- DL manuals

- Bard

- Heat Pump

- Q24H3-A

- Installation instructions manual

Bard Q24H3-A Installation instructions manual

Page

1 of 42

INSTALLATION INSTRUCTIONS

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Manual No.: 2100-652A

Supersedes: 2100-652

Date: 10-11-17

Q-TEC

TM

SERIES

PACKAGED HEAT PUMP

Models:

Q24H3-A

Q24H3-B

Q24H3-C

Q30H3-A

Q30H3-B

Q30H3-C

Q36H3-A

Q36H3-B

Q36H3-C

Q43H3-A

Q43H3-B

Q43H3-C

Q48H3-A

Q48H3-B

Q48H3-C

Q60H3-A

Q60H3-B

Q60H3-C

Summary of Q24H3-A

Page 1

Page 1 of 42 installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual no.: 2100-652a supersedes: 2100-652 date: 10-11-17 q-tec tm series packaged heat pump models: q24h3-a q24h3-b q24h3-c q30h3-a q30h3-b q30h3-c q36h3-a q36h3-b q36h3-c q43h3-a q43h3-b q43h...

Page 2: Contents

Manual 2100-652a page 2 of 42 contents getting other information and publications ........ 3 q-tec series general information ........................... 4 q-tec model nomenclature ..................................... 4 shipping damage .................................................... 7 unit rem...

Page 3

Manual 2100-652a page 3 of 42 getting other information and publications these publications can help when installing the air conditioner or heat pump. They can usually be found at a local library or can be purchased directly from the publisher. Be sure to consult the most current edition of each sta...

Page 4

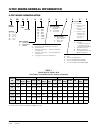

Manual 2100-652a page 4 of 42 table 1 factory built-in electric heat (see table 2 for available electric heat by unit model) nominal kw at 240v at 208v at 480v at 460v kw 1-ph amps 3-ph amps btuh kw 1-ph amps 3-ph amps btuh kw 3-ph amps btuh kw 3-ph amps btuh 5.0 5.0 20.8 17,065 3.75 18.0 12,799 6.0...

Page 5

Manual 2100-652a page 5 of 42 model rated volts & phase no. Field power circuits single circuit dual circuit minimum circuit ampacity maximum external fuse or ckt. Brkr. Field power wire size ground wire minimum circuit ampacity maximum external fuse or ckt. Breaker field power wire size ground wire...

Page 6

Manual 2100-652a page 6 of 42 figure 1 unit dimensions.

Page 7: Warning

Manual 2100-652a page 7 of 42 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. The skid must remain attached to the unit until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immed...

Page 8: Warning

Manual 2100-652a page 8 of 42 handling unit after removal from skid the unit will have to be turned sideways and removed from the skid to fit through a 36" doorway. If the door height allows, the unit can be slid sideways through the door. If the unit cannot be slid through the door, then the unit w...

Page 9

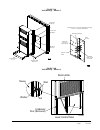

Manual 2100-652a page 9 of 42 figure 6 ducted application figure 5 installation with duct-free plenum.

Page 10

Manual 2100-652a page 10 of 42 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acc...

Page 11

Manual 2100-652a page 11 of 42 fresh air intake this unit is equipped with a fresh air damper assembly. The damper blade is locked in the closed position when the unit is shipped from the factory. To allow the damper to operate, remove the two plastic locking pins, one on each end of the blade. This...

Page 12

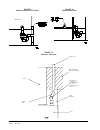

Manual 2100-652a page 12 of 42 figure 10 standard rear drain figure 9 optional side drain (side view) q-t ec unit water trap figure 11 rear drain (top view) wall (maximum 10" for rear drain) couplings not shown but recommended for ease of removability for service sleeve drain line wall bracket unit.

Page 13

Manual 2100-652a page 13 of 42 mis -2469 dr ai n b ox w all s leeve ove rf lo w t ube ca ul k a ro und t ube figure 12a.

Page 14

Manual 2100-652a page 14 of 42 supplied with drain box kit 3/4" plastic pipe nipple horizontal to floor) (tighten threads so tee is threads) (apply teflon tape to rear drain connection in q/tec product 1/2" slip x 1/2" slip x 3/4" npt tee supplied with drain box kit plug installed in side q/tec drai...

