- DL manuals

- Bard

- Air Conditioner

- QA241D

- Installation instructions manual

Bard QA241D Installation instructions manual

Bard Manufacturing Company

Bryan, Ohio 43506

Since 1914 . . . Moving ahead, just as planned.

Manual:

2100-438C

Supersedes:

2100-438B

File:

Vol II Tab 14

Date:

06-02-04

© Copyright 2004

Models:

QA241D

QA301D

QA361D

QA421D

QA481D

QA601D

QTEC SERIES

PACKAGED

AIR CONDITIONER

INSTALLATION

INSTRUCTIONS

MIS-1554

Summary of QA241D

Page 1

Bard manufacturing company bryan, ohio 43506 since 1914 . . . Moving ahead, just as planned. Manual: 2100-438c supersedes: 2100-438b file: vol ii tab 14 date: 06-02-04 © copyright 2004 models: qa241d qa301d qa361d qa421d qa481d qa601d qtec series packaged air conditioner installation instructions mi...

Page 2: Contents

Contents i figures figure 1 unit dimensions .......................................... 6 figure 2 air seal on bottom of unit ........................... 7 figure 3 removal of unit from skid ......................... 7 figure 4 unit on appliance cart for moving ............... 8 figure 5 installation...

Page 3

Manual 2100-438 page 1 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. National ele...

Page 5

Manual 2100-438 page 3 table 1 factory built-in electric heat table sl e d o m a d 1 4 2 a q a d 1 0 3 a qb d 1 4 2 a qb d 1 0 3 a qc d 1 4 2 a qc d 1 0 3 a q a d 1 6 3 a q a d 1 2 4 a q a d 1 8 4 a q b d 1 6 3 a q b d 1 2 4 a q b d 1 8 4 a q c d 1 6 3 a q c d 1 2 4 a q c d 1 8 4 a qa d 1 0 6 a qb d...

Page 6

Manual 2100-438 page 4 electrical specifications continued on page 5 table 2a ! " # maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. Based on 75° c copper wire. All wiring must conform to the national electrical code and all local codes. The...

Page 7

Manual 2100-438 page 5 ! " # maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. Based on 75° c copper wire. All wiring must conform to the national electrical code and all local codes. These “minimum circuit ampacity” values are to be used for...

Page 8

Manual 2100-438 page 6 figure 1 unit dimensions.

Page 9: Warning

Manual 2100-438 page 7 a shipping brackets b front wheels over edge c front wheels on floor shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. The skid must remain attached to the unit until the unit is ready for installation. If damage is ...

Page 10: Warning

Manual 2100-438 page 8 handling unit after removal from skid the unit will have to be turned sideways and removed from the skid to fit through a 36” doorway. If the door height allows, the unit can be slid sideways through the door. If the unit can not be slid through the door, then the unit will ha...

Page 11

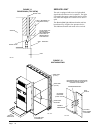

Manual 2100-438 page 9 figure 6 ducted application figure 5 installation with free blow plenum mis-1573 suspended ceiling fixed ceiling duct duct flange 8 ft. - 7 in. Minimum recommended ceiling height 7 ft. - 4 in. Unit height 12 in. Minimum 2 in. Minimum from duct flange to duct bottom 8 ft. - 4.5...

Page 12

Manual 2100-438 page 10 duct work all duct work must be properly sized for the design air flow requirement of the equipment. Air conditioning contractors of america (acca) is an excellent guide to proper sizing. All duct work or portions thereof not in the conditioned space should be properly insula...

Page 13

Manual 2100-438 page 11 fresh air intake this unit is equipped with a fresh air damper assembly. The damper blade is locked in the closed position when the unit is shipped from the factory. To allow the damper to operate remove the two plastic locking pins, one on each end of the blade. This will al...

Page 14

Manual 2100-438 page 12 mis-1061 service light the unit is equipped with a service light which signals the user that service is required. The light is located in the upper control panel and is visible only when the hinged service/filter access door is open. The service unit light indicates that the ...

Page 15: Installation Instructions

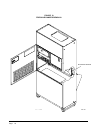

Manual 2100-438 page 13 installation instructions mounting the unit when installing a qt ec unit near an interior wall on the left side, a minimum of 8 inches is required; 12 inches is preferred. When installing a qt ec unit near an interior wall on the right side, a minimum of 18 inches is required...

Page 16

Manual 2100-438 page 14 the standard climate control option x is a remote thermostat connection terminal block. See figure 16 for wiring diagram. Compatible thermostats are listed in table 4. The climate control option g is an electronic, non- programmable manual or auto changeover thermostat. The s...

Page 17: Caution

Manual 2100-438 page 15 low voltage connections for ddc control fan only energize g cooling mode energize y, g 1st stage heating energize g, w1 2nd state heating energize g, w2 (if employed) ventilation energize g, o1 dehumidification energize contact between 1 and 2 general this unit is equipped wi...

Page 18

Manual 2100-438 page 16 mis-1285 thermostat plug terminals p2 and p4 (viewed from pin end) blower motor low voltage plug (viewed from pin end) figure 15 table 4 wall thermostats and subbase combinations t a t s o m r e h t e s a b b u s s e r u t a e f t n a n i m o d e r p 9 4 0 - 3 0 4 8 ) 0 8 3 -...

Page 19

Manual 2100-438 page 17 figure 16 remote thermostat wiring diagram “x” thermostat option note: on option x or g the cs2000 (or other field provided means to control ventilation) must be used if any of the motorized ventilation options are installed..

Page 20

Manual 2100-438 page 18 figure 17 unit mounted thermostat wiring diagram “g” thermostat option note: on option x or g the cs2000 (or other field provided means to control ventilation) must be used if any of the motorized ventilation options are installed..

Page 21

Manual 2100-438 page 19 figure 18 unit mounted thermostat wiring diagram “e” thermostat option.

Page 22: Start Up

Manual 2100-438 page 20 start up description of standard equipment high pressure switch provides refrigerant circuit high pressure protection. Includes lockout circuit that is resettable from room thermostat. Compressor control module provides short cycle protection for the compressor which extends ...

Page 23

Manual 2100-438 page 21 all three phase scroll compressors used in the qt ec series are wired identically internally. As a result, once the correct phasing is determined for a specific system or installation, connecting properly phased power leads to the same fusite terminal should maintain proper r...

Page 24

Manual 2100-438 page 22 6. Some service requires the need to remove the unit from the wall including replacement of the indoor coil and/or the outdoor coil. Also servicing the outdoor fan motor or fan blade will require removing the unit from the wall if the unit is installed at a height that is not...

Page 25

Manual 2100-438 page 23 3. Underneath the heat recovery cassette there is a power connector for the lower blower assembly. To disconnect this plug, the tabs on both sides of the plug must be squeezed to release the plug. While squeezing the tabs, pull the plug out of the socket. 4. The qerv is plugg...

Page 26

Manual 2100-438 page 24 figure 19 fresh air damper removal mis-1627 mounting screw.

Page 27

Manual 2100-438 page 25 figure 20 qerv removal mis-1039 mounting screws front fill lower blower assembly power connector power connectors.

Page 28

Manual 2100-438 page 26 crv / qerv operation qerv is energized by applying 24 vac to the “f” terminal of the low voltage terminal strip on units with “x” climate control option. It is energized by the “a1” terminal of the thermostat on units with “e” climate control option. It is energized by applyi...

Page 29

Manual 2100-438 page 27 figure 21 air conditioning mode circuit diagram mis-1200

Page 30

Manual 2100-438 page 28 figure 22 dehumidification mode circuit diagram mis-1199.

Page 31: Troubleshooting

Manual 2100-438 page 29 troubleshooting table 5 troubleshooting n o t p m y s e s u a c e l b i s s o p k c e h c o t t a h w ri a p e r r o k c e h c o t w o h r o s s e r p m o c t o n s e o d r o t c a t n o c e z i g r e n e ) g n it a e h r o g n il o o c ( g n ir i w ti u c ri c l o rt n o c ,...

Page 32

Manual 2100-438 page 30 fan blade setting dimensions any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions in table 6 be checked and blade adjusted in or out of the motor shaft accordingly. 1 2 3 4 5 maximum esp (inches wc) shown is with 1” th...

Page 33

Manual 2100-438 page 31 low side pressure ± 2 psig high side pressure ± 5 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the charge should be removed, system evacuated and recharged to serial plate ...