Page 1 of 26 bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual : 2100-665d supersedes: 2100-665c date: 3-5-18 note: lc6000 controller is required for operation when multiple multi-tec wall-mount air conditioners are used. Service instructions multi-tec ® wall-mount air condi...

Manual 2100-665d page 2 of 26 figures and tables figure 1 multi-tec wall-mount unit model nomenclature ........................................3 figure 2 tec-eye display and interface ................6 figure 3 tec-eye connection to unit control ........6 figure 4 quick menu icons .....................

Manual 2100-665d page 3 of 26 general information reference supplemental instructions 7960-801 for complete details. Free cooling unit system the bard free cooling unit system is composed of multi-tec wall-mounted air conditioners matched with an lc6000 supervisory controller or bard th- tune stand-...

Manual 2100-665d page 4 of 26 sizing of systems for proposed installation should be based on heat loss and heat gain calculations made according to methods of air conditioning contractors of america (acca). The air duct should be installed in accordance with the standards of the national fire protec...

Manual 2100-665d page 5 of 26 electrical shock hazard. Have a properly trained individual perform these tasks. Failure to do so could result in electric shock or death. ! Warning fire hazard. Maintain minimum 1/4" clearance between the supply air duct and combustible materials in the first 3' feet o...

Manual 2100-665d page 6 of 26 figure 3 tec-eye connection to unit control modular phone connector for tec-eye hand-held diagnostic tool using the tec-eye tm tec-eye hand-held diagnostic tool the microprocessor control used in the multi-tec wall-mount air conditioners allows for complete control and ...

Manual 2100-665d page 7 of 26 it is important to check the software version during installation to ensure that the latest version has been installed. Current software versions, change log and installation instructions are available on the bard website at http://www.Bardhvac.Com/software-download/ no...

Manual 2100-665d page 8 of 26 quick menu setpoints if at any time the unit(s) loses communication with the lc6000 controller, the unit(s) will go to stand alone mode. The setpoints are synced with the lc6000 when communication is established. The unit will save and control to these values until comm...

Manual 2100-665d page 9 of 26 figure 7 executing run test time/date/timezone sync on multi-tec wall-mount unit models with a software version number mts1000.2.0.0 and higher, when the wall-mount unit is connected and correctly addressed to a lc6000 supervisory controller, local time, date, and timez...

Manual 2100-665d page 10 of 26 alarms note: screenshots shown in this manual reflect default settings (when applicable). Acknowledging/clearing alarms alarm conditions activate a red led indicator that backlights the alarm function key. As an option, an alarm condition may also be enunciated by an a...

Manual 2100-665d page 11 of 26 alarm adjustment mixed air alarm the mixed air alarm is used to indicate proper operation of the economizer. An alarm will be generated when the mixed air temperature is above or below two independent setpoints. This alarm can be adjusted by changing the alarm setpoint...

Manual 2100-665d page 12 of 26 figure 12 adjusting damper alarm values 4. Press up or down keys to scroll to alarm config (a7) ; press enter key. 5. Press enter key to scroll to desired value oat , diff , del , ldel or two count del (see figure 11). 6. Press up or down keys to adjust value. 7. Press...

Manual 2100-665d page 13 of 26 note: screenshots shown in this manual reflect default settings (when applicable). On/off control the wall-mount unit can be turned on and off with the tec-eye. When the unit is set to on, the system will heat and cool the space either in standalone mode or when connec...

Manual 2100-665d page 14 of 26 to adjust these parameters: 1. Press menu key to go to the main menu screen. 2. Press up or down keys and enter key to enter user password 2000. 3. Press up or down keys to scroll to sys config ; press enter key. 4. Press up or down keys to scroll to cooling setup (a2)...

Manual 2100-665d page 15 of 26 freecooling if the unit is equipped with an economizer, and conditions are acceptable for economizer operation, the multi-tec wall-mount unit will utilize freecooling operation before the use of any cooling operation requiring compressor operation to reduce the energy ...

Manual 2100-665d page 16 of 26 3. Press up or down keys to scroll to sys config ; press enter key. 4. Press up or down keys to scroll to unit config (a6) ; press enter key. 5. Press enter key to scroll to mixed fc set , gain , integral or derivative (see figure 20). 6. Press up or down keys to adjus...

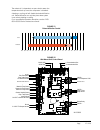

Manual 2100-665d page 17 of 26 mis-3869 dirty filter switch + communication wire - communication wire 24vac gnd 24vac hot 24vac + y to compressor ccm 24vac + stage 1 heat stage 1 heat blower relay 24vac + ground 2-10 vdc to damper actuator analog ground evap. Temp sensor 24 vdc to outdoor air sensor...

Manual 2100-665d page 18 of 26 general refrigerant information general 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi/250 psi low). 4. R-410a is a binary ...

Manual 2100-665d page 19 of 26 table 4 multi-tec cooling pressures air temperature entering outdoor coil °f low side pressure ± 4 psig high side pressure ± 10 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the ...

Manual 2100-665d page 20 of 26 componentry electrical shock hazard. Disconnect vac power supply before servicing. Failure to do so could result in electric shock or death. ! Warning high pressure switch all w**a/w**l wall-mount air conditioner series models are supplied with a high pressure switch. ...

Manual 2100-665d page 21 of 26 module (ccm) also monitors the high pressure switch, and will allow one automatic retry (after soft lockout delay) before disabling the compressor in a hard lockout (requires manual reset). If hard lockout does occur, the alr terminal on the ccm will become active with...

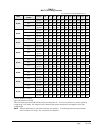

Manual 2100-665d page 22 of 26 w18a**a w24a**a w24a**b w24a**c w30a**a w30a**b w30a**c w36a**a w36a**b w36a**c w42a**a w42a**b w42a**c w48a**a w48a**b w48a**c w60a**a w60a**b w60a**c w72a**a w72a**b w72a**c table 5a multi-tec optional accessories – right hand ehw2ta-a05 x x ehw2ta-a08 x x ehw2ta-a10...

Manual 2100-665d page 23 of 26 table 5b multi-tec optional accessories – left hand w18l**a w24l**a w24l**b w30l**a w30l**b w30l**c w36l**a w36l**b w36l**c w42l**a w42l**b w42l**c w48l**a w48l**b w48l**c w60l**a w60l**b w60l**c w72l**a w72l**b w72l**c ehw2ta-a05l x x ehw2ta-a08l x x ehw2ta-a10l x x e...

Manual 2100-665d page 24 of 26 maintenance and troubleshooting standard maintenance procedures 4. Manually spin fan and blower motors to ensure they turn freely. All motors are permanently lubricated, so no oil is necessary. 5. Inspect free cooling damper actuator and linkage. 6. Install new air fil...

Manual 2100-665d page 25 of 26 troubleshooting nidec selectech series ecm motors if the motor is running 1. It is normal for the motor to rock back and forth on start up. Do not replace the motor if this is the only problem identified. 2. If the system is excessively noisy, does not appear to change...

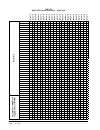

Figure 25 motor connections manual 2100-467h page 23 of 23 figure 11 troubleshooting ge x13-series ecm2.3 ™ motors cont’d. Model x13 communication diagnostics the x13 motor is communicated through 24 vac low voltage (thermostat control circuit wiring). 1. Start with unit wiring diagram to confirm pr...