Page 15

Manual 2100-652a page 15 of 42 mis-2471 a remove knock-out for indoor drain hose connector figure 12c (if used).

Page 16

Manual 2100-652a page 16 of 42 drain pan. Drain hose from indoor move hose from attachment in lower drain pan and slide onto drain box barb fitting, securing with supplied clamp if outdoor pan is bypassed. ( will reduce risk of algae growth in the outdoor pan but at a slight cooling performance redu...

Page 17

Manual 2100-652a page 17 of 42 washer sleeve stud mis-2689 nut lower control panel condenser door (removed) return grille figure 13b unit mounting – method 2 figure 13a unit mounting – method 1 bottom trim piece bottom trim extension mounting bracket side trim (2 pcs.) side trim (2 pcs.) cabinet sid...

Page 18: Installation

Manual 2100-652a page 18 of 42 installation mounting the unit when installing a q-tec unit near an interior wall on the left side, a minimum of 8" is required but 12" is preferred. When installing a q-tec unit near an interior wall on the right side, a minimum of 18" is required as additional space ...

Page 19

Manual 2100-652a page 19 of 42 optional climate controls sequence of operation the standard climate control option x is a remote thermostat connection terminal block. See figure 17a on page 22 for wiring diagram. Compatible thermostats are listed in table 4 on page 21. See figure 17b on page 23 for ...

Page 20: Caution

Manual 2100-652a page 20 of 42 when the thermostat is set in the automatic mode, the thermostat can change automatically to the heat or cool modes to maintain the temperature set on the thermostat. The co 2 controller will energize the vent option and the id blower when the room co 2 levels rise ove...

Page 21

Manual 2100-652a page 21 of 42 mis-1285 figure 16 table 4 wall thermostats and controls thermostat predominant features 8403-067 carbon dioxide sensor with lcd for sensor readings 8403-060 (1120-445) 3 stage cool; 3 stage heat programmable/non-programmable electronic hp or conventional auto or manua...

Page 22

Manual 2100-652a page 22 of 42 g brown/white red/white yellow blue brown orange orange bard part black/white r y o/b b red/yellow w2 e c w3 o1 g c w2 5 y1 r r y1 l o/b w2 w1/e c a l cs9be-thoc thermostat 7 remote thermostat wiring diagram #8403-060 "x" thermostat option mis-2687 b sc w1 w1/e sc a sc...

Page 23

Manual 2100-652a page 23 of 42 y1 g a c w1/e w2 o/b l r 2 4 5 3 1 yellow bard part #8403-060 w2 r 9 relay brown/white 4 8 brown red/yellow o1 l orange blue red/white y black/white 3 b "x" thermostat option with demand ventilation w3 orange e remote thermostat wiring diagram part #8201-062 w1 c therm...

Page 24

Manual 2100-652a page 24 of 42 2 orange red/white blue 9 w1/e 10 6 temp. And humidity controller part #8403-060 5 black/white g o/b 3 11 8 4102-060 r y1 plug #2 c w2 1 yellow 12 red/yellow brown 7 orange a brown/white 4 figure 18 unit mounted thermostat wiring diagram "d" thermostat option.

Page 25

Manual 2100-652a page 25 of 42 3 2 4 5 1 orange bl ack /w hite orange red/white blue 9 analog temp. And humidity part #8403-060 5 black/white g o/b 3 11 8 4102-059 a r y1 plug #2 c 1 yellow 12 red/yellow brown 7 a brown/white 2 out 24 vac re d/w hite br ow n/w hite 4 w2 orange red/white 4 co2 contro...

Page 26

Manual 2100-652a page 26 of 42 5 1 2 brown/white 7 yellow orange red/white plug #2 4102-078 orange 8 12 9 black/white blue 3 6 red/yellow brown 11 10 4 w2 a sc sc w1/e g o/b r y1 c sc temp. And humidity controller b-cs9be-tho c-cs9be-thoc figure 20 unit mounted thermostat wiring diagram "b" or "c" t...

Page 27: Start Up

Manual 2100-652a page 27 of 42 start up these units require r-410a refrigerant and polyol ester oil. General 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 ps...

Page 28

Manual 2100-652a page 28 of 42 description of standard equipment solid state electronic heat pump control provides efficient 30-minute defrost cycle. A thermistor sensor and speed up terminal for service along with a 10-minute defrost override are standard on the electronic heat pump control. High/l...

Page 29

Manual 2100-652a page 29 of 42 service hints 1. Caution user to maintain clean air filters at all times and to not needlessly close off supply air registers. This may reduce airflow through the system, which shortens equipment service life as well as increasing operating costs and noise levels. 2. S...

Page 30

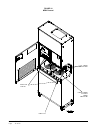

Manual 2100-652a page 30 of 42 q-tec energy recovery ventilator (option) before starting, make sure that the power has been turned off. The return air grille panel must be removed. The energy recovery ventilator (qerv) can be seen after the panel has been removed. To gain access to the mist eliminat...

Page 31

Manual 2100-652a page 31 of 42 figure 21 fresh air damper removal mounting screw.

Page 32

Manual 2100-652a page 32 of 42 figure 22 qerv removal mounting screws front fill lower blower assembly power connector power connectors.

Page 33

Manual 2100-652a page 33 of 42 sequence of operation cooling – circuit r-y makes at thermostat, pulling in compressor contactor and starting the compressor and outdoor motor. The g (indoor motor) circuit is automatically completed on any call for cooling operation or can be energized by manual fan s...

Page 34

Manual 2100-652a page 34 of 42 there is a cycle speed up jumper on the control. This can be used for testing purposes to reduce the time between defrost cycle operation without waiting for time to elapse. Use a small screwdriver or other metallic object, or another ¼" qc, to short between the speedu...

Page 35

Manual 2100-652a page 35 of 42 high pressure switch operation – the control has a built-in lockout system that allows the unit to have the high pressure switch trip up to two times in 1 hour and only encounter a “soft” lockout. A “soft” lockout shuts the compressor off and waits for the pressure swi...

Page 36: Troubleshooting

Manual 2100-652a page 36 of 42 troubleshooting sympton description, check and possible causes what and how to check/repair compressor will not start (heating or cooling) 1. Check for led illumination. Is there an led illuminated on the board (flashing)? Yes = go to step #2; no = go to step #3 2. Che...

Page 37

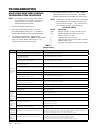

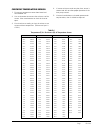

Manual 2100-652a page 37 of 42 checking temperature sensor 1. Disconnect temperature sensor from board and from outdoor coil. 2. Use an ohmmeter to measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance use sensor ambien...

Page 38

Manual 2100-652a page 38 of 42 troubleshooting ecm™ blower motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/pro...

Page 39

Manual 2100-652a page 39 of 42 manual 2100-522b page 36 of 38 troubleshooting ge ecm ™ motors cont’d. Motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts...

Page 40

Manual 2100-652a page 40 of 42 fan blade setting dimensions any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions in table 7 be checked and blade adjusted in or out of the motor shaft accordingly. Maximum esp (inches wc) shown is with 1" thick...

Page 41

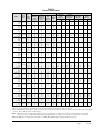

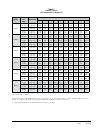

Manual 2100-652a page 41 of 42 model return air temp. Pressure air temperature entering outdoor coil 75° 80° 85° 90° 95° 100° 105° 110° 115° 120° q24h3 75 db 62 wb low side high side 118 326 119 340 121 358 122 377 125 399 128 422 132 449 135 477 138 508 140 525 80 db 67 wb low side high side 126 33...

Page 42

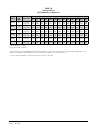

Manual 2100-652a page 42 of 42 model return air temp. Pressure air temperature entering outdoor coil 0° 5° 10° 15° 20° 25° 30° 35° 40° 45° 50° 55° 60° q24h3 70 low side high side 35 284 42 290 49 297 57 304 64 313 72 322 79 331 86 342 94 353 101 365 109 378 117 392 124 406 q30h3 70 low side high sid...