- DL manuals

- Bard

- Air Conditioner

- PA13241-A

- Installation Instructions Manual

Bard PA13241-A Installation Instructions Manual

Manual 2100-467D

Page

1 of 25

SINGLE PACKAGE

AIR CONDITIONERS

MODELS

PA13241-A

PA13301-A

PA13361-A

PA13361-B

PA13422-A

PA13422-B

PA13422-C

PA13482-A

PA13482-B

PA13482-C

PA13602-A

PA13602-B

PA13602-C

INSTALLATION INSTRUCTIONS

Manual :

2100-467D

Supersedes:

2100-467C

File:

Volume II Tab 10

Date:

08-12-08

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914 . . . Moving ahead just as planned.

© Copyright 2006

Summary of PA13241-A

Page 1

Manual 2100-467d page 1 of 25 single package air conditioners models pa13241-a pa13301-a pa13361-a pa13361-b pa13422-a pa13422-b pa13422-c pa13482-a pa13482-b pa13482-c pa13602-a pa13602-b pa13602-c installation instructions manual : 2100-467d supersedes: 2100-467c file: volume ii tab 10 date: 08-12...

Page 2

Manual 2100-467d page 2 of 25 contents getting other informations and publications ........ 3 general instructions important ................................................................ 4 shipping damage .................................................... 4 general ................................

Page 3

Manual 2100-467d page 3 of 25 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-467d page 4 of 25 general instructions important the equipment covered in this manual is to be installed by trained, experienced service and installation technicians. All duct work, supply and return ducts, must be properly sized for the design airflow requirement of the equipment. Acca ...

Page 5

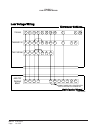

Manual 2100-467d page 5 of 25 table 2 electrical specifications l e d o ma - 1 4 2 3 1 a pa - 1 0 3 3 1 a pa - 1 6 3 3 1 a pb - 1 6 3 3 1 a pa - 2 2 4 3 1 a pb - 2 2 4 3 1 a pc - 2 2 4 3 1 a pa - 2 8 4 3 1 a pb - 2 8 4 3 1 a pc - 2 8 4 3 1 a pa - 2 0 6 3 1 a pb - 2 0 6 3 1 a pc - 2 0 6 3 1 a p – g n...

Page 6

Manual 2100-467d page 6 of 25 table 3 optional field installed heater packages only to be used with the models indicated e g a k c a p r et a e h l e d o m & stl o v e s a h pa - 1 4 2 3 1 a pa - 1 0 3 3 1 a pa - 1 6 3 3 1 a pb - 1 6 3 3 1 a pa - 2 2 4 3 1 a pb - 2 2 4 3 1 a pc - 2 2 4 3 1 a pa - 2 ...

Page 7

Manual 2100-467d page 7 of 25 table 4 optional field installed electric heater table r et a e h e g a k c a p . O n l e d o m stl o v ti n u s e s a h p yti c a p a c & w k .R t h stl o v 0 4 2 @ yti c a p a c & w k .R t h stl o v 8 0 2 @ v 8 0 2/ 0 4 2 .R t h s p m a r et a e h l a nr et ni ti u cr...

Page 8

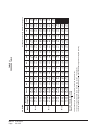

Manual 2100-467d page 8 of 25 figure 1 dimensions of units mis-2142 unit dimension chart condenser air intake grille condenser air intake grille blower motor access door condenser fan g 47 11/16" h compressor access door control panel door heater package access panel return opening supply opening dr...

Page 9

Manual 2100-467d page 9 of 25 installation location general the unit must be located outside, or in a well ventilated area. It must not be in the space being heated or cooled. A sound absorbing material should be considered if the unit is to be installed in such a position or location that might cau...

Page 10: Side

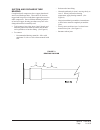

Manual 2100-467d page 10 of 25 24" min. 36" min. 24" min. The distance between 1 inch clearance air inlet air inlet supply and return ducts building heater package access control panel access blower service access blower and blower motor heater package control panel comp- ressor nearest structure ne...

Page 11

Manual 2100-467d page 11 of 25 figure 4 elevated mounting platform 48" min. 32°f or lower climate 12" min. If in on surface of platform both legs must rest 48" min. 32°f or lower climate 12" min. If in on surface of platform both legs must rest metal frame mis-2144 platform can be as shown or solid ...

Page 12

Manual 2100-467d page 12 of 25 figure 5 condensate drain trap 5. Other installations – many other installations are possible with the packaged air conditioner. No matter what the installation, always consider the following facts: a. Insure that the discharge air is not obstructed in any way so as to...

Page 13

Manual 2100-467d page 13 of 25 table 6 thermostat wire size a v r e m r o f s n a r t a l f e g u a g e r i w m u m i x a m e c n a t s i d t e e f n i 5 5 3 . 2 0 2 8 1 6 1 4 1 2 1 5 4 0 6 0 0 1 0 6 1 0 5 2 transformer taps 230/208v, 1 phase and 3 phase equipment employ dual primary voltage transfo...

Page 14: Unit Control Panel

Manual 2100-467d page 14 of 25 l unit control panel c e y w2 o g mis-2149 b y terminal r g c heat on units with 15 or more kw c low voltage wiring b r w rc r y1 l g c g block r e y l thermostat subbase 3 1 2 w1 w2 f rc b unit 24v remove jumper for 2 stage electric b yo 1120-445 aux e a d y2 o w1 e t...

Page 15

Manual 2100-467d page 15 of 25 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 p...

Page 16

Manual 2100-467d page 16 of 25 three phase scroll compressor start up information (model pa13361-b) scroll compressors, like several other types of compressors, will only compress in one rotational direction. Direction of rotation is not an issue with single phase compressors since they will always ...

Page 17

Manual 2100-467d page 17 of 25 adjustable delay-on-make and break timer on a call for compressor operation the delay-on-make period begins which will be 10% of the delay-on-break setting. When the delay-on-make is complete and the high pressure switch (and low pressure switch if employed) is closed,...

Page 18

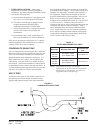

Manual 2100-467d page 18 of 25 fan blade settings shown in figure 8 are the correct fan blade setting dimensions for proper air delivery across the outdoor coil. Any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions below be checked and blade ...

Page 19

Manual 2100-467d page 19 of 25 (continued on page 20 in table 11) l e d o m ri a nr ut e r er ut ar e p m e t er u s s er p° 5 6° 0 7° 5 7° 0 8° 5 8° 0 9° 5 9° 0 0 1° 5 0 1° 0 1 1° 5 1 1° 0 2 1° 5 2 1 4 2 3 1 a p 5 7 ° b d 2 6 ° b w e di s w o l e di s h gi h 5 2 1 8 3 2 7 2 1 2 6 2 9 2 1 6 8 2 1 3 ...

Page 20

Manual 2100-467d page 20 of 25 table 11 pressure table cooling air t emperature entering out door coil degree f low side pressure +2 psig high side pressure +5 psig l e d o m ri a nr ut e r er ut ar e p m e t er u s s er p° 5 6° 0 7° 5 7° 0 8° 5 8° 0 9° 5 9° 0 0 1° 5 0 1° 0 1 1° 5 1 1° 0 2 1° 5 2 1 ...

Page 21

Manual 2100-467d page 21 of 25 suction and discharge tube brazing compliant scroll compressors have copper plated steel suction and discharge tubes. These tubes are far more rugged and less prone to leaks than copper tubes used on other compressors. Due to different thermal properties of steel and c...

Page 22

Manual 2100-467d page 22 of 25 note: affects models pa13241, pa13301, pa13361 troubleshooting ge ecm 2.3 ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5...

Page 23

Manual 2100-467d page 23 of 25 troubleshooting ge ecm2.3 ™ motors cont’d. Replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programme...

Page 24

Manual 2100-467d page 24 of 25 figure 13 ↓ ↓ note: bard models pa13422, pa13482 & pa13602 contain the x13-series motors. Troubleshooting ge x13-series ecm2.3 ™ motors if the motor is running 1. It is normal for the motor to rock back and forth on start up. Do not replace the motor if this is the onl...

Page 25

Manual 2100-467d page 25 of 25 figure 14 troubleshooting ge x13-series ecm2.3 ™ motors cont’d. Model x13 communication diagnostics the x13 motor is communicated through 24 vac low voltage (thermostat control circuit wiring). 1. Start with unit wiring diagram to confirm proper connections and voltage...