3276.7 0 max -3276.8 to 3276.8 100 offset -99.9 to 99.9 0 nu13 min -3276.8 to 3276.7 max -3276.8 to 3276.8 offset -99.9...

Page 82

Manual 2100-642 page 82 of 82 screen menu item range default value current i/o value out of range alarm will show if input out of range power delay 0-999 sec 5 sec power up delay run delay 0-999 sec 5 sec units temp /other/ pressure other humidity zone 2 same as humidity zone 1 above humidity zone 3...