- DL manuals

- Bard

- Chiller

- QC501

- Installation Instructions Manual

Bard QC501 Installation Instructions Manual

Summary of QC501

Page 1

Page 1 of 27 installation instructions bard manufacturing company, inc. Bryan, ohio 43506 www.Bardhvac.Com manual no.: 2100-416j supersedes: 2100-416i date: 6-14-16 qc series chilled water unit model: qc501.

Page 2: Contents

Manual 2100-416j page 2 of 27 contents getting other information and publications .... 3 for more information, contact these publishers: ...... 3 qc general information ......................................... 4 qc model nomenclature ....................................... 4 shipping damage ..........

Page 3

Manual 2100-416j page 3 of 27 getting other information and publications these publications can help when installing the air conditioner or heat pump. These can usually be found at the local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Na...

Page 4

Manual 2100-416j page 4 of 27 models kw qc501-a 240v-1 208v-1 btuh btuh 5.0 16,380 12,290 10.0 32,670 24,570 15.0 49,150 36,860 models single circuit dual circuit rated volts & phases no. Field power circuits minimum circuit ampacity maximum external fuse or circuit breaker field power wire size gro...

Page 5

Manual 2100-416j page 5 of 27 gpm ewt cfm btuh capacity (1000) btuh capacity (1000) water coil pressure drop stage 1 stage 1 and 2 total sensible latent total sensible latent psig ft. Hd. 6 42 1000 15.1 10.5 4.6 38.5 25.3 13.2 1.9 4.4 8 16.4 11.1 5.3 41.5 26.8 14.7 3.3 7.5 10 17.4 11.7 5.7 43.2 27.4...

Page 6

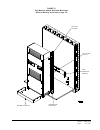

Manual 2100-416j page 6 of 27 figure 1 unit dimensions.

Page 7: Warning

Manual 2100-416j page 7 of 27 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. The skid must remain attached to the unit until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immed...

Page 8

Manual 2100-416j page 8 of 27 removal of wall bracket from shipping location the wall brackets are attached to the back of the unit. Remove and retain the wall brackets for use when attaching the unit to the wall. In those installations where a wall sleeve is required these two wall brackets are to ...

Page 9

Manual 2100-416j page 9 of 27 figure 4 installation of unit through wall with wall sleeve.

Page 10

Manual 2100-416j page 10 of 27 figure 6 ducted application figure 5 installation with free blow plenum ceiling floor floor.

Page 11

Manual 2100-416j page 11 of 27 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acc...

Page 12

Manual 2100-416j page 12 of 27 condensate drain the condensate drain hose is routed down from the evaporator drain pan on the right side of the unit into the compressor compartment. There are three locations that the drain can exit the cabinet. For a stand pipe type of drain, the drain hose can exit...

Page 13

Manual 2100-416j page 13 of 27 barometric fresh air damper (optional) before starting the removal make sure the power has been turned off. The hinged return air grille panel must be opened. The fresh air damper assembly can be seen on the back of the unit. Refer to figure 10. 1. The fresh air damper...

Page 14

Manual 2100-416j page 14 of 27 figure 10 fresh air damper removal mounting screw.

Page 15

Manual 2100-416j page 15 of 27 q-tec energy recovery ventilator option before starting the removal make sure that the power has been turned off. The hinged return air grille panel must be opened. The energy recovery ventilator (qerv) can be seen after the panel is opened. To gain access to the mist ...

Page 16: Installation Instructions

Manual 2100-416j page 16 of 27 installation instructions mounting the unit when installing a qc unit near an interior wall on the left side, a minimum of 8" is required; 12" is preferred. When installing a qc unit near an interior wall on the right side, a minimum of 12" is required as additional sp...

Page 17

Manual 2100-416j page 17 of 27 figure 13 unit mounting without ventilation wall sleeve (refer to mounting instructions on page 16) side trim (2 pieces) side trim (2 pieces) wall mounting bracket bottom trim extension bottom trim piece.

Page 18

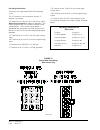

Manual 2100-416j page 18 of 27 figure 14 component location side field wire entrance remote thermostat terminal block indoor blower control box/ circuit breaker panel wiring – main power refer to the unit rating plate and/or table 2 for wire sizing information and maximum fuse or circuit breaker siz...

Page 19: Caution

Manual 2100-416j page 19 of 27 tap range 240v 253 - 216 208v 220 - 18 thermostat predominant features 8403-060 (1120-445) 3 stage cool; 3 stage heat programmable/non-programmable electronic hp or conventional auto or manual changeover the unit rating plate lists a “maximum time delay relay fuse” or ...

Page 20

Manual 2100-416j page 20 of 27 low voltage connections these units use a grounded 24 volt ac low voltage circuit. The “r” terminal is the hot terminal and the “c” terminal is grounded. “g” terminal or pins 6 and 1 of p2 are the fan inputs. Both must be energized for proper fan operation. This is don...

Page 21

Manual 2100-416j page 21 of 27 figure 16 remote thermostat wiring diagram “x” option.

Page 22

Manual 2100-416j page 22 of 27 figure 17 remote thermostat wiring diagram “d” thermostat option.

Page 23: Start Up

Manual 2100-416j page 23 of 27 model rated esp max. Esp rated cfm optional cfm continuous cfm cfm @ max. Esp qc501 0.0 0.8 1200 1000 1000 1175 maximum esp (" wc) shown is with 1" thick disposable filter (reduced by .2 for 2" filter). Rated cfm for ducted applications – required for maximum performan...

Page 24

Manual 2100-416j page 24 of 27 troubleshooting indoor ecm™ blower motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom ca...

Page 25

Manual 2100-416j page 25 of 27 replacing ecm control module to replace the control module for the ge variable-speed indoor blower motor you need to take the following steps: 1. You must have the correct replacement module. The controls are factory programmed for specific operating modes. Even though...

Page 26

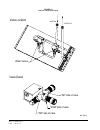

Manual 2100-416j page 26 of 27 figure 21 internal 2-way valve piping "no" side of valve "nc" side of valve "com" side of valve valve detail mis-1899 a valve location water valves water out water in.

Page 27

Manual 2100-416j page 27 of 27 figure 22 internal 3-way valve piping "nc" side of valve "com" side of valve "no" side of valve valve detail mis-1900 a valve location water out water valves water in.