- DL manuals

- Bard

- Heat Pump

- PH13242-A

- Installation Instructions Manual

Bard PH13242-A Installation Instructions Manual

Manual

2100-468E

Page

1 of 27

SINGLE PACKAGE

HEAT PUMPS

INSTALLATION INSTRUCTIONS

© Copyright 2006

Manual :

2100-468E

Supersedes:

2100-468D

File:

Volume II Tab 11

Date:

05-28-09

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914 . . . Moving ahead, just as planned.

MODELS

PH13242-A

PH13302-A

PH13362-A

PH13362-B

PH13422-A

PH13422-B

PH13422-C

PH13482-A

PH13482-B

PH13482-C

PH13602-A

PH13602-B

PH13602-C

Summary of PH13242-A

Page 1

Manual 2100-468e page 1 of 27 single package heat pumps installation instructions © copyright 2006 manual : 2100-468e supersedes: 2100-468d file: volume ii tab 11 date: 05-28-09 bard manufacturing company, inc. Bryan, ohio 43506 since 1914 . . . Moving ahead, just as planned. Models ph13242-a ph1330...

Page 2

Manual 2100-468e page 2 of 27 contents getting other informations and publications general instructions important ................................................................ 3 shipping damage .................................................... 4 general ...........................................

Page 3

Manual 2100-468e page 3 of 27 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-468e page 4 of 27 general instructions important the equipment covered in this manual is to be installed by trained, experienced service and installation technicians. Any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning un...

Page 5

Manual 2100-468e page 5 of 27 * 75 degree c copper wire ** maximum time delay fuse of hacr type circuit breaker table 2 electrical data le d o ma -2 42 31 h pa -2 03 31 h pa -2 63 31 h pb -2 63 31 h pa -2 24 31 h pb -2 24 31 h pc -2 24 31 h pa -2 84 31 h pb -2 84 31 h pc -2 84 31 h pa -2 06 31 h pb ...

Page 6

Manual 2100-468e page 6 of 27 table 3 optional field installed heater packages only to be used with the heat pump models indicated re ta e h e ga kc a p le d o m d na stl o v es a h pa -2 42 31 h pa -2 03 31 h pa -2 63 31 h pb -2 63 31 h pa -2 24 31 h pb -2 24 31 h pc -2 24 31 h pa -2 84 31 h pb -2 ...

Page 7

Manual 2100-468e page 7 of 27 table 4 optional field installed electric heater table 1 t ime delay fuses of hacr type circuit breakers must be used for 60 and smaller sizes. S tandard fuses or circuit breakers are s uit able for sizes 70 and larger . 480v circuit breakers are not hacr type. 2 based ...

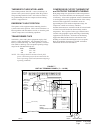

Page 8

Manual 2100-468e page 8 of 27 return opening drain access supply opening high voltage knockout low voltage knockout access door control panel door heater package access panel compressor heater package knockout a e c d l w b f condenser air condenser air intake grille intake grille access door blower...

Page 9

Manual 2100-468e page 9 of 27 installation location general the unit must be located outside, or in a well ventilated area. It must not be in the space being heated or cooled. A sound absorbing material should be considered if the unit is to be installed in such a position or location that might cau...

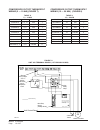

Page 10

Manual 2100-468e page 10 of 27 figure 2 slab mounting at ground level 36" min. 24" min. 24" min. The distance between 1 inch clearance access air in le t comp- nearest structure air inlet s uppl y and r et ur n d uct s nearest structure n eares t s truc ture bu ild in g control panel access control ...

Page 11

Manual 2100-468e page 11 of 27 figure 4 elevated mounting platforms both legs must rest on surface of platform 32°f or lower climate 12" min. If in 48" min. 48" min. 32°f or lower climate 12" min. If in on surface of platform both legs must rest platform can be as shown or solid poured concrete, bri...

Page 12

Manual 2100-468e page 12 of 27 air filters air filters for the return air side of the system are not provided as part of the various types of applications for these models, and must be field supplied and installed as part of the final installation. Prior thought should be given to return air locatio...

Page 13

Manual 2100-468e page 13 of 27 thermostats see specific wiring information for the different models, heater kws, and voltages. Table 6 heat pump thermostats important note: only the thermostat and subbase combinations as shown above will work with this equipment. The thermostat and subbase must be m...

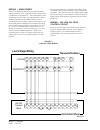

Page 14: Low Voltage Wiring

Manual 2100-468e page 14 of 27 figure 6 low voltage wiring wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount of ...

Page 15

Manual 2100-468e page 15 of 27 thermostat indicator lamps the red lamp marked “em. Ht.” comes on and stays on whenever the system switch is placed in em. Ht. Position. The green lamp marked “check” will come on if there is any problem that prevents the compressor from running when it is supposed to ...

Page 16

Manual 2100-468e page 16 of 27 compressor cutoff thermostat wiring (5 — 10 kw) (figure 7) compressor cutoff thermostat wiring (15 — 20 kw ) (figure 8) table 9 15 — 20 kw l e d o m w k s t l o v e s a h p a - 2 0 3 3 1 h p 5 1 0 3 2 1 a - 2 6 3 3 1 h p 5 1 0 3 2 1 b - 2 6 3 3 1 h p 5 1 0 3 2 3 a - 2 ...

Page 17

Manual 2100-468e page 17 of 27 start up these units require r-410a refrigerant and polyol ester. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 psi/2...

Page 18

Manual 2100-468e page 18 of 27 start up and operation three phase scroll compressor start up information (models ph13362-b, ph13422-b, -c; ph13482-b, -c; ph13602-b, -c) all units with three phase scroll compressors are equipped with a three phase line monitor to prevent compressor damage due to phas...

Page 19

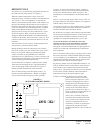

Manual 2100-468e page 19 of 27 mis-1191 defrost cycle the defrost cycle is controlled by temperature and time on the solid state heat pump control. See figure 9. When the outdoor temperature is in the lower 40°f temperature range or colder, the outdoor coil temperature is 32°f or below. This coil te...

Page 20

Manual 2100-468e page 20 of 27 troubleshooting m o t p m y s s e s u a c e l b i s s o p r i a p e r / k c e h c o t w o h & t a h w ll i w r o s s e r p m o c g n it a e h ( t r a t s t o n ) g n il o o c r o c o t r m o r f v 4 2 r o f k c e h c l o r t n o c p m u p t a e h e h t n o t u p n i r ...

Page 21

Manual 2100-468e page 21 of 27 checking temperature sensor check out 1. Disconnect temperature sensor from board and from outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance; use s...

Page 22

Manual 2100-468e page 22 of 27 fan blade settings shown in figure 10 are the correct fan blade setting dimensions for proper air delivery across the outdoor coil. Any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions in table 10 be checked and...

Page 23

Manual 2100-468e page 23 of 27 table 11 pressure table air t emperature entering out door coil degree f cooling low side pressure +2 psig high side pressure +5 psig h e a ting air t emperature entering out door coil degree f t ables based upon rated cfm (airflow) across the evaporator coil. If incor...

Page 24

Manual 2100-468e page 24 of 27 table 12 pressure table cooling air t emperature entering out door coil degree f low side pressure +2 psig high side pressure +5 psig air t emperature entering out door coil degree f h e a ting t ables based upon rated cfm (airflow) across the evaporator coil. If incor...

Page 25

Manual 2100-468e page 25 of 27 suction and discharge tube brazing compliant scroll compressors have copper plated steel suction and discharge tubes. These tubes are far more rugged and less prone to leaks than copper tubes used on other compressors. Due to different thermal properties of steel and c...

Page 26

Manual 2100-468e page 26 of 27 figure 12 ↓ ↓ troubleshooting ge x13-series ecm2.3 ™ motors if the motor is running 1. It is normal for the motor to rock back and forth on start up. Do not replace the motor if this is the only problem identified. 2. If the system is excessively noisy, does not appear...

Page 27

Manual 2100-468e page 27 of 27 figure 13 troubleshooting ge x13-series ecm2.3 ™ motors cont’d. Model x13 communication diagnostics the x13 motor is communicated through 24 vac low voltage (thermostat control circuit wiring). 1. Start with unit wiring diagram to confirm proper connections and voltage